Electronic-controlled engine under-vehicle accelerator constant-rotation-speed switching switch control device

A switch and fixed speed technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of poor control of engine speed accuracy, long time required, and failure to work normally, so as to avoid failure to work normally, The effect of high speed control precision and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

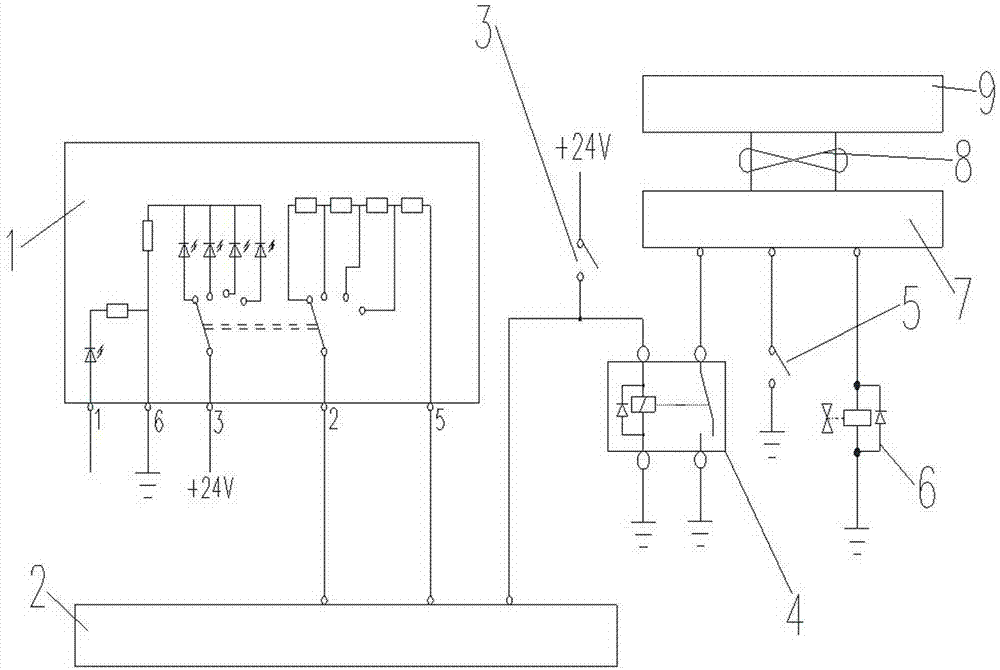

[0012] Attached below figure 1 The present invention will be further described.

[0013] The electronically controlled engine car under the throttle fixed speed switch control device, including the engine ECU 2, the central computer 7 of the vehicle body, the solenoid valve 6 of the power take-off connected to the cylinder of the power take-off through the air circuit and electrically connected to the central computer 7 of the vehicle body, and the setting The power take-off position switch 3 on the top of the power take-off cylinder, the multi-state switch 1 and the power take-off switch 5 electrically connected to the central computer 7 of the vehicle body, the 1 pin of the multi-state switch 1 is electrically connected to the vehicle power supply, and the 6 pin is grounded , its pin 3 is connected to the 24V power supply, its pin 2 and pin 5 are electrically connected to the engine ECU 2, one end of the power take-off position switch 3 is electrically connected to the 24V p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap