Multi-color light curing 3D printing pen

A 3D printing pen and light curing technology, applied in the direction of 3D object support structure, additive manufacturing, accessories for processing main materials, etc., to achieve the effect of simple structure, convenient operation and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

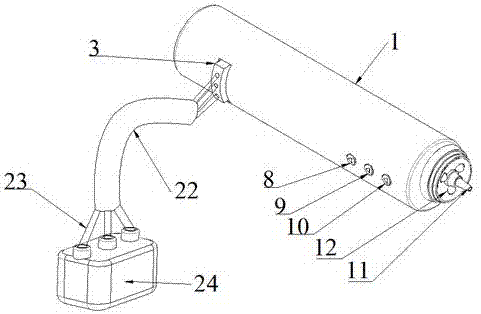

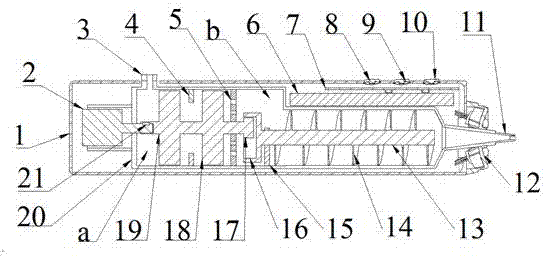

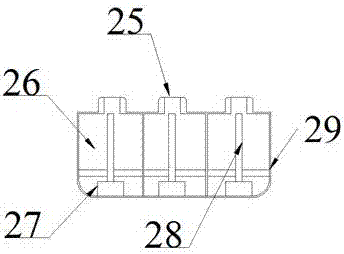

[0024] Such as Figure 1-3 shown.

[0025] A multi-color light-curing 3D printing pen, which prints a pen body 1 and a primary color material box 24, and the primary color material box 24 sends the three primary color raw materials stored therein into the printing pen body 1 through a feeding tube, and is installed in the printing pen body 1 The stirring module of the printing pen body is stirred and mixed, and then transported to the nib 11 located at the outlet end of the printing pen body 1 through the screw conveying module to print out the 3D object of the required color. A light source 12 for fast photocuring of 3D real objects; the stirring module and the screw conveying module use the same motor 2 as power, and the rotating speed of the stirring module is greater than the rotating speed of the screw conveying module. Such as figure 1 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com