Mechanism for automatically calibrating needle

An automatic calibration, needle technology, applied in measuring devices, instruments, optical devices, etc., can solve problems affecting product qualification rate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

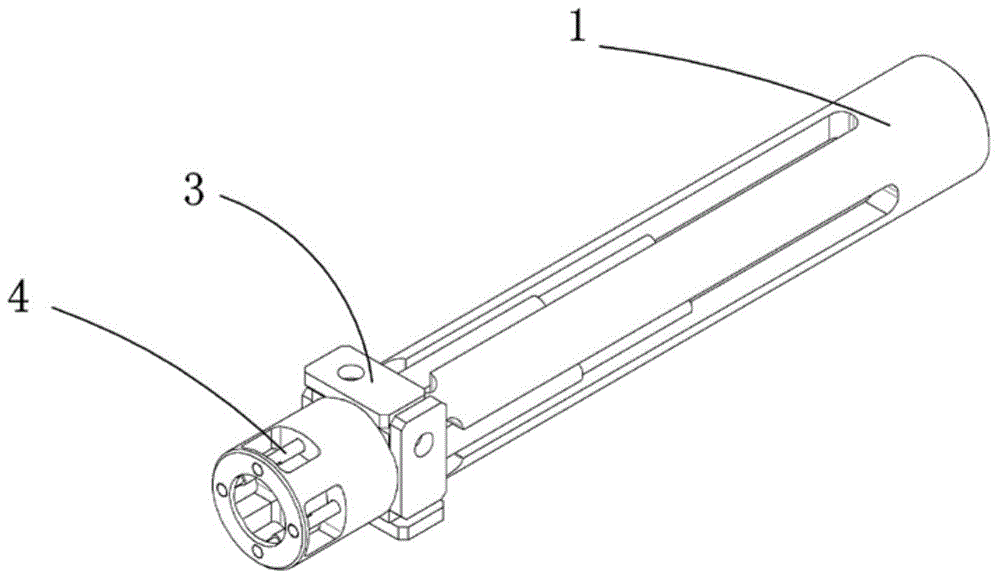

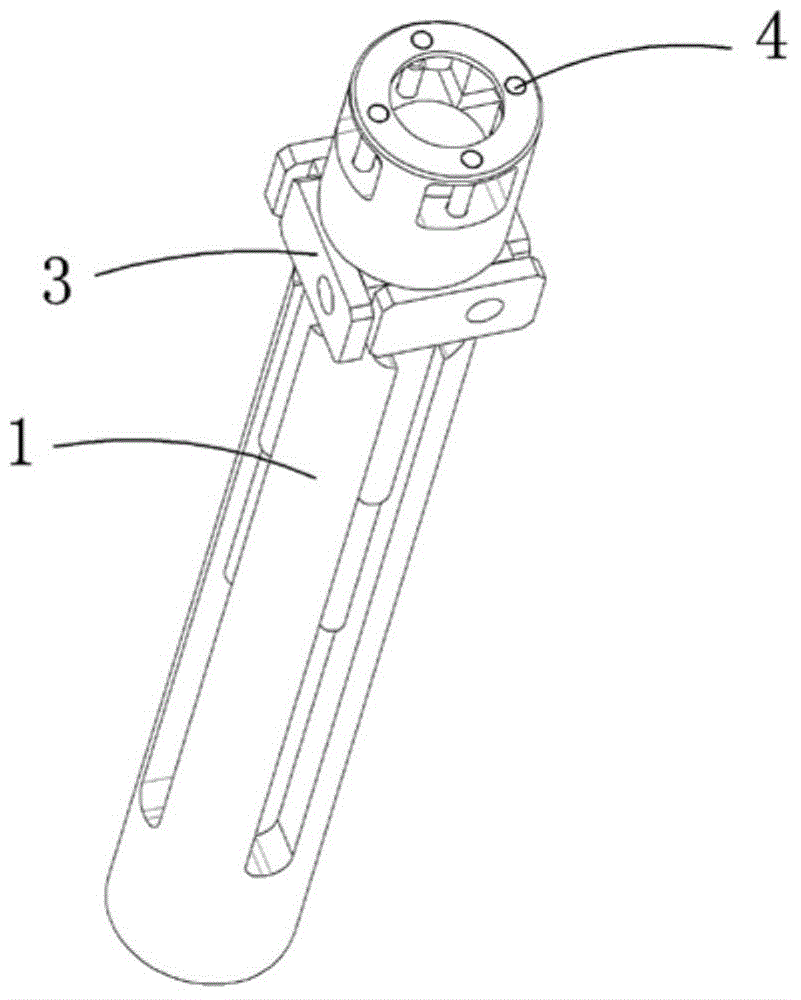

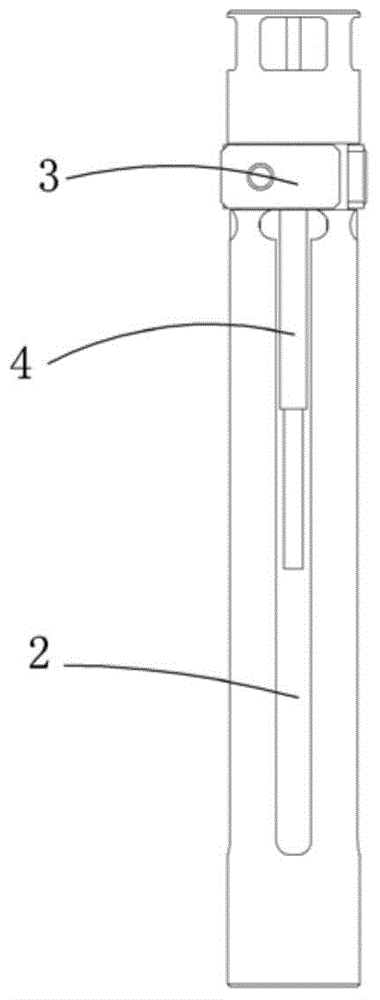

[0020] Examples, see attached Figure 1~3 , an automatic calibration needle mechanism, which includes a through-beam sensor 1, the front part of the through-beam sensor is a torus structure, and the rear part is a hollow cylinder with four slots 2 on the side wall , the torus structure at the front of the through-beam sensor and the hollow cylinder structure at the rear are integrally formed, and four sets of through-beam sensor pressing blocks 3 are symmetrically installed between the torus structure and the hollow cylinder; Four through-beam sensor fixing columns 4 are symmetrically installed on the annular wall of the torus structure, and the four through-beam sensor fixing columns respectively pass through the rear end of the torus structure and extend into the hollow cylinder. In the body, through-beam sensors are installed in each through-beam sensor fixing column.

[0021] The through-beam sensor is provided with a through-beam sensor amplifier, and the four through-be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com