Coaxial high-precision rear fork

A high-precision, leveling fork technology used in axle suspensions, bicycle accessories, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

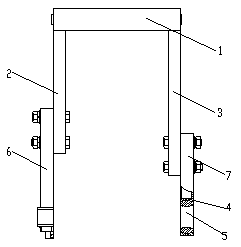

[0016] The accompanying drawing is a schematic diagram of the structure of the present invention, as shown in the figure: the flat fork with high coaxiality and precision in this embodiment includes the end shaft tube 1, the leg tube I2 and the leg tube II3, and the leg tube I2 and the leg tube II3 are respectively It is fixedly connected with the shaft tube 1 at the end, and the leg tube I2 is used to install the motor vehicle transmission, and the transmission installation parts can be fixedly arranged; the leg tube II3 is provided with the axle seat 5 for rotating with the wheel shaft; the end of the leg tube II3 A drum-shaped sleeve 4 with a drum-shaped inner circle is provided, and the outer circle of the axle seat 5 is a drum-shaped structure, and the drum-shaped sleeve 4 is sleeved on the outer circle of the axle seat 5 and is slidably fitted.

[0017] The drum-shaped sleeve 4 is fixedly arranged on the leg pipe II3 through the brake installation leg pipe 7, and the brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com