Full-automatic box-packed stem unpacking equipment

A fully automatic, box-packing technology, which is applied in the field of tobacco equipment, can solve the problems of high labor intensity, residual film fragments, and difficulty in taking out, etc., to achieve the effect of convenient automatic separation, quality assurance, and automatic unpacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

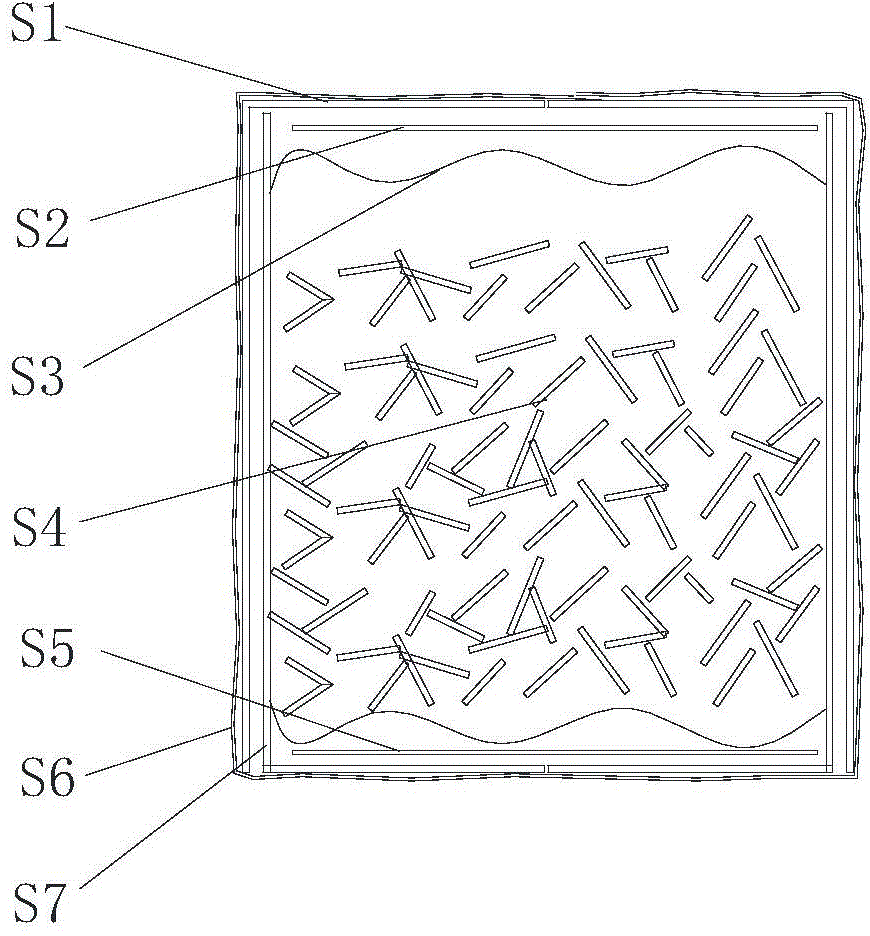

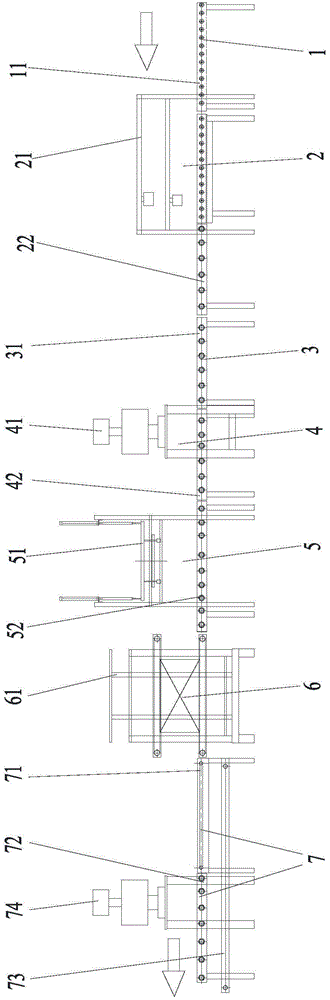

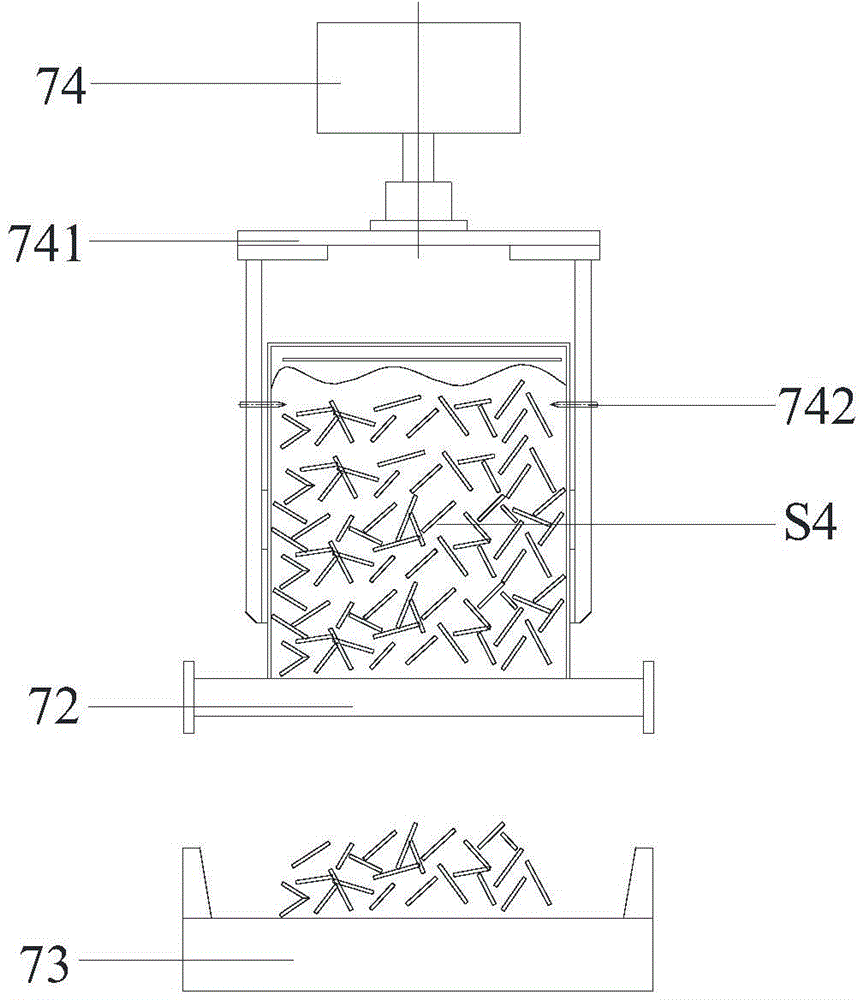

[0023] See figure 2 and image 3 , figure 2 Schematic diagram of the structure of the fully automatic box-packed stem stick unpacking equipment in the embodiment of the present invention, the direction of the arrow in the figure is the forward direction of the tobacco stem box; image 3 It is a working schematic diagram of the seventh station in the fully automatic box-packed stalk unpacking equipment according to the embodiment of the present invention.

[0024] The fully automatic box-packed stem bar unpacking equipment provided by the embodiment of the present invention includes a first station 1, a second station 2, a third station 3, a fourth station 4, The fifth station 5, the sixth station 6 and the seventh station 7, wherein:

[0025] The first station 1 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com