A heat pipe radiator for high-power LED lamps

A technology for LED lamps and heat pipe radiators, which is applied to cooling/heating devices, lighting and heating equipment, lighting devices and other directions of lighting devices, can solve the problems of easy bending of heat pipes, poor shock resistance, and high initial cost, and achieve weight reduction. , Good anti-vibration and anti-shock performance, high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

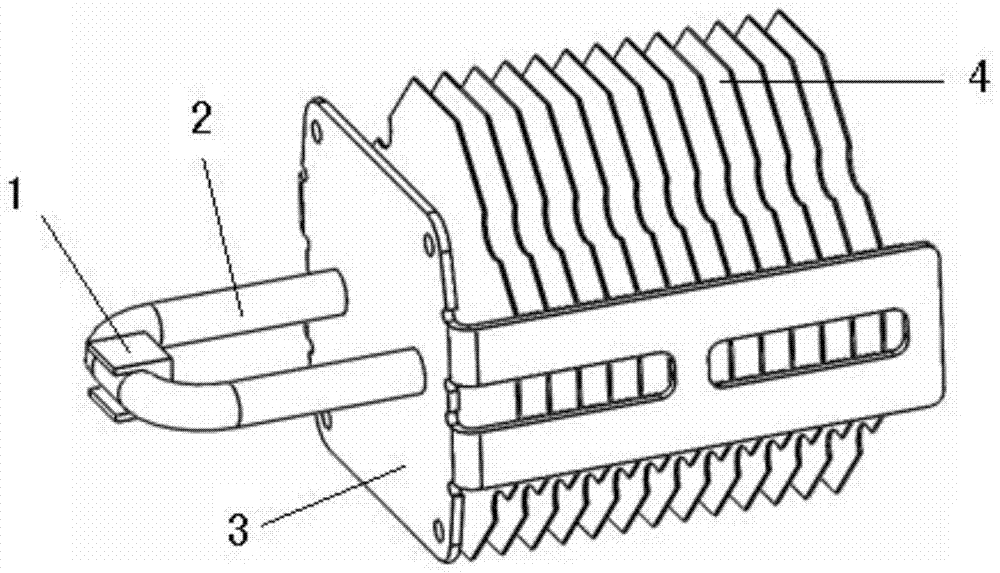

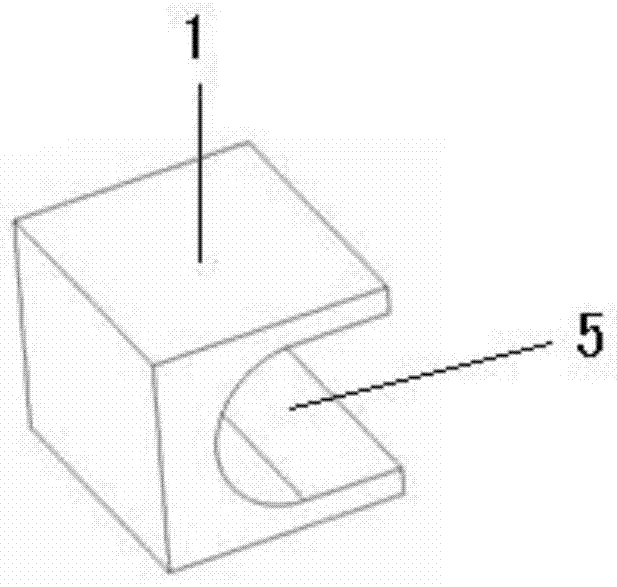

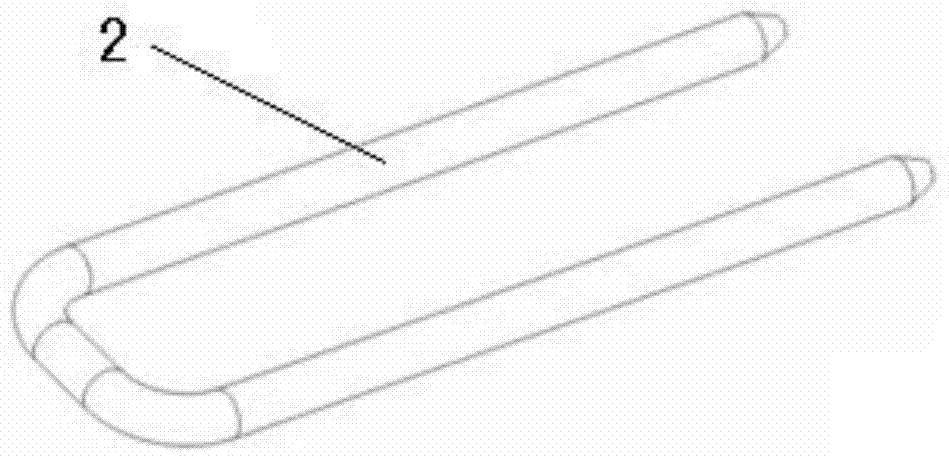

[0028] Please combine Figure 1 to Figure 7 As shown, a heat pipe 2 radiator of the present invention for high-power LED lamps, the heat pipe 2 radiator is composed of a heat load mounting table 1, a heat pipe 2, a plurality of heat sinks 4 and a guard plate 3, wherein the heat pipe 2 is a U-shaped heat pipe 2, the heat load mounting platform 1 is welded to the bend of the heat pipe 2, the U-shaped heat pipe 2 can export the heat on the heat load mounting platform 1 to the heat sink 4 with twice the efficiency, and the heat pipe 2 runs through the guard plate 3 and some cooling fins 4, some cooling fins 4 are arranged in rows on the heat pipe 2, and the intervals between the cooling fins 4 are equal to make the heat dissipation more uniform.

[0029] On the basis of the above, the present invention also has the following implementation modes, please continue to refer to Figure 1 to Figure 7 as shown,

[0030] In a further embodiment of the present invention, the heat load m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com