Testing system of logging while drilling ground machine

A logging-while-drilling and testing system technology, which is applied in the field of oil exploration and logging, can solve problems such as collapse or blockage, difficulty in obtaining logging data, putting down, and difficult instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

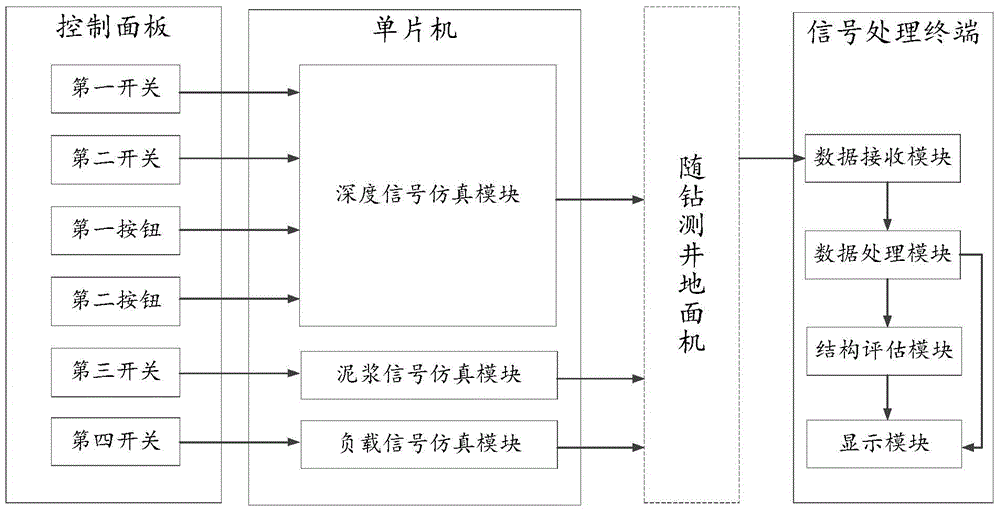

[0024] See figure 1 , an embodiment of the present invention provides a logging-while-drilling surface machine testing system, including a single-chip microcomputer, a control panel, and a signal processing terminal, wherein,

[0025] The control panel is provided with several switches and buttons for controlling the single-chip microcomputer;

[0026] Described single-chip microcomputer comprises depth signal emulation module, mud signal emulation module and load signal emulation module and control module; Described depth signal emulation module is used for producing the depth sensor signal that is processed when the logging while drilling surface machine to be tested works Simulation signal; the mud signal simulation module is used to generate a simulation signal similar to the mud pressure sensor signal processed when the logging while drilling surface machine to be tested works; the load signal simulation module is used to generate a simulation signal similar to the drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com