Magnetic bearing motor and its magnetic bearing assembly

A technology of magnetic bearings and components, applied in the direction of bearing components, bearings, bearing unloading, etc., can solve the problems that magnetic bearings cannot enter the mass production stage smoothly, the auxiliary magnet adsorption angle is incorrect, and cannot run smoothly, etc., to achieve low friction , avoid manufacturing, improve the effect of operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

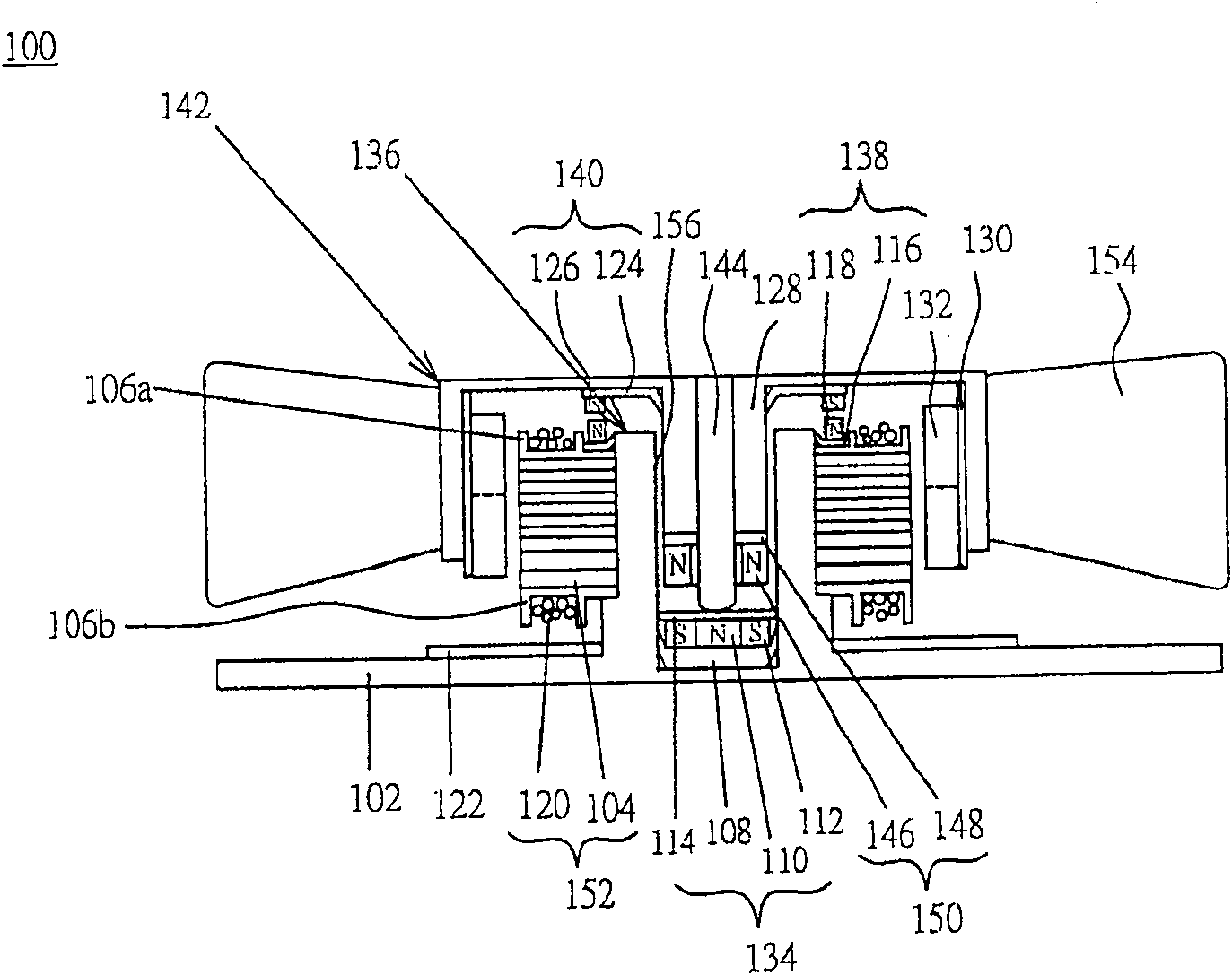

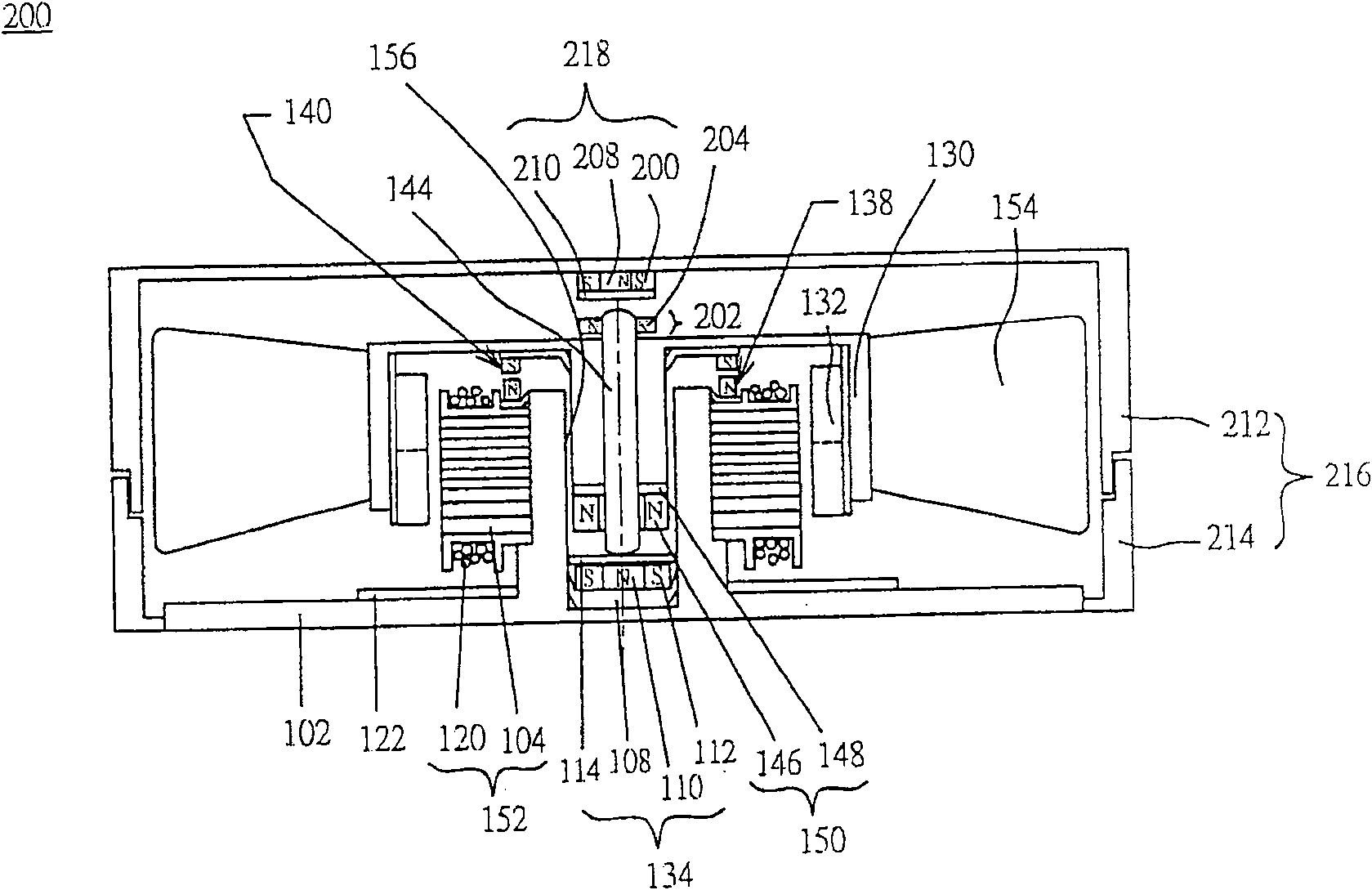

[0036] figure 1is a schematic diagram illustrating the magnetic bearing motor 100 according to the first preferred embodiment of the present invention. Please refer to figure 1 , the magnetic bearing motor 100 is composed of a rotating assembly 142 and a stator assembly 136, wherein in a static state, there is only a single point of contact between the rotating assembly 142 and the stator assembly 136, and in a running state, the contact between the rotating assembly 142 and the stator assembly 136 There is only a single point of contact or no contact between them.

[0037] The stator assembly 136 is composed of the stator base 102 , the stator poles 152 , and the magnetic positioning assemblies 134 , 138 . The stator base 102 is a convex component or a cylindrical component with an opening 156 at the center for carrying the rotating component 142 . The material of the stator base 102 is, for example, plastic, nonmagnetic rigid material, metal, or alloy.

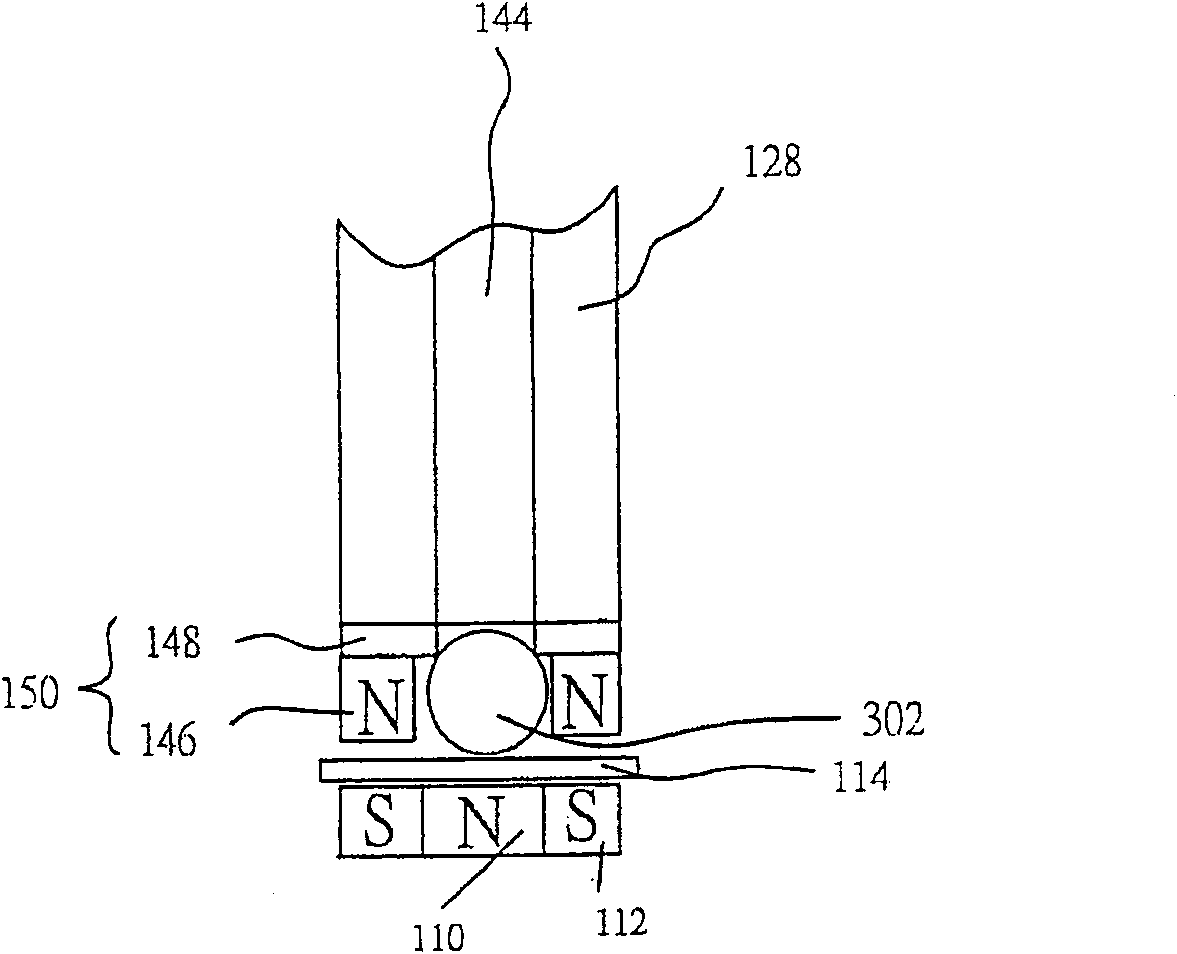

[0038] The stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com