Novel material melting device of three-color 3D printing head

A 3D printer, a new type of technology, applied in the field of printing, can solve problems such as increasing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

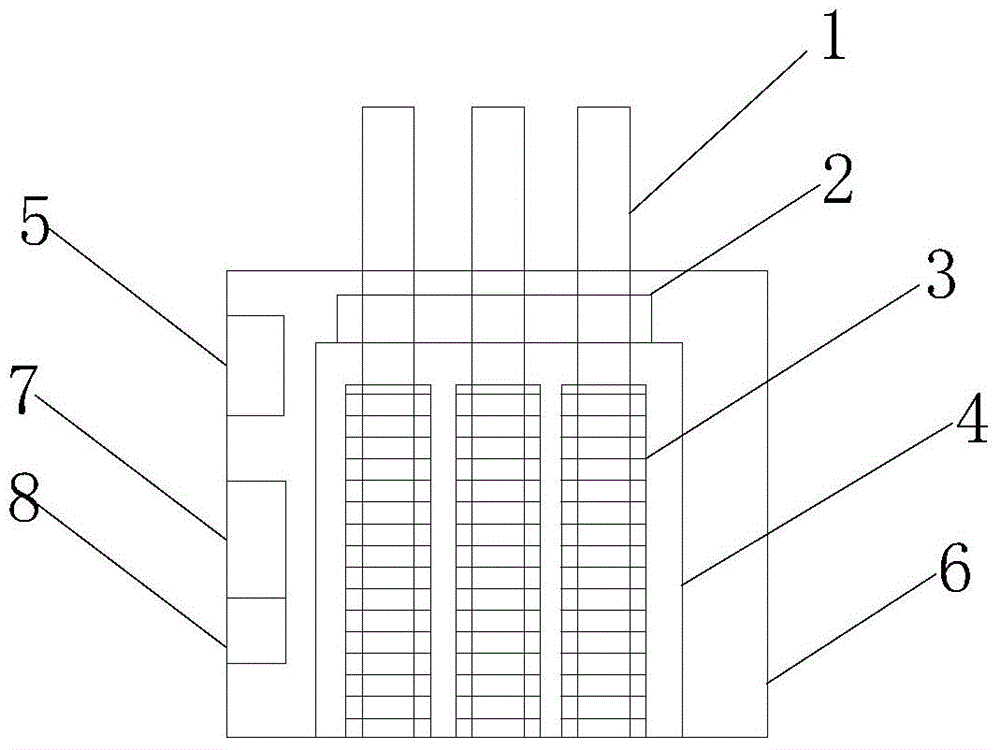

[0008] A new type of melting device for a three-color 3D printer head proposed by the present invention, as shown in the accompanying drawings, the device includes a feeding pipeline 1, a feeding detection device 2, a heating wire 3, a heat preservation chamber 4, a temperature detector 5, Shell 6 controller 7 and heating power supply 8, described feeding pipeline 1 penetrates insulation chamber 4 to the bottom of casing 6 from the top of casing 6, and heating wire 3 is installed in described insulation chamber 4, and described heating wire 3 is in each One set of feed pipes 1 is arranged respectively, surrounding the wall of the heating pipe 1 , the temperature detector 5 is installed on the upper left of the housing 6 , and a controller 7 and a heating power source 8 are arranged on the lower left of the housing 6 .

[0009] The concrete implementation process of the present invention is: the product material enters in the melting material device through the feed pipe 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com