Method and device for measuring dynamic tensile rigidity of outer panels of motor vehicle components

A technology of dynamic stretching and measurement method, which is applied in the direction of testing the strength of materials by applying a stable bending force, which can solve the problems of damaged motor vehicle quality and achieve the effect of improving dynamic stretching rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

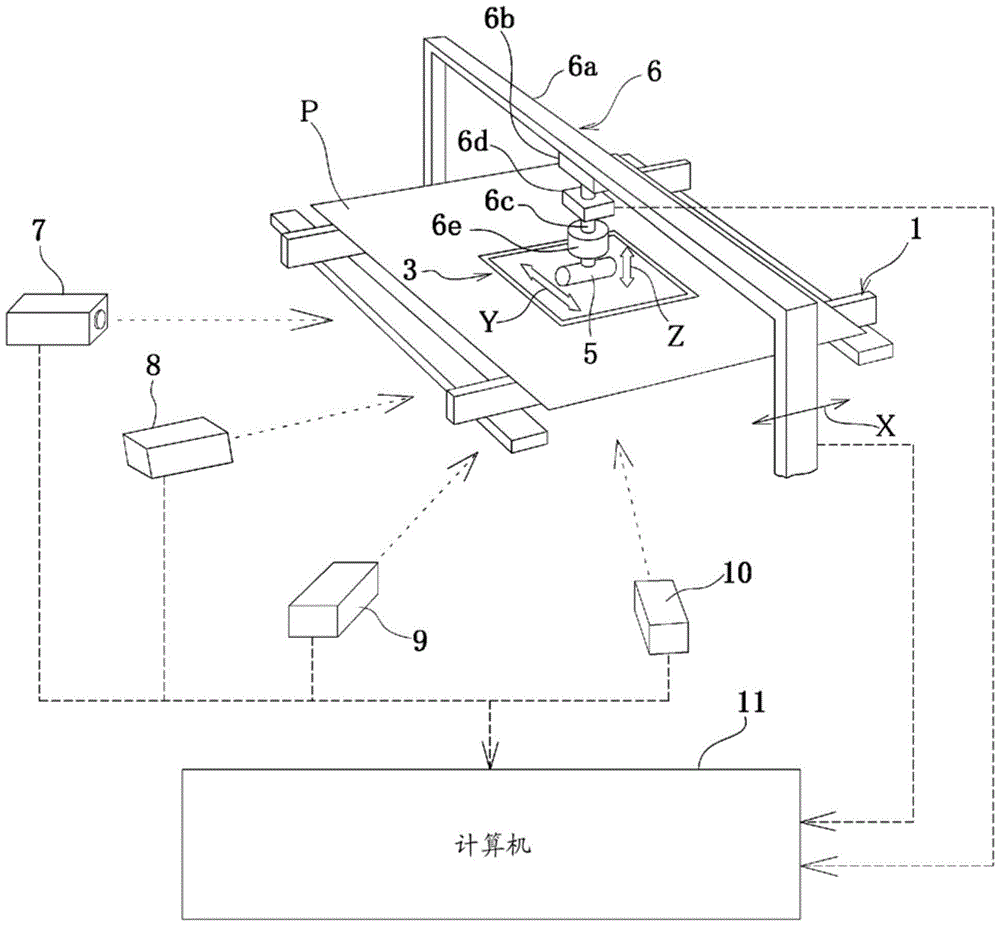

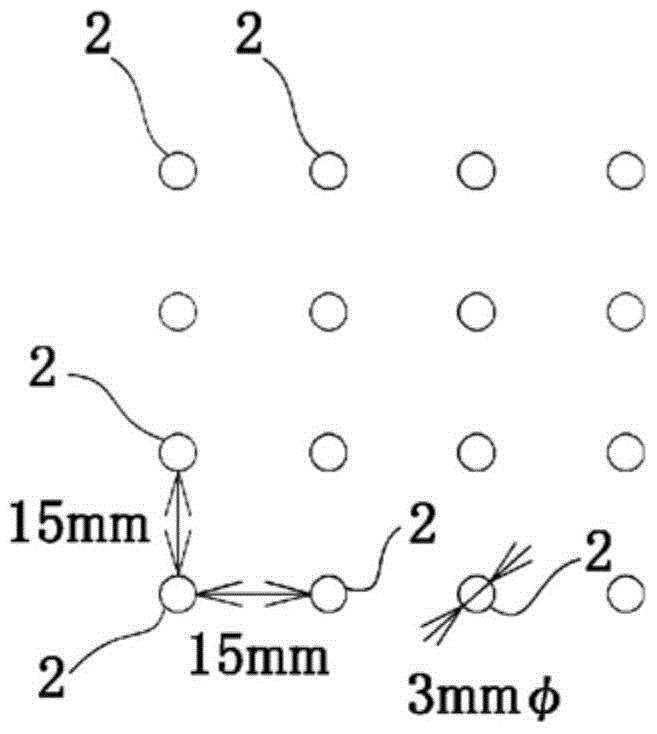

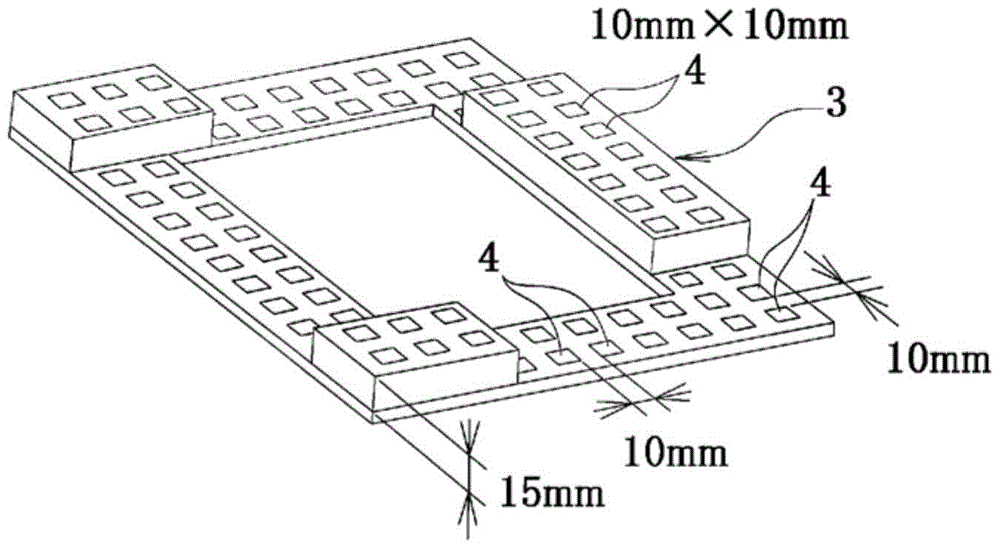

[0052] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. it's here, figure 1 It shows one embodiment of the dynamic tensile rigidity measuring device of the outer panel of the automotive part of the present invention used in one embodiment of the method of measuring the dynamic tensile rigidity of the outer panel of the automotive part of the present invention schematic diagram, figure 2 It is a plan view showing an example of a grid pattern used in the dynamic tensile rigidity measurement device of the outer panel of the automotive part of the above-mentioned embodiment, image 3 It is a perspective view showing an example of a reference mark used in the dynamic tensile rigidity measurement device of an outer panel of an automotive component according to the above-mentioned embodiment.

[0053] The device for measuring the dynamic tensile rigidity of an outer panel of a motor vehicle part according to this embodiment press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com