Magneto-rheological torsion damper of electric wheel

A torsional shock absorber and magneto-rheological technology, applied in the direction of spring/shock absorber, motion deposition, power device, etc., can solve the problems of reducing the working performance and life of the motor, and the impact of the NVH performance of the car, so as to reduce the impact and improve The effect of hub shaft torque fluctuation and maximum controllable damping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

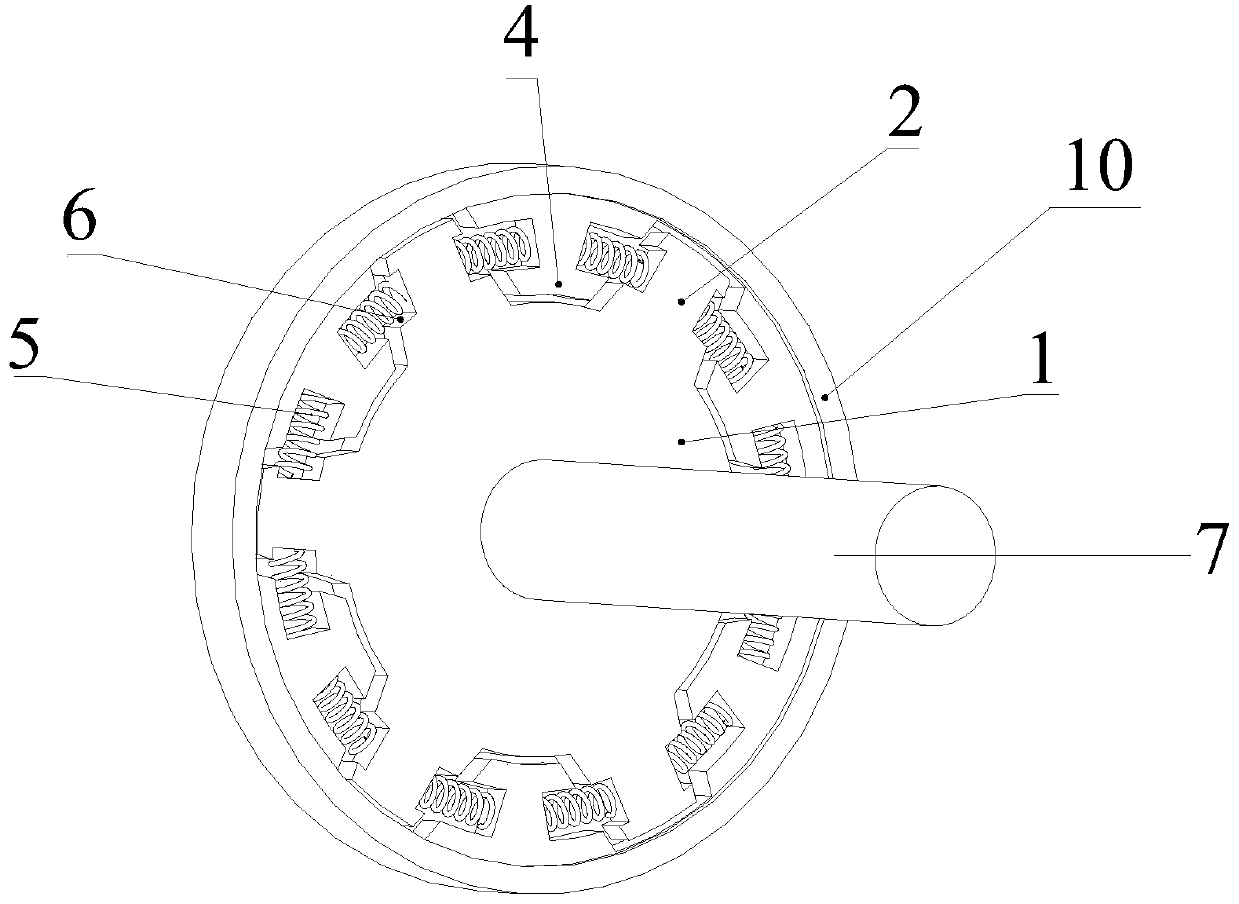

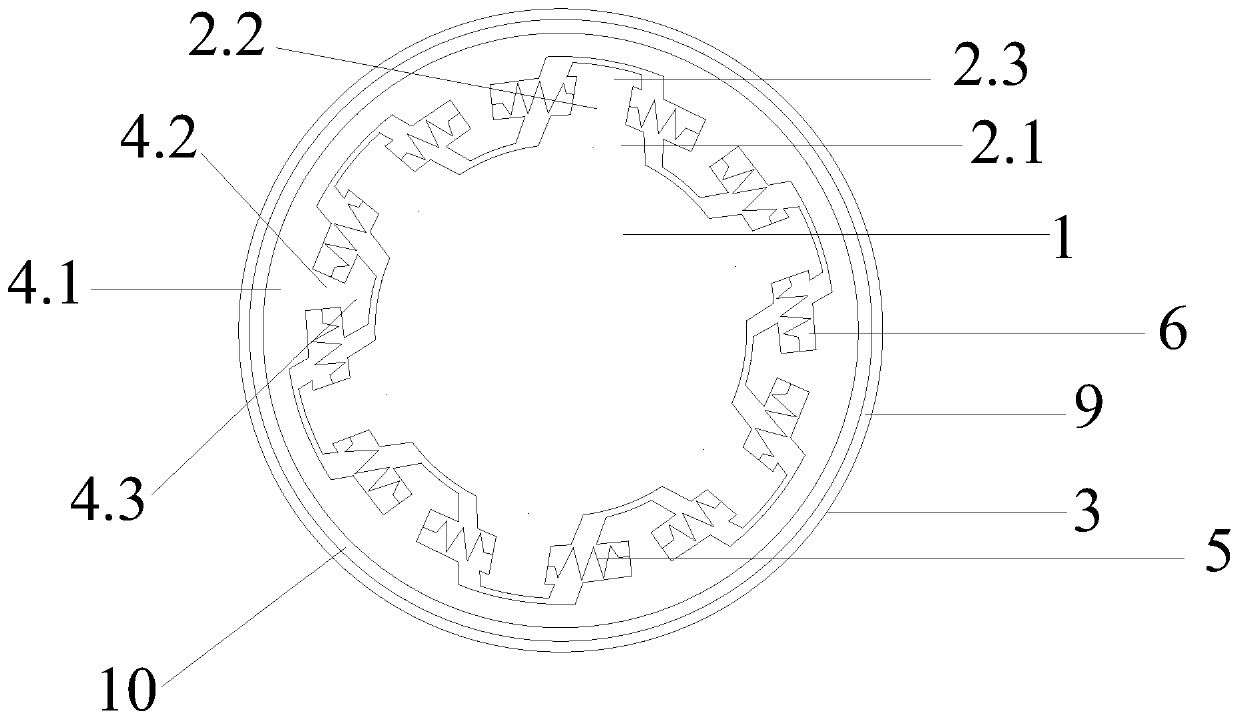

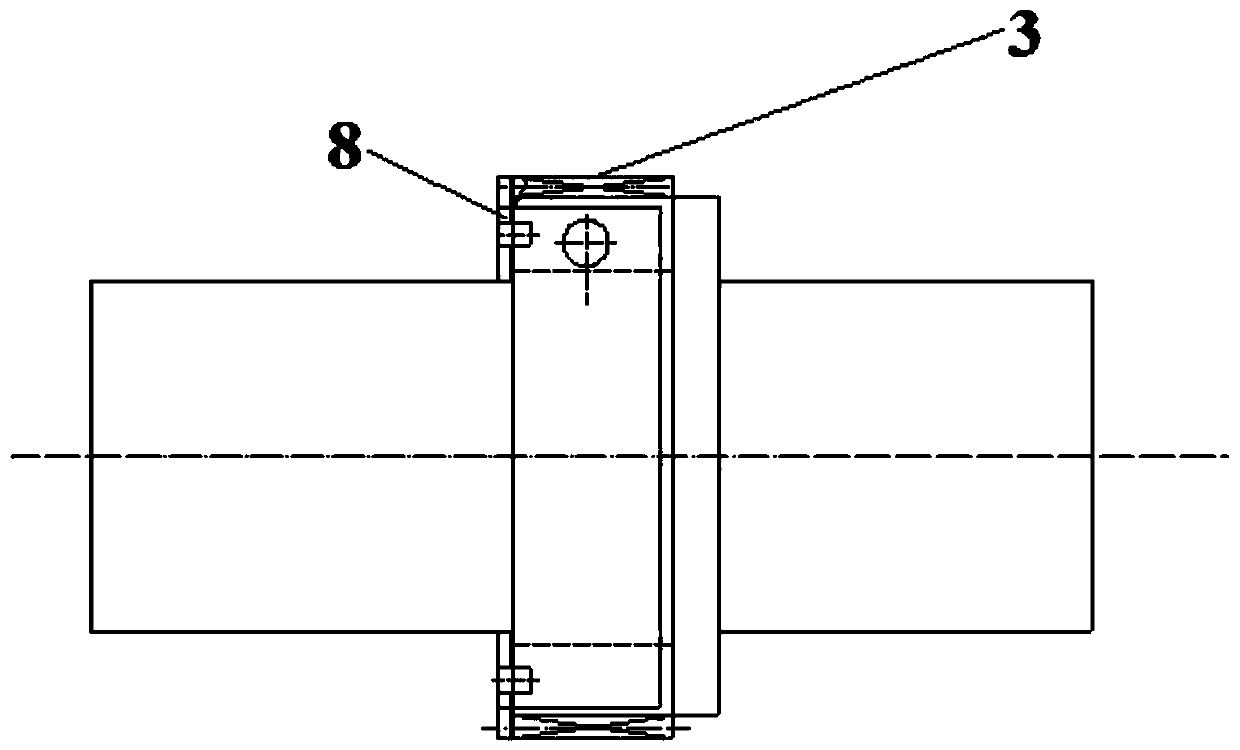

[0018] Such as figure 1 The magneto-rheological torsional shock absorber for electric wheels shown in —3 includes a motor rotor connected to the power output end of the hub motor and a hub rotor fixed to the hub.

[0019] The motor rotor includes a motor rotor connection plate 1, and the motor rotor shaft teeth 2 are arranged at intervals on the circumferential side surface of the motor rotor connection plate 1, and the middle part of the motor rotor connection plate 1 is fixedly connected with the output shaft of the reducer perpendicular to the hub motor. Fixed connecting shaft 7.

[0020] The hub rotor includes a hub rotor ring 10 and hub rotor shaft teeth 4 arranged at intervals on the circumferential inner surface of the hub rotor ring 10 , and the hub rotor shaft teeth 4 are arranged between two adjacent motor rotor shaft teeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com