Aggregate distribution device of dosing machine for stirring station

A distribution device and batching machine technology, which is applied in the direction of selling raw material supply devices, mixing plants, clay preparation devices, etc., can solve the problems of aggregate bin confusion, aggregate bin mixing, driver's vision blocking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

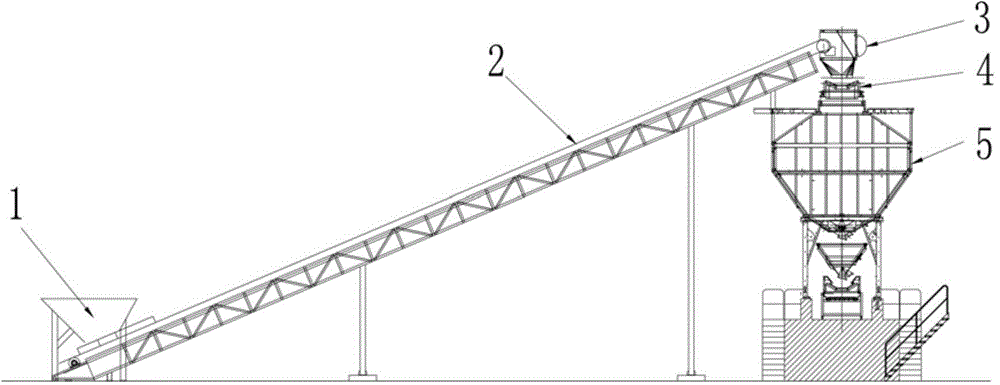

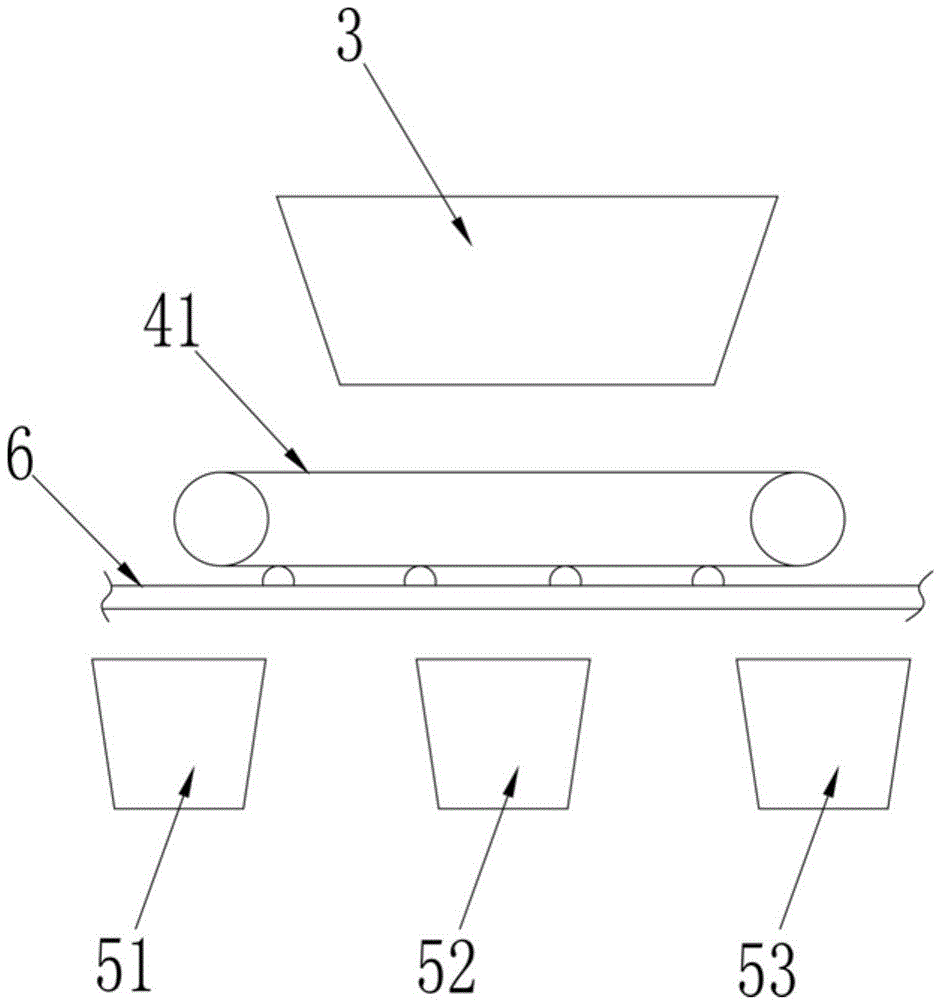

[0020] Such as Figure 1-2 As shown, an aggregate distribution device of a batching machine in a mixing station of the present invention includes: a distribution bin 1, a first conveyor belt 2, a hopper 3, and a batching trolley 4; the distribution bin 1 is set on the ground, and the batching trolley 4 is set in the bin 5 The hopper 3 is set above the batching trolley 4, and the second conveyor belt 41 is used to transport the aggregates of the distribution bin 1 into the hopper 3, and the aggregates in the hopper 3 pass through the bin 5 of the batching trolley 4; The batching trolley 4 is provided with a second conveyor belt 41, the conveying direction of the second conveyor belt 41 is adjustable; the silo 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com