Test macro of engine pedestal and method for constant-velocity control

An engine bench and test system technology, which is applied in the direction of engine testing, machine/structural component testing, vehicle testing, etc., can solve the problems of testing engine torque, power, and control results that are not very ideal, and the experiment is meaningless. Achieve the effect of high speed control accuracy, small fluctuation and stable adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

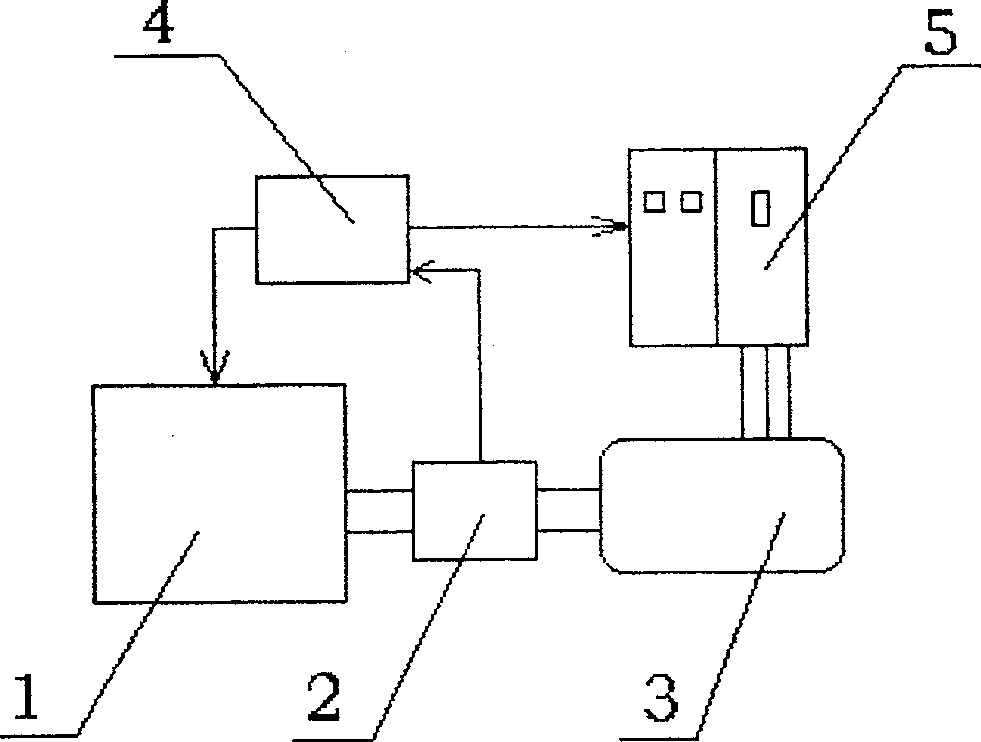

[0015] The system composition of the constant speed control method for the engine bench test system proposed by the present invention is as follows: figure 1 shown. They are engine 1, torque sensor 2, AC frequency conversion motor 3 (hereinafter referred to as motor), computer measurement and control system 4, four-quadrant AC frequency converter 5 (hereinafter referred to as frequency converter), in which engine 1, torque sensor 2, AC frequency conversion motor 3 three Or coaxial rigid connection.

[0016] The torque sensor 2 is a dynamic torque sensor capable of measuring dynamic torque changes of the transmission shaft.

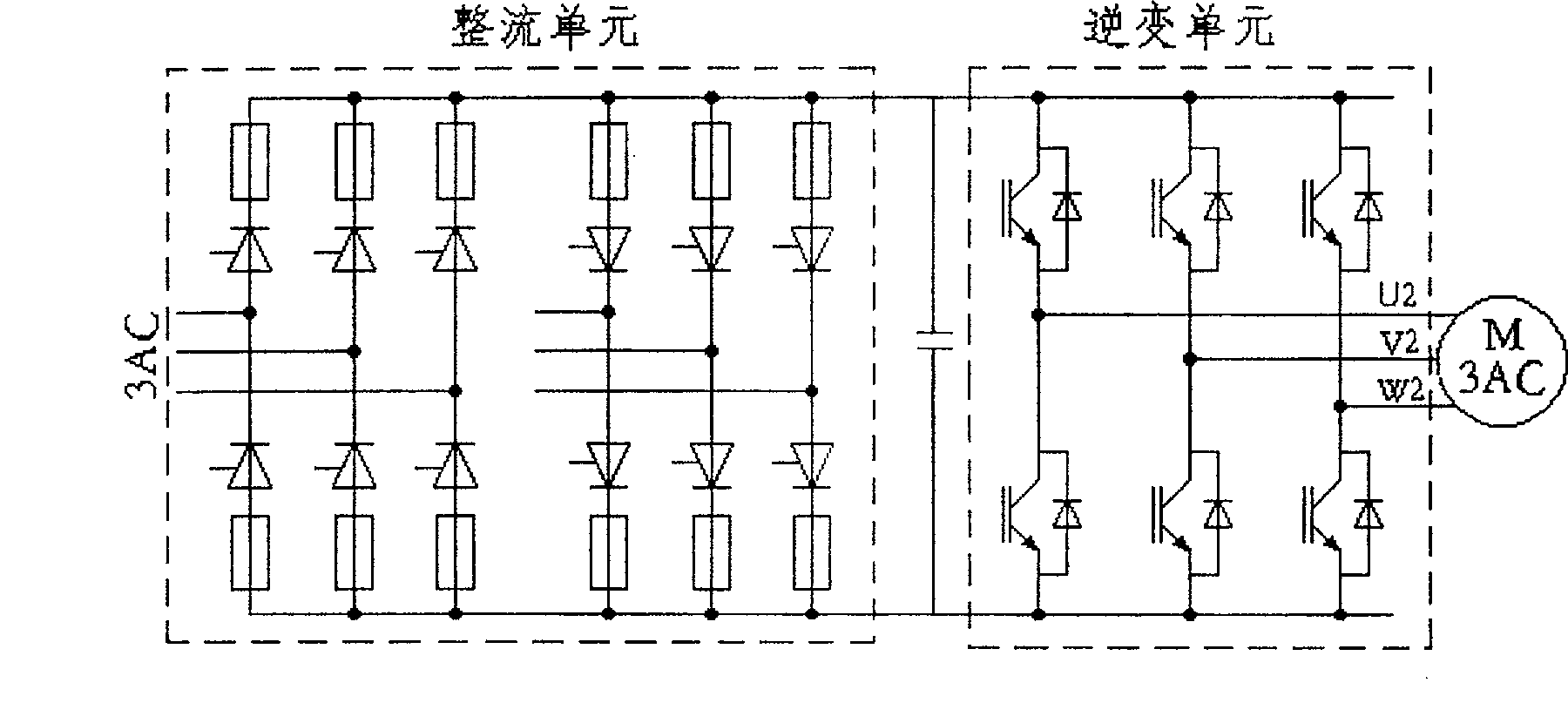

[0017] The AC variable frequency motor 3 retains the characteristics of simple structure and low maintenance of ordinary asynchronous motors. It adopts the way of forced ventilation cooling to reduce the calorific value of the motor at low speed. It is not restricted by the power frequency grid.

[0018] The computer measurement and control system 4 mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com