Hydrodynamic test model transverse moment measuring device

A technology of test model and moment measurement, which is applied in the direction of measuring device, fluid dynamics test, torque measurement, etc., and can solve the problem that the heeling moment cannot be measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

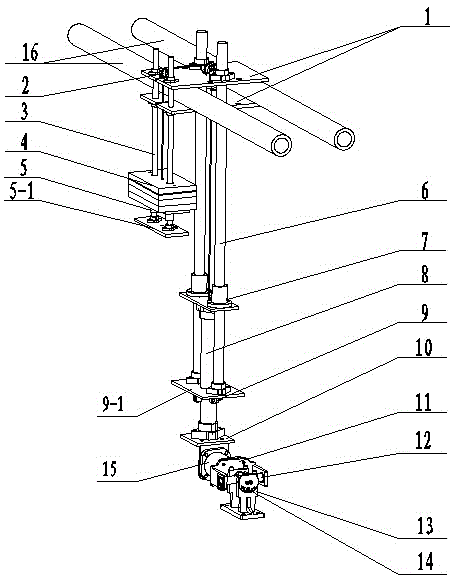

[0007] Such as figure 1 As shown, the present invention includes a pair of fixed connecting plates 1, connecting cable guide pulley 2, unloading unit fixed shaft 3, unloading weight 4, unloading unit sliding seat 5, supporting unit fixed shaft 6, supporting unit sliding seat 7, supporting Main shaft 8, supporting main shaft guide 9, right-angle adapter seat 10, rotation support in pitch direction 11, cross connecting shaft 12, rotation support in heel direction 13, heel angle adjustment plate 14 and six-component force measuring balance 15, steel The cable guide pulley 2 is installed on a pair of fixed connecting plates 1, the steel cable is wound on the cable guiding pulley 2, and the two ends of the steel cable are respectively connected with the unloading weight 4 and the supporting spindle 8, and the pair of fixed connecting plates 1 There are positioning holes for the fixed shaft of the unloading unit and the positioning holes for the fixed shaft of the support unit respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com