Geotechnical engineering drum type centrifuge device

A centrifuge and drum technology, applied in the field of centrifuges, can solve the problems of low transmission efficiency, belt slack or aging, large vibration, etc., and achieve the effects of high speed control accuracy, rapid start-up and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

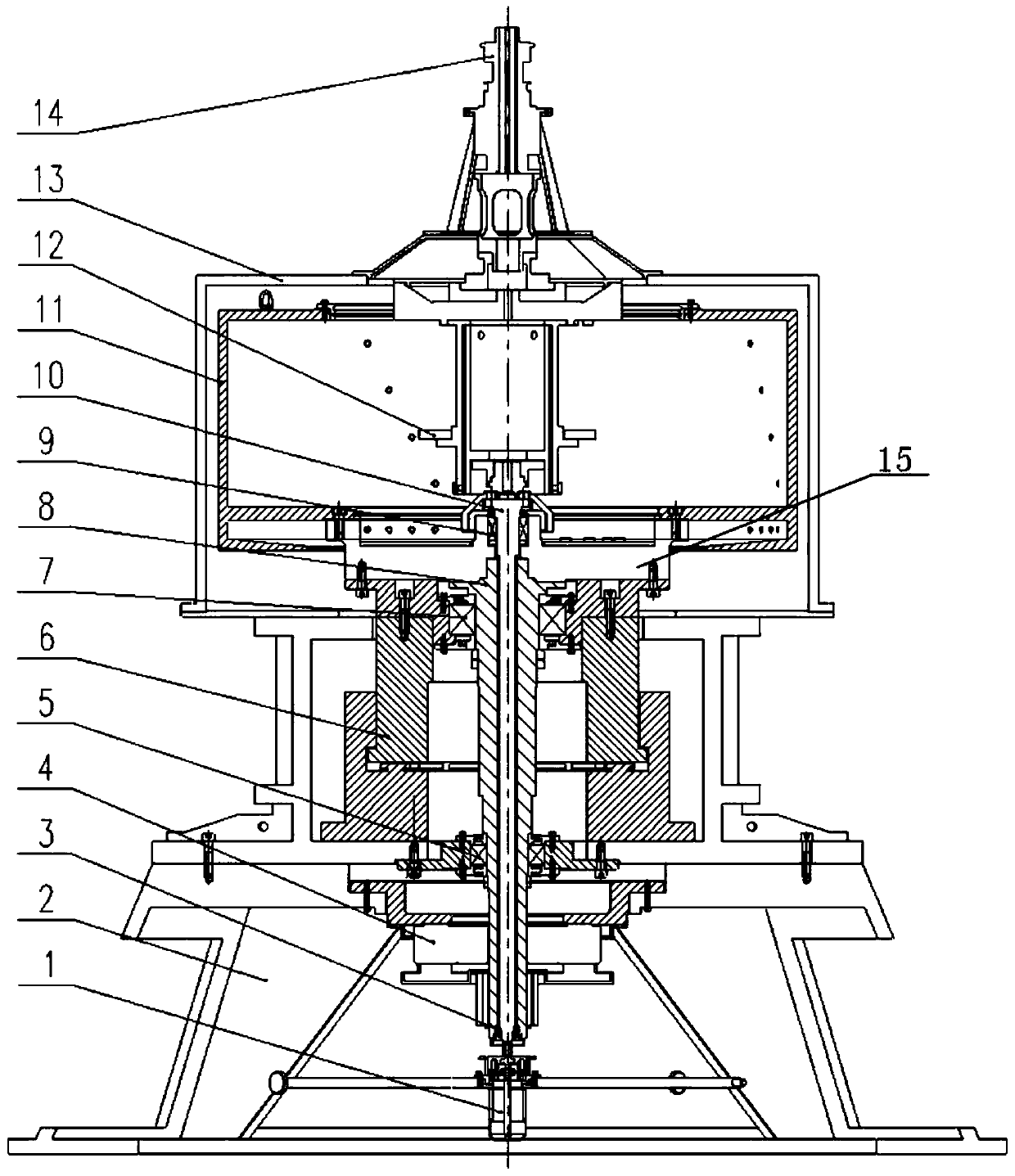

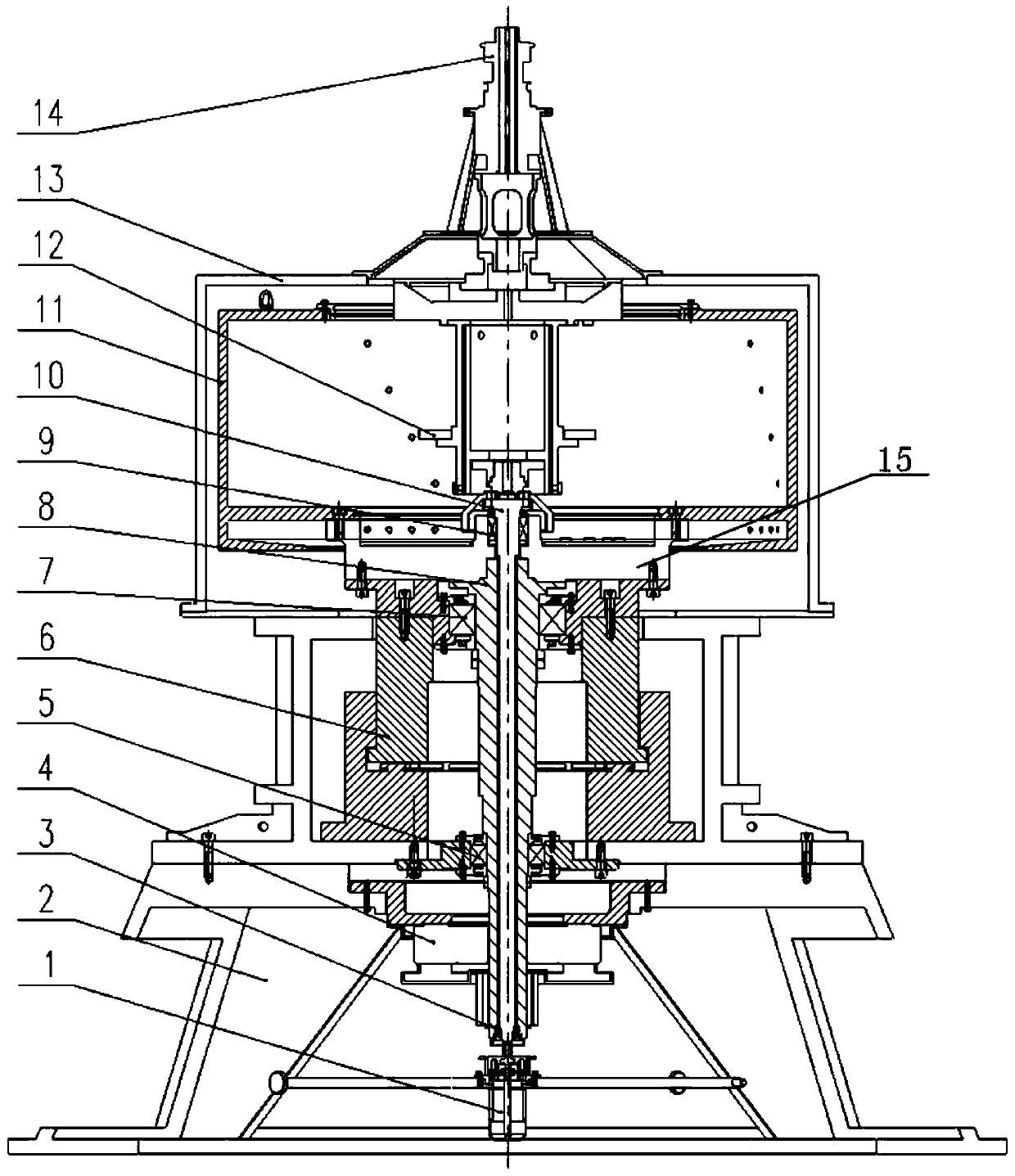

[0023] Example 1, such as figure 1 and figure 2 Shown:

[0024] A geotechnical drum centrifuge device comprising

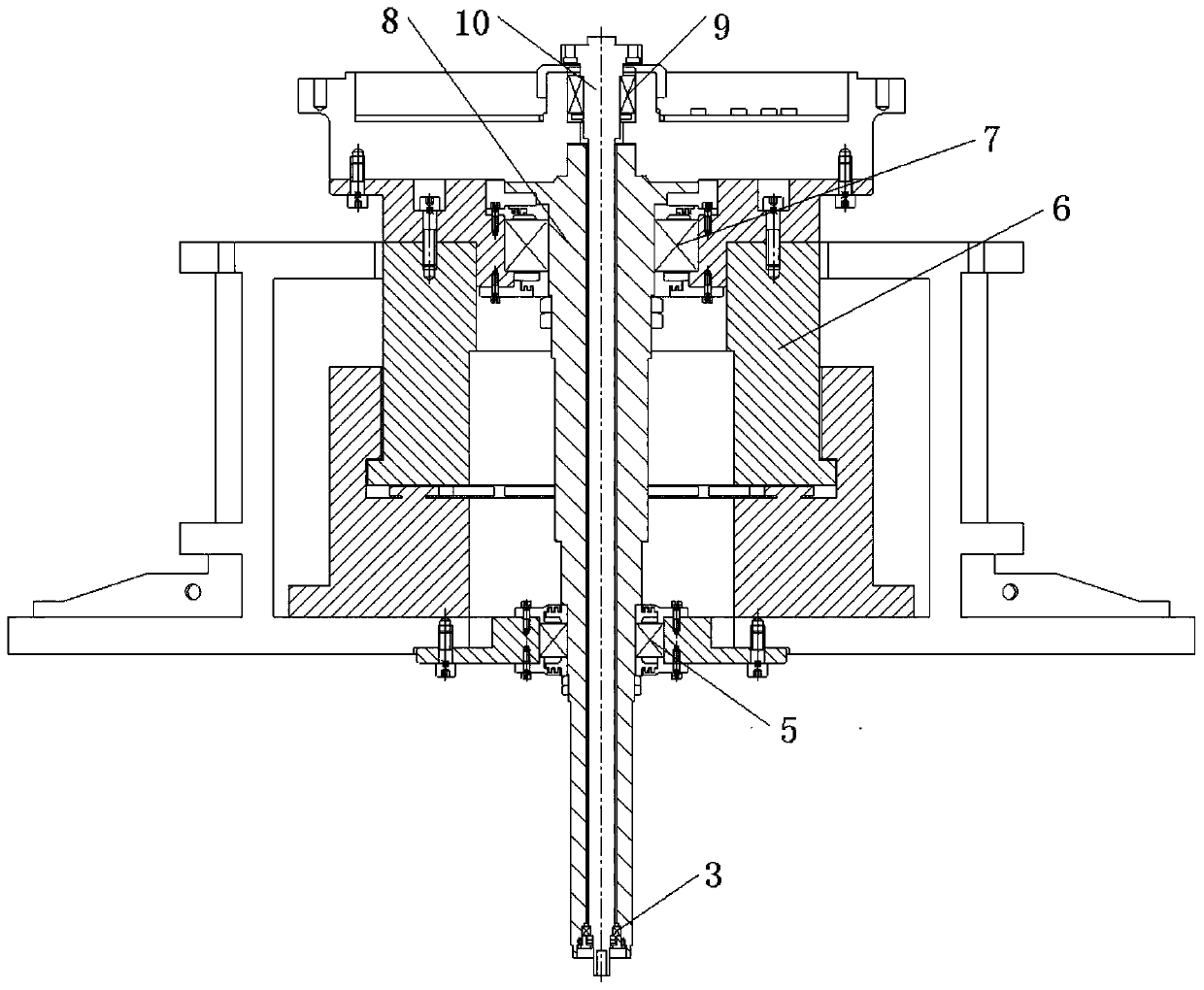

[0025] An outer shaft 8; the outer shaft 8 is a hollow shaft, and the outer shaft 8 is used to drive the model groove 11 to rotate;

[0026] The inner shaft 10; the inner shaft 10 is installed inside the outer shaft 8, the inner shaft 10 is driven by the inner shaft motor 1, and the inner shaft 10 is used to drive the actuator platform 12 to rotate; the outer shaft 8 does not contact the inner shaft 10, and the outer shaft 8 and The inner shaft 10 is coaxially set;

[0027] The outer shaft motor 4 is a direct drive motor, and the outer shaft 8 passes through the outer shaft motor 4 and is driven by the outer shaft motor 4; the outer shaft 8 and the inner shaft 10 realize their synchronous or asynchronous motion through a cross-coupling control method.

[0028] The outer shaft motor 4 in this application adopts a high-power direct-drive motor; the inner shaft ...

Embodiment 2

[0032] Example 2, such as figure 1 and figure 2 Shown:

[0033] The difference between this embodiment and embodiment 1 is:

[0034] The centrifuge device also includes a cylindrical roller bearing for radially supporting the outer shaft 8, and a vertical thrust sliding bearing 6 for radially supporting the outer shaft 8 and axially supporting the rotating body.

[0035] In this embodiment, the rotating body includes a model groove 11, an actuator platform 12, inner and outer shafts, etc.;

Embodiment 3

[0036] Example 3, such as figure 1 and figure 2 Shown:

[0037] The difference between this embodiment and embodiment 2 is:

[0038] The outer wall of the outer shaft 8 is fixedly connected with the thrust head of the vertical thrust sliding bearing 6, the bearing seat of the vertical thrust sliding bearing 6 is fixed on the base 2, and the bottom of the model groove 11 is fixedly connected with the thrust head of the vertical thrust sliding bearing 6 .

[0039] In this embodiment, preferably, the outer shaft is fixedly connected to the model groove through the instrument cabin 15, and an instrument cabin 15 and a connecting piece are also arranged between the bottom of the model groove 11 and the thrust head of the vertical thrust sliding bearing 6. Such a design is In order to better cooperate with the installation of the model groove 11 and the vertical thrust sliding bearing 6 and the cable arrangement of the equipment, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com