Blood-taking needle assembling equipment

A technology for assembling equipment and blood collection needles, which is applied in the direction of assembly machines, metal processing equipment, metal processing, etc. It can solve the problems of high equipment precision requirements, inability to operate synchronously, and easily affected equipment, and achieve high assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered.

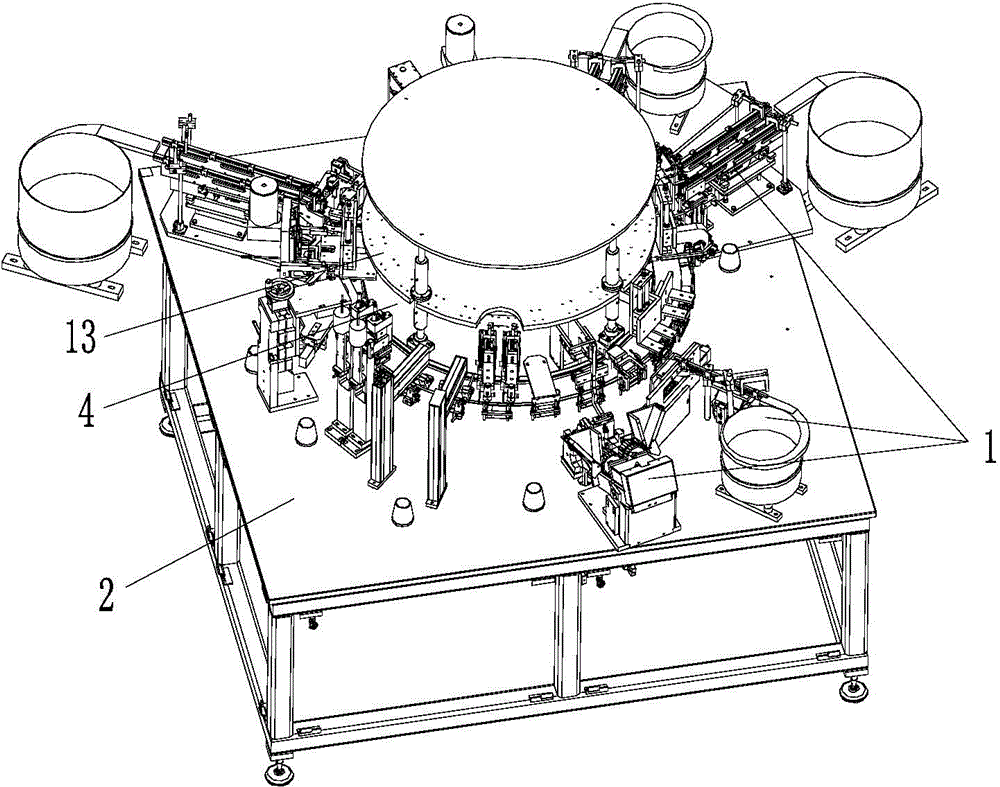

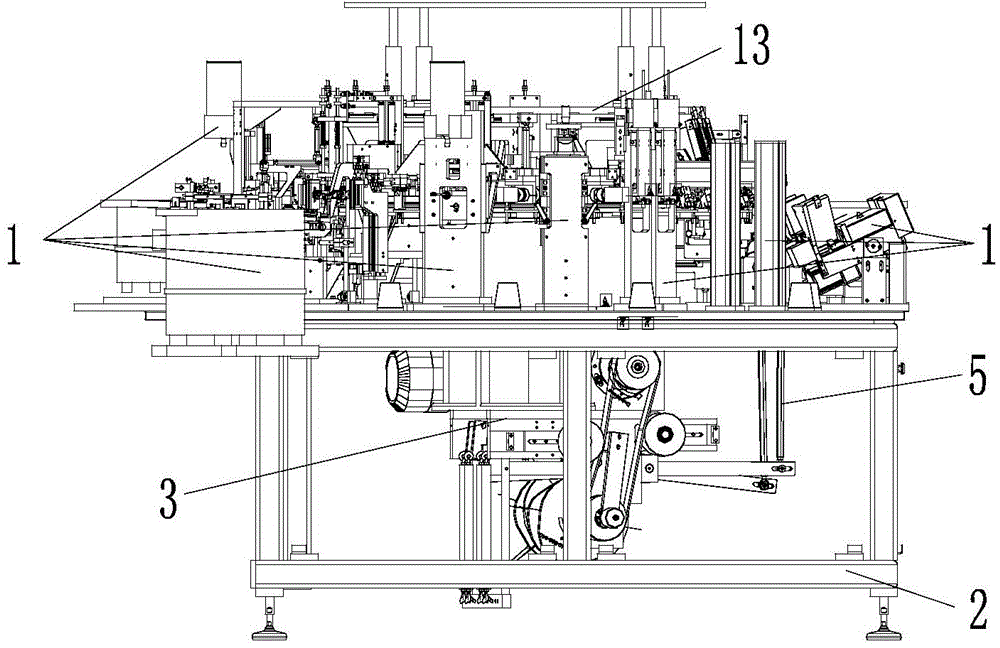

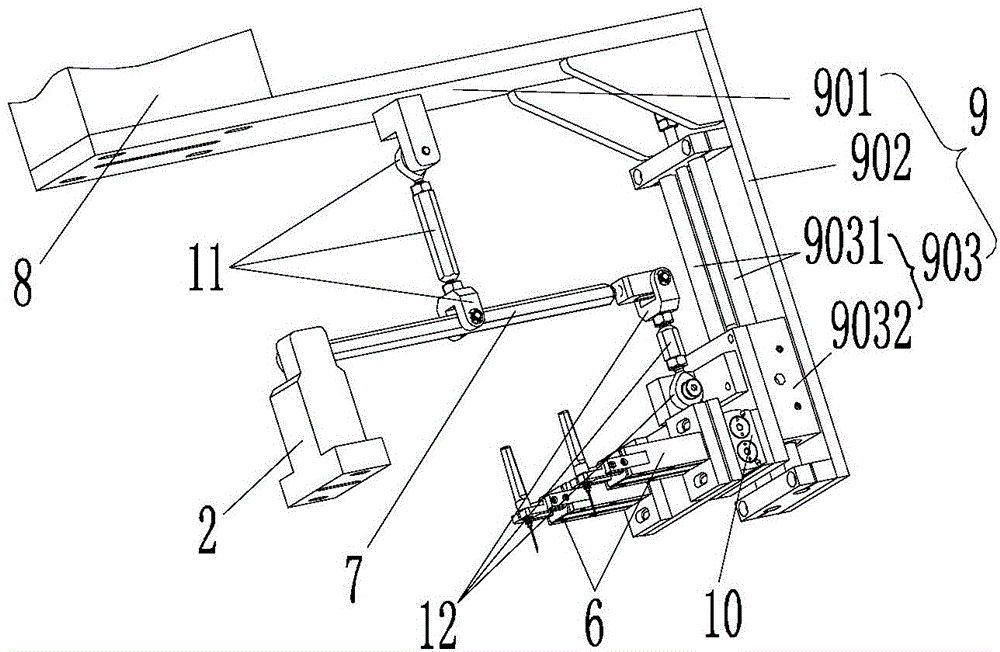

[0032] figure 1 It is a schematic structural diagram of a blood collection needle assembly device in a preferred embodiment of the present invention; figure 2 Yes figure 1 side view of image 3 It is a structural schematic diagram of the turnover workstation of the preferred embodiment of the present invention; Figure 4 It is one of the structural schematic diagrams of the cam driving mechanism in the preferred embodiment of the present invention; Figure 5 It is the second structural diagram of the cam driving mechanism in the preferred embodiment of the present invention; Image 6 is a structural schematic diagram of the driving force conversion mechanism in a preferred embodiment of the present invention; Figure 7 It is a schematic structural view of the feed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap