Patents

Literature

37results about How to "High speed control precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

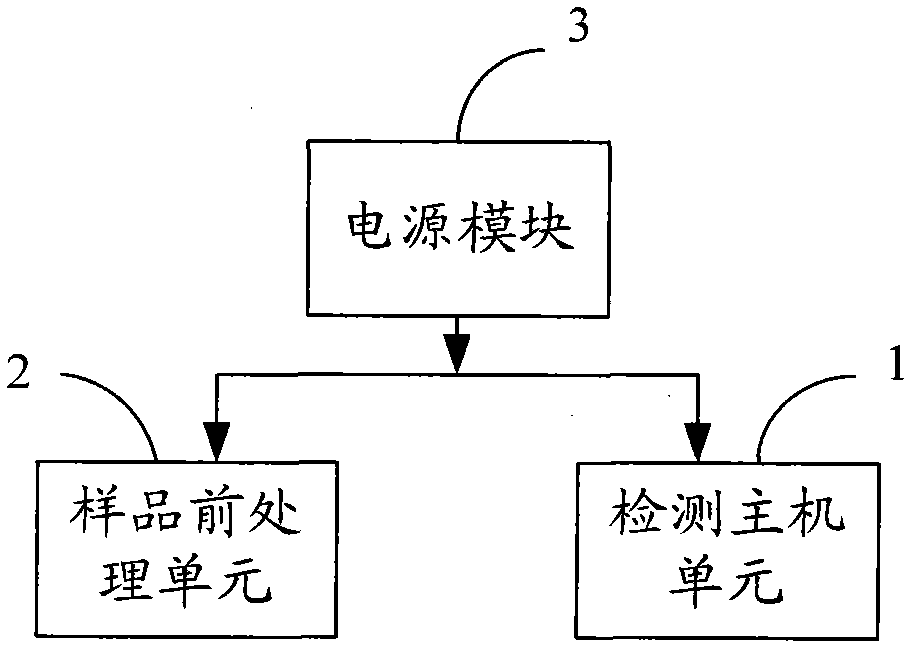

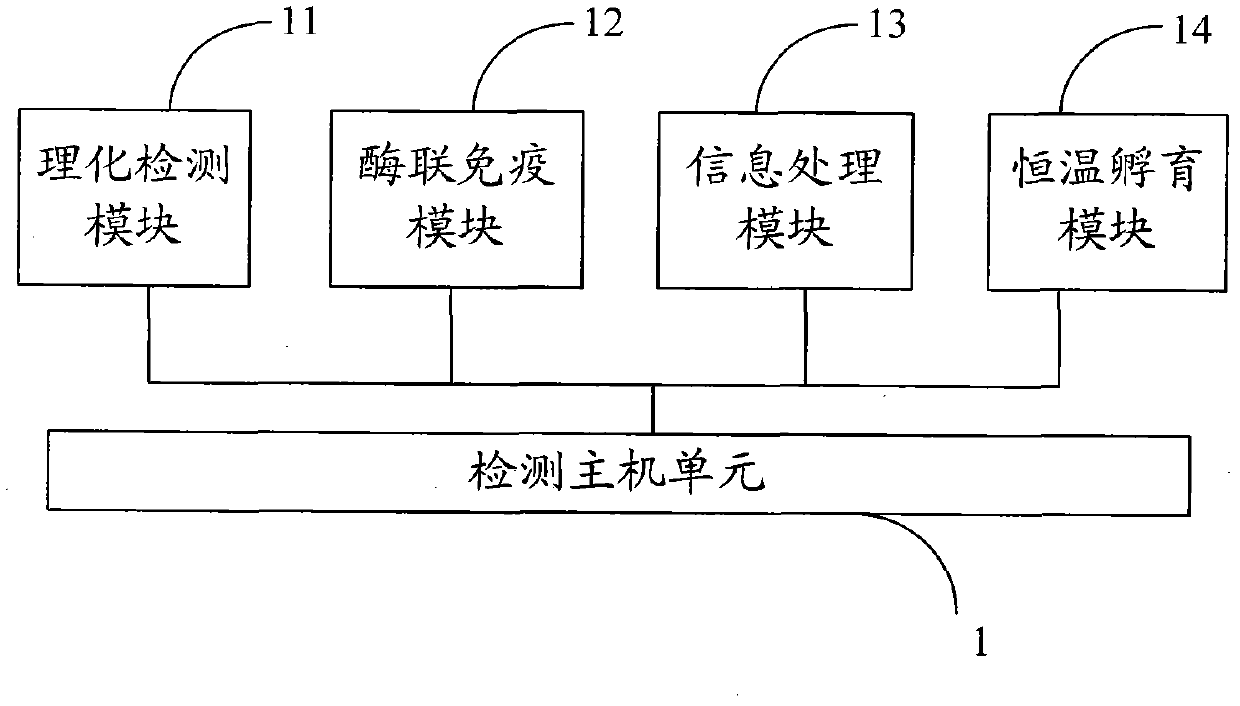

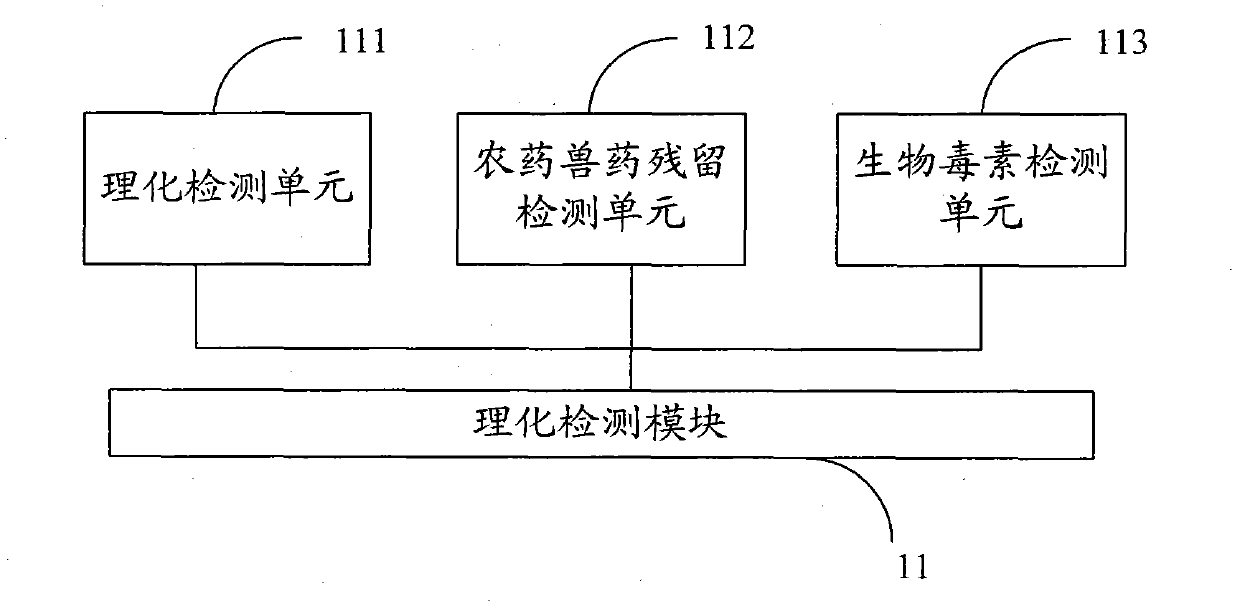

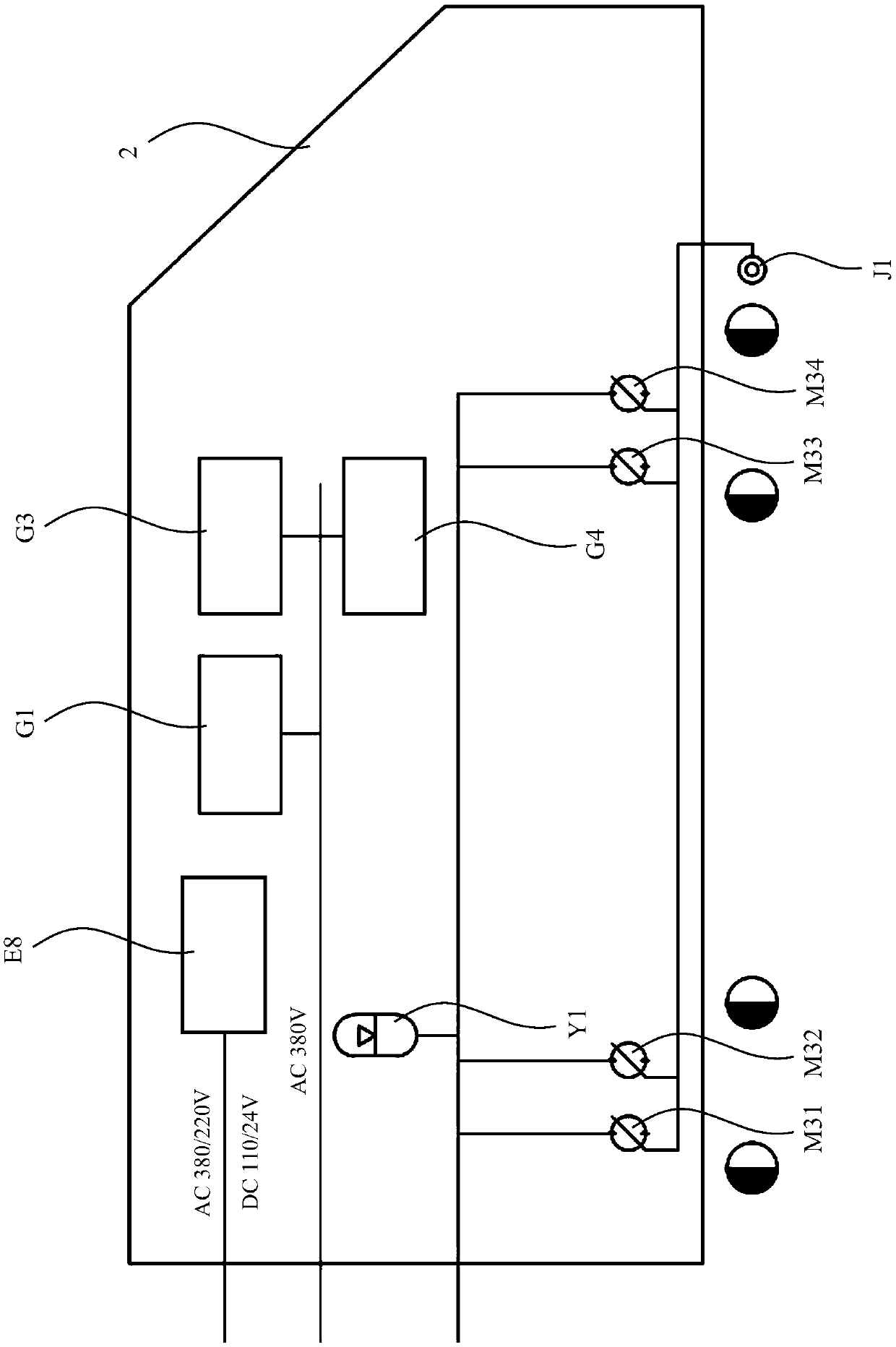

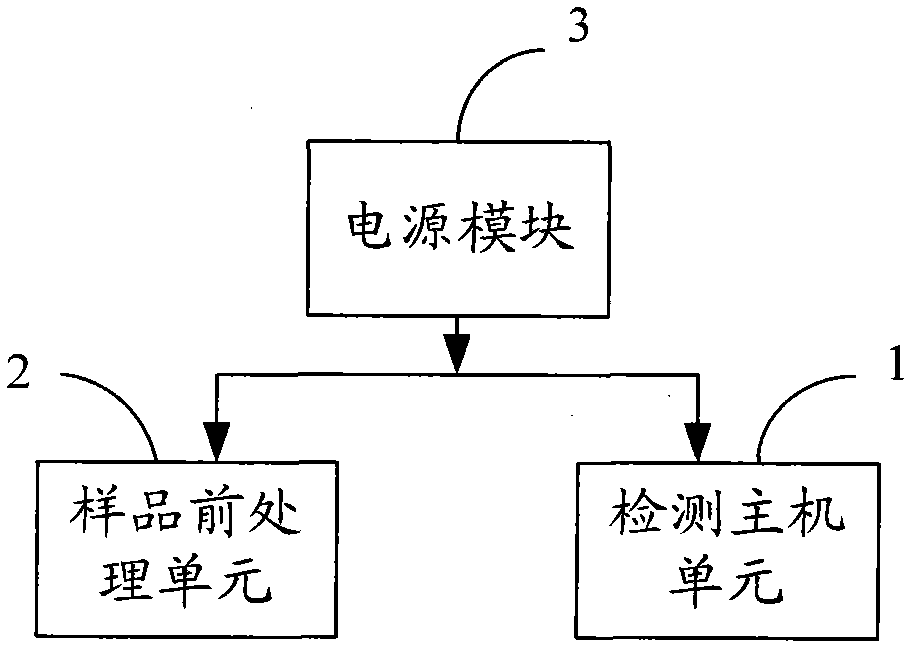

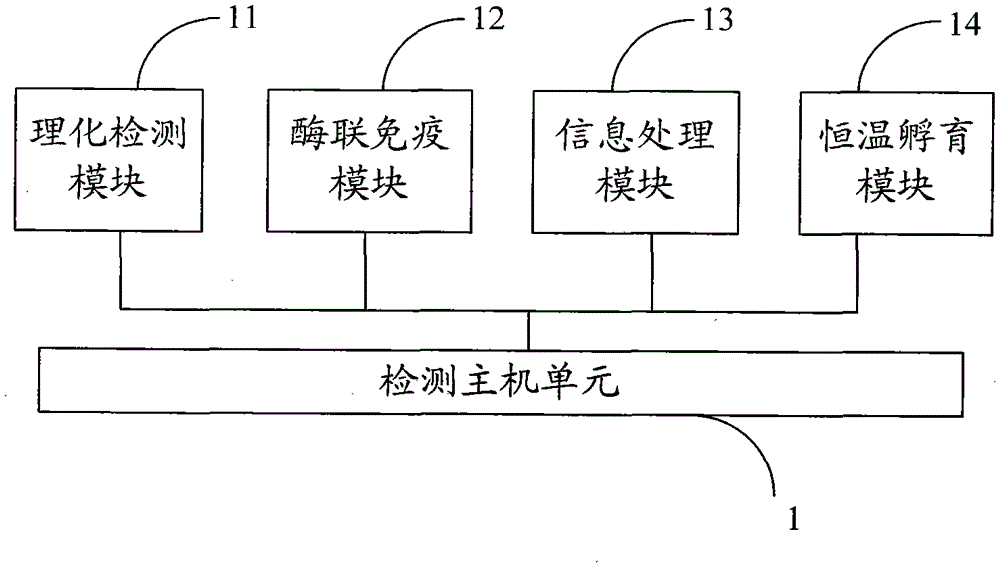

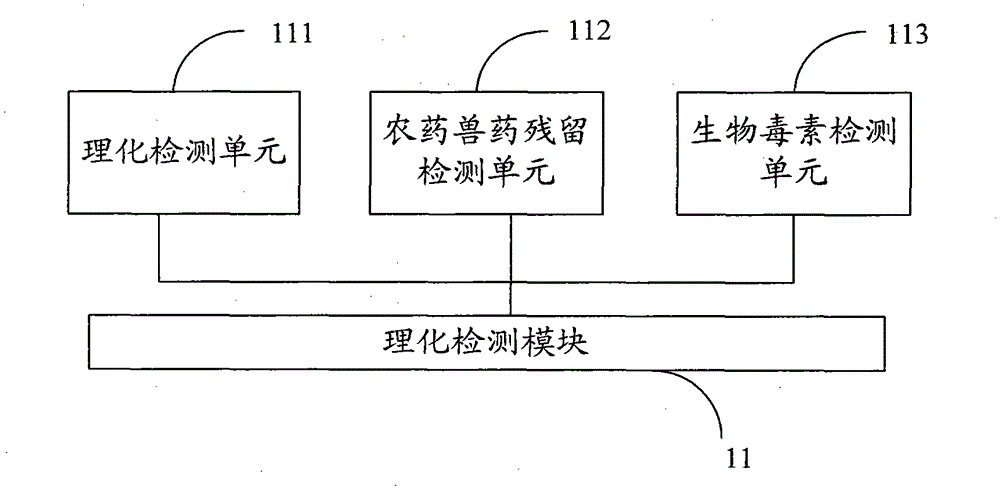

Digital rapid food safety detection system

ActiveCN103323584AMeet the needs of security routine testingThe detection process is fastColor/spectral properties measurementsBiological testingInformatizationTemperature control

The invention belongs to the field of rapid food safety detection, and provides a digital rapid food safety detection system, which mainly comprises a detection host machine unit, a sample pretreatment unit and a power supply module, can be provided for detecting a plurality of physical and chemical items, pesticide and veterinary drug residues, and biotoxins, has characteristics of rapid detection, high sensitivity, high informatization degree, and sample treatment-sample detection-informatization management integration, is an optimal selection for safe and rapid on-site detection, meets requirements of enterprise laboratories on food safety routine detection, and has strong promotion and application values. In addition, the detection host machine unit has the following characteristics that: temperature control precision and rotation speed control precision are high, functions of precise timing, short shock inching, temperature calibration and power-down recovery are provided, three functions such as constant temperature maintaining, oscillation and timing can be manually switched, the machine with a plurality of uses can be achieved, and equipment utilization can be increased.

Owner:北京倍肯恒业科技发展股份有限公司

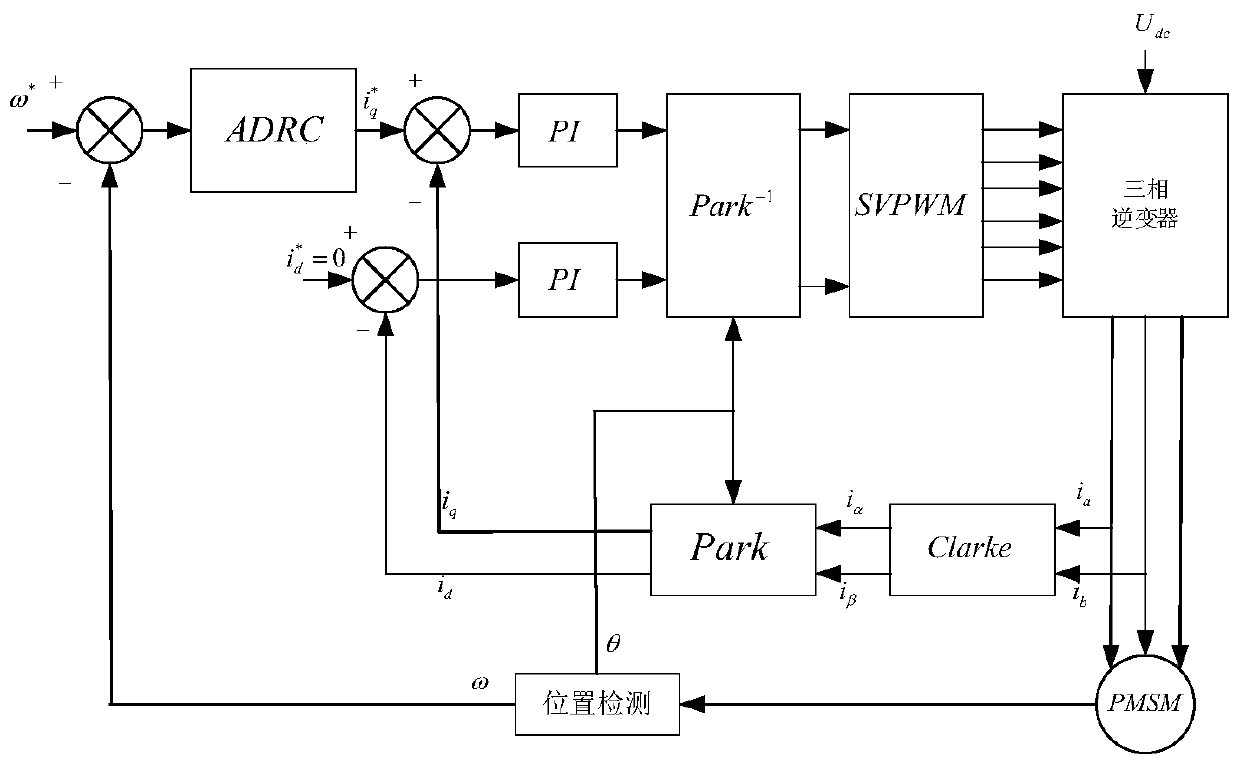

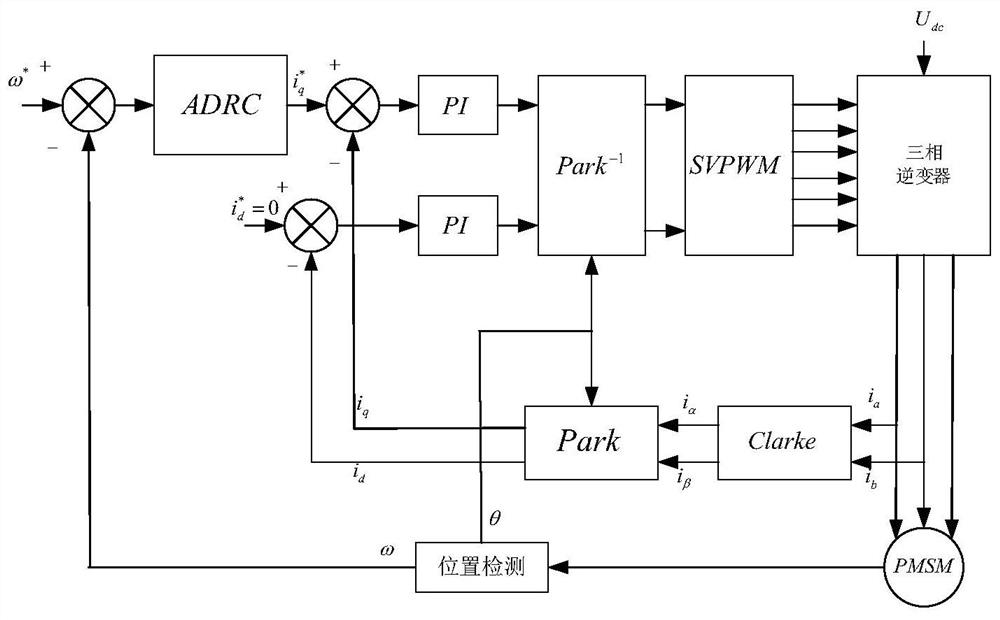

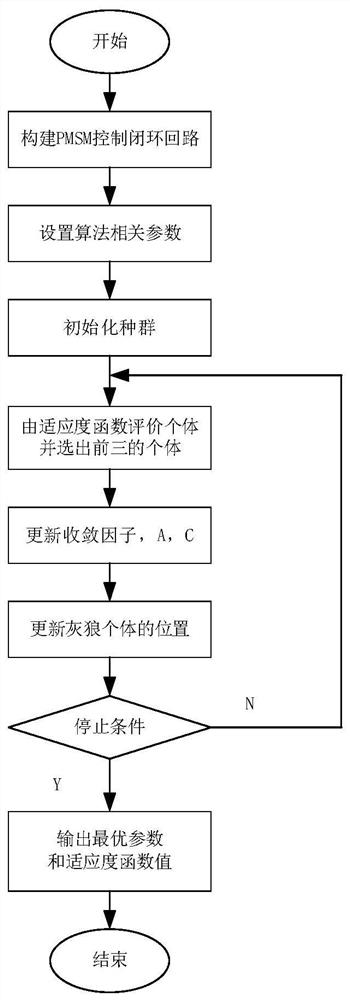

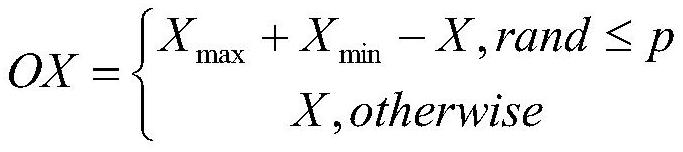

Parameter setting method for auto-disturbance rejection controller of speed loop of permanent magnet synchronous motor

ActiveCN110729939AFast convergenceImprove global search performanceElectronic commutation motor controlElectric motor controlLocal optimumControl engineering

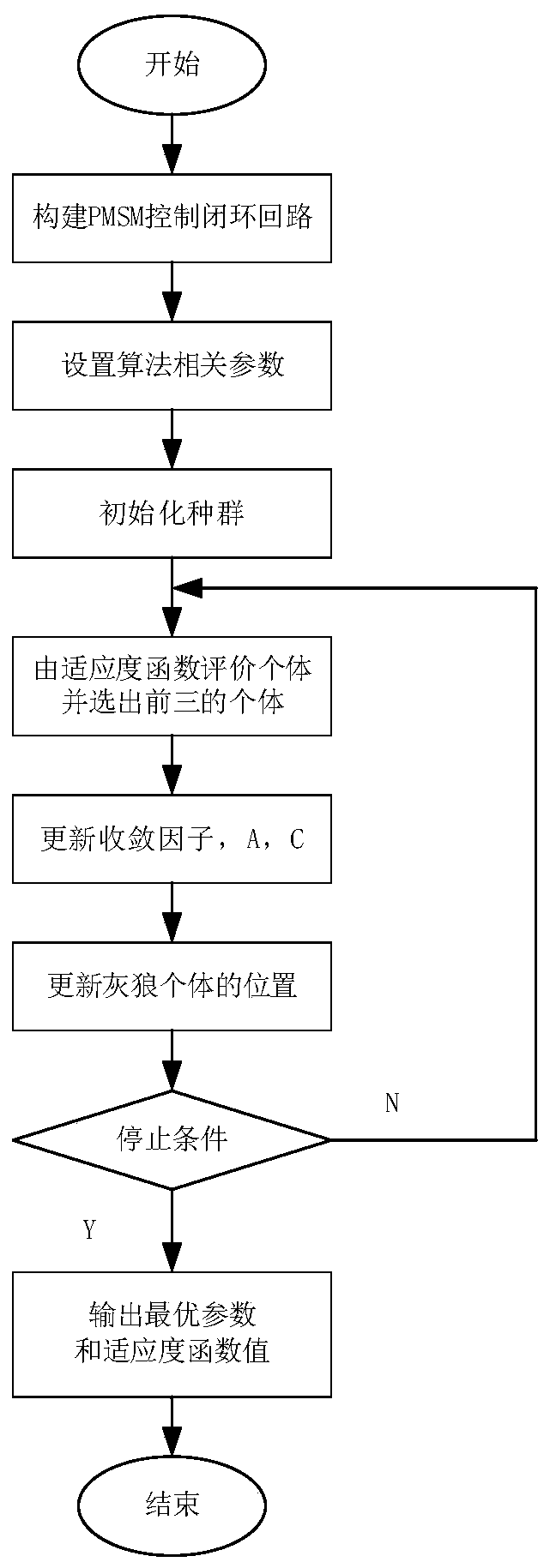

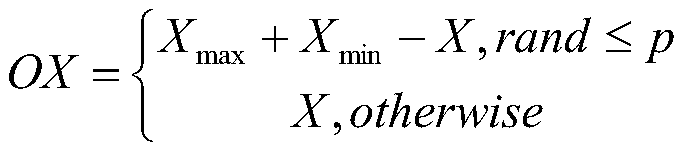

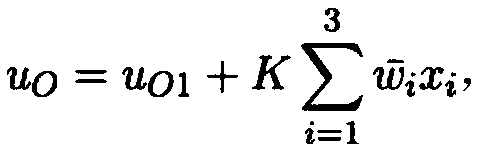

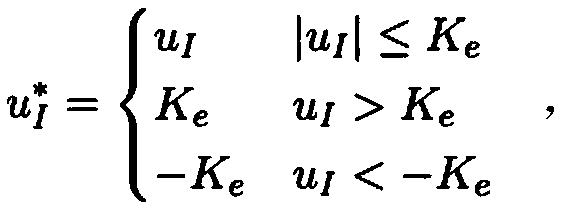

The invention discloses a parameter setting method for an auto-disturbance rejection controller of a speed loop of a permanent magnet synchronous motor. A speed and current double-closed-loop controlstructure is established, a grey wolf population strategy is initialized according to tent mapping reverse learning, a convergence factor which nonlinearly changes along with the increase of the number of iterations is adopted, a left flight strategy is introduced into a wolf group position updating link in an algorithm to perform mutation operation, and finally, set parameters are obtained. According to the invention, the grey wolf optimization algorithm population is improved from initialization. A grey wolf population is initialized according to a tent mapping reverse learning strategy, a convergence factor which nonlinearly changes along with the increase of the number of iterations is designed, and a left flight strategy is introduced into a wolf group position updating link, so thatan improved grey wolf optimization algorithm is provided. The diversity of the initial population of the algorithm can be improved, the adaptability and adjustability to complex search are better, thealgorithm can be prevented from falling into local optimum, the convergence rate and global optimization capability of the algorithm are improved, and the effect is better than the effects of other improved grey wolf optimization algorithms.

Owner:JIANGSU UNIV OF SCI & TECH

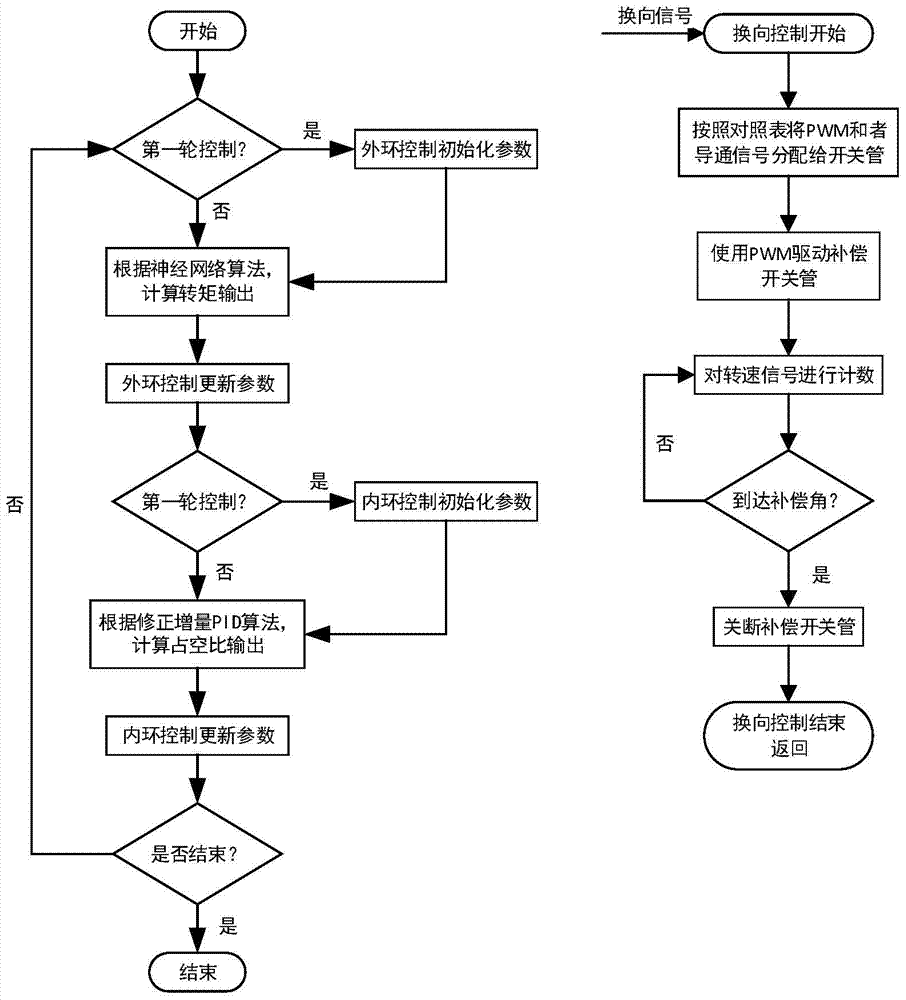

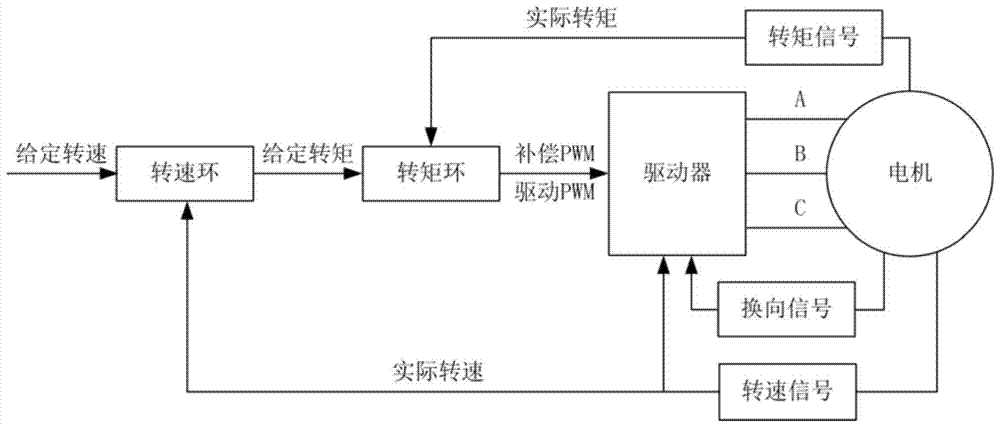

Torque feedback and commutation compensation-based brushless motor control method

InactiveCN105305895AImproved torque rippleIncreased torque rippleTorque ripple controlElectronic commutatorsBrushless motorsInner loop

The invention aims at providing a control method for a novel brushless motor to reduce torque ripples when the brushless motor runs by introducing a torque loop and a commutation compensation. According to the specific technical scheme, the method comprises the following steps: (1) determining a torque required by the motor by a difference value between a given rotating speed and an actual rotating speed; (2) determining the duty ratio by the difference value between the given torque of an outer loop and the actual torque of the motor; (3) simultaneously carrying out the step (1) and the step (2), and adopting a control strategy for switch tube lag shutdown to reduce the torque ripples caused by a commutation; and (4) driving a switch according to the duty ratio as shown in the specification obtained by a front double closed loop control algorithm and the direction of the torque. According to the method, the working range of the motor is expanded through a commutation compensation method for a lagging commutation; a neural network control algorithm used by the outer loop is quick in response, small in steady state error and small in overshoot; an inner loop utilizes a torque loop instead of a current loop, so that the control accuracy on the motor is greatly improved; and the ripples of the motor in the commutation are reduced.

Owner:JILIN UNIV

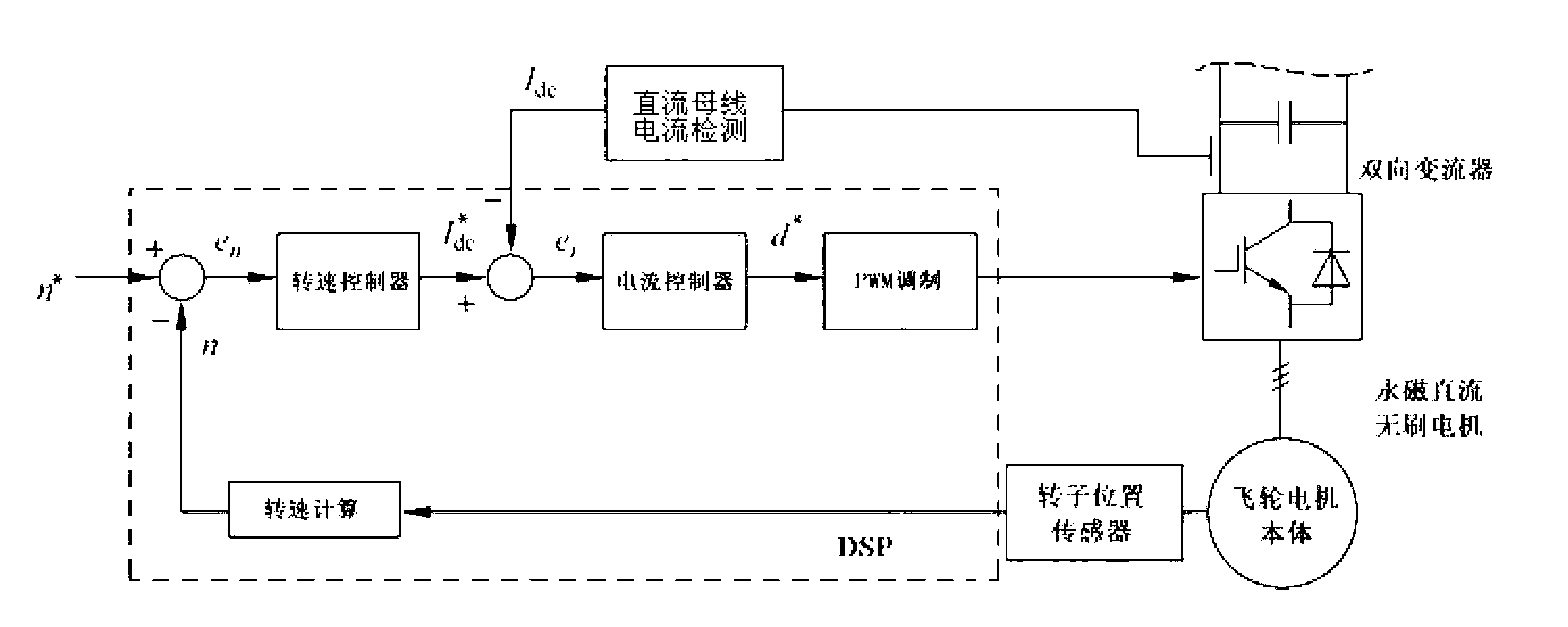

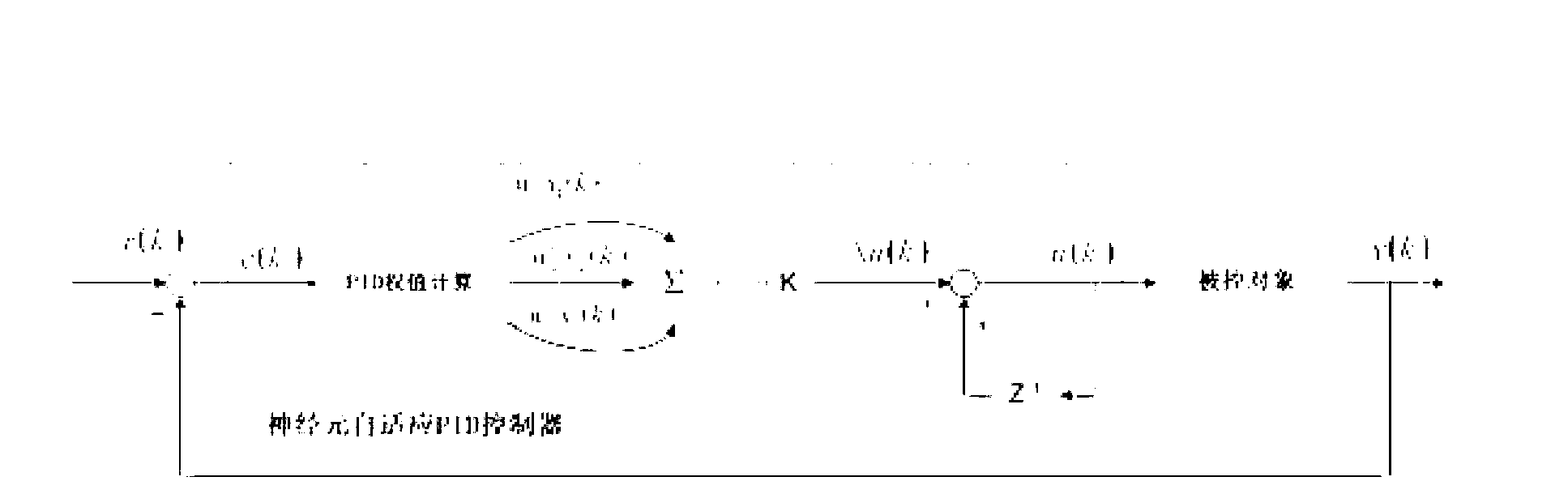

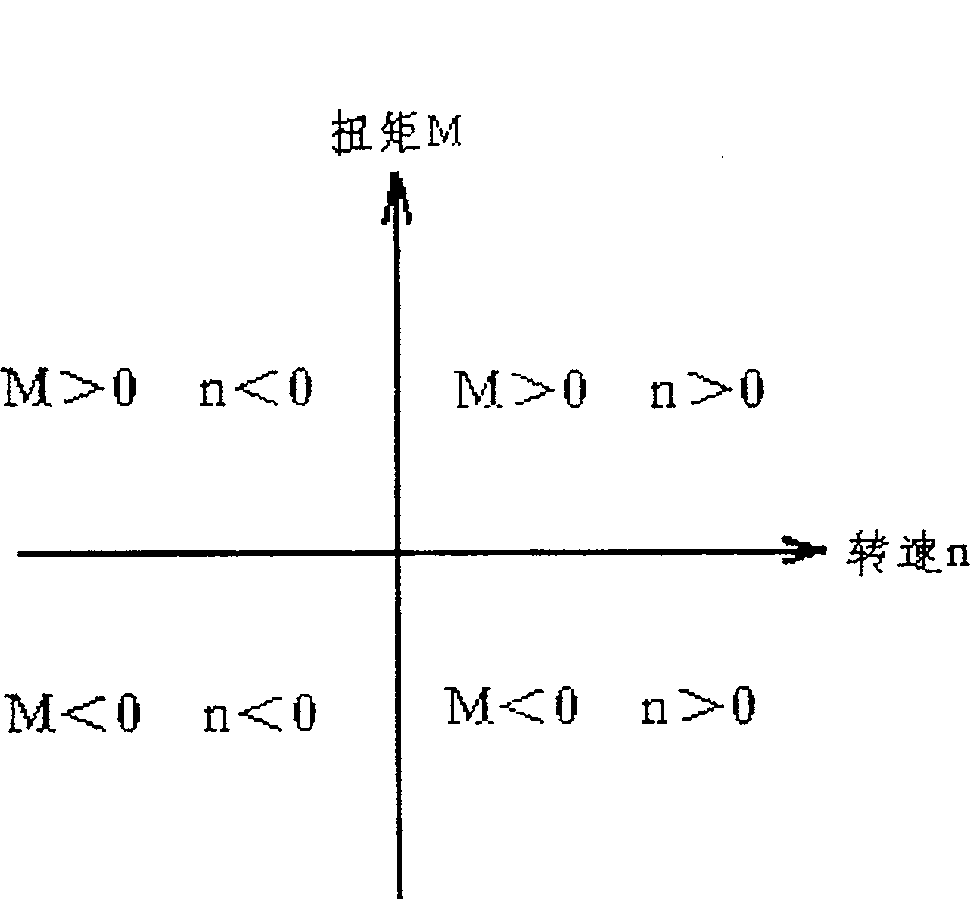

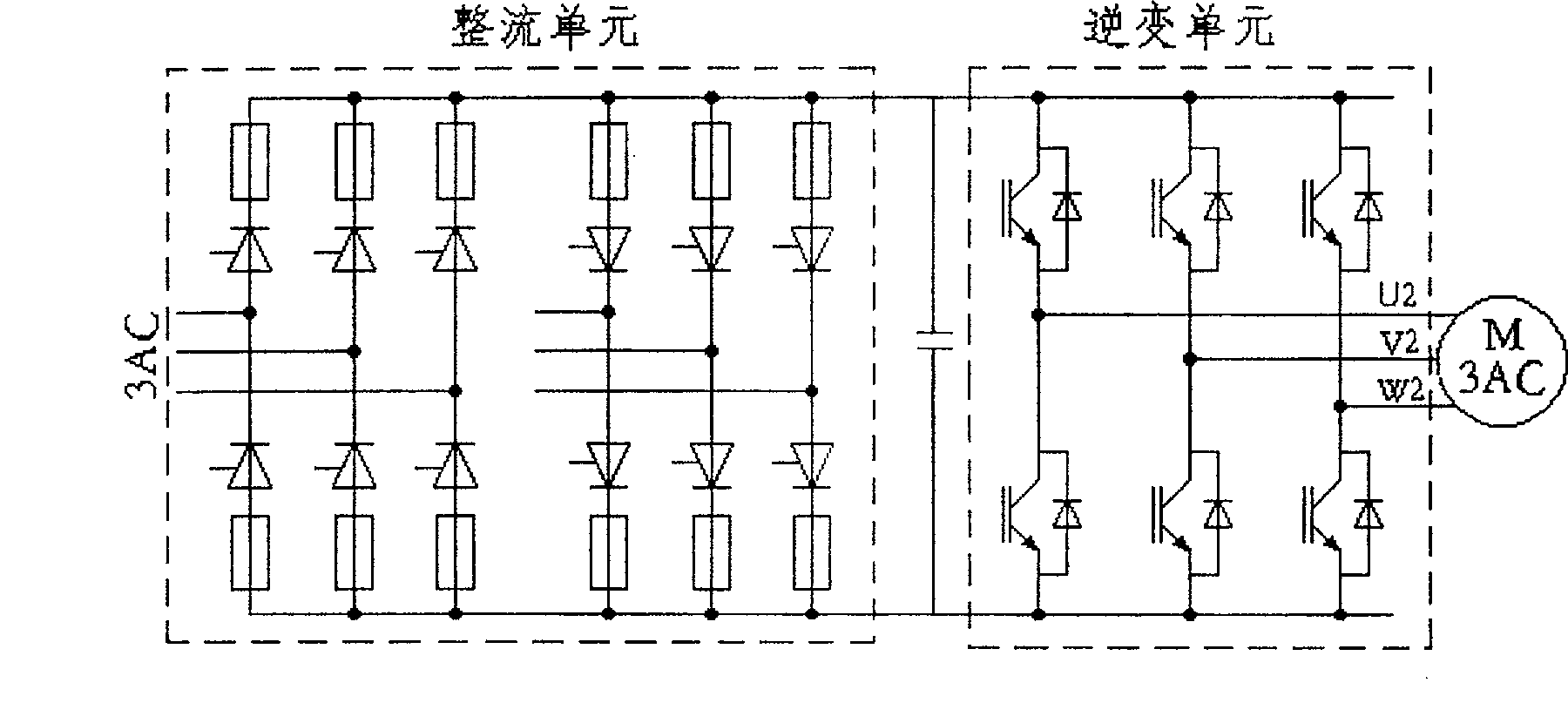

Control method for mechanical energy storage system

ActiveCN103248292AHigh speed control precisionImprove robustnessSingle motor speed/torque controlAc network load balancingWind drivenFlywheel energy storage

The invention discloses a control method for a mechanical energy storage system, which comprises the following steps that 1, one flywheel energy storage unit is connected in parallel with one wind driven generator, or a flywheel energy storage matrix is formed by the one flywheel energy storage unit and a plurality of other flywheel energy storage units; 2, a rotor position sensor acquires a rotating speed of a flywheel motor, and a current sensor acquires a current signal of a DC (Direct Current) bus; 3, a sampling value of a rotating speed error is calculated; 4, a neuron self-adaptive PID (Proportion Integration Differentiation) controller is used as a rotating speed controller, and an output control quantity of the neuron self-adaptive PID controller is calculated; 5, a current error signal of the DC bus is calculated; and 6, the current error signal is input into a current controller for controlling output of a PWM (Pulse-Width Modulation) wave, and PWM drives a bidirectional converter to control the flywheel motor to operate in an accelerated or decelerated manner. The control method is fundamentally different from other control methods designed for a three-phase permanent magnetic synchronous flywheel driving motor; vector control does not need to be carried out; and rotating speed control accuracy of the flywheel energy storage system and robustness of the system are greatly improved.

Owner:迪比(重庆)智能科技研究院有限公司 +1

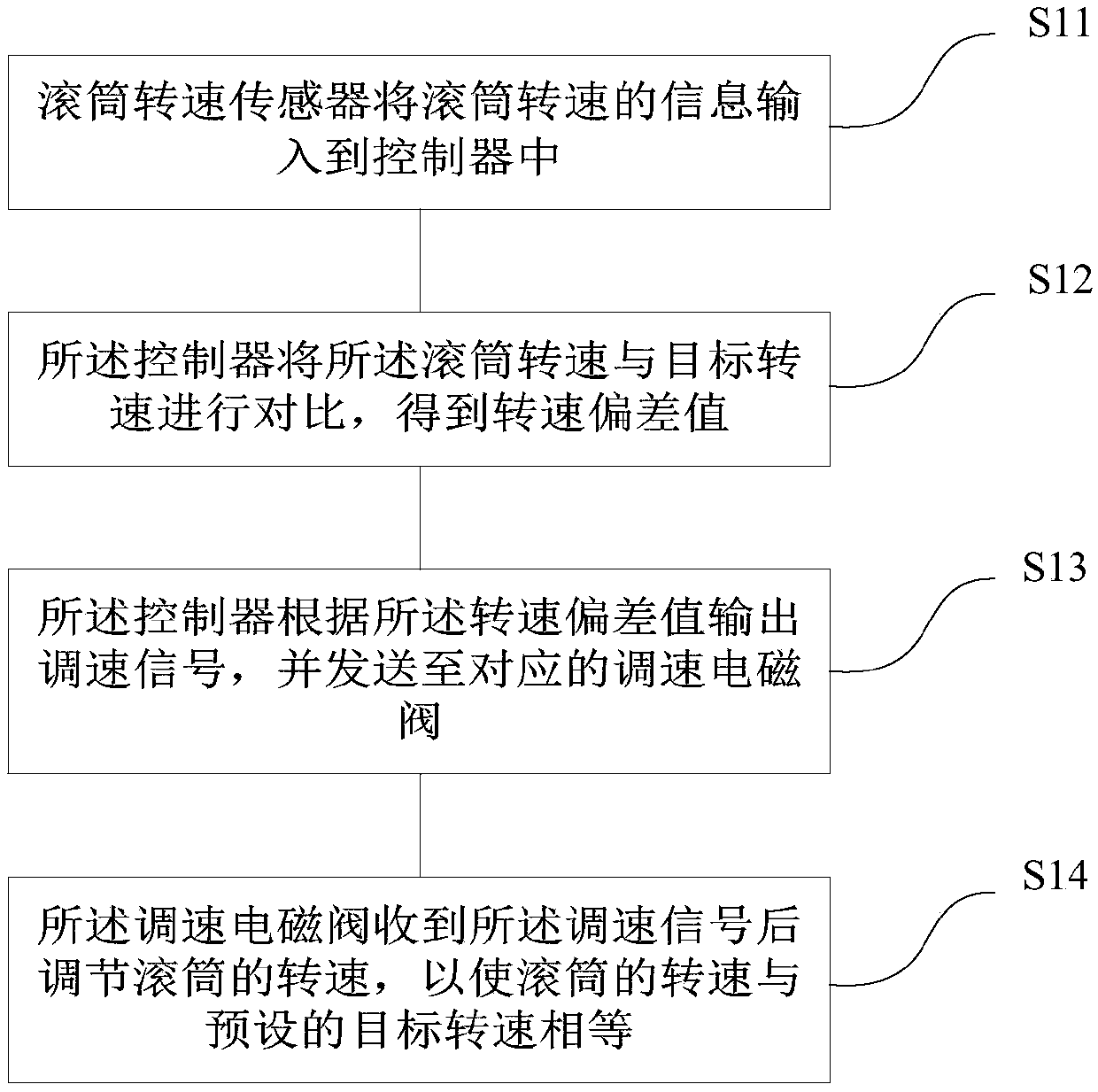

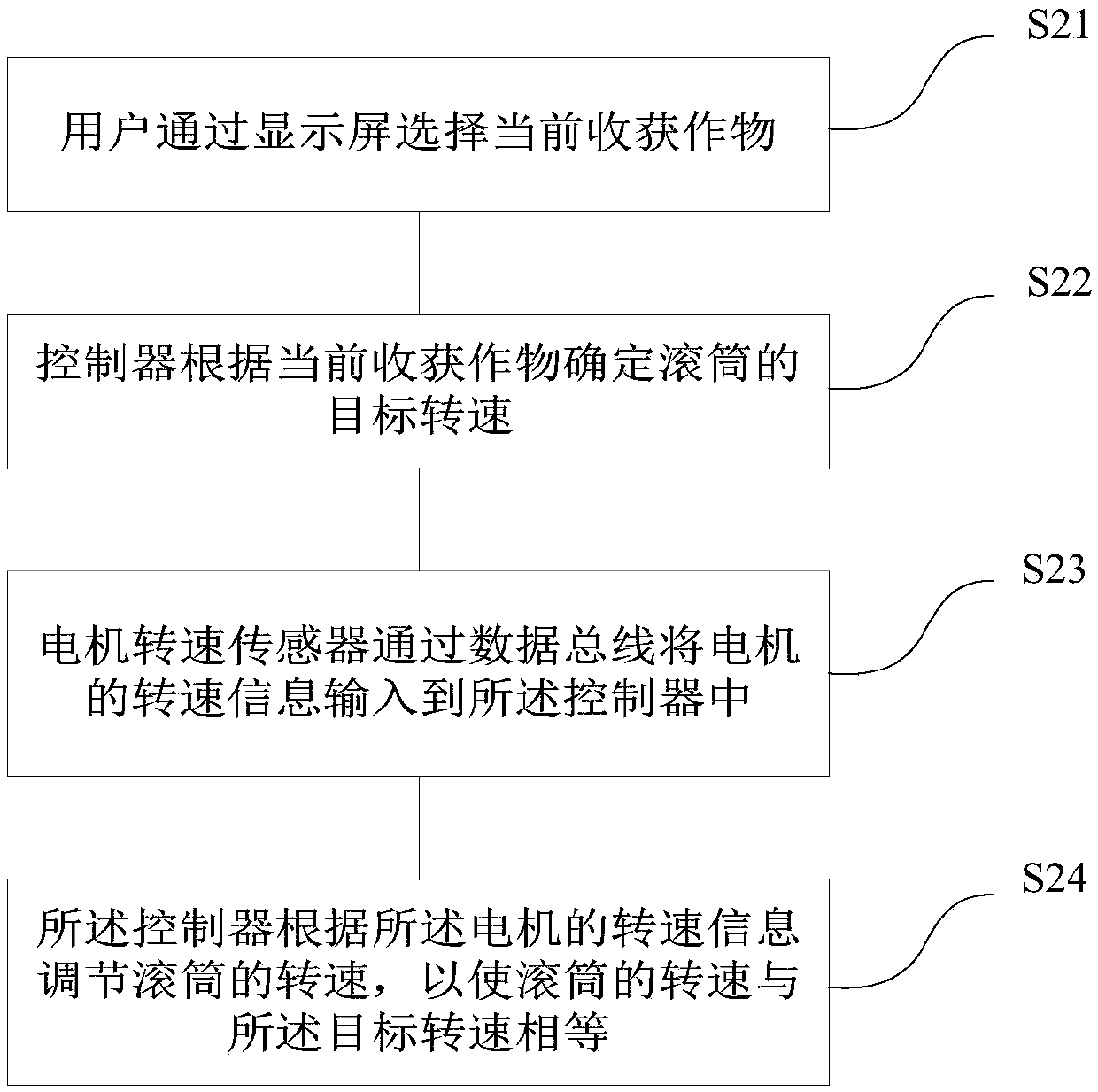

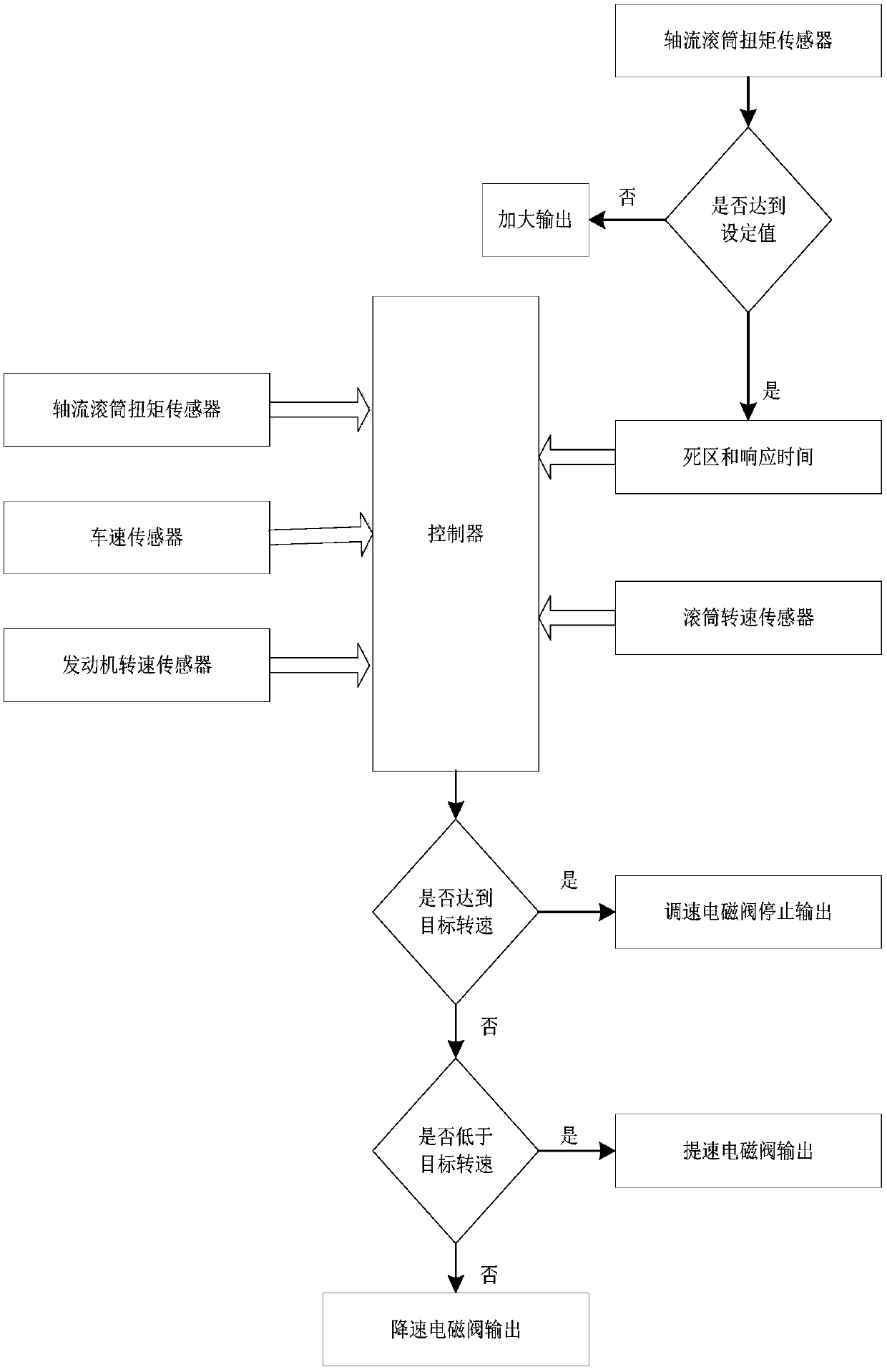

Method and device for controlling rotating speed of roller

InactiveCN110089262AHigh speed control precisionConstant speedMowersControllers with particular characteristicsMachine controlSolenoid valve

The invention provides a method and device for controlling the rotating speed of a roller, and relates to the technical field of agricultural machine control. The method for controlling the rotating speed of the roller comprises the steps that information of the rotating speed of the roller is input into a controller through a roller rotating speed sensor the controller compares the rotating speedof the roller with target rotating speed, and a rotating speed deviation value is obtained; the controller outputs a speed regulating signal according to the rotating speed deviation value, and sendsthe speed regulating signal to a corresponding speed regulating solenoid valve; after the speed regulating solenoid valve receives the speed regulating speed signal, the rotating speed of the rolleris regulated, so that the rotating speed of the roller is equal to the target rotating speed. According to the method and device, the technical problems that the rotating speed control precision of the roller of an agricultural machine is not high, and the rotating speed of the roller is not constant are solved.

Owner:LOVOL HEAVY IND CO LTD

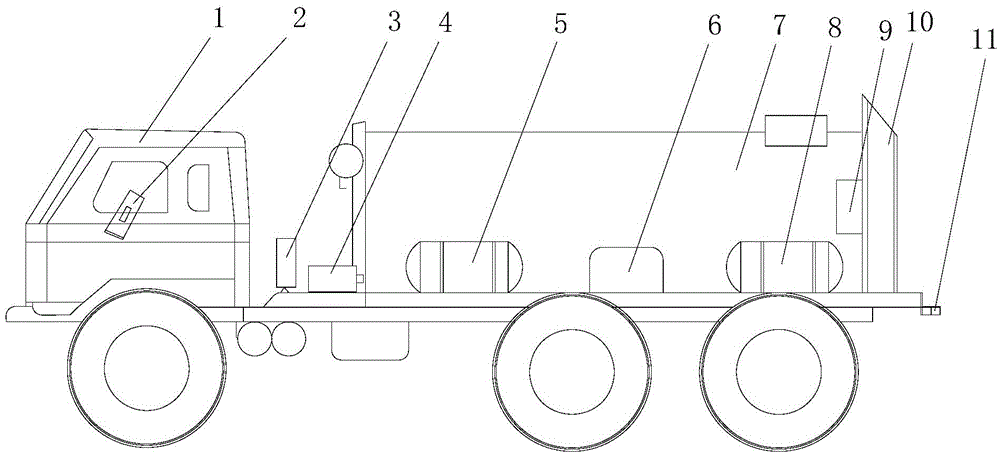

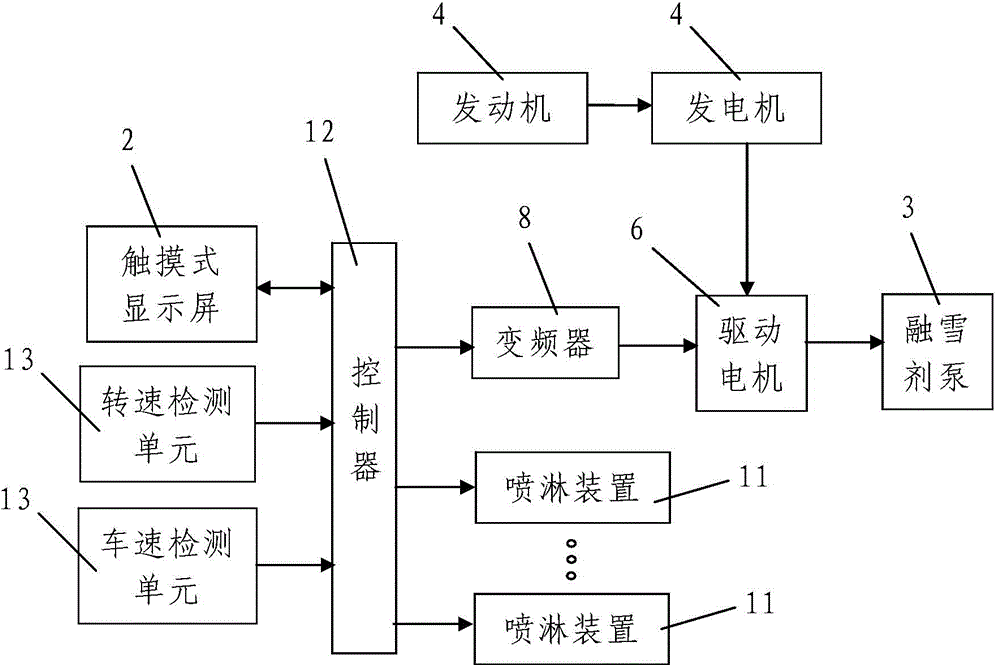

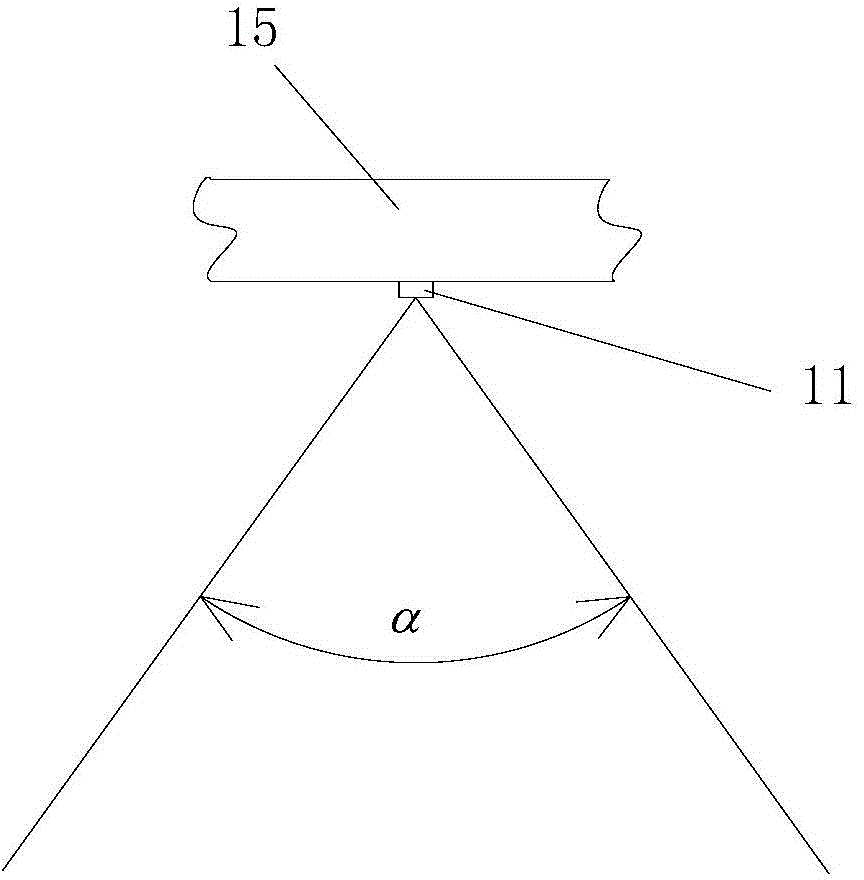

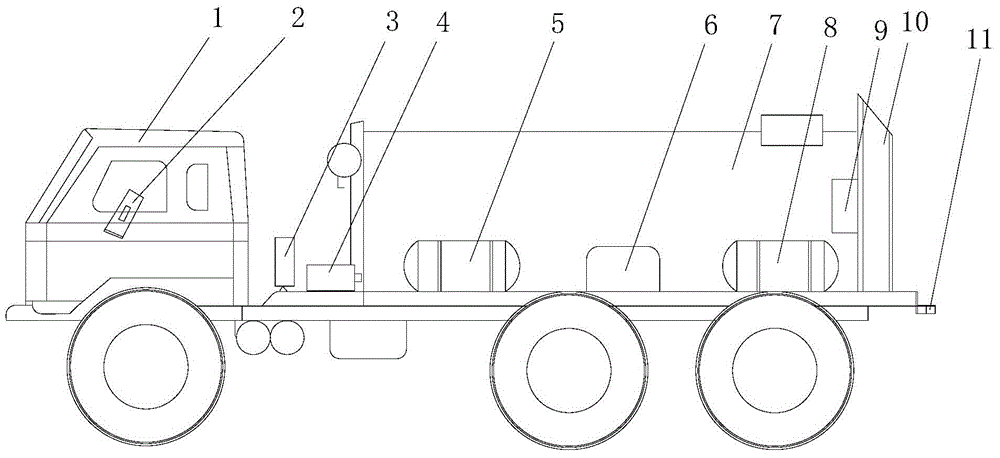

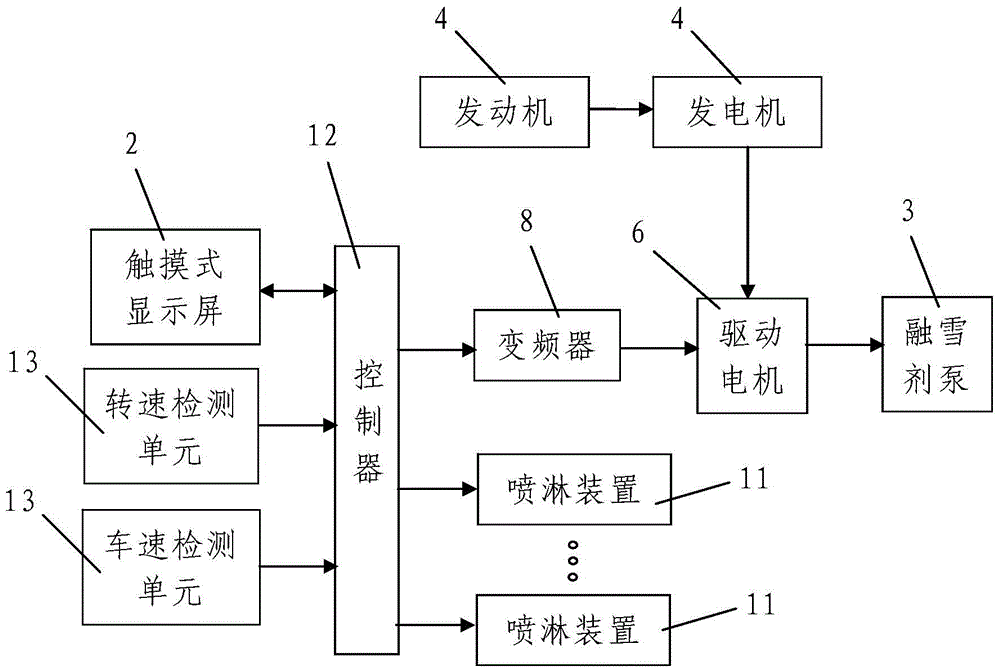

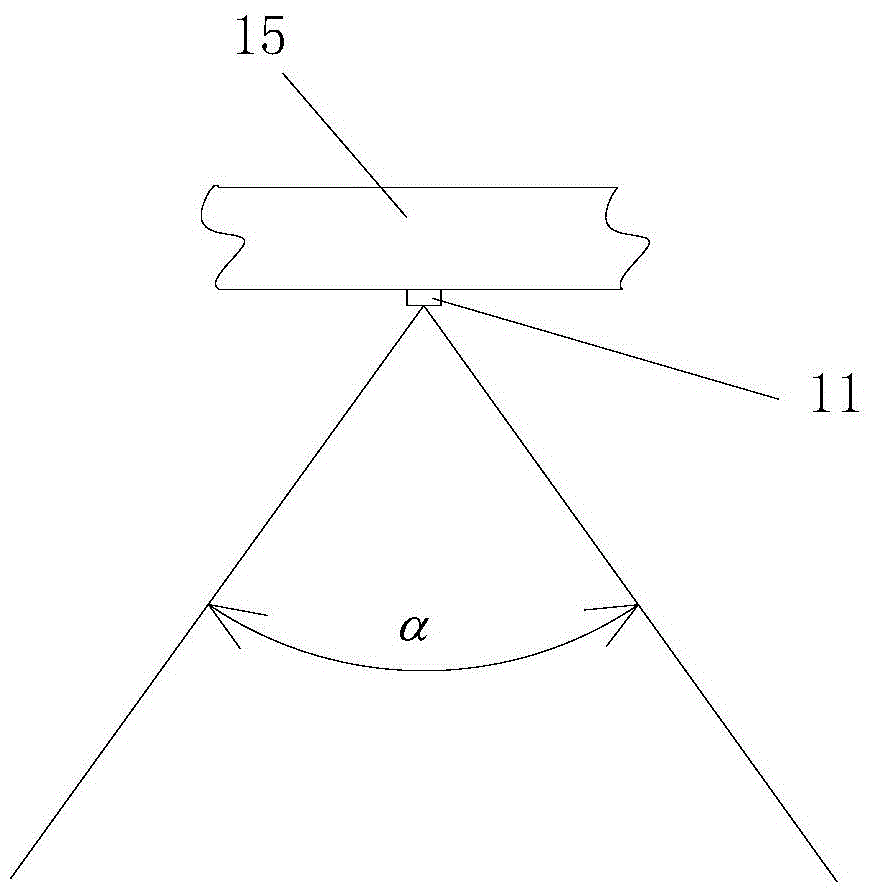

Spreading vehicle for emulsion type snow-melting agent and spreading operation control method

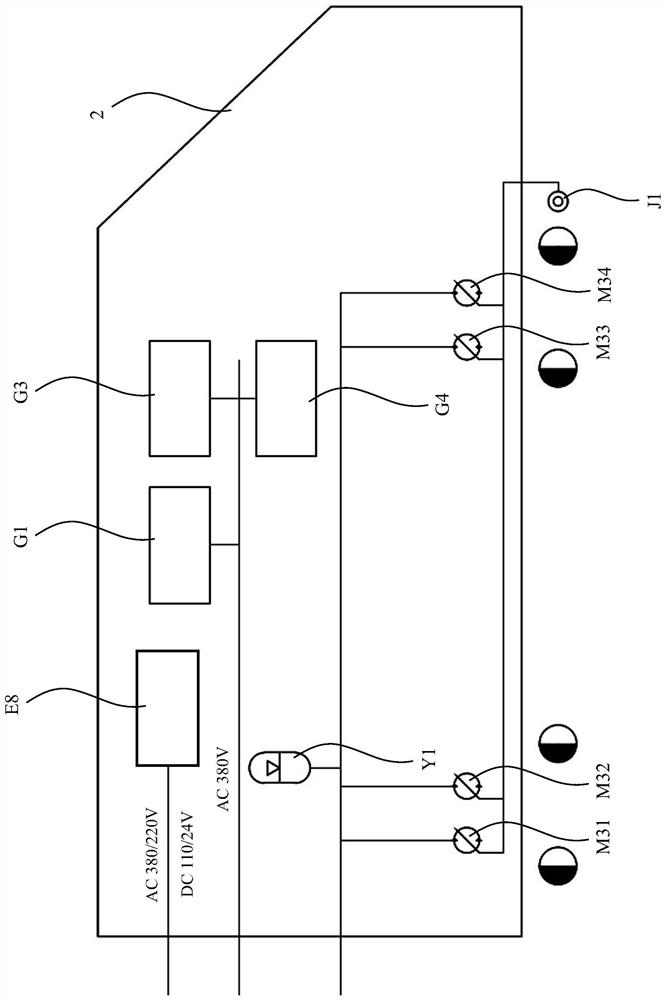

InactiveCN104790337ASimple structureReasonable designWay cleaningSpeed/accelaration control using electric meansEmulsionSpeed control system

The invention discloses a spreading vehicle for an emulsion type snow-melting agent. The spreading vehicle comprises a bearing vehicle body, a snow-melting agent storing tank and a spraying system used for spraying snow-melting agent in the snow-melting agent storing tank onto a road. The spraying system comprises multiple spraying devices, a conveying pipeline, a snow-melting agent pump and an alternating-current variable-frequency speed control system used for controlling the speed of the snow-melting agent pump. The snow-melting agent pump is a quantitative pump and is installed on the conveying pipeline. The spreading vehicle is simple in structure, reasonable in design, easy and convenient to operate and good in use effect, and the spreading amount of the snow-melting agent is controlled by controlling the speed of the snow-melting agent pump through the alternating-current variable-frequency speed control system. The invention further discloses a spreading operation control method of the spreading vehicle for the emulsion type snow-melting agent. The spreading operation control method comprises the steps that firstly, spreading control parameters are set; secondly, the bearing vehicle body is started, and the spraying devices are opened; thirdly, the bearing vehicle body moves, and the snow-melting agent is spread. The spreading operation control method has the advantages that the steps are simple, design is reasonable, implementation is convenient, the spreading amount control effect is good, and the spreading amount and the spreading uniformity of the snow-melting agent can be effectively controlled.

Owner:CHANGAN UNIV

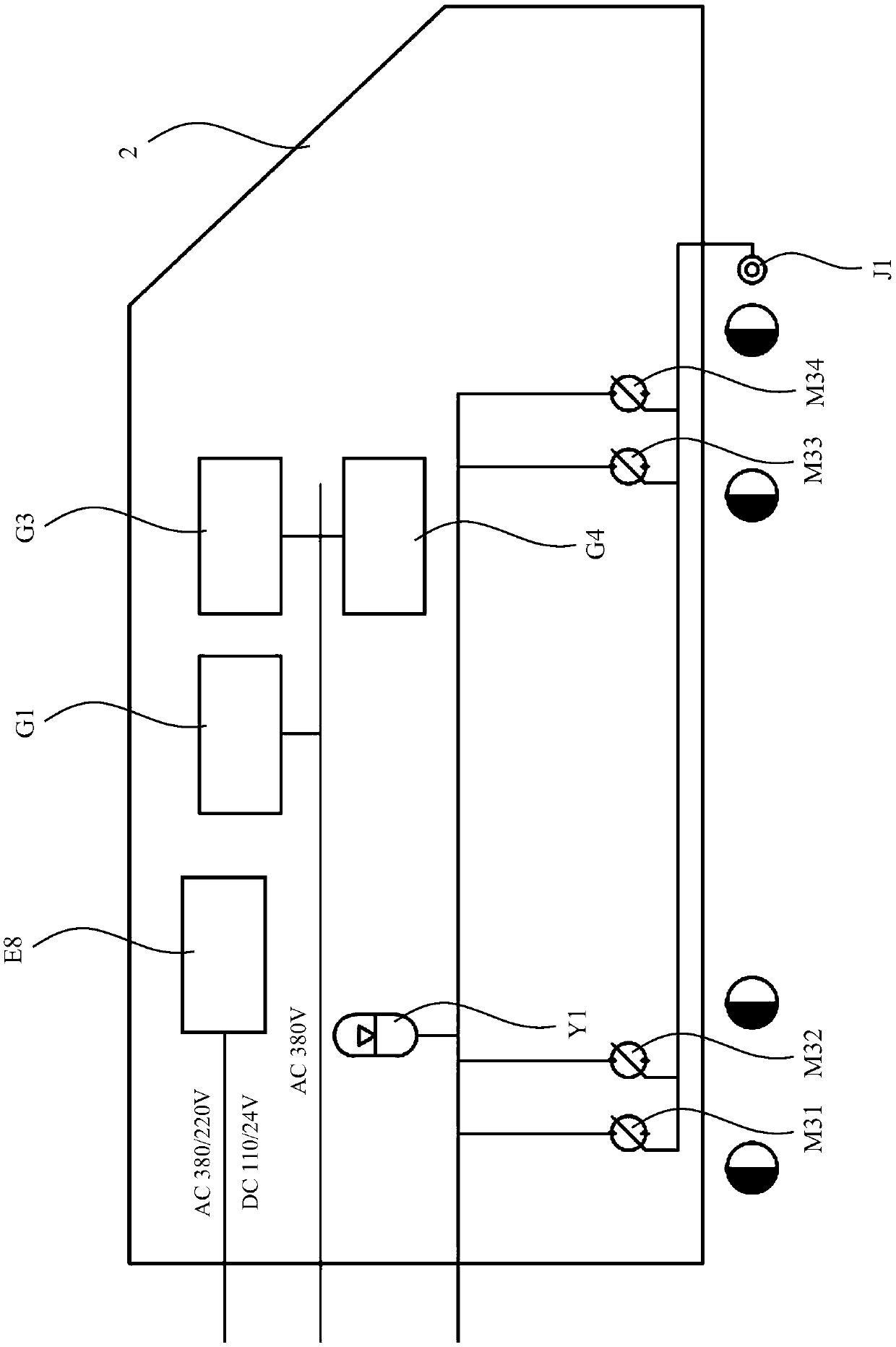

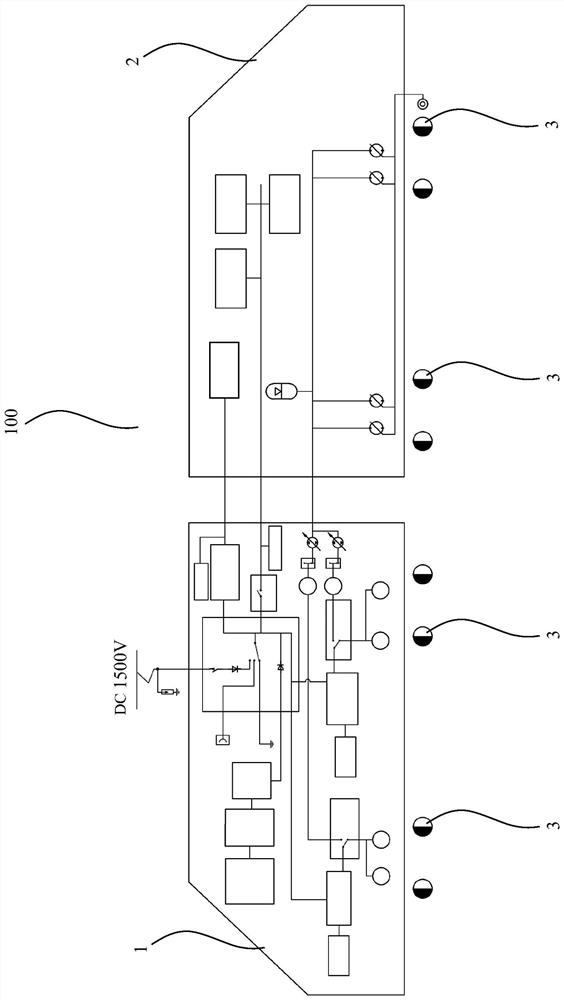

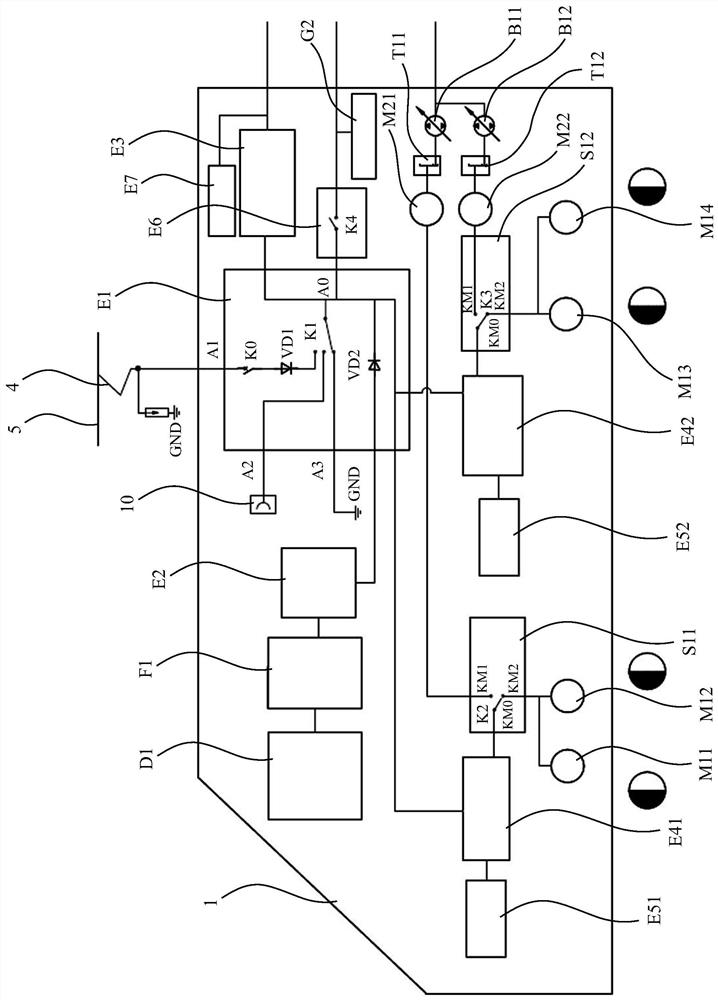

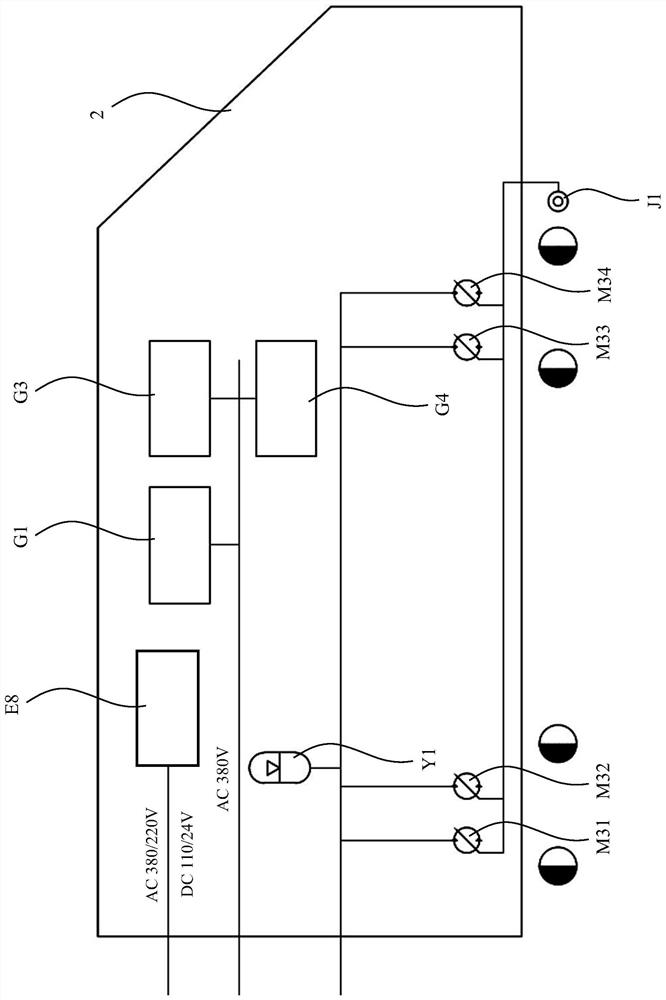

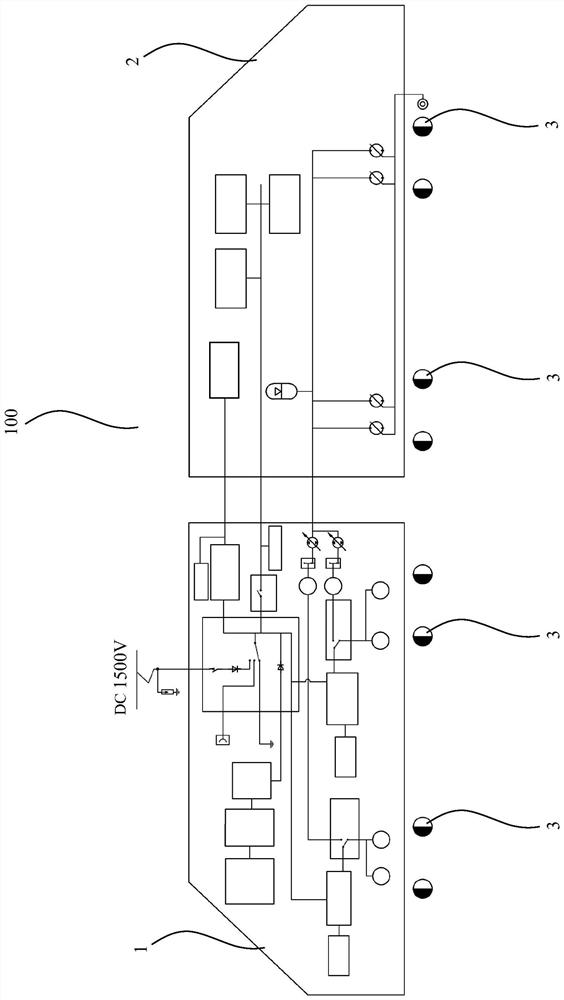

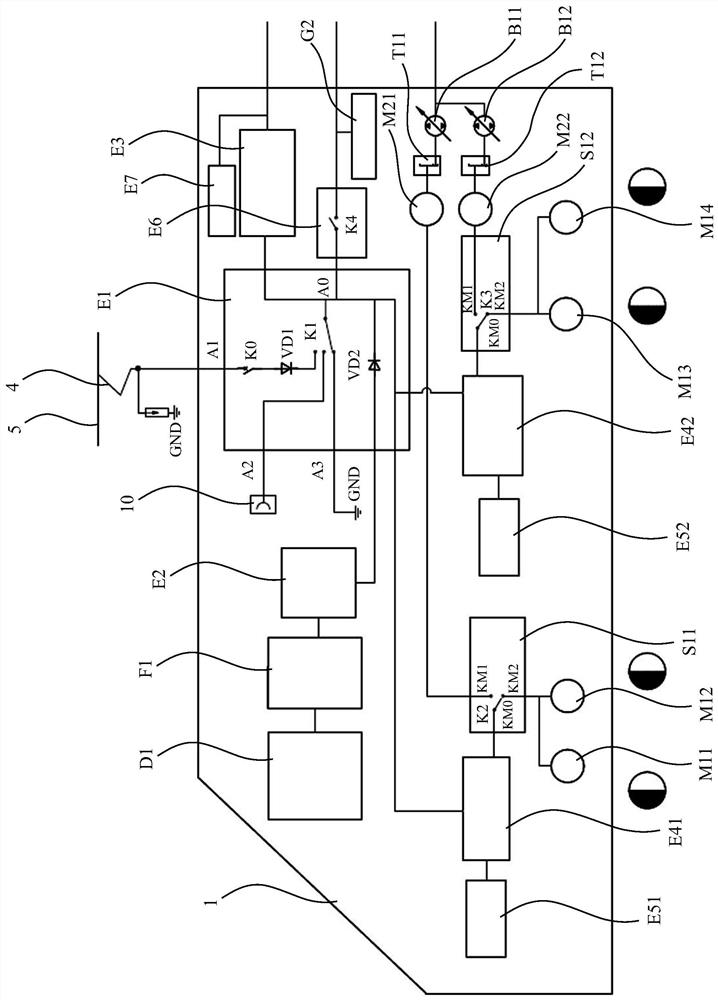

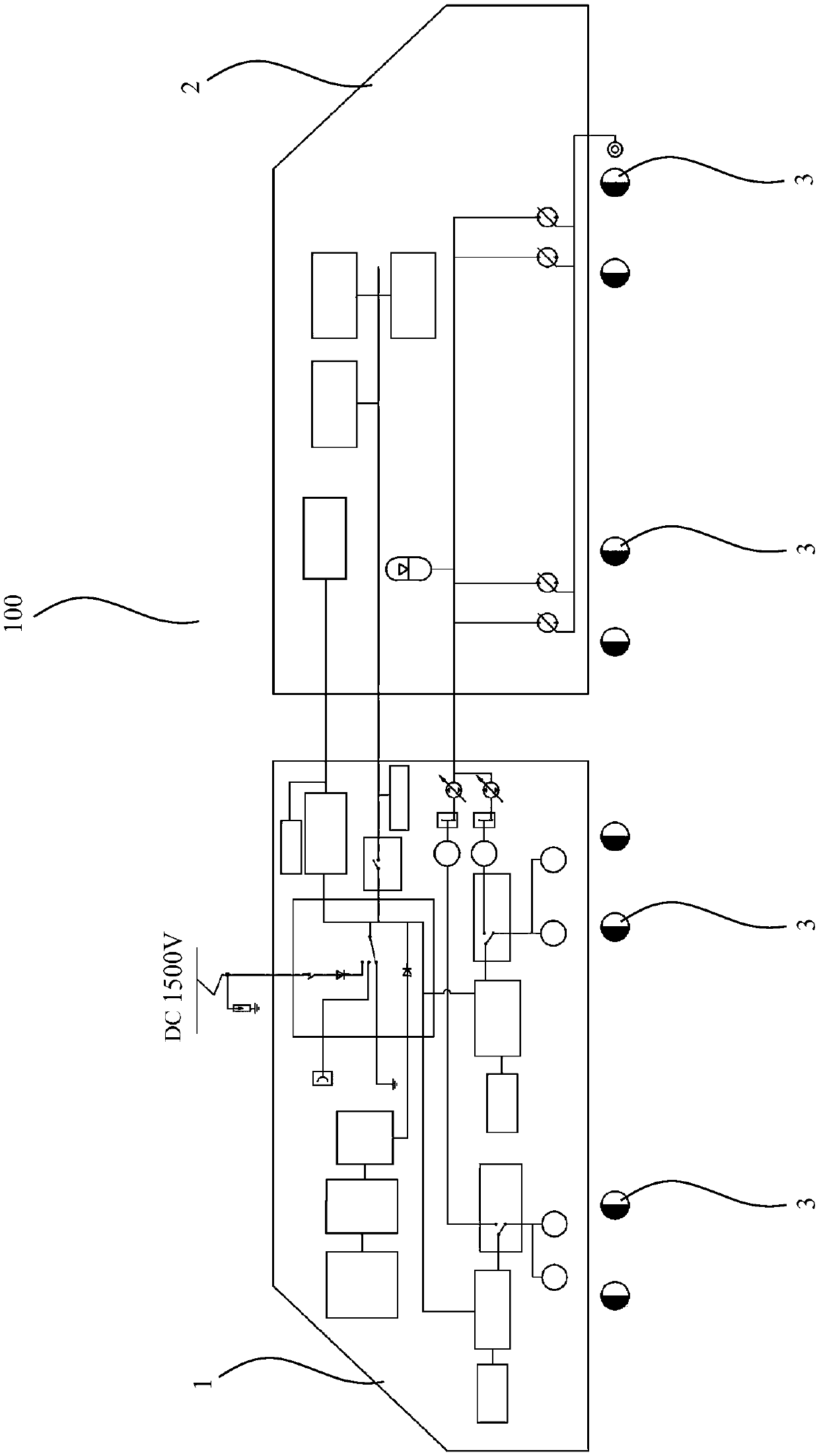

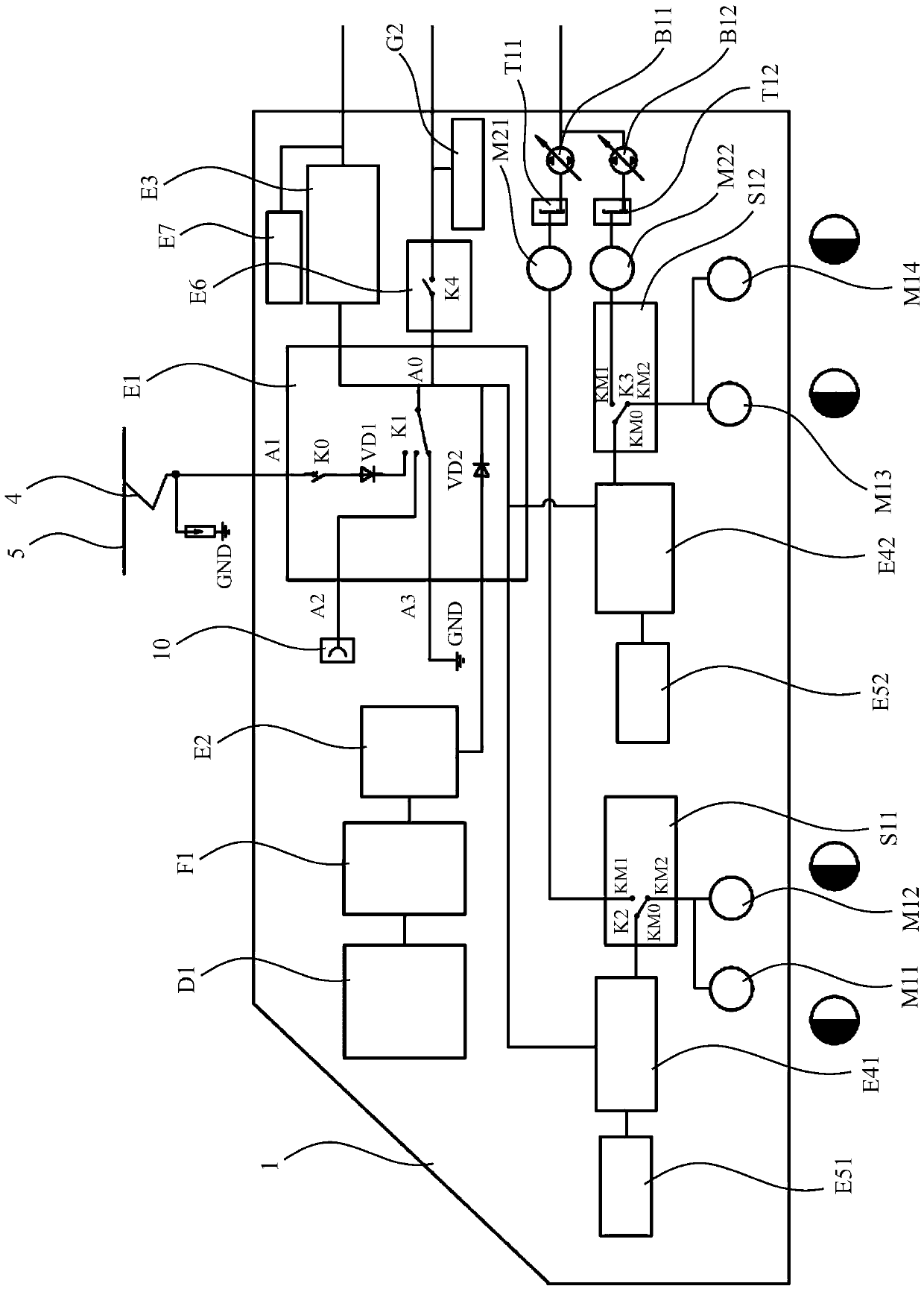

Rail operation vehicle transmission system

ActiveCN109577117AIncrease speedThe structure of electric transmission is matureRailway track constructionElectricityLow speed

The invention discloses a rail operation vehicle transmission system. A rail operation vehicle comprises a power vehicle and an operation vehicle; the rail operation vehicle transmission system comprises a vehicle power supply system, a high speed running system and a low speed running power source, a low constant speed running system and an operation system, wherein the vehicle power supply system, the high speed running system and the low speed running power source are placed on the power vehicle; the low constant speed running system is placed on the operation vehicle; and the operation system is partially or totally placed on the operation vehicle. The vehicle power supply system provides a power supply for the operation system and can selectively provide power supply for the high speed running system or the low speed running power source; and the high speed running system adopts an electric drive traction system. The low speed running power source provides a hydraulic power sourcefor the low constant speed running system; and the low constant speed running system adopts an electric drive hydrostatic transmission traction system. According to the rail operation vehicle transmission system, a technical problem of power transmission of a double-power-source rail operation vehicle in high speed running and low running modes can be solved to satisfy requirements on a running speed and control accuracy under different working conditions.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

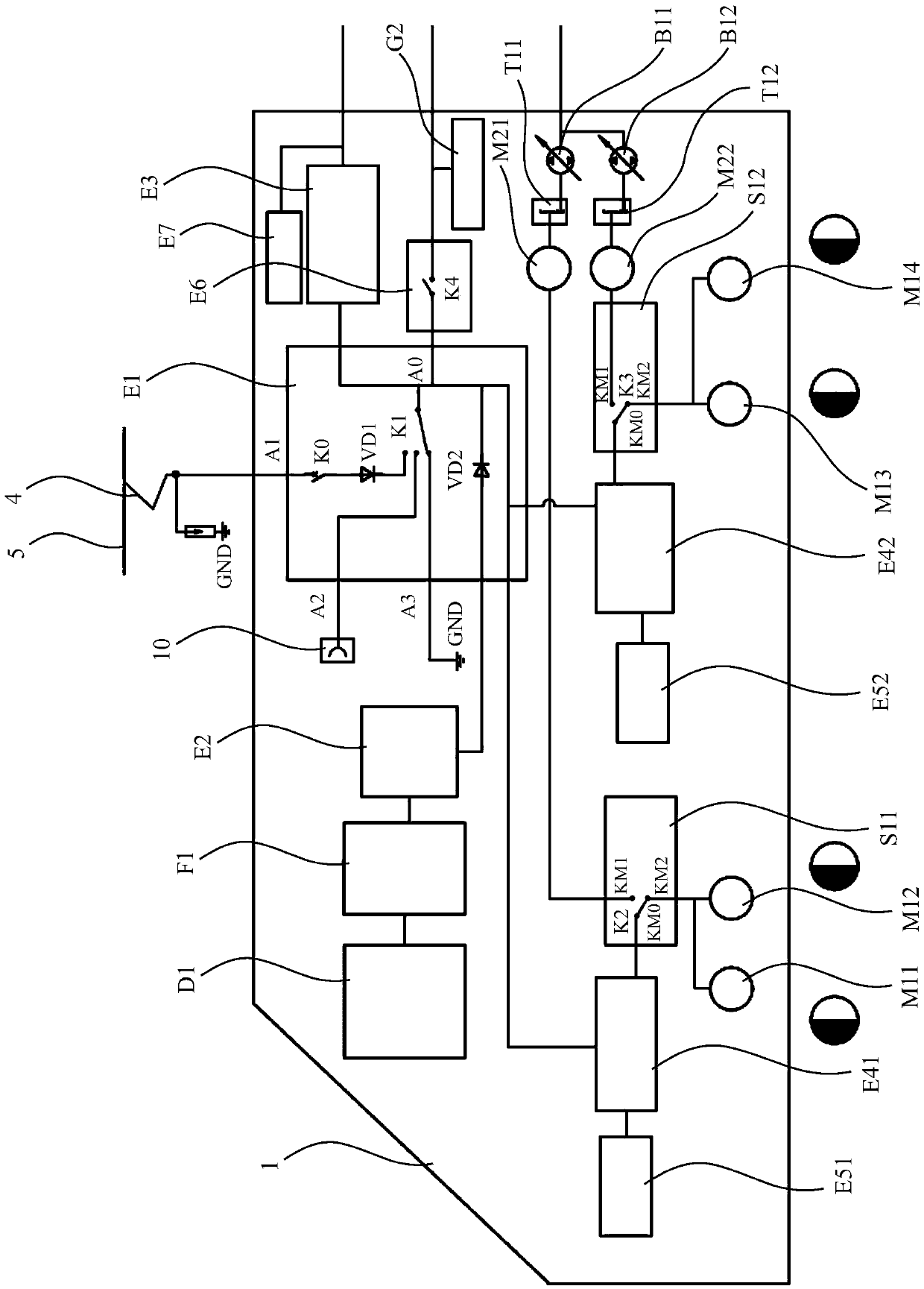

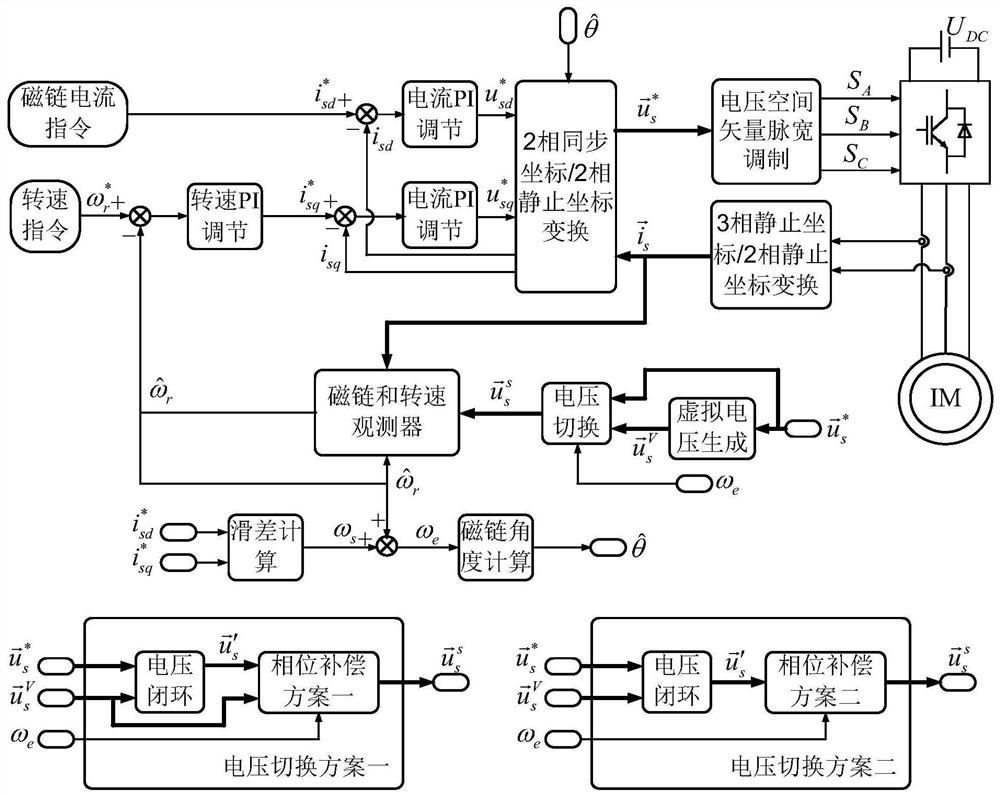

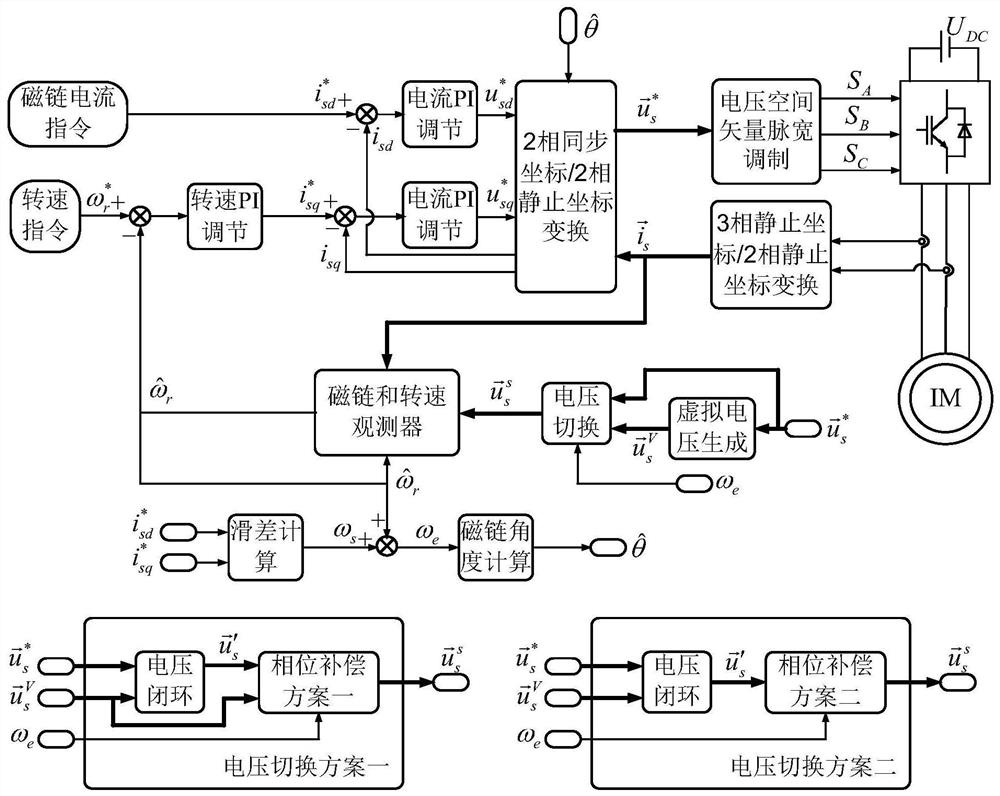

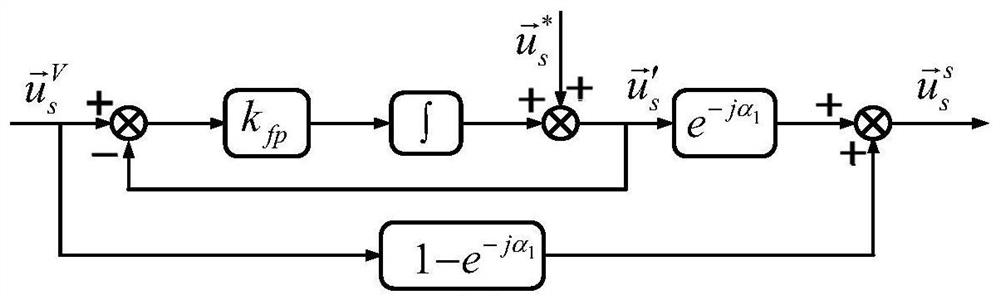

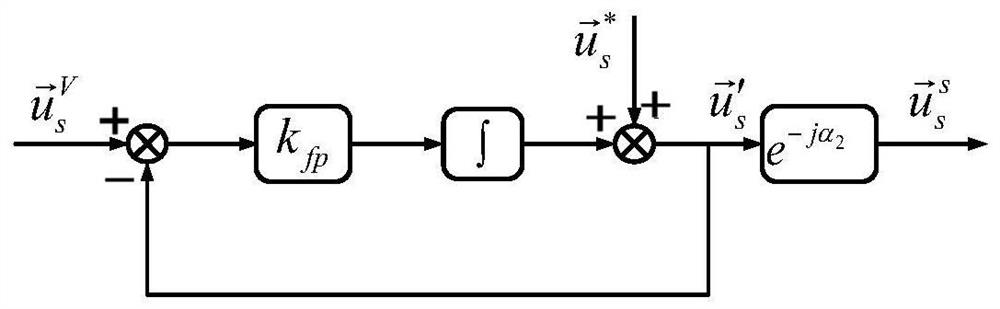

Asynchronous motor control method without speed sensor driving

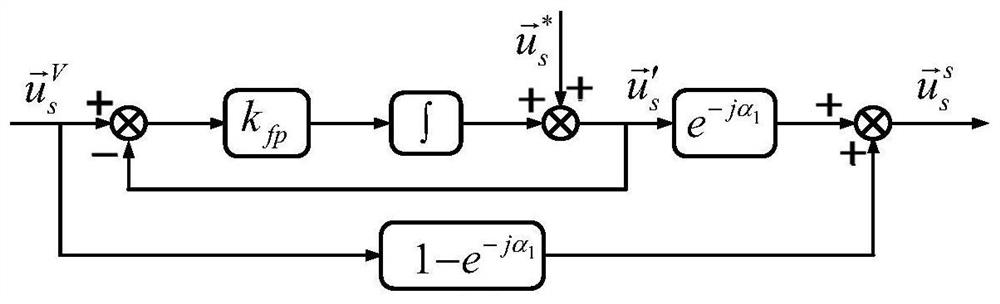

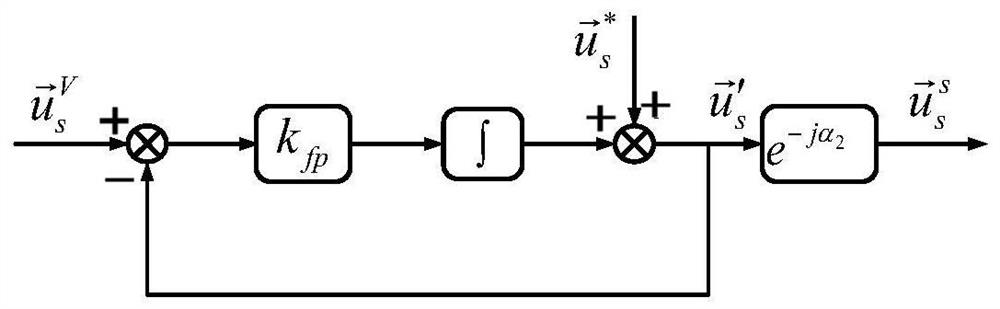

ActiveCN112436774AAccurate speedGuaranteed uptimeElectronic commutation motor controlVector control systemsOvervoltageVoltage amplitude

The invention discloses an asynchronous motor control method without speed sensor driving, and belongs to the technical field of motors. Through adopting a voltage switching structure, the input voltage amplitudes and phases of flux linkage and a rotating speed observer are adaptively adjusted, so that the input voltage of the flux linkage and the rotating speed observer at a low speed is virtualvoltage, and the stable and reliable operation of an asynchronous motor driven by a speed sensorless control system at the low speed is ensured; the input voltage of the flux linkage and the rotatingspeed observer is close to the actual voltage at a high speed, so that the rotating speed control precision of the asynchronous motor driven by the speed sensorless control system during medium-high rotating speed operation is ensured; and the rotating speed of the motor and the flux linkage orientation angle of the motor are estimated, and the asynchronous motor is driven to operate normally by adopting a vector control method, so that the actual flux linkage current, the actual torque current and the estimated rotating speed of the motor are respectively consistent with the reference flux linkage current, the reference torque current and the reference rotating speed of the motor, and smooth switching between the virtual voltage and the actual reference voltage is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

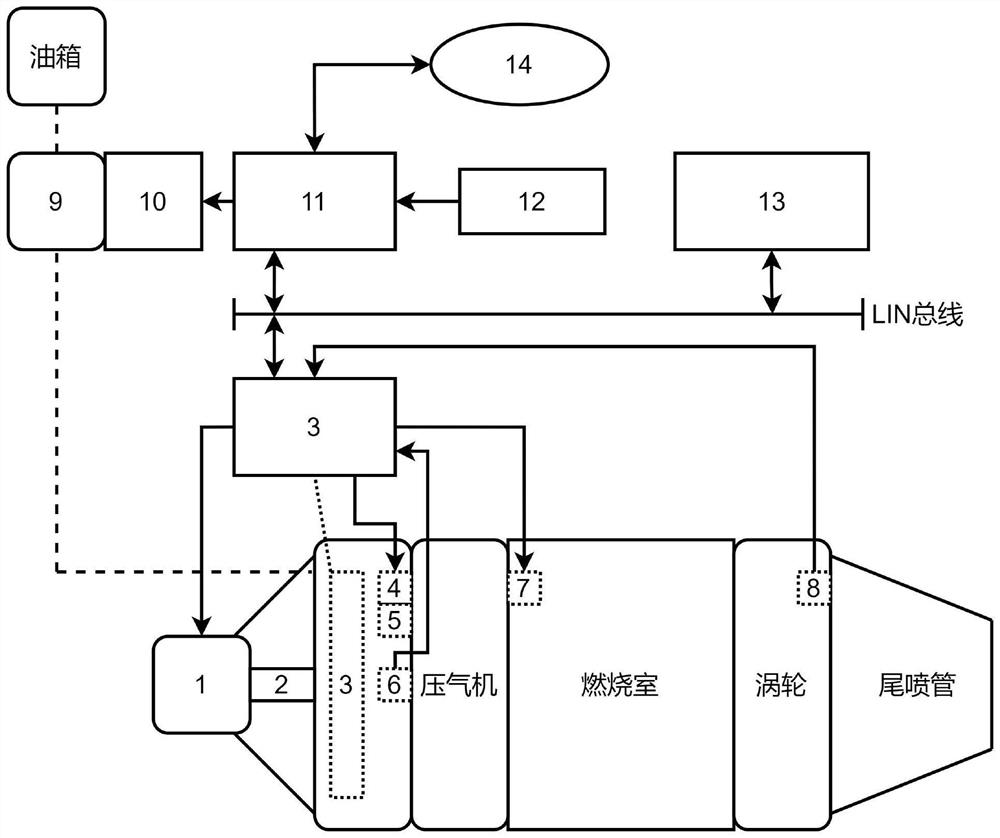

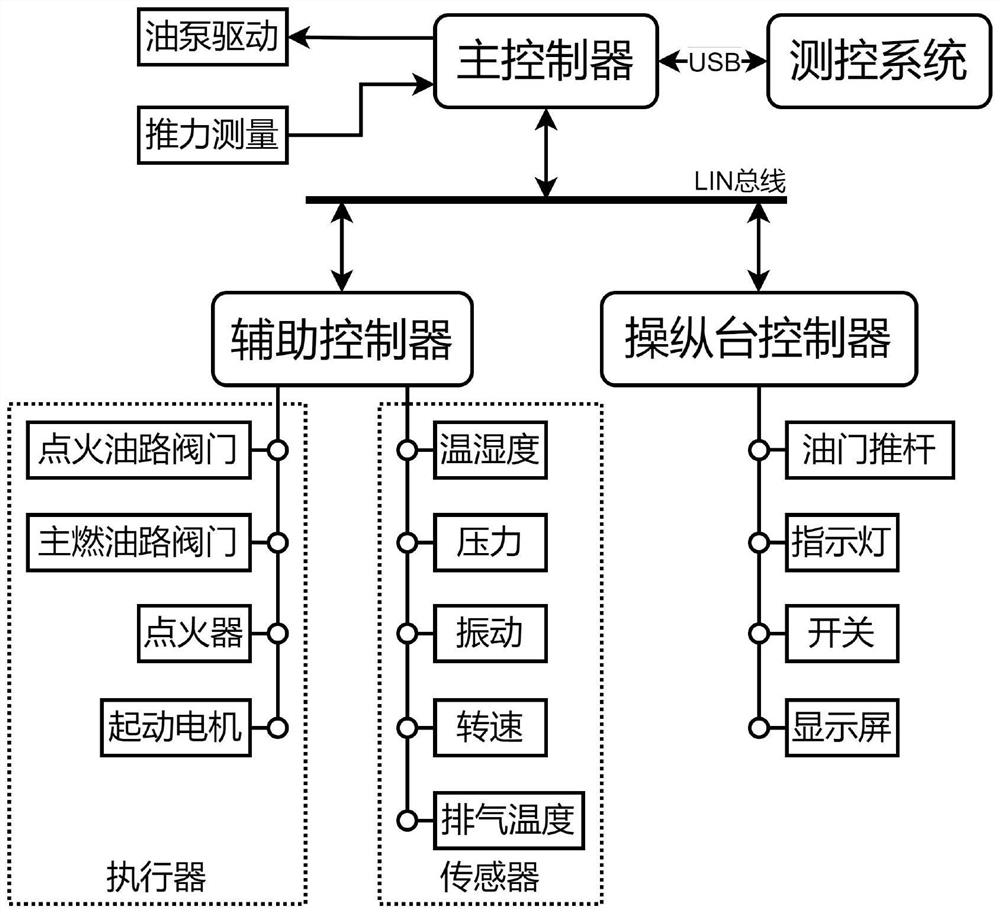

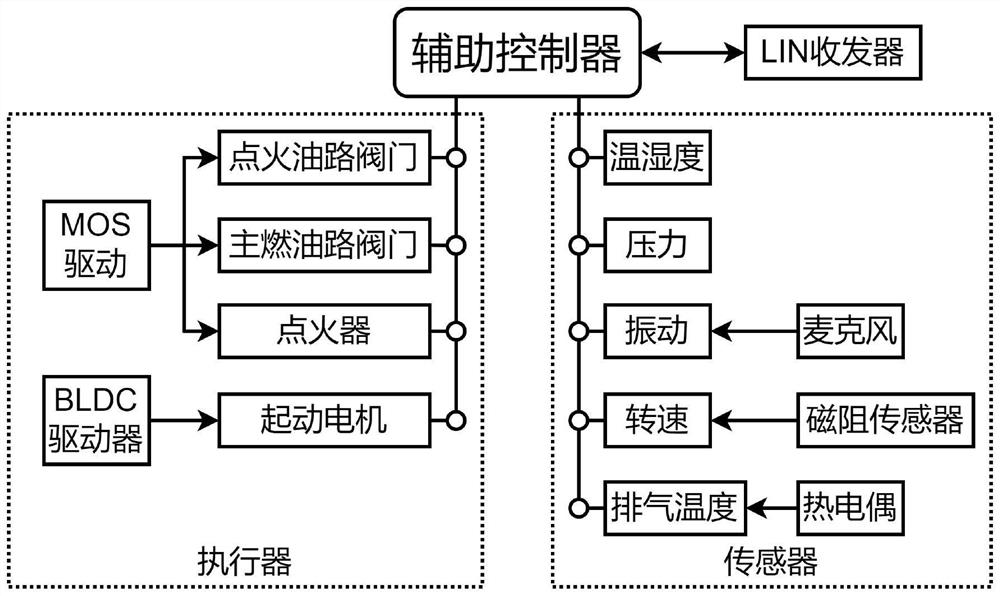

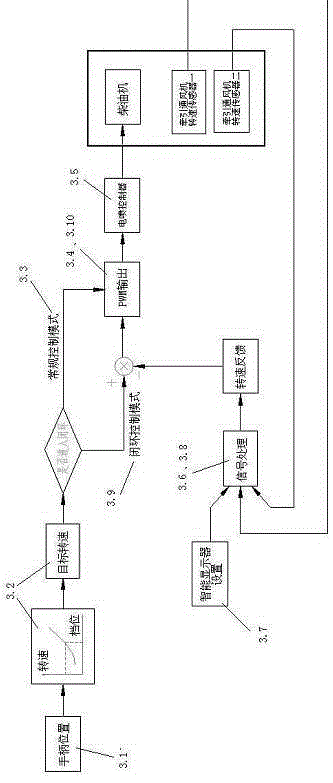

Micro turbojet engine control system and starting control method

PendingCN114687867AFirmly connectedEasy to installGas turbine plantsTurbine/propulsion fuel controlVibration measurementControl system

The invention discloses a micro turbojet engine control system and a starting control method. The micro turbojet engine control system comprises an auxiliary controller, a main controller, a console controller and a measurement and control system. Wherein the auxiliary controller is installed in an engine shell, and starting motor driving, hot fire head driving, valve driving, vibration measurement, temperature measurement and rotating speed measurement are achieved; the main controller directly drives the oil pump, controls the auxiliary controller to realize a main control algorithm, and measures thrust through an engine pedestal; the console controller is used for giving action instructions of each actuating mechanism, giving signals of an accelerator push rod and acquiring feedback signals; the auxiliary controller, the main controller and the console controller are communicated through a bus; and the measurement and control system is connected to the main controller, so as to display parameters of the sensor, manually control the actuating mechanism and record test data. Starting and operation control over the micro turbojet engine is achieved through the control system, and the micro turbojet engine control system has the advantages of being simple in connection, high in control precision, flexible in combination, convenient to test and the like.

Owner:DALIAN UNIV OF TECH

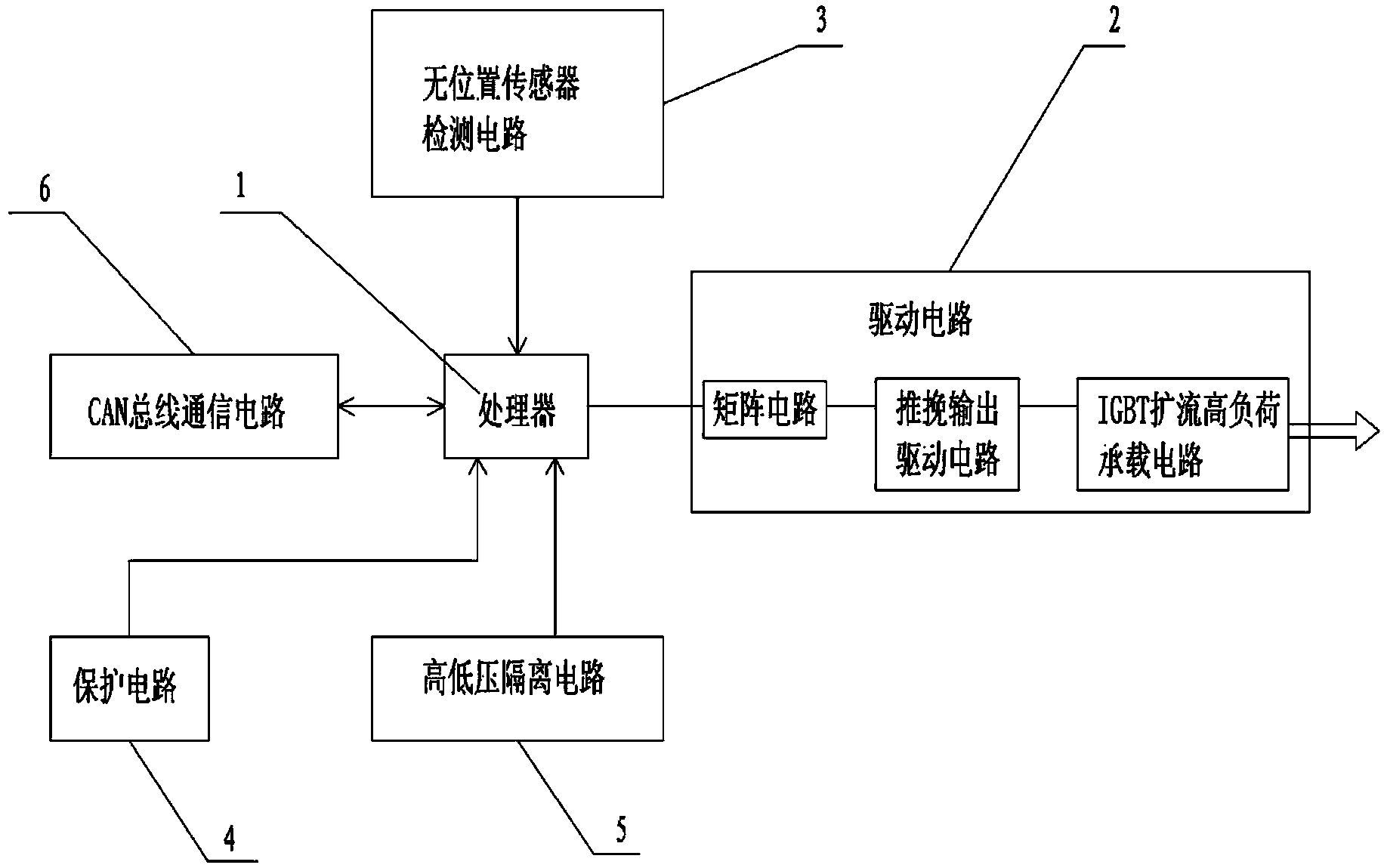

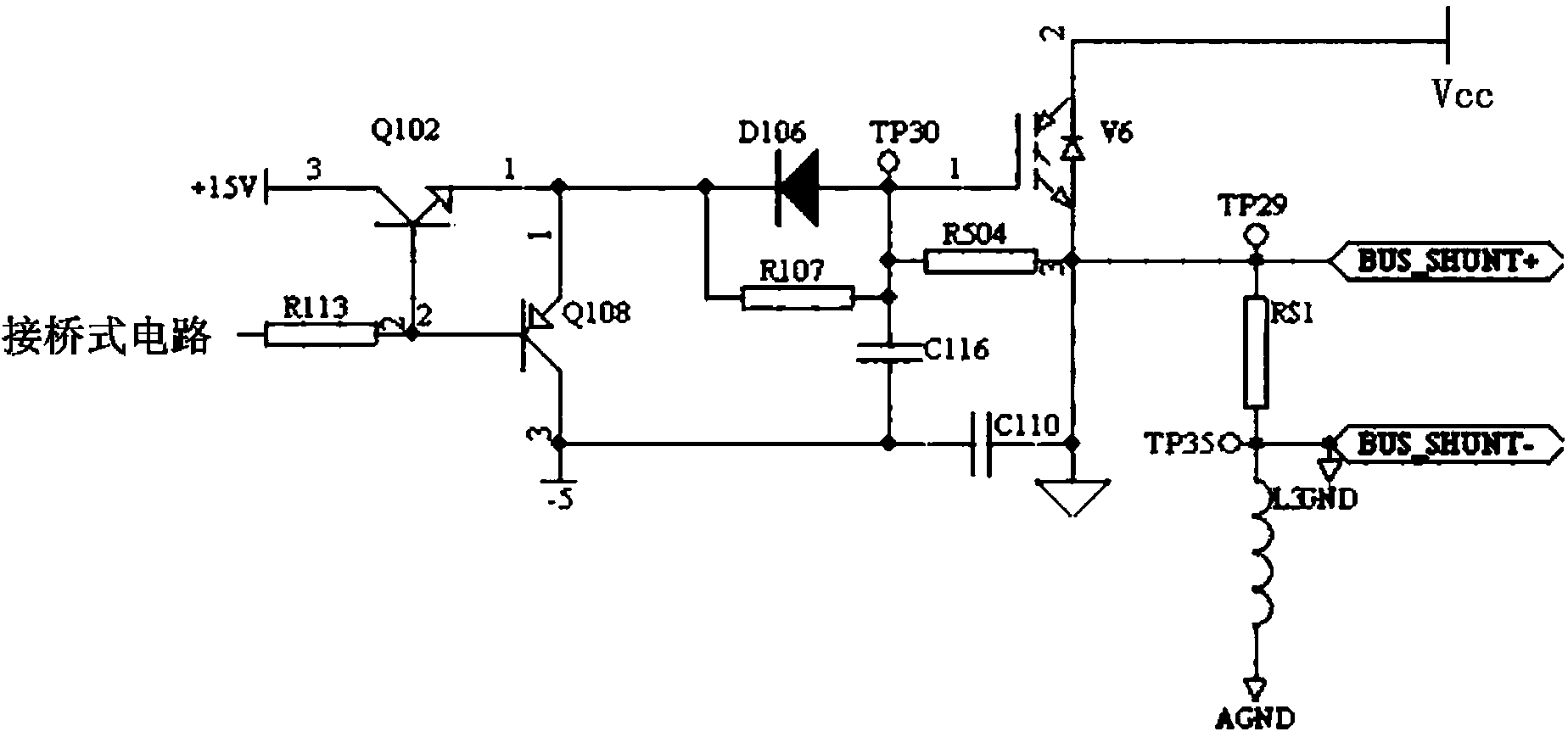

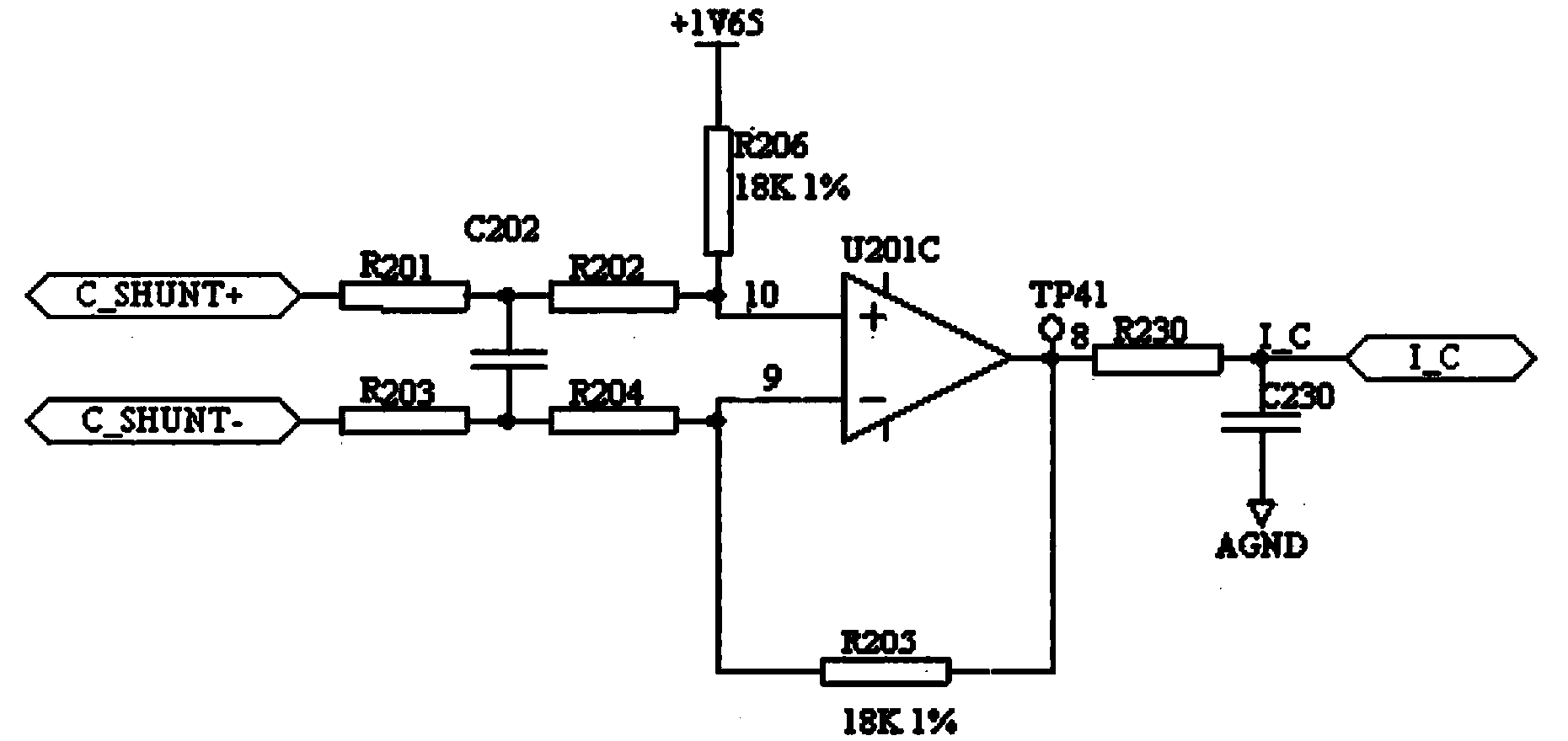

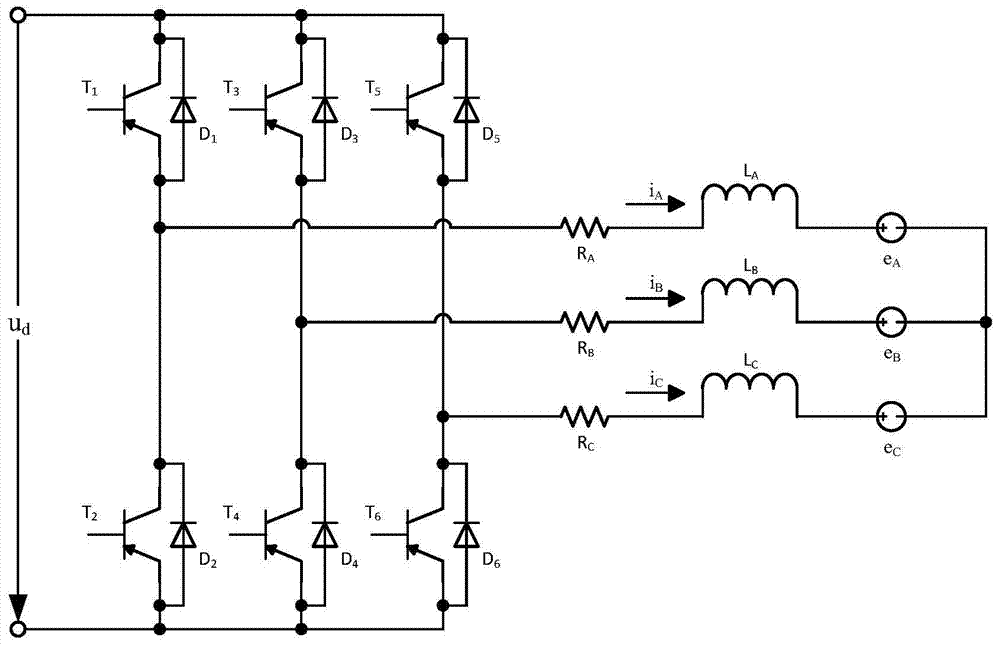

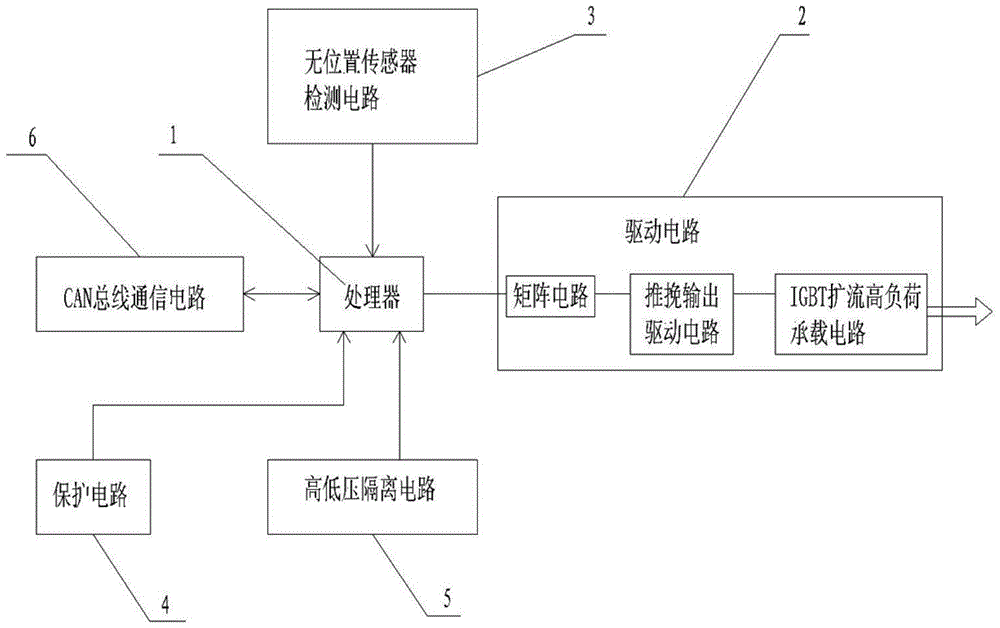

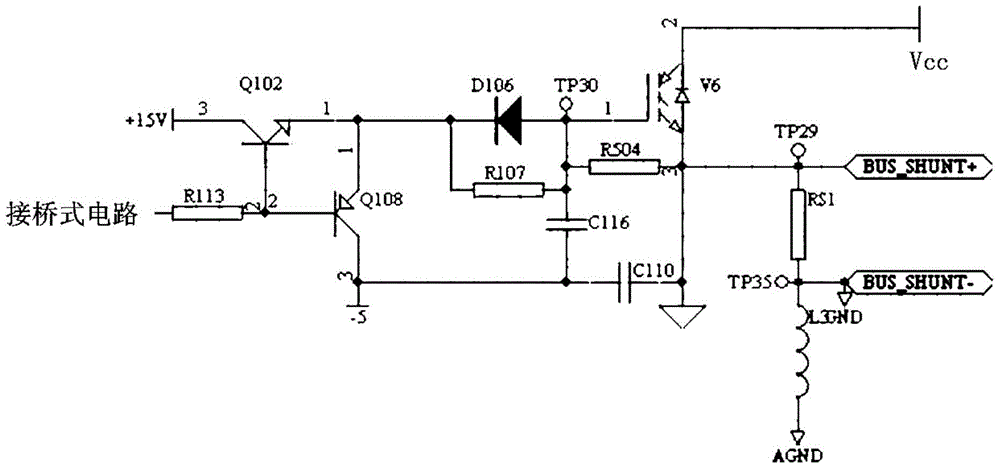

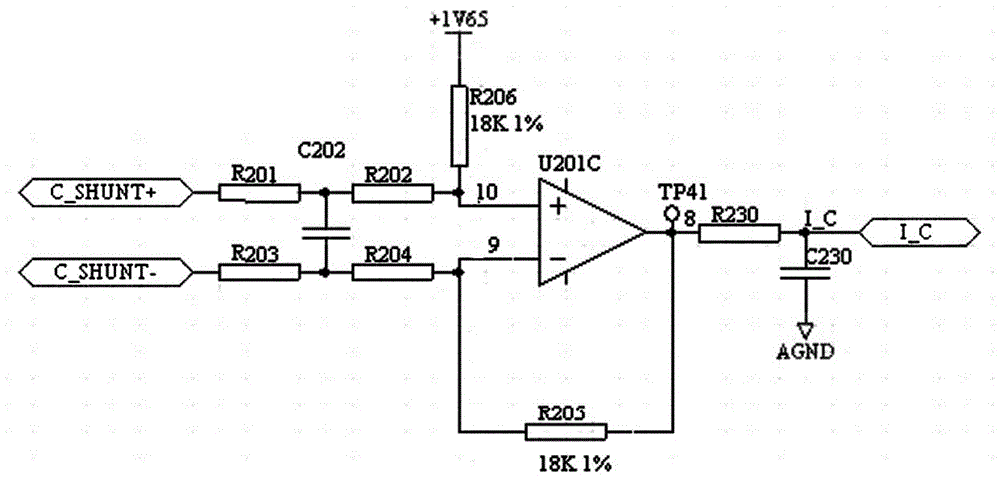

Motor sensorless drive control system

ActiveCN104167961AHigh speed control precisionQuick responseSingle motor speed/torque controlOvervoltageNew energy

The invention discloses a motor sensorless drive control system which is applicable to a 10000-120000 RPM high-speed motor. The system mainly includes a DSP control processor, a bridge-type matrix circuit, a push-pull output drive circuit, an IGBT current-enlarging high-load bearer circuit, a high-speed sensorless detection circuit, a protection circuit, a CAN bus communication circuit, a high-low voltage isolation circuit and the like. PMSM control waveforms which are output by the DSP processor undergo power amplification through the bridge-type matrix circuit and the push-pull output drive circuit and then drive an IGBT current-enlarging module to control the high-speed motor. The system has undervoltage, overvoltage, overcurrent and temperature protection, fault memory protection, and CAN online system update program refresh functions and a fault diagnosis function which meets the ISO15765. The control system is adaptive to different kinds of permanent-magnet synchronous motors and capable of meeting control demands of new-energy automobiles at home and abroad and has characteristics of small volume, high controllable rotating speed and high efficiency.

Owner:GUANGDONG GUANGSHUN NEW ENERGY POWER TECH CO LTD +2

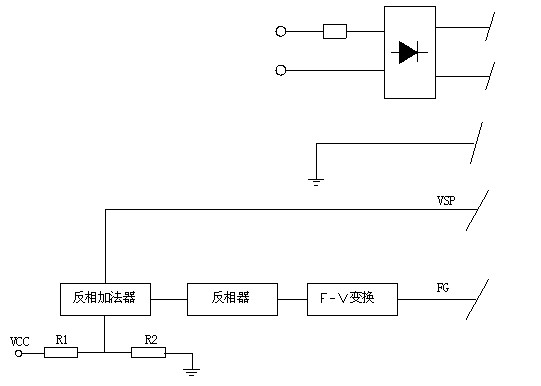

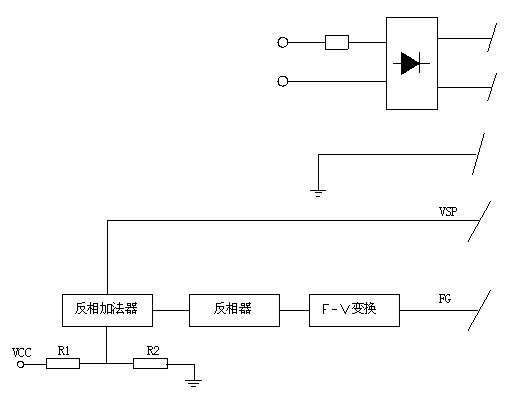

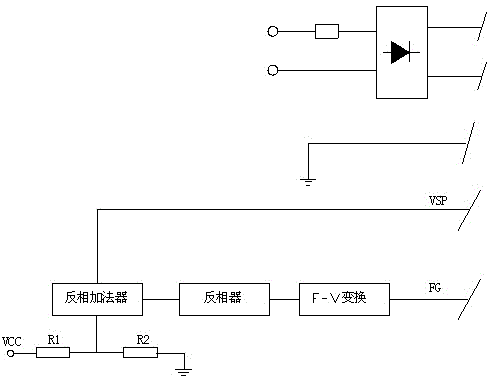

Outer rotor embedded automatic control constant speed DC brushless axial flow fan and constant speed control method

InactiveCN102072182AReduce development costsReduce manufacturing costPump controlNon-positive displacement fluid enginesAutomatic controlElectric machine

The invention relates to an outer rotor embedded automatic control constant speed DC brushless axial flow fan and a constant speed control method, which can realize constant speed automatic control over the rotating speed of an outer rotor embedded axial flow fan. The outer rotor embedded automatic control constant speed DC brushless axial flow fan comprises an axial flow fan and a DC converter. An automatic control constant speed detection circuit is arranged in the axial flow fan. A detection head in a frequency-to-converter (F / V) converter in the automatic control constant speed detection circuit is positioned on one side of an outer rotor, and is used for detecting the rotating speed of the outer stator. The output end of an inverted adder in the automatic control constant speed detection circuit is connected with the power input end of the axial flow fan, and is used for adjusting the rotating speed of the axial flow fan. The outer rotor embedded automatic control constant speed DC brushless axial flow fan and the constant speed control method have the advantages of: 1, low cost of subsequent product development of a client; 2, simple use; 3, high rotating speed control accuracy; 4, low fan manufacturing cost; 5, long motor service life; and 6, high safety factor.

Owner:HANGZHOU DUNLI ELECTRIC APPLIANCES

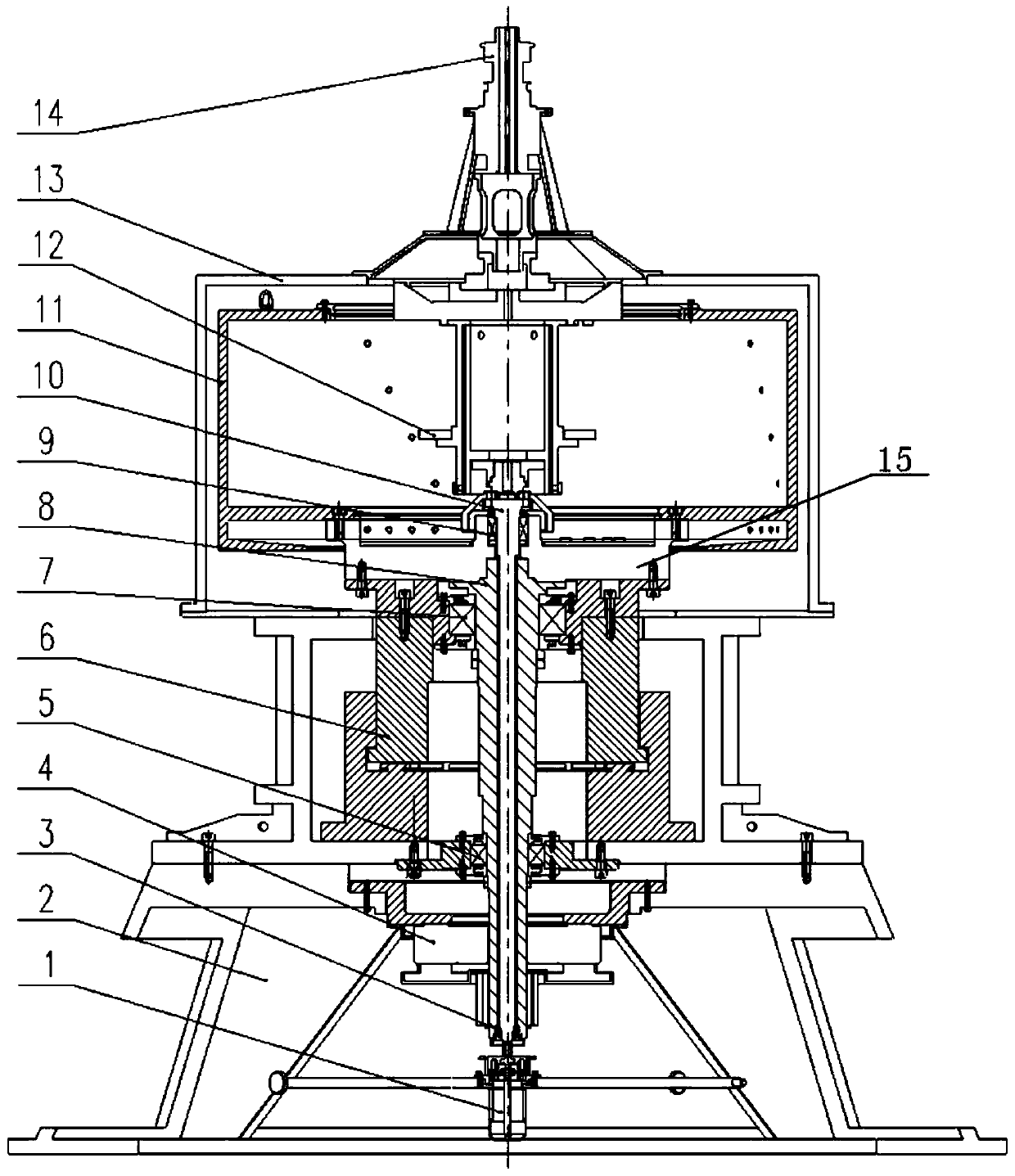

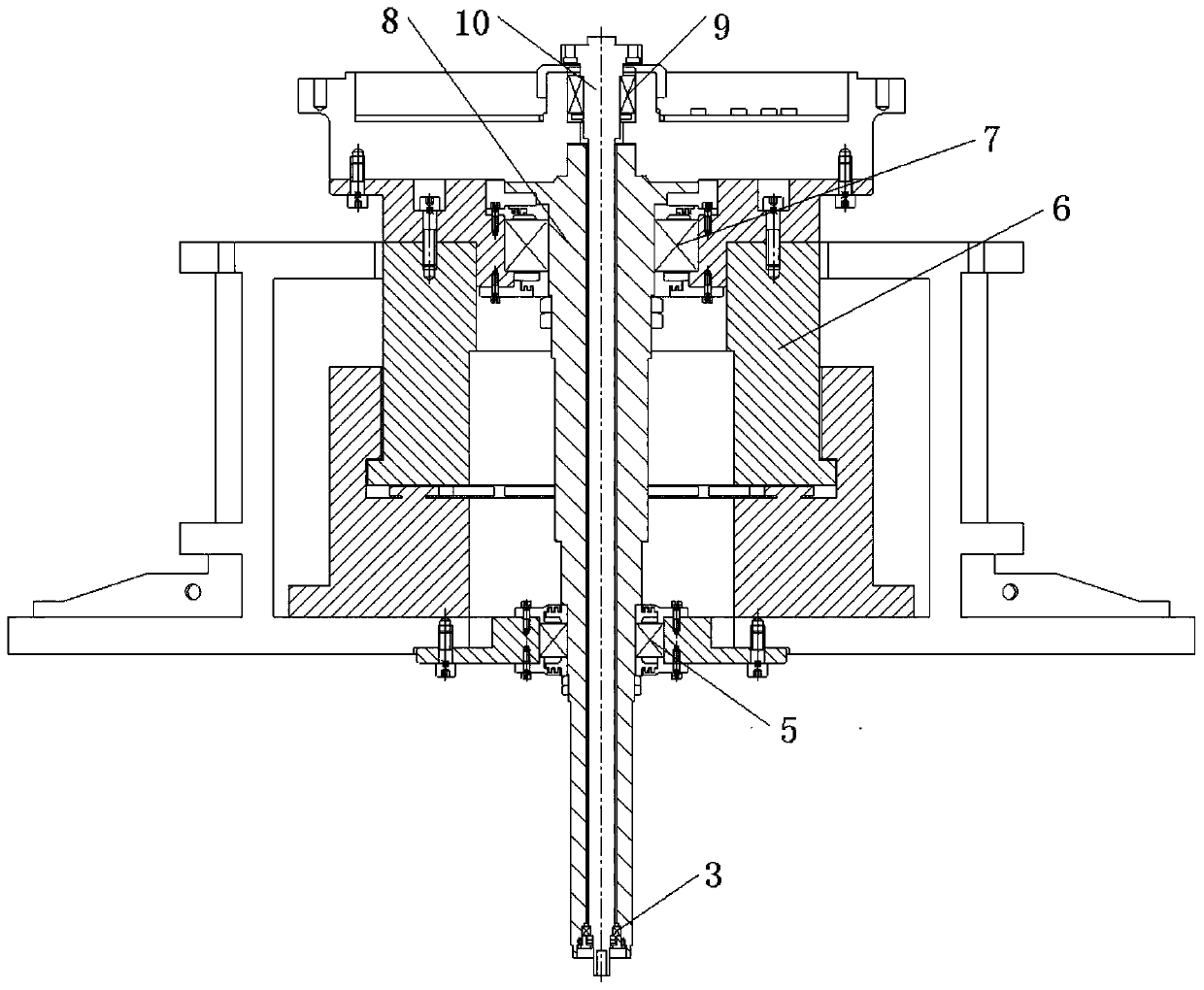

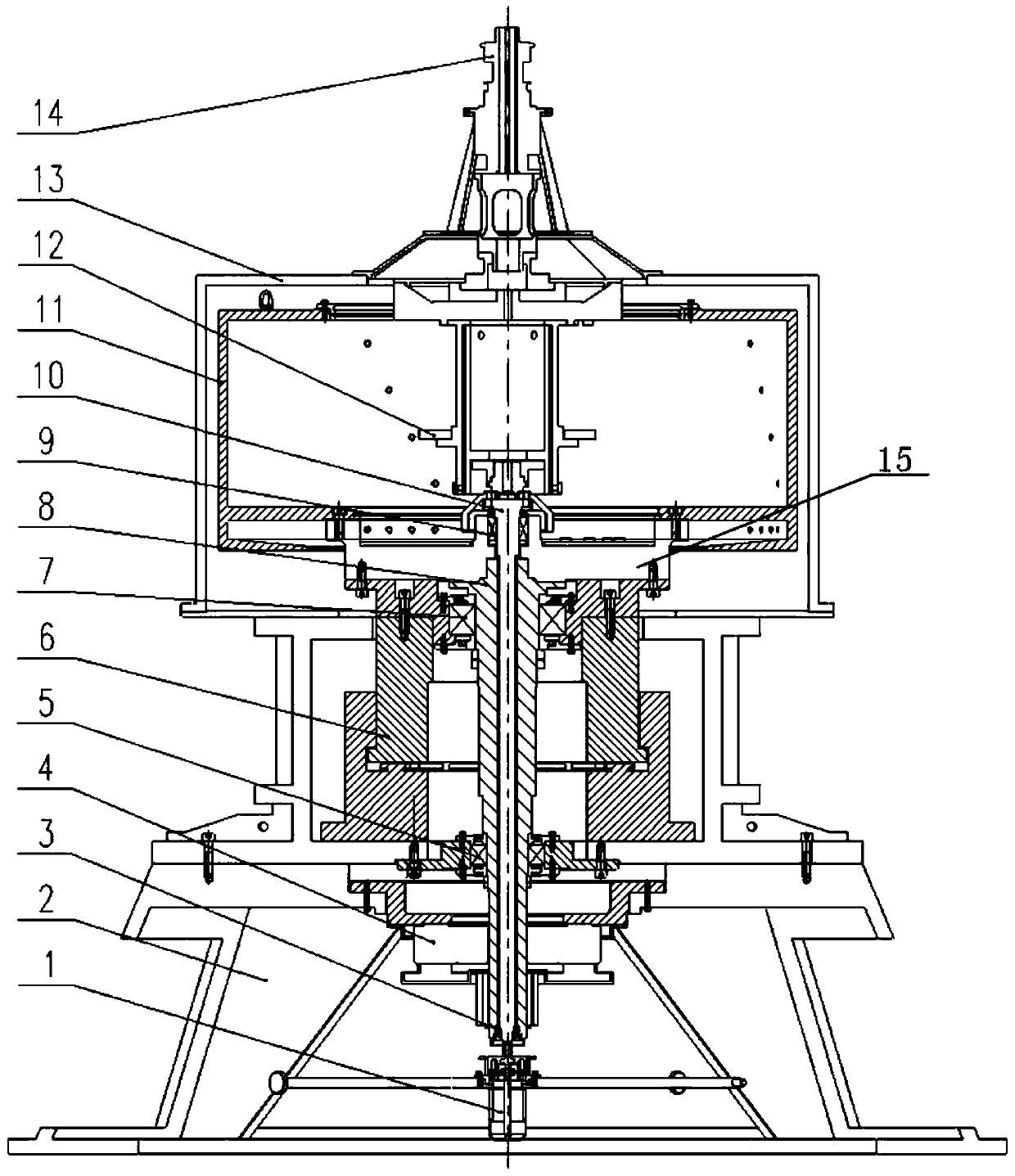

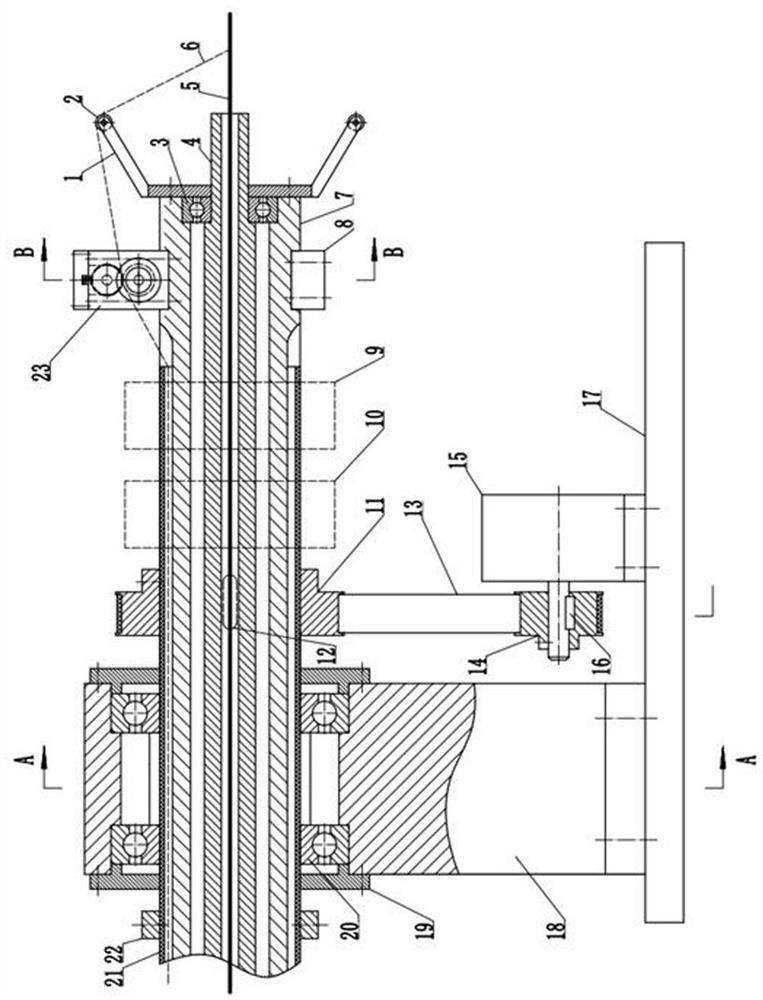

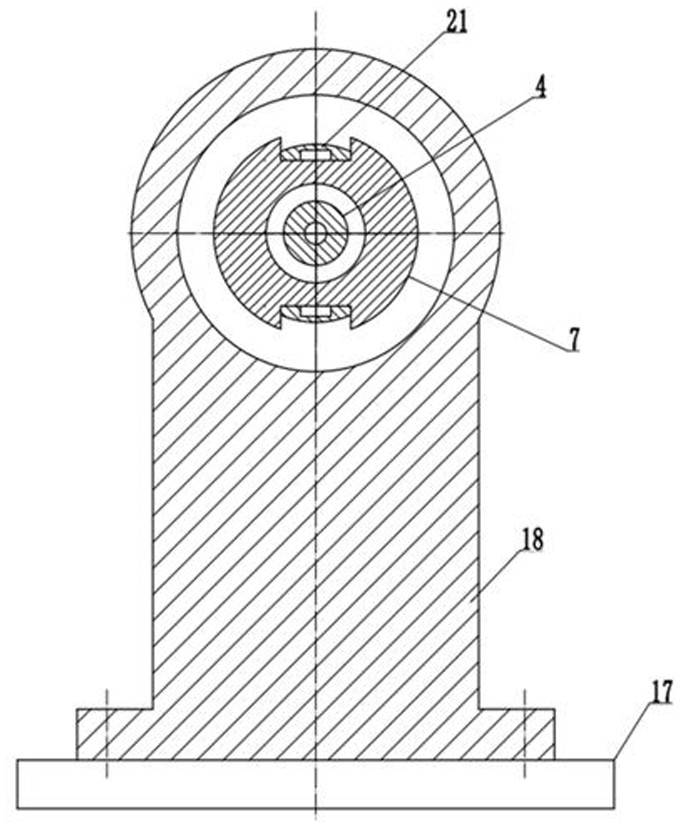

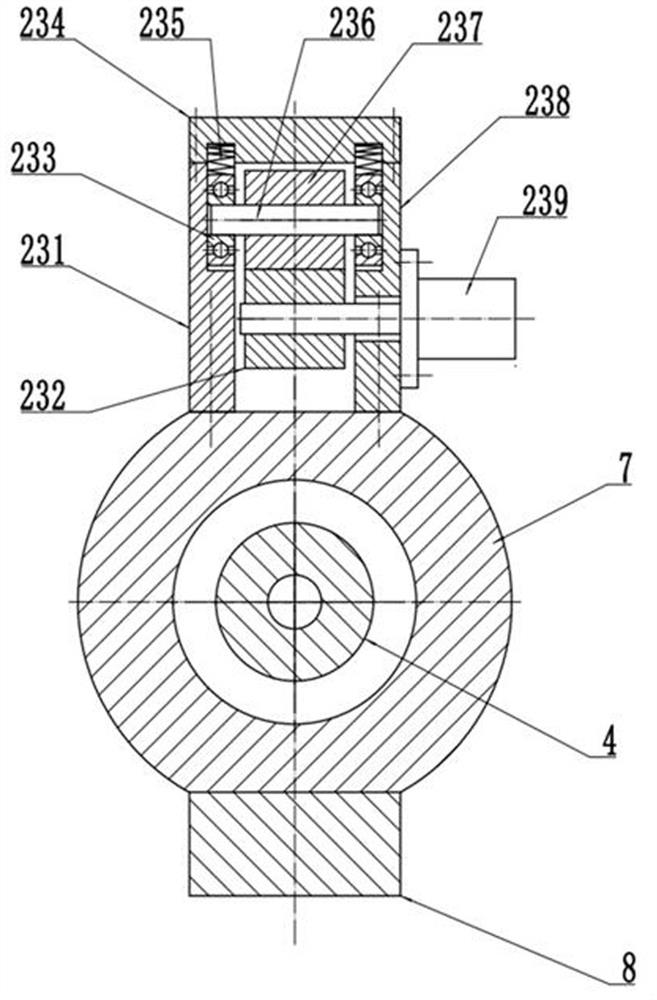

Geotechnical engineering drum type centrifuge device

The invention discloses a geotechnical engineering drum type centrifuge device, which includes an outer shaft and an inner shaft. The outer shaft is a hollow shaft, and used for driving a model grooveto rotate; the inner shaft is installed inside the outer shaft, driven by an inner shaft motor, and used for driving an actuator platform to rotate; the outer shaft and the inner shaft do not touch,and the outer shaft and the inner shaft are arranged on the same axis; the outer shaft motor is a direct drive motor, and the outer shaft passes through the outer shaft motor and is driven by the outer shaft motor; and synchronous or asynchronous motion of the outer shaft and the inner shaft is achieved through a cross coupling control method. According to the geotechnical engineering drum type centrifuge device, the outer shaft is directly driven by the direct drive motor, and the characteristics of rapid start, high rotating speed control accuracy, stable operation and the like are achieved;and synchronous or asynchronous motion of the outer shaft and the inner shaft is achieved through the cross coupling control method, and the vibration effect caused by synchronization of mechanical connection (a clutch) can be avoided.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

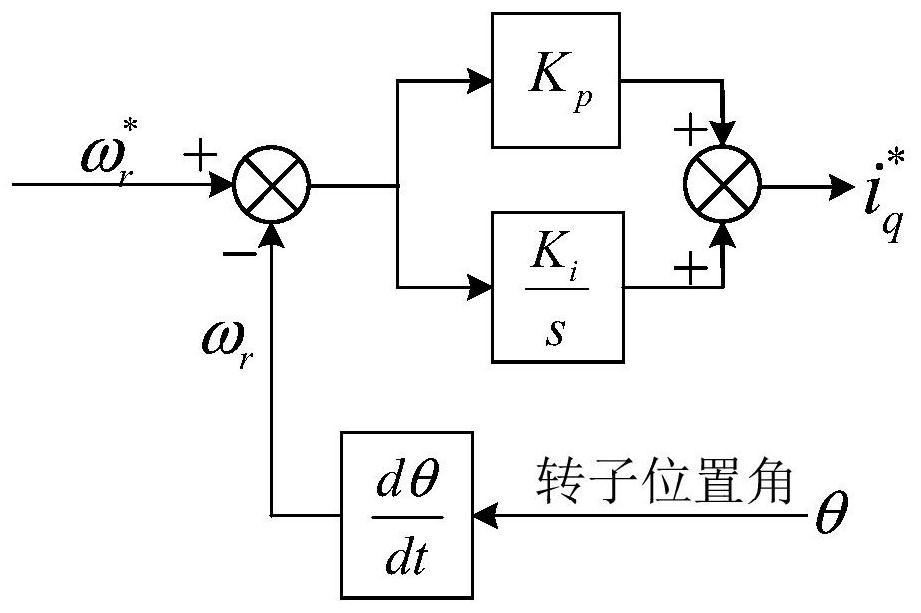

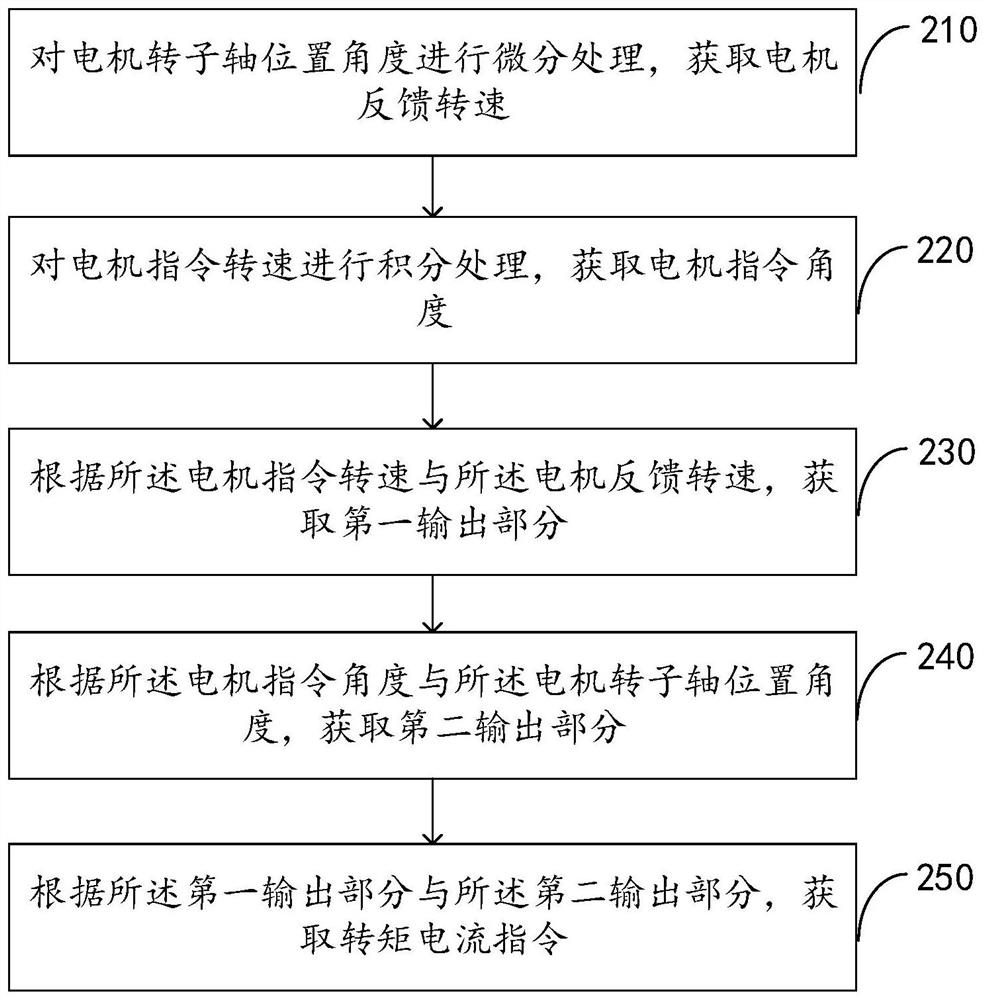

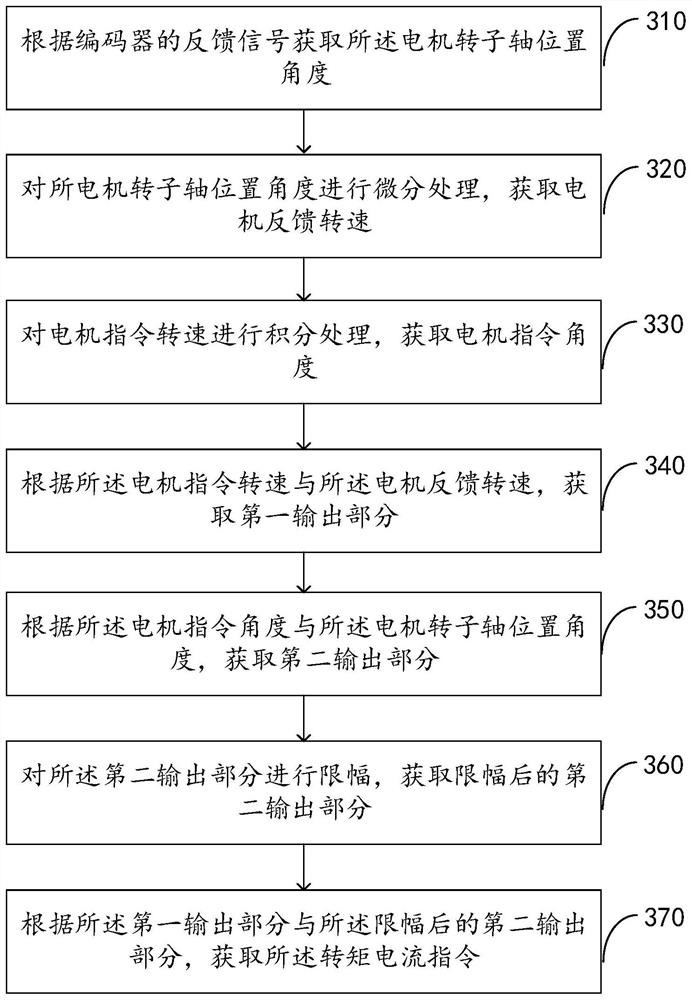

Motor speed loop PI control method and system, equipment and storage medium

ActiveCN112701976AEnsure speed cycle consistencyHigh speed control precisionElectronic commutation motor controlElectric motor controlPhysicsEngineering

The invention relates to a motor speed loop PI control method and system, equipment and a computer storage medium. The method comprises the following steps: carrying out the differential processing of the position angle of a motor rotor shaft, and obtaining the feedback rotating speed of a motor; performing integral processing on the motor instruction rotating speed to obtain a motor instruction angle; obtaining a first output part according to the motor instruction rotating speed and the motor feedback rotating speed; obtaining a second output part according to the motor instruction angle and the motor rotor shaft position angle; and obtaining a torque current instruction according to the first output part and the second output part. The rotating speed control precision of the low-line-number encoder at a low speed is improved, and the rotating speed period consistency of the motor is ensured.

Owner:SUZHOU WEICHUANG ELECTRICAL EQUIP TECH

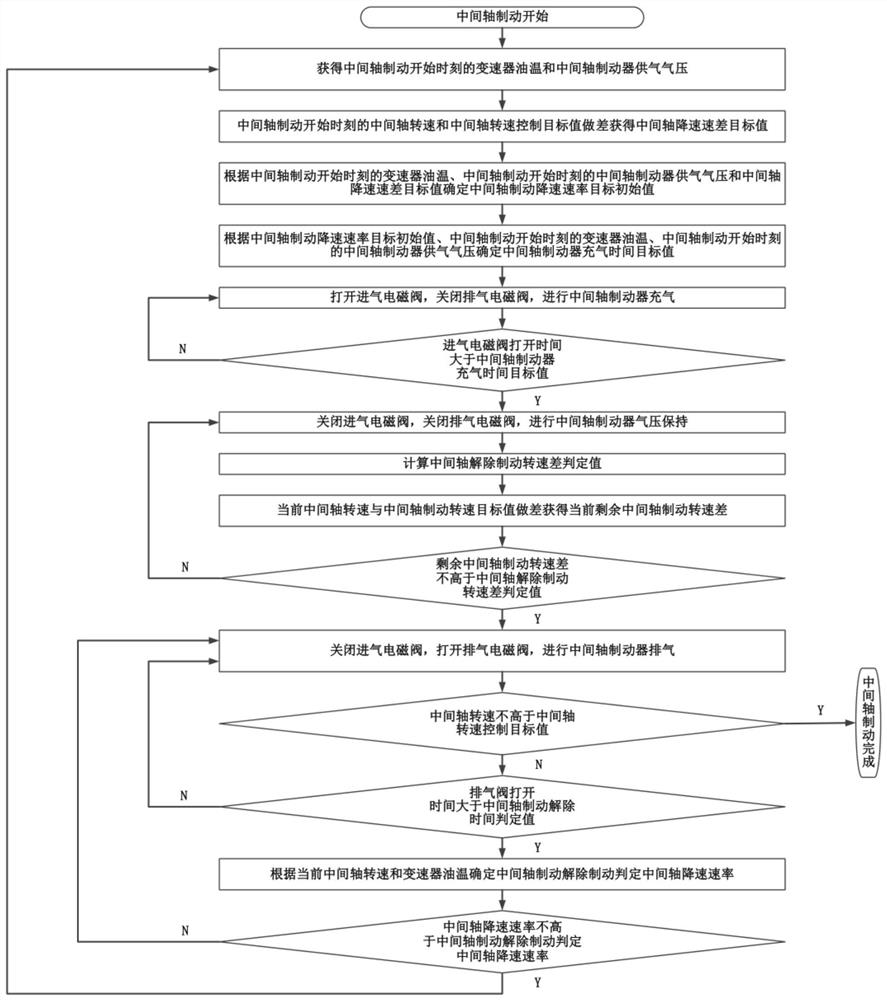

Intermediate shaft brake control method

PendingCN114382808APrevent overbraking problemsHigh control precisionBrake actuating mechanismsActuatorsAutomotive engineeringVariator

The invention relates to the technical field of automatic transmission control, and discloses an intermediate shaft brake control method. The intermediate shaft brake is inflated by opening the air inlet electromagnetic valve and closing the air exhaust electromagnetic valve, and the intermediate shaft braking capacity is established; after a period of time, the air inlet electromagnetic valve and the exhaust electromagnetic valve are closed, so that the air pressure of the intermediate shaft brake is kept, and the intermediate shaft is braked with stable braking torque; before the intermediate shaft rotating speed reaches the intermediate shaft rotating speed control target value, an exhaust electromagnetic valve is opened, intermediate shaft brake exhaust and intermediate shaft braking release are carried out, and if the intermediate shaft rotating speed does not reach the intermediate shaft rotating speed control target value and intermediate shaft braking release is carried out, the process is repeated; and until the intermediate shaft rotating speed reaches the intermediate shaft rotating speed control target value. Rapid speed reduction of the intermediate shaft is achieved, the rotating speed control precision of the intermediate shaft is improved, and it is guaranteed that when the rotating speed of the intermediate shaft reaches the target rotating speed of the intermediate shaft, intermediate shaft braking is relieved.

Owner:FAW JIEFANG AUTOMOTIVE CO

A method for controlling the spraying operation of an emulsion-type deicing agent spraying vehicle

InactiveCN104790337BSimple structureReasonable designWay cleaningSpeed/accelaration control using electric meansEmulsionSpeed control system

The invention discloses a spreading vehicle for an emulsion type snow-melting agent. The spreading vehicle comprises a bearing vehicle body, a snow-melting agent storing tank and a spraying system used for spraying snow-melting agent in the snow-melting agent storing tank onto a road. The spraying system comprises multiple spraying devices, a conveying pipeline, a snow-melting agent pump and an alternating-current variable-frequency speed control system used for controlling the speed of the snow-melting agent pump. The snow-melting agent pump is a quantitative pump and is installed on the conveying pipeline. The spreading vehicle is simple in structure, reasonable in design, easy and convenient to operate and good in use effect, and the spreading amount of the snow-melting agent is controlled by controlling the speed of the snow-melting agent pump through the alternating-current variable-frequency speed control system. The invention further discloses a spreading operation control method of the spreading vehicle for the emulsion type snow-melting agent. The spreading operation control method comprises the steps that firstly, spreading control parameters are set; secondly, the bearing vehicle body is started, and the spraying devices are opened; thirdly, the bearing vehicle body moves, and the snow-melting agent is spread. The spreading operation control method has the advantages that the steps are simple, design is reasonable, implementation is convenient, the spreading amount control effect is good, and the spreading amount and the spreading uniformity of the snow-melting agent can be effectively controlled.

Owner:CHANGAN UNIV

A control method of asynchronous motor without speed sensor drive

ActiveCN112436774BAccurate speedGuaranteed uptimeElectronic commutation motor controlVector control systemsMotor speedOvervoltage

The invention discloses a control method of an asynchronous motor driven by a speed sensor, which belongs to the technical field of motors. The invention adjusts the input voltage amplitude and phase of the flux linkage and rotational speed observer adaptively through the voltage switching structure, so that the input voltage of the flux linkage and rotational speed observer is a virtual voltage at low speed, and ensures the asynchronous speed under the drive of the speed sensorless control system. Stable and reliable operation of the motor at low speeds; the input voltage of the flux linkage and speed observer is close to the actual voltage at high speeds, ensuring the speed control accuracy of the asynchronous motor driven by the speed sensorless control system at medium and high speeds; The motor flux orientation angle is estimated, and the vector control method is used to drive the asynchronous motor to run normally, so that the actual flux current, actual torque current, and estimated motor speed of the motor are respectively related to the reference flux current, reference torque current, and motor reference speed. Consistent, the smooth switching between the virtual voltage and the actual reference voltage is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

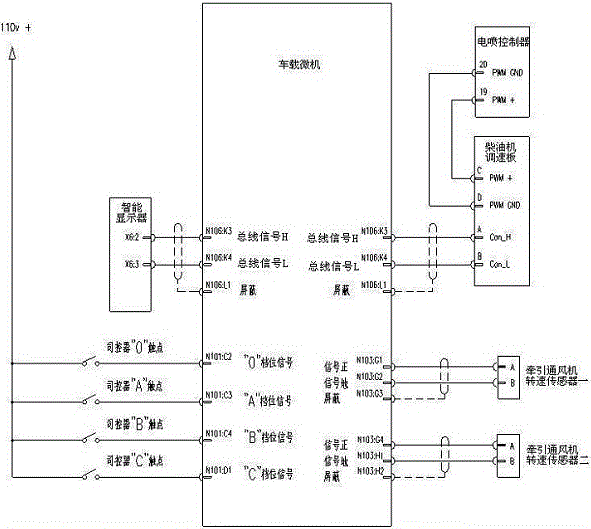

Closed-loop speed regulation system and speed regulation method of diesel locomotive diesel engine

ActiveCN103410619BImprove reliabilityHigh measurement accuracyFuel-injection pumpsMachines/enginesMicrocomputerHigh speed control

The invention relates to the technical field of internal-combustion electromechanical transmission systems, in particular to a closed-loop speed regulation system and a speed regulation method for a diesel locomotive diesel engine. The speed board is externally connected with an EFI controller, and the on-board microcomputer is also equipped with two traction fan speed sensors to form a dual backup system. The determination of the current speed of the diesel engine in the present invention adopts a double backup sensor system, adds a feedback control link, and the control mode can be automatically switched between the conventional mode and the closed-loop mode, and has better reliability and higher speed control precision.

Owner:CRRC QISHUYAN CO LTD

Anti-reverse paddleless mixer

ActiveCN103846038BSolve the phenomenon of reverse swingHigh speed control precisionRotating receptacle mixersTransportation and packagingBiochemical engineeringReducer

An anti-reversal paddleless mixer, the power device of the main equipment of the paddleless mixer is a DC motor, and the DC motor is equipped with a one-way anti-reverse reducer. The invention solves the reverse swing phenomenon caused by the inertial impact of the slurry during the positioning process of the paddleless mixer.

Owner:SHANGHAI AEROSPACE CHEM ENG INST

Transmission system of a rail working vehicle

ActiveCN109577117BIncrease speedThe structure of electric transmission is matureRailway track constructionLow speedElectric drive

The invention discloses a rail operation vehicle transmission system. A rail operation vehicle comprises a power vehicle and an operation vehicle; the rail operation vehicle transmission system comprises a vehicle power supply system, a high speed running system and a low speed running power source, a low constant speed running system and an operation system, wherein the vehicle power supply system, the high speed running system and the low speed running power source are placed on the power vehicle; the low constant speed running system is placed on the operation vehicle; and the operation system is partially or totally placed on the operation vehicle. The vehicle power supply system provides a power supply for the operation system and can selectively provide power supply for the high speed running system or the low speed running power source; and the high speed running system adopts an electric drive traction system. The low speed running power source provides a hydraulic power sourcefor the low constant speed running system; and the low constant speed running system adopts an electric drive hydrostatic transmission traction system. According to the rail operation vehicle transmission system, a technical problem of power transmission of a double-power-source rail operation vehicle in high speed running and low running modes can be solved to satisfy requirements on a running speed and control accuracy under different working conditions.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

A Parameter Setting Method of the Speed Loop Active Disturbance Rejection Controller of Permanent Magnet Synchronous Motor

ActiveCN110729939BFast convergenceImprove global search performanceElectronic commutation motor controlAC motor controlLocal optimumLoop control

The invention discloses a parameter tuning method of the speed loop self-disturbance rejection controller of a permanent magnet synchronous motor, establishes a double closed-loop control structure of speed and current, and initializes the gray wolf population strategy according to the Tent mapping reverse learning, and adopts the non-linear method as the number of iterations increases Change the convergence factor, and introduce the levy flight strategy in the update link of the wolf pack position in the algorithm for mutation operation, and finally obtain the adjusted parameters. The present invention improves the gray wolf optimization algorithm population from the initialization, initializes the gray wolf population according to the tent mapping reverse learning strategy, designs a convergence factor that changes non-linearly with the increase of the number of iterations, and introduces the levy flight strategy in the wolf group position update link. An improved gray wolf optimization algorithm is proposed, which can increase the diversity of the initial population of the algorithm, better adaptability and adjustment to complex searches, avoid falling into local optimum, improve the convergence speed of the algorithm and the global optimization ability, and the effect It is better than other improved gray wolf optimization algorithms.

Owner:JIANGSU UNIV OF SCI & TECH

A kind of power transmission method of rail working vehicle

ActiveCN109606395BIncrease speedStable jobElectric motor propulsion transmissionTrackwayControl theory

The invention discloses a track operation vehicle power transmission method. A track operation vehicle comprises a power vehicle and an operation vehicle. The method comprises the following steps: A)setting an overall power supply system, a high-speed walking system and a low-speed walking power source on the power vehicle, setting a low-constant speed walking system on the operation vehicle, andsetting an operation system on the operation vehicle independently or on the power vehicle and the operation vehicle; B) supplying power to the operation system from the overall power supply system,selectively supplying power to the high-speed walking system and the low-speed walking power source, and providing an electric transmission traction system for the high-speed walking system; C) providing a hydraulic power source for the low-constant speed walking system from the low-speed walking power source, and providing an electric transmission static hydraulic transmission traction system forthe low-constant speed walking system. By adopting the method, the technical problem of power transmission of a double-power source tract operation vehicle in high-speed walking and low-speed walkingmodes can be solved, and requirements on walking speeds and control precision under different working conditions can be met.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

Outer rotor embedded automatic control constant speed DC brushless axial flow fan and constant speed control method

InactiveCN102072182BReduce development costsReduce manufacturing costPump controlNon-positive displacement fluid enginesAutomatic controlElectric machine

The invention relates to an outer rotor embedded automatic control constant speed DC brushless axial flow fan and a constant speed control method, which can realize constant speed automatic control over the rotating speed of an outer rotor embedded axial flow fan. The outer rotor embedded automatic control constant speed DC brushless axial flow fan comprises an axial flow fan and a DC converter. An automatic control constant speed detection circuit is arranged in the axial flow fan. A detection head in a frequency-to-converter (F / V) converter in the automatic control constant speed detection circuit is positioned on one side of an outer rotor, and is used for detecting the rotating speed of the outer stator. The output end of an inverted adder in the automatic control constant speed detection circuit is connected with the power input end of the axial flow fan, and is used for adjusting the rotating speed of the axial flow fan. The outer rotor embedded automatic control constant speed DC brushless axial flow fan and the constant speed control method have the advantages of: 1, low cost of subsequent product development of a client; 2, simple use; 3, high rotating speed control accuracy; 4, low fan manufacturing cost; 5, long motor service life; and 6, high safety factor.

Owner:HANGZHOU DUNLI ELECTRIC APPLIANCES

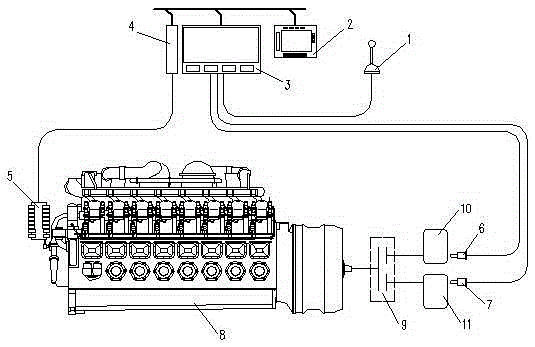

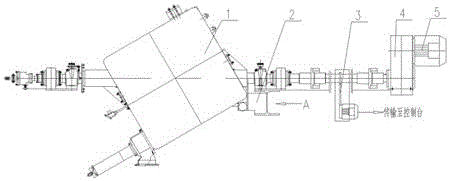

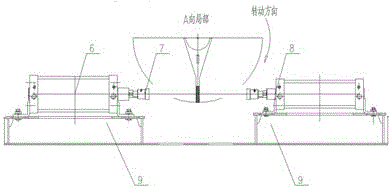

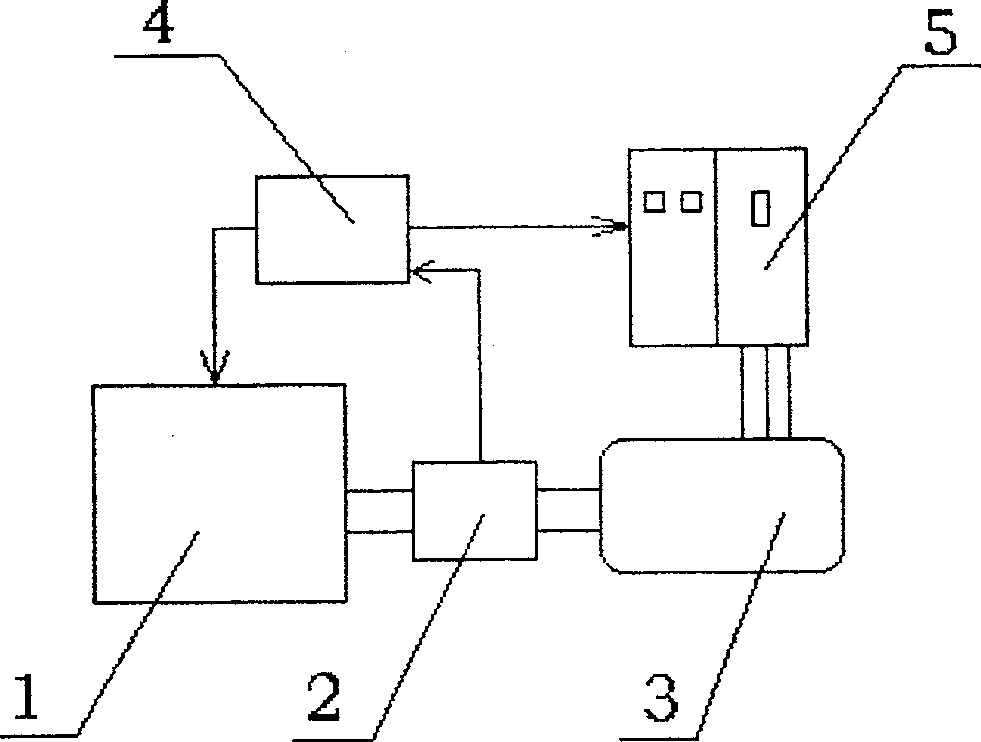

Test macro of engine pedestal and method for constant-velocity control

InactiveCN100526837CHigh control precisionFast dynamic responseVehicle testingEngine testingComputer control systemElectricity

The invention discloses an engine bench test system and a constant speed control method thereof. The system includes a torque sensor (2), a motor (3), a computer measurement and control system (4), and an AC frequency converter (5); The engine, the AC inverter, and the torque sensor are electrically connected; the AC inverter is electrically connected to the motor; one end of the torque sensor (2) is rigidly connected with the output shaft of the motor (3), and the other end is used for coaxial rigid connection with the output shaft of the engine. connect. By directly controlling the speed of the motor, the engine is stabilized at the set speed point, with high control precision, small fluctuations, and a smooth adjustment process. The maximum fluctuation of each speed point is about 1rpm. It solves the problem that the torque control method cannot stabilize the speed at the set speed under severe working conditions such as engine performance decline, single-cylinder fire failure, and short-term oil shortage, and truly meets the requirements of the engine test.

Owner:BYD CO LTD

A brushless motor control method based on torque feedback and commutation compensation

InactiveCN105305895BImproved torque rippleIncreased torque rippleTorque ripple controlElectronic commutatorsBrushless motorsElectric machine

Owner:JILIN UNIV

A motor sensorless drive control system

ActiveCN104167961BHigh speed control precisionQuick responseSingle motor speed/torque controlOvervoltageNew energy

The present invention is a motor sensorless drive control system, suitable for high-speed motors of 10000-120000 RPM, mainly composed of DSP control processor, bridge matrix circuit, push-pull output drive circuit, IGBT current expansion high load carrying circuit, high-speed sensorless detection circuit, protection circuit, CAN bus communication circuit, high and low voltage isolation circuit, etc. The PMSM control waveform is output by the DSP processor, and the power is amplified by the bridge matrix circuit and the push-pull output drive circuit to drive the IGBT current expansion module to control the high-speed motor. It has undervoltage, overvoltage, overcurrent, temperature protection, fault memory protection, CAN online system upgrade program refresh, and fault diagnosis functions that meet ISO15765. This control system is suitable for various permanent magnet synchronous motors and meets the control requirements of new energy vehicles at home and abroad. It has the characteristics of small size, high controllable speed and high efficiency.

Owner:GUANGDONG GUANGSHUN NEW ENERGY POWER TECH CO LTD +2

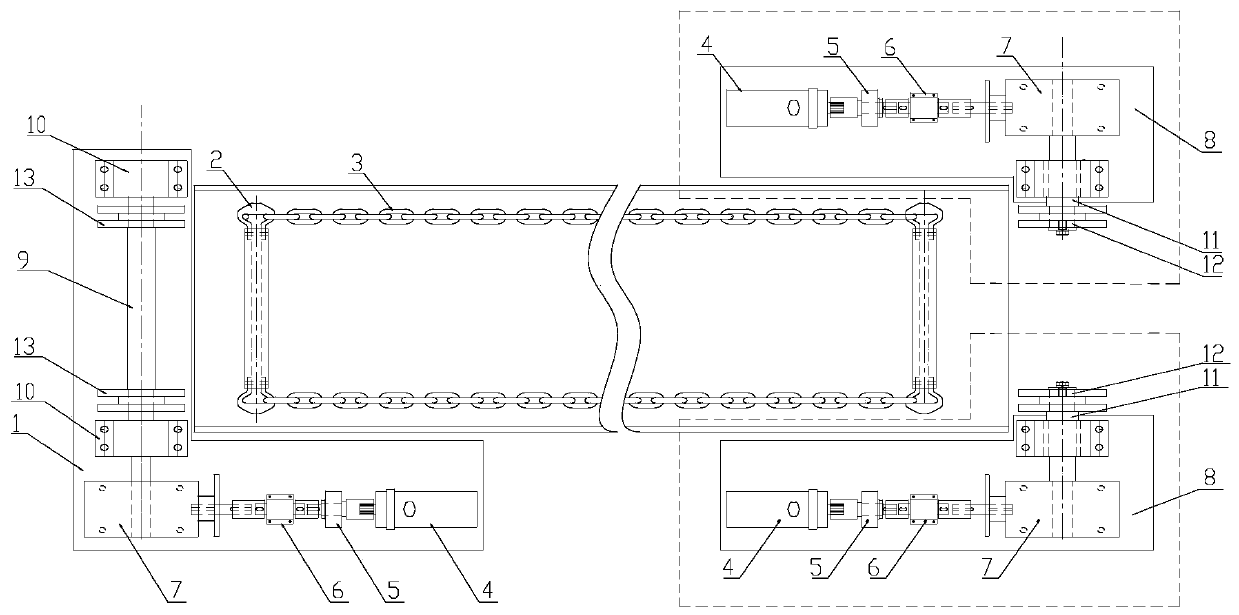

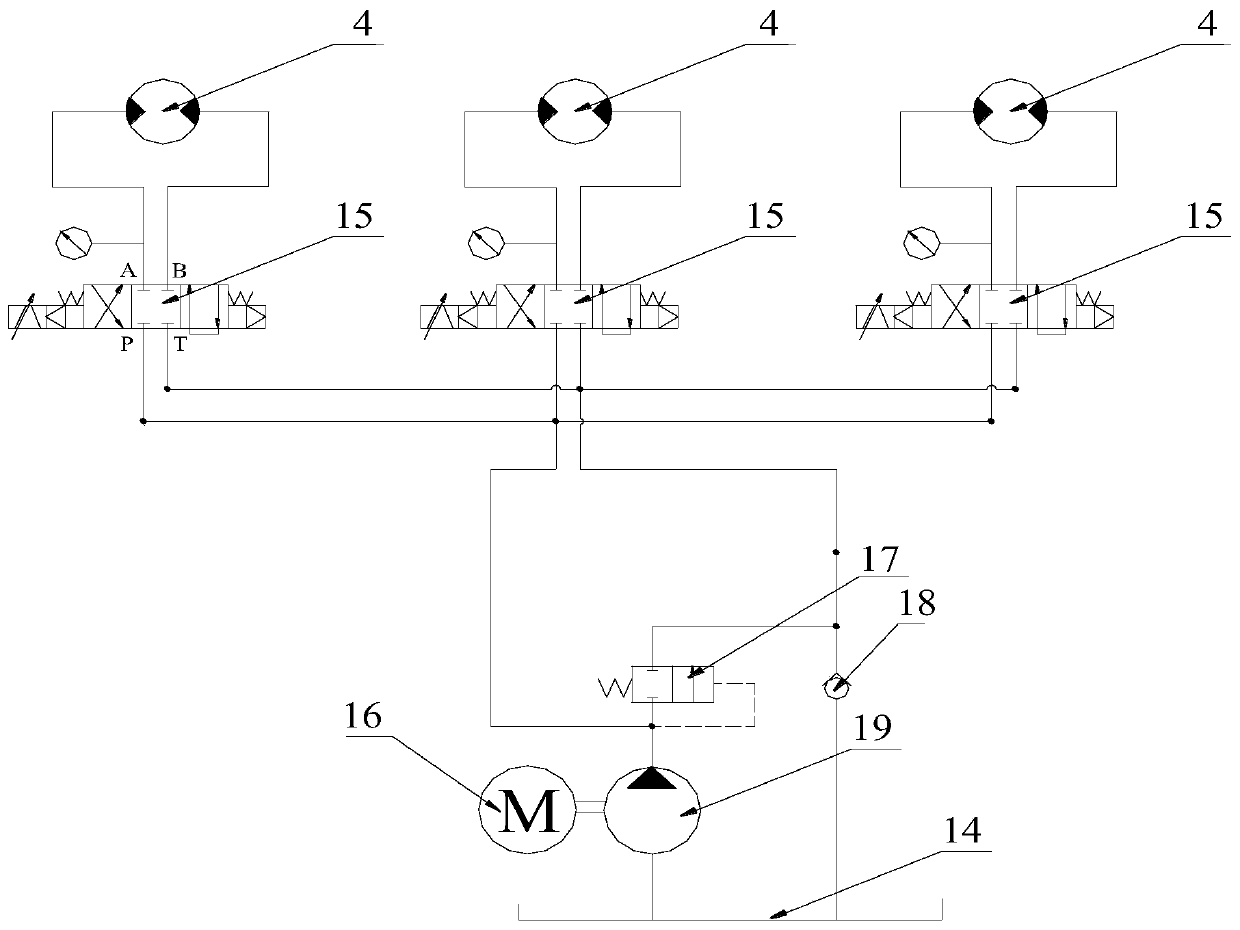

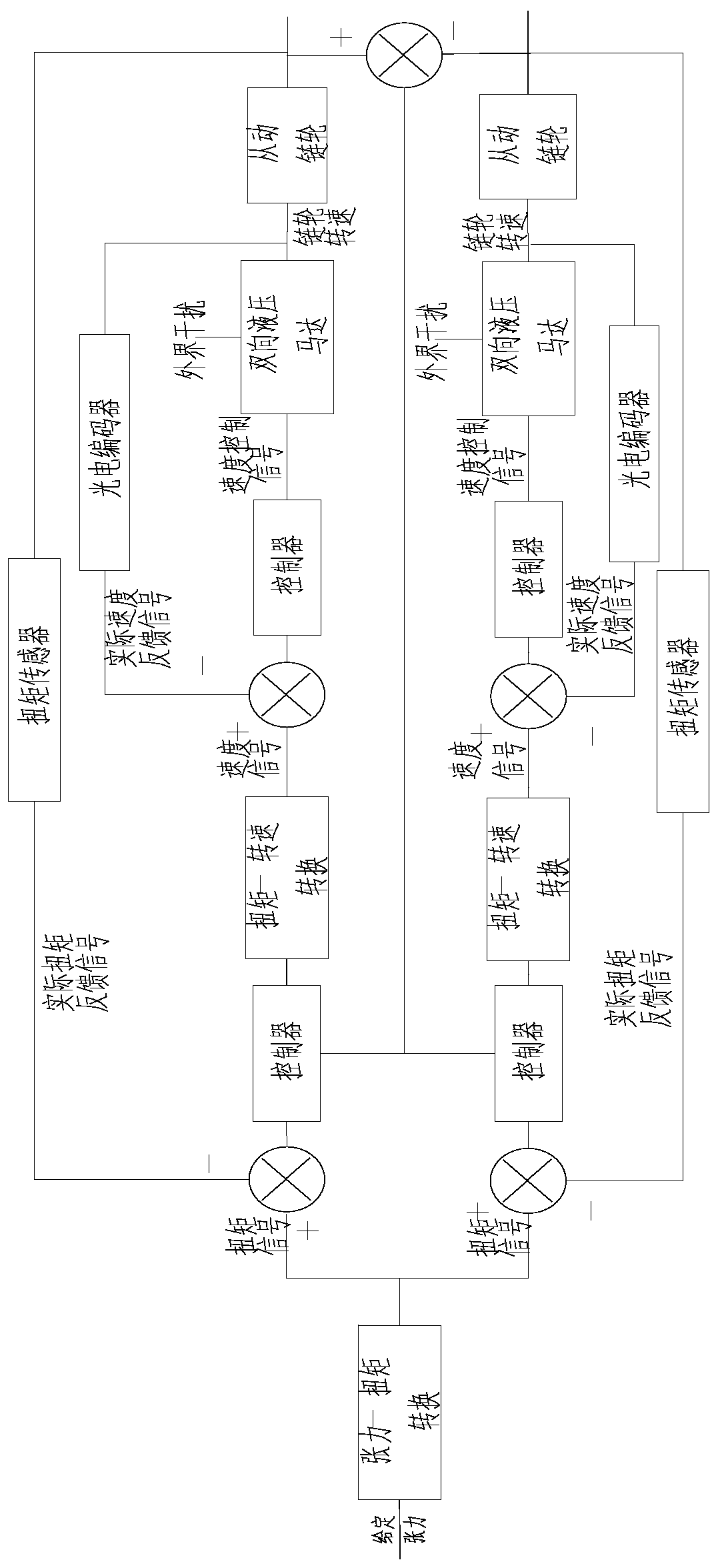

A driving device of a heavy-duty scraper machine and its hydraulic system

ActiveCN110092140BHigh speed control precisionIncrease power ratioConveyorsControl devices for conveyorsHydraulic motorControl engineering

The invention discloses a driving device of a heavy-load scraper conveyor and a hydraulic system of the driving device. The driving device comprises a supporting plate, an active driving device, two driven driving devices and the hydraulic driving system, wherein the active driving device comprises a main fixing table provided with a power device, the power device comprises a bidirectional hydraulic motor, a photoelectric encoder, a torque sensor and a right-angle speed reducer which are connected together in sequence, the right-angle speed reducer is connected with a chain wheel shaft, two driving chain wheels are symmetrically arranged at the two ends of the chain wheel shaft, the driven driving devices comprise small fixing tables provided with power devices, right-angle speed reducerson the small fixing tables are connected with cantilever shafts, driven chain wheels are arranged on the cantilever shafts, the two driving chain wheels and the two driven chain wheels are connected together correspondingly through two parallel scraper chains, a plurality of scrapers are connected between the two scraper chains, and the hydraulic driving device provides power. The device is simplein structure, high in reliability, capable of achieving rapid starting and stopping under a large load and capable of effectively adjusting the tension difference between the two scraper chains of the scraper conveyer.

Owner:CHINA UNIV OF MINING & TECH

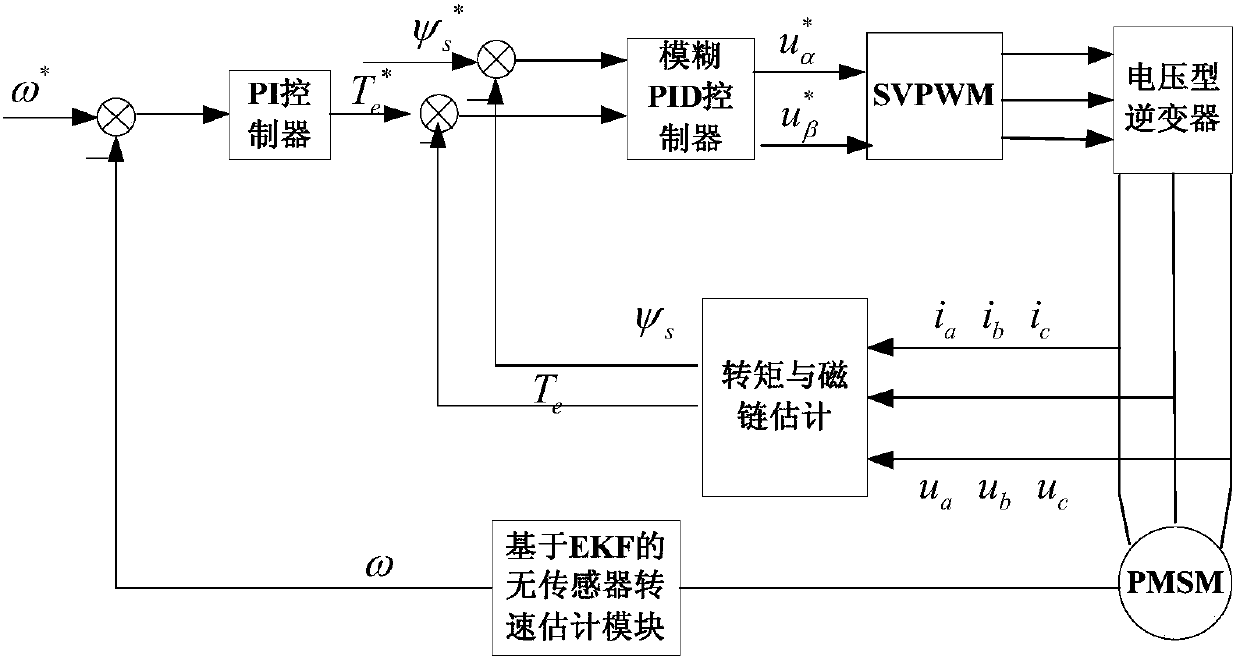

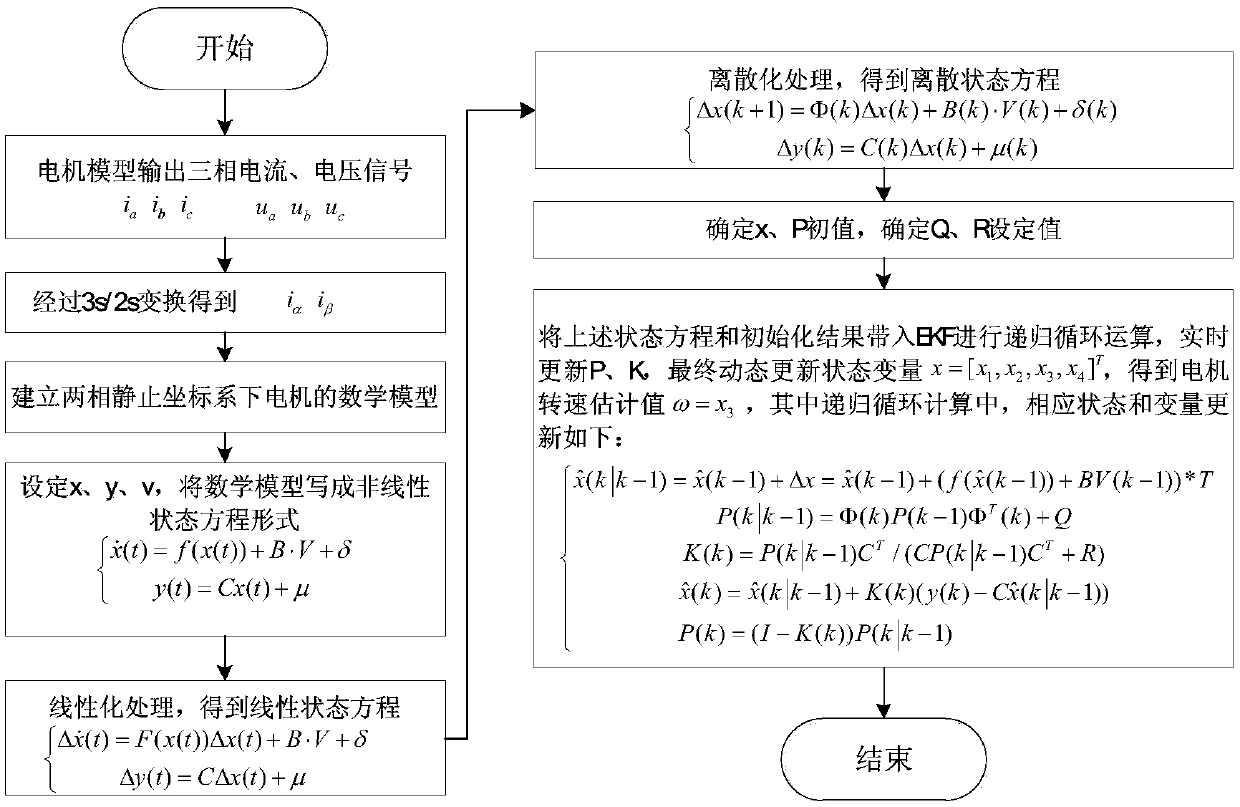

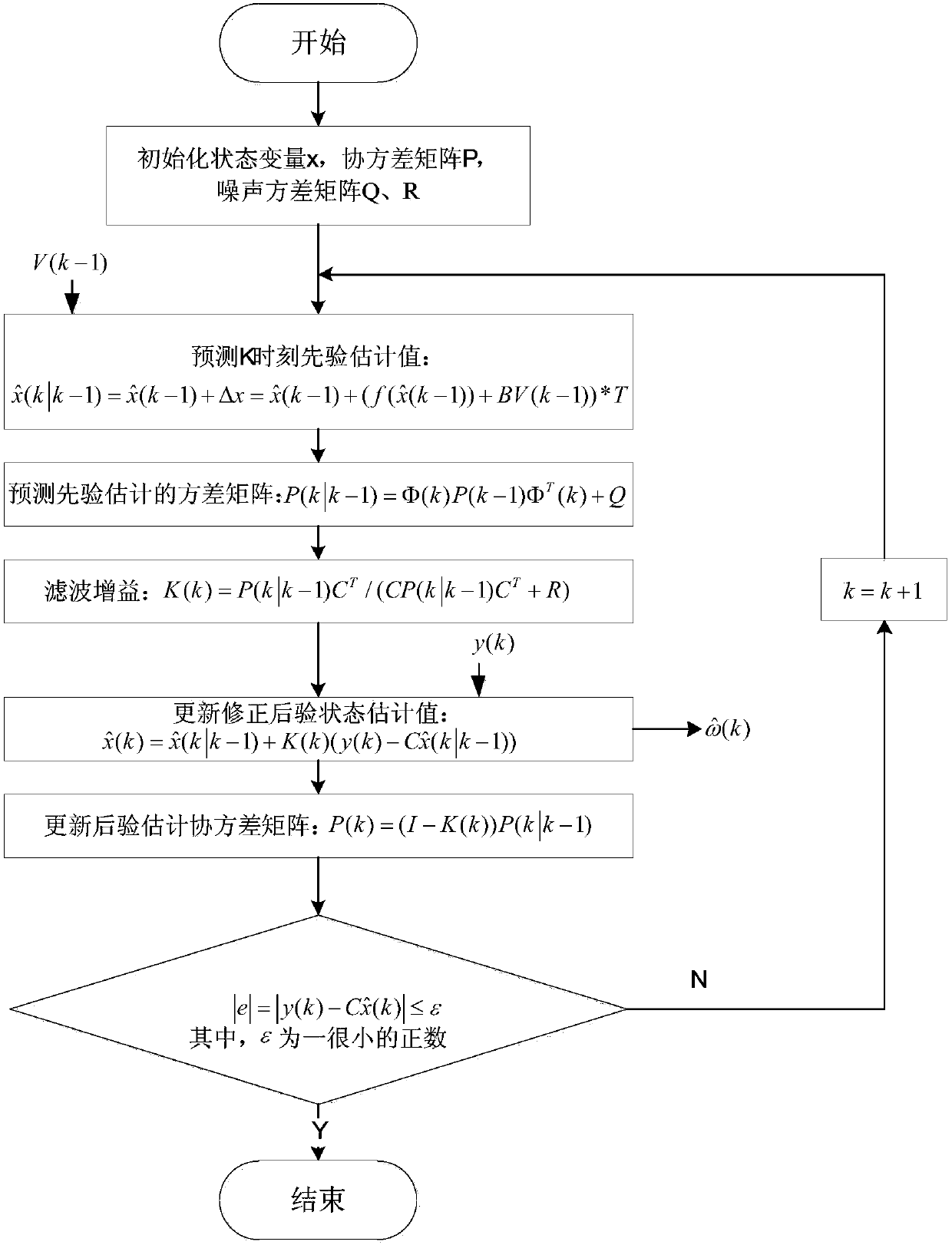

Speed control method of sensorless ultra-high speed permanent magnet synchronous motor based on ekf

ActiveCN106130426BImprove speed control performanceImprove robustnessElectronic commutation motor controlAC motor controlMathematical modelPermanent magnet synchronous motor

Owner:NANJING UNIV OF SCI & TECH

Taping machine main shaft structure and timing interruption control method thereof

ActiveCN113666197AChange tape tensionSmall transmission errorFilament handlingElectric machineControl theory

The invention discloses a taping machine main shaft structure and a timing interruption control method thereof. The main shaft structure comprises a base plate, a main transmission device, a belt feeding device and a belt wrapping device. According to the main shaft structure, the belt feeding device is additionally arranged between a belt releasing device and a belt winding device, so that the belt releasing tension and the belt winding tension are mutually independent, and the belt winding tension can be independently adjusted; a Mylar motor directly drives a Mylar to move, a transmission chain is short, and the transmission error is small; the rotation angle of a main shaft is measured through a rotary encoder, so that the number of pulses sent to a mylar motor driver is accurately controlled, and no accumulative error exists; angular displacement measurement is directly adopted for the main shaft, angular position control is adopted for the Mylar motor, and compared with traditional rotating speed measurement, the rotating speed control precision is higher, and the response speed is higher; timing interruption is carried out every several milliseconds, even if the rotating speed of the main shaft generates large disturbance, the Mylar motor can drive the Mylar to move along with rotation of the main shaft in time, and quantitative adjustment can be achieved.

Owner:江苏安澜万锦电子股份有限公司

Track operation vehicle power transmission method

ActiveCN109606395AIncrease speedFulfil requirementsElectric motor propulsion transmissionElectric power transmissionTraction system

The invention discloses a track operation vehicle power transmission method. A track operation vehicle comprises a power vehicle and an operation vehicle. The method comprises the following steps: A)setting an overall power supply system, a high-speed walking system and a low-speed walking power source on the power vehicle, setting a low-constant speed walking system on the operation vehicle, andsetting an operation system on the operation vehicle independently or on the power vehicle and the operation vehicle; B) supplying power to the operation system from the overall power supply system,selectively supplying power to the high-speed walking system and the low-speed walking power source, and providing an electric transmission traction system for the high-speed walking system; C) providing a hydraulic power source for the low-constant speed walking system from the low-speed walking power source, and providing an electric transmission static hydraulic transmission traction system forthe low-constant speed walking system. By adopting the method, the technical problem of power transmission of a double-power source tract operation vehicle in high-speed walking and low-speed walkingmodes can be solved, and requirements on walking speeds and control precision under different working conditions can be met.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

A digital food safety rapid detection system

ActiveCN103323584BMeet the needs of security routine testingThe detection process is fastColor/spectral properties measurementsBiological testingInformatizationTemperature control

The invention belongs to the field of rapid food safety detection, and provides a digital rapid food safety detection system, which mainly comprises a detection host machine unit, a sample pretreatment unit and a power supply module, can be provided for detecting a plurality of physical and chemical items, pesticide and veterinary drug residues, and biotoxins, has characteristics of rapid detection, high sensitivity, high informatization degree, and sample treatment-sample detection-informatization management integration, is an optimal selection for safe and rapid on-site detection, meets requirements of enterprise laboratories on food safety routine detection, and has strong promotion and application values. In addition, the detection host machine unit has the following characteristics that: temperature control precision and rotation speed control precision are high, functions of precise timing, short shock inching, temperature calibration and power-down recovery are provided, three functions such as constant temperature maintaining, oscillation and timing can be manually switched, the machine with a plurality of uses can be achieved, and equipment utilization can be increased.

Owner:北京倍肯恒业科技发展股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com