Anti-reverse paddleless mixer

A mixer, anti-reverse technology, applied in mixers with rotating containers, mixers, dissolving and other directions, can solve problems such as reverse swing, and achieve the effect of high speed control accuracy and hard torque characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more obvious and comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

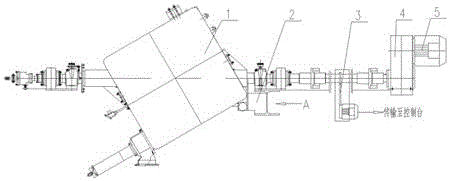

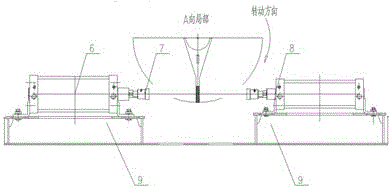

[0021] refer to figure 1 and figure 2 , the power device of the main equipment 1 of the paddleless mixer in this embodiment is a DC motor 5 , and the DC motor 5 is equipped with a one-way anti-reverse reducer 4 . The DC motor 5 has the ability of stepless speed regulation, and has the characteristics of hard torque characteristics and high speed control precision. By cooperating with the one-way anti-reverse reducer 4, it solves the problem of the paddleless mixer due to The inertial impact of the slurry produces a reverse swing phenomenon.

[0022] Preferably, in this embodiment, the operating speed of the main equipment 1 is 0.5-20 rpm, and the use of different operating speeds at different stages of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com