Intermittent presser foot applied to sewing machine, sewing machine and process adopting sewing machine to perform vamp processing

A sewing machine and sewing machine needle technology, applied in the field of sewing machines, can solve the problems that are not conducive to the consistency of shoe upper product quality specifications, low proficiency processing efficiency, etc., and achieve the effect of meeting the integration of product quality specifications and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

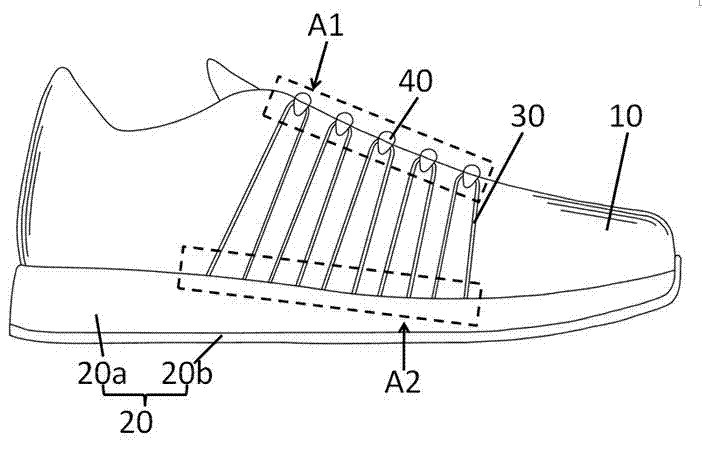

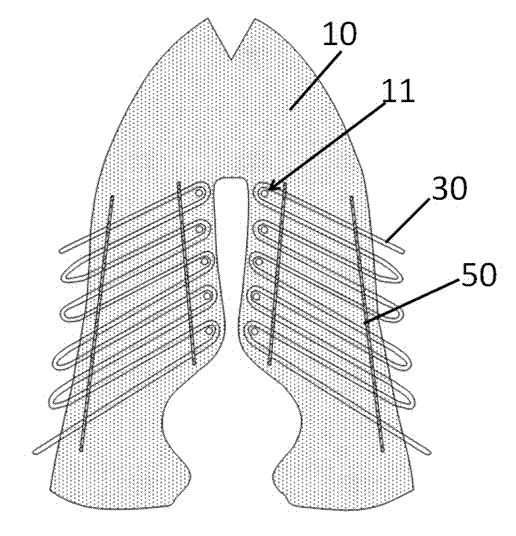

[0036] In order to better understand the technical solutions of the present invention, the following will be described in detail in conjunction with relevant figures. It should be understood that the following specific examples are not intended to limit the specific implementation aspects of the technical solution of the present invention, but are only applicable implementation aspects of the technical solution of the present invention. It needs to be explained first that the expression of the positional relationship of each component in this article, such as that component A is located above component B, is based on the representation of the relative position of each component in the illustration, and is not intended to limit the actual positional relationship of each component.

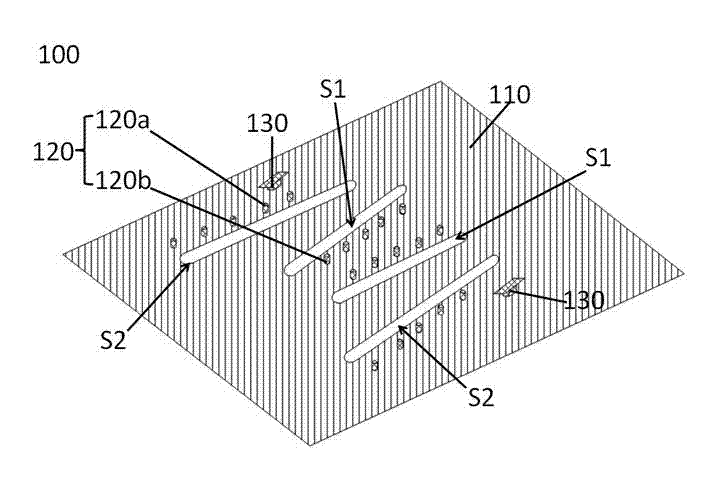

[0037] Please check figure 2 , figure 2 A schematic diagram of a positioning mold that can be used in the present invention is shown. Such as figure 2 As shown, the positioning mold 100 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com