Automatic lubricating device

An automatic lubrication and oil cylinder technology, applied in the direction of engine lubrication, engine components, mechanical equipment, etc., can solve the problems of low standardization of operation, poor lubrication continuity, equipment failure, etc., achieve wide application range, solve lubrication, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

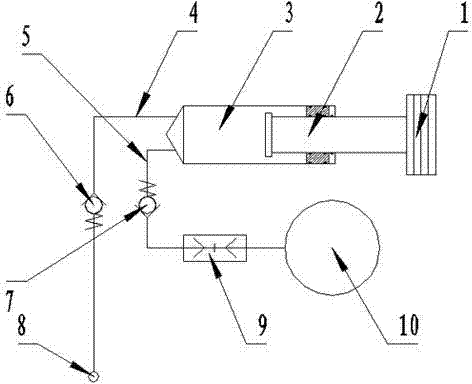

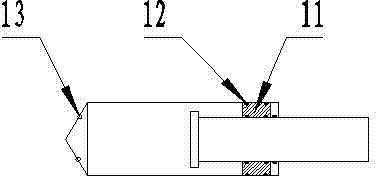

[0015] As shown in the figure: an automatic lubricating device, including an inertial weight 1, a piston 2, an oil cylinder 3, an oil storage bag 10 and a pipeline connecting various components, the inertial weight 1 is connected to the piston 2, and the piston 2 Installed in the oil cylinder 3, it can do axial push-pull movement in the oil cylinder 3. The oil cylinder 3 is connected to the oil filling pipeline 4 and the oil replenishing pipeline 5. The oil filling pipeline 4 is connected to the equipment that needs to be lubricated through the oil filling joint 8 , the oil replenishment pipeline 5 is connected with the oil storage bag 10 through the quick connector group 9 .

[0016] Further, the inertial weight 1 is composed of a plurality of weight blocks, the number of weights can be increased or decreased according to the acceleration of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap