Contact line geometric parameter measuring and calibrating method applicable to high-speed motor car

A technology of high-speed moving trains and geometric parameters, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low measurement accuracy, inaccurate measurement results, and inability to install measurement equipment such as laser rangefinders, etc., to achieve accurate measurement results , Eliminate the effect of image distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Such as Figure 1-5 Shown, the present invention comprises the steps:

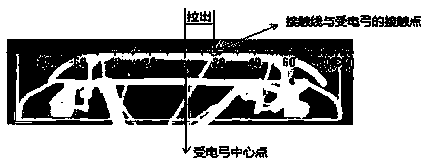

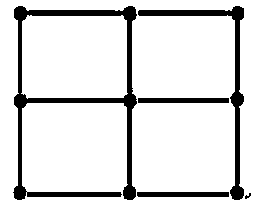

[0040] A1 Prepare a 9-point calibration board: use aluminum alloy profiles to customize the calibration board, set nine high-temperature hot spots of cement resistors at equal intervals on the surface of the calibration board, and set nylon clips between the bottom of each cement resistor and the calibration board to prevent cement The heat generated by the resistance is transmitted to the calibration board, which affects the thermal imaging accuracy. The manufacturing and assembly accuracy of the 9-point calibration board is controlled below 1mm. In addition, set the actual coordinates (u, v, w) of nine cement resistance high temperature hot spots, where w is a constant. Such as Figure 5 As shown, the method of setting u and v in the 9 real coordinates is as follows: Assume that point 1 in the figure is (0, 0), the actual distance between point 1 and point 2 is Δx, and the actual distance betwee...

Embodiment 2

[0047] This scheme is preferably as follows on the basis of Example 1: the calibration requirement in step a2 is that the height of the three cement resistance high-temperature hot spots on the calibration board is at 6300 ± 1 mm on the track plane, and the three cement resistance high-temperature hot spots in the middle row are at 5800 ± 1 mm. 1mm, the bottom row of cement resistance high temperature hot spot is at 5300±1mm. The 9-point calibration plate can better reflect the situation of the points on the pantograph lifting plane, so that the distortion coefficient calculated based on the 9-point calibration plate is more accurate, and the later calculated conduction height and pull-out value are also more accurate.

Embodiment 3

[0049] The scheme is preferably as follows on the basis of the foregoing embodiments: the specific method for correcting the pixel coordinates (x', y', w') of the infrared camera imaging in step a4 is as follows:

[0050] a41 Calculation of mapping coefficients: According to the relatively fixed plane of the pantograph lift and the camera target plane, the pixel coordinates (x', y', w') of the infrared camera imaging and the actual coordinates of the pantograph lift plane (u, v ,w) There is a mapping relationship that satisfies the following formula:

[0051] [ x ′ , y ′ , w ′ ] = [ u , v , w ] a 11 a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com