Electrical Zero Force Plug Connector

A plug-in connector, zero-force technology, applied in the direction of connection, connecting device components, circuits, etc., can solve problems such as inability to ensure locking connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

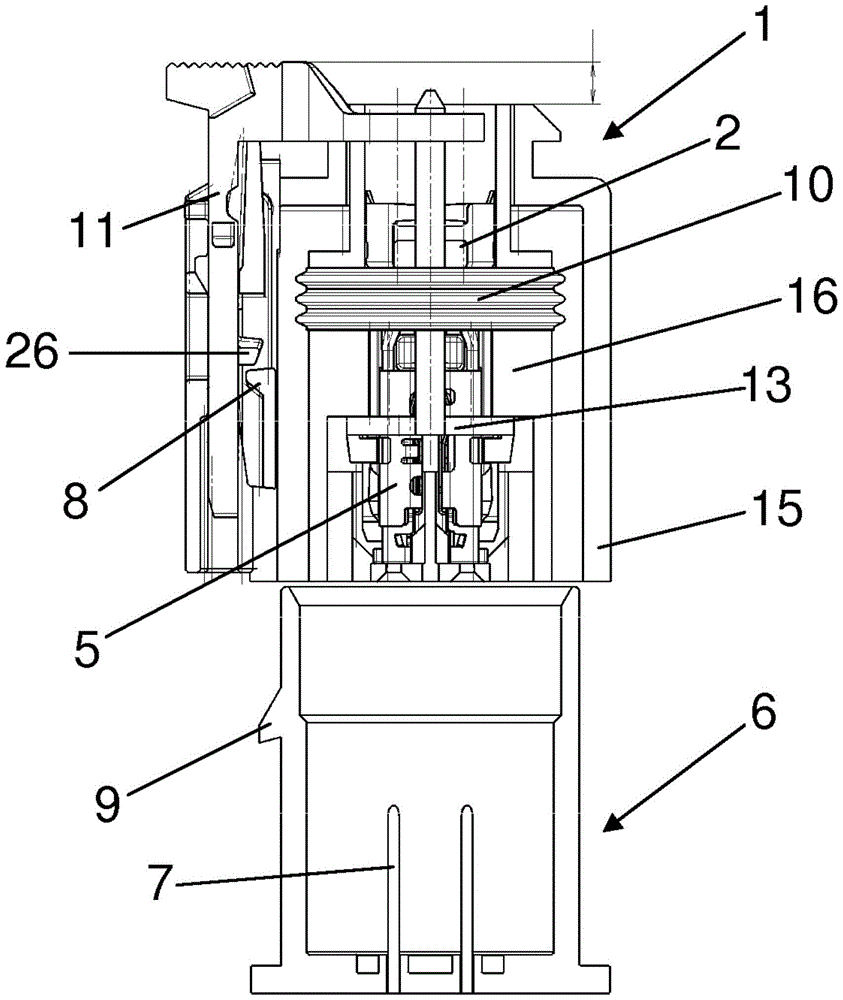

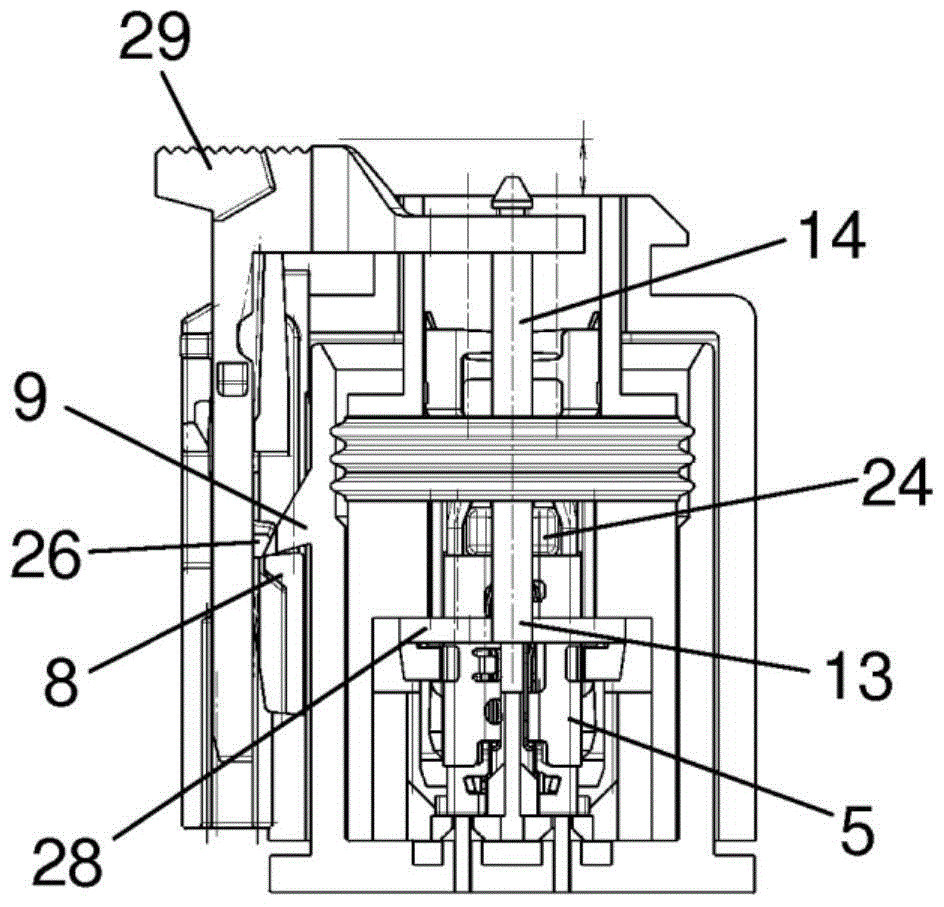

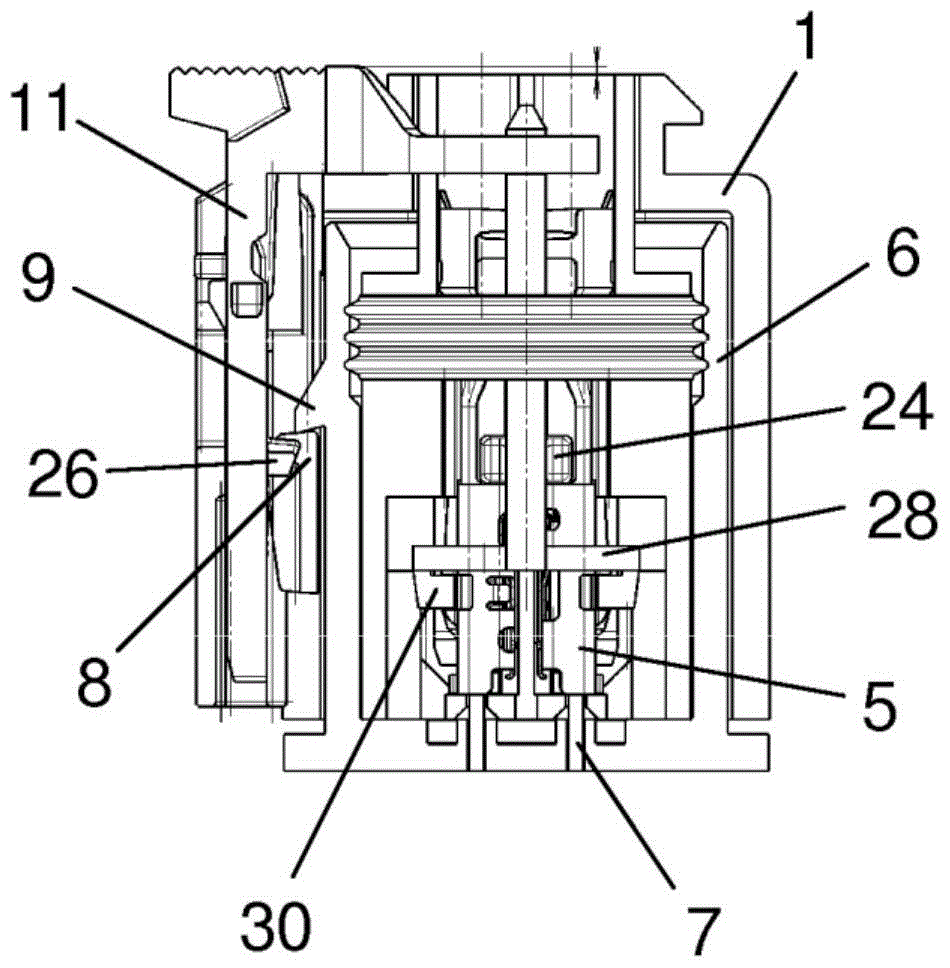

[0018] exist figure 1 shows two interconnectable plug connector parts 1 , 6 of the zero-force plug connector according to the invention in the still unconnected state. The plug connector parts 1 , 6 are also referred to here, in particular, as plug socket housing 1 and socket 6 .

[0019] The plug socket housing 1 consists of an outer enveloping housing 15 and an inner contact carrier 16, which can be embodied either in one piece or as separate parts connected to each other, and can be clearly defined in the Figure 5 seen in. The contact carrier 16 has a plurality of tubular receptacles 25 into which the bushing contacts 2 made of metal are inserted.

[0020] As already described in DE 10 2005 040 952 A1, Figure 7 The bushing contact 2 is shown as a separate component in two views a) and b). The bushing contact 2 is formed by a metallic base body 4 which is connected to an electrical line 22 . The line 22 has an electrical conductor 17 which is electrically and mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com