cone crusher

A cone crusher and frame technology, which is applied in the field of mining equipment, can solve the problems of easy centrifugal separation of the stop push plate, locking of the main shaft, unreasonable oil channel lubrication lines, etc., so as to increase the radial stability and improve the rotary pendulum. speed, ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

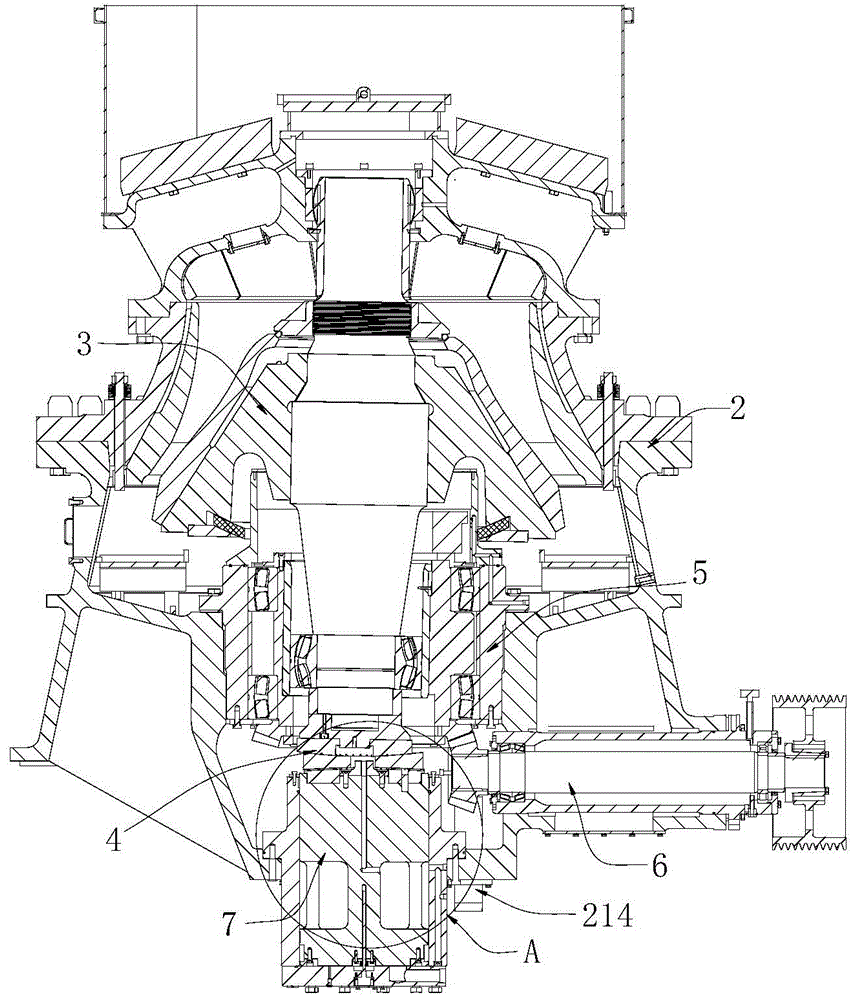

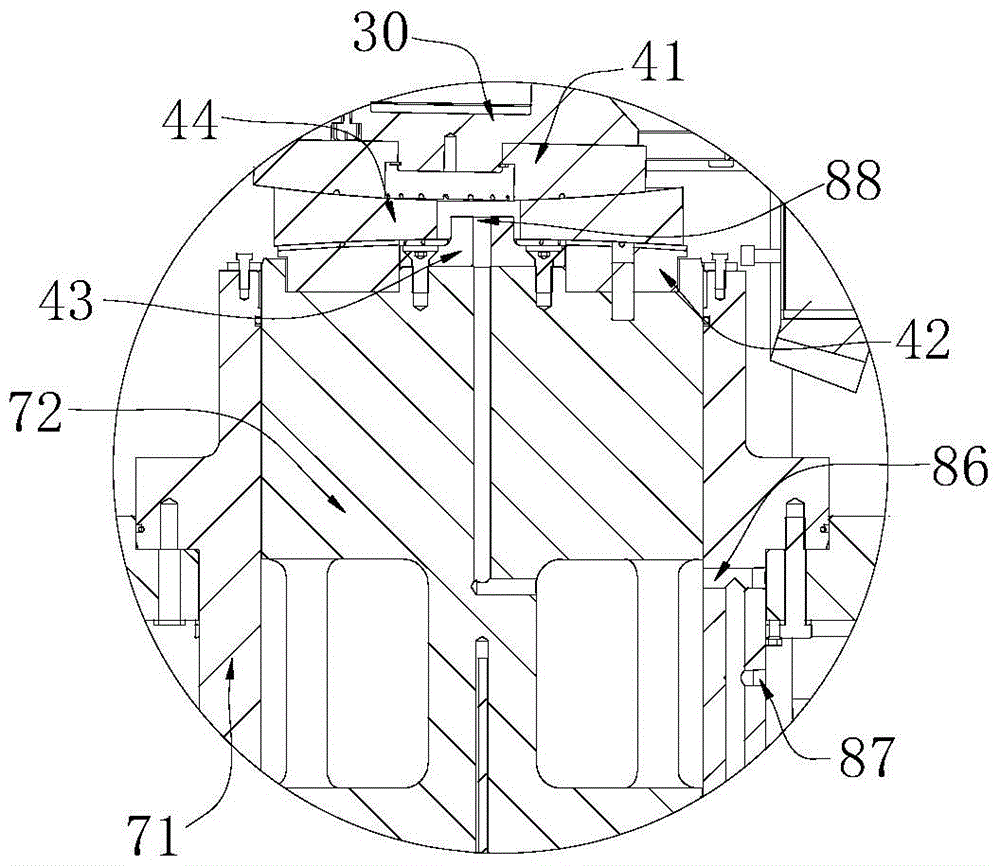

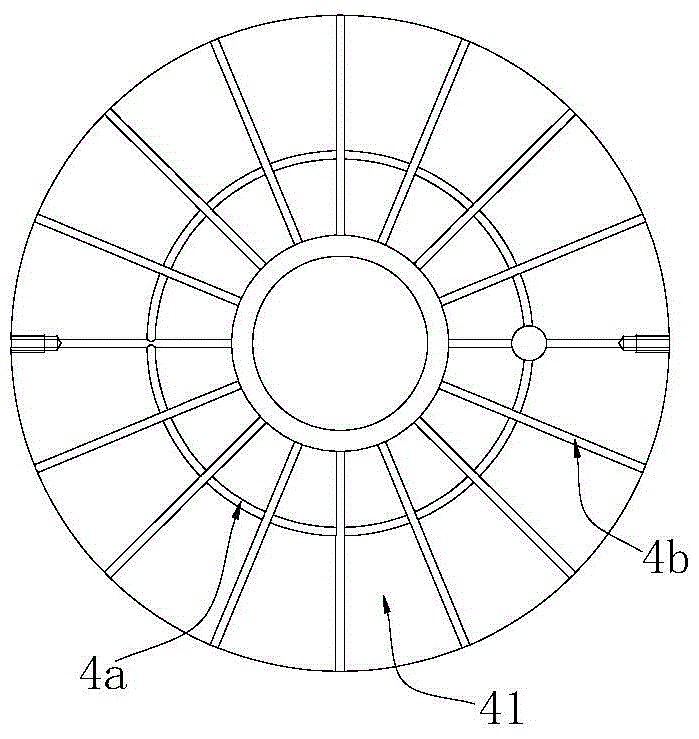

[0015] like Figure 1~Figure 3 The shown cone crusher includes a frame 2, and a transmission mechanism 6, an eccentric mechanism 5, a hydraulic lifting mechanism 7, a moving cone main shaft group 3 and a support assembly 4 arranged in the frame 2; the eccentric mechanism 5 and The transmission mechanism 6 is connected by transmission, and the lower end of the movable cone spindle group 3 is positioned and installed in the eccentric mechanism 5; the hydraulic lifting mechanism 7 includes a hydraulic cylinder block 71, and a piston 72 that is arranged in the hydraulic cylinder block 71 and can move axially. The piston 72 is connected with the movable cone spindle group 3 through the support assembly 4 .

[0016] The support assembly 4 is arranged between the hydraulic lifting mechanism 7 and the movable cone main shaft group 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com