A network frequency adjustment method for rapid load reduction of generator sets

A technology of generator set and adjustment method, which is applied in the direction of electrical components, circuit devices, AC network circuits, etc., can solve problems such as the inability to effectively reduce the number of non-stops of the unit, instability of the power grid, and inconsistent frequency matching between the machine and the network, so as to prevent incomplete combustion Stable, reduce the number of non-stops, and avoid the effect of network collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

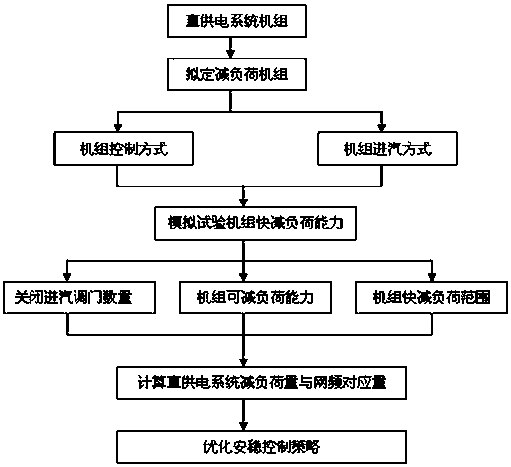

[0016] According to the frequency adjustment capability and load situation of each unit in the direct power supply system from large power to large load, the rapid load reduction unit is formulated. A factory has 3 350MW units (marked #1, #2, #3), 2 41.5MW units (labeled #4, #5), and 2 30MW gas-fired units (labeled #6, #7) ) constitute a large power system with a maximum total capacity of 1193MW. The large load side is the electrolytic aluminum project, and the transient load demand is 810MW of active power and 305Mvar of reactive power, which is supplied by the large power system composed of the above-mentioned "3 large machines + 4 small machines". After testing the primary frequency modulation response characteristics of three 350MW units, it can realize 3s action under the three working conditions of 60% PN (PN refers to the rated load of the unit), 75% PN and 90% PN, according to the frequency adjustment within 15S. Through the comprehensive analysis of load adjustment r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com