Method and system for reducing stack transfer amount of hot rolled slab warehouse of iron and steel enterprise

A slab and enterprise technology, applied in the field of operation management information in the storage area of iron and steel enterprises, can solve the problems of large stacking times, production capacity reduction, complex hot rolling procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

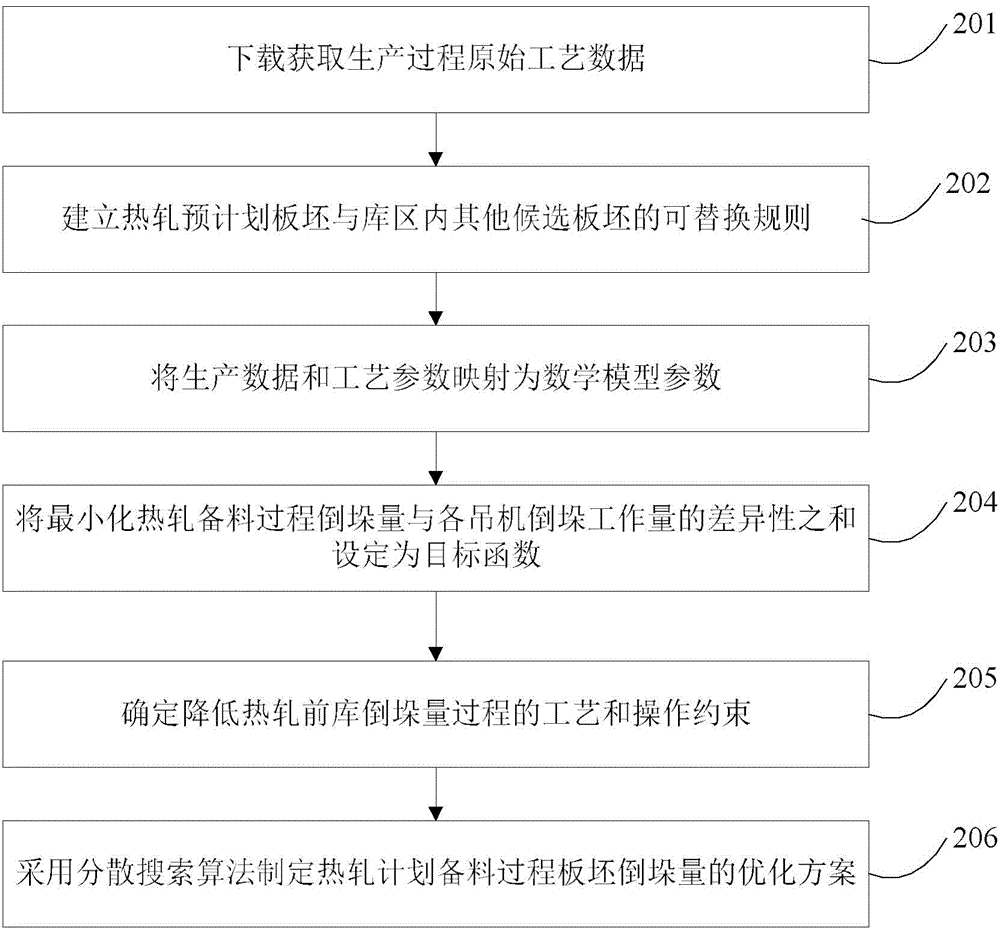

[0095] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

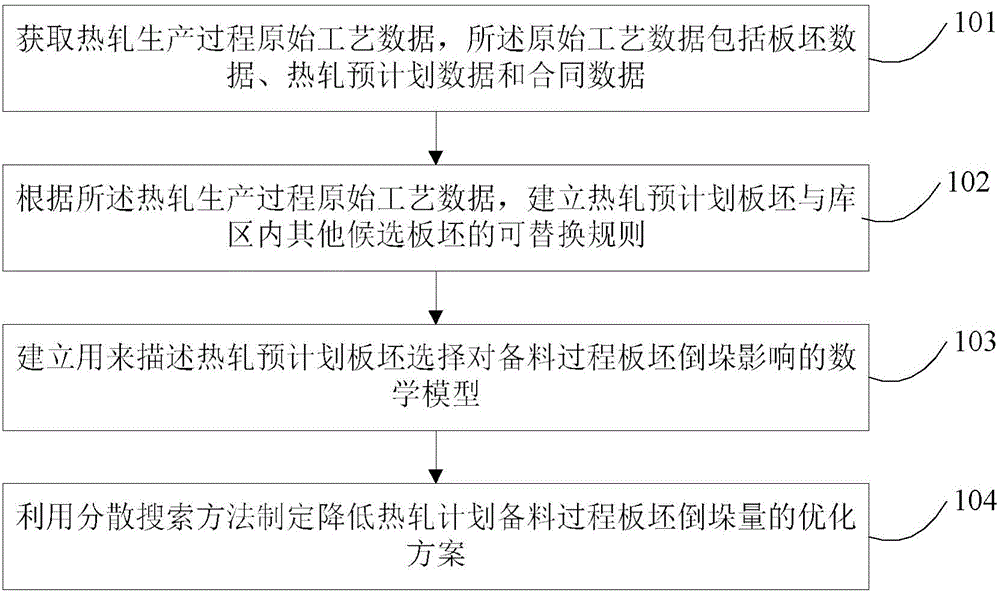

[0096] figure 1 It shows a schematic flowchart of a method for reducing the amount of stacking of hot-rolled slab warehouses in iron and steel enterprises provided by the first embodiment of the present invention, as shown in figure 1 As shown, the method of this embodiment is as follows.

[0097] 101. Obtain original process data of the hot rolling production process, where the original process data includes slab data, hot rolling pre-plan data and contract data.

[0098] In this step, it should be noted that the slab data includes: slab number, contract number, physical location identification, status, tapping mark, billet thickness, billet width, billet length, billet w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com