Torque feedback and commutation compensation-based brushless motor control method

A brushless motor and control method technology, applied in the direction of torque ripple control, electronic commutator, etc., can solve the problems of large fluctuation, current fluctuation, and low speed control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

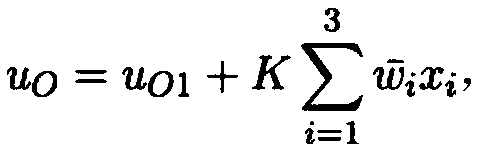

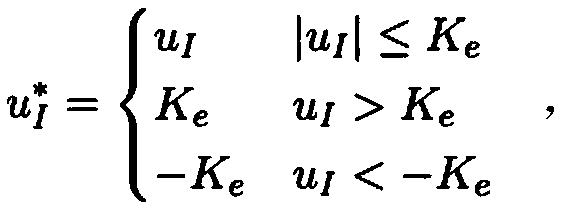

[0055] See figure 1 , the present invention uses double-closed-loop control in the control method, the outer loop of which is a speed loop, and the size of the given torque is determined according to the given speed and the actual speed. The inner loop is the torque loop, and the PWM output of the drive circuit is absolutely controlled by comparing the given torque of the outer loop with the motor torque measured or obtained through state observation. Its implementation method can be PID control, fuzzy control, neural network and other control methods. In the control method given below, the outer loop uses the neural network control algorithm, and the inner loop uses the modified incremental PID algorithm.

[0056] Step 1. The torque required by the motor is determined by the difference between the given speed and the actual speed, that is, the outer loop control. The specific process is:

[0057] 1. Initialization parameters:

[0058] Let the current round of control be th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com