Vehicle automatic correction brake co-axial combined bottom fork

An automatic correction and brake technology, applied in axle suspension, bicycle accessories, transportation and packaging, etc., can solve the problems of energy and power waste, deterioration of vehicle operating conditions, and increase of vehicle maintenance costs, so as to save energy and power, prolong The effect of using cycle and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

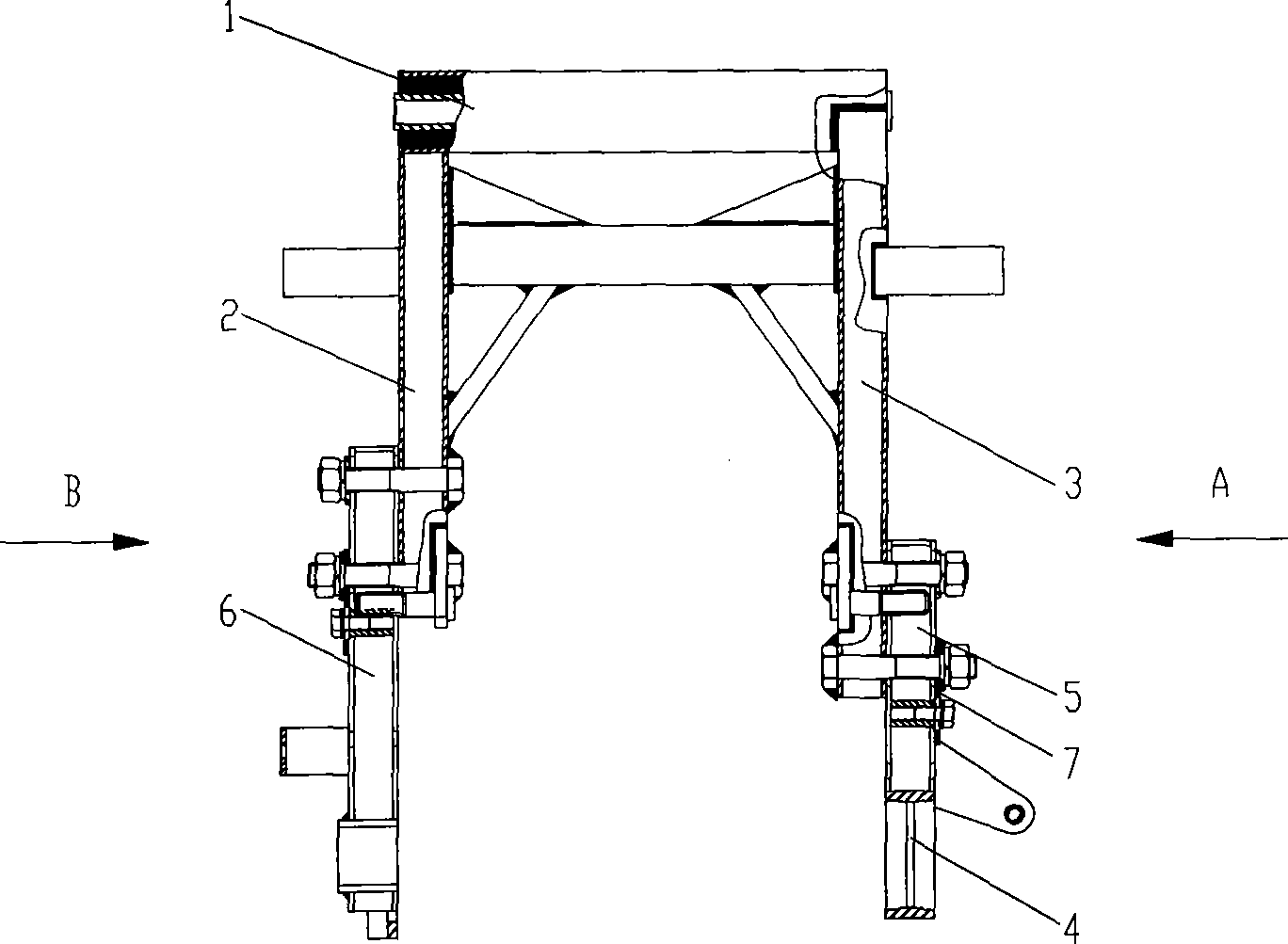

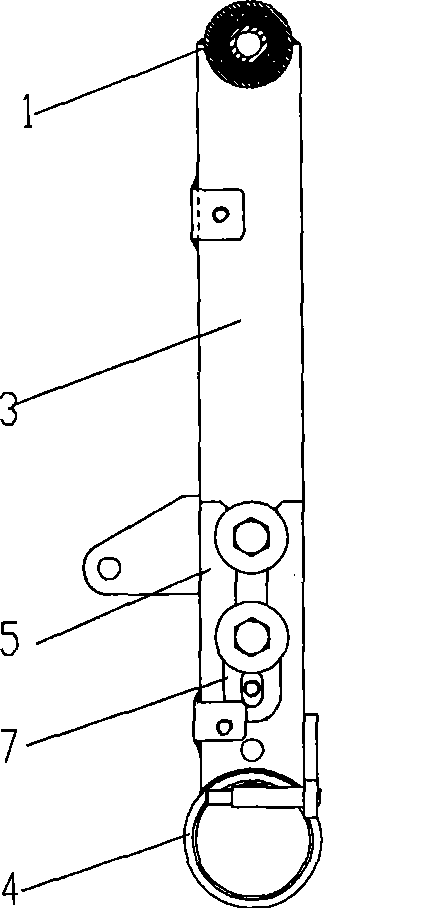

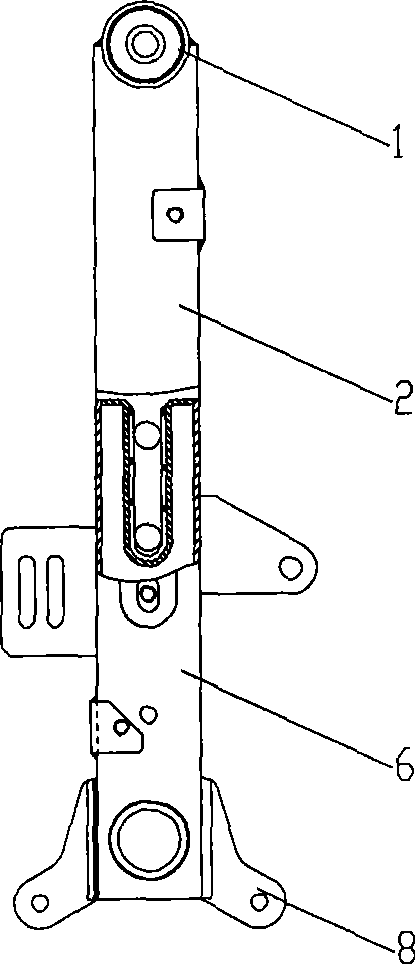

[0024] figure 1 It is a structural schematic diagram of the first embodiment of the present invention, figure 2 for figure 1 View along direction A, image 3 for figure 1 View along the B direction, as shown in the figure: the combined flat fork for automatically correcting the coaxiality of the brake of the motor vehicle in this embodiment includes the end shaft tube 1, the leg tube I 2 and the leg tube II 3, and the leg tube I 2 and the leg tube II 3 are respectively fixedly connected with the end shaft tube 1, the leg tube I2 is fixedly provided with the transmission mounting lug 8, and the leg tube II 3 is provided with the axle seat 4; during assembly, the brake 13 is fixedly arranged on the leg tube II 3, The axle seat 4 is set on the outer circle of the bearing seat 10 of the wheel shaft 9 to support the wheel axle 9. The diameter of the inner hole where the axle seat 4 cooperates with the bearing seat 10 gradually increases from the middle to both ends. In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com