Coil and fabrication device therefor, and coil fabrication method

A technology for manufacturing devices and coils, applied in the field of coils and manufacturing devices thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

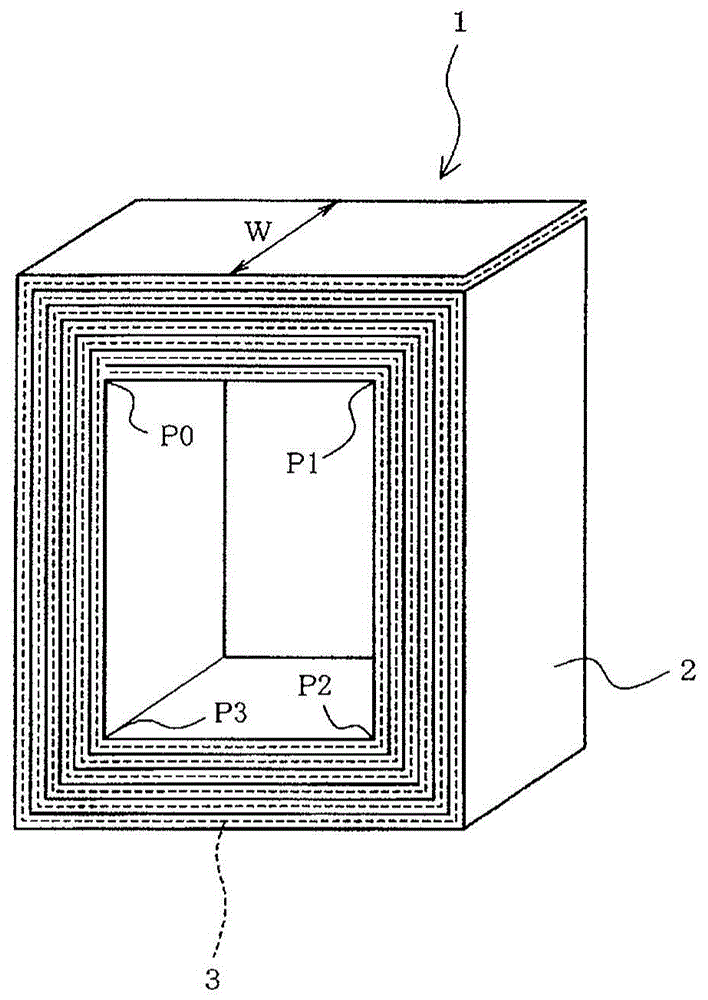

[0019] Below, refer to Figure 1 to Figure 4 A first embodiment applied to a coil used in a transformer will be described.

[0020] Such as image 3 As shown, the manufactured coil 1 is formed by forming a strip-shaped metal sheet 2 and a strip-shaped insulating sheet 3 relative to the coil frame (refer to figure 1 The reference number 16) is wound and constituted in multiple layers, and is formed, for example, in a square tube shape as a whole. The metal sheet 2 is, for example, a metal thin plate material made of aluminum, and the insulating sheet 3 is, for example, insulating paper. Coil 1 is formed as the image 3 The metal sheet 2 denoted by the reference symbol W does not deviate in the width direction, and no gap occurs between the layers wound in multiple layers. In addition, the metal sheet 2 may also be formed of other metal materials such as copper.

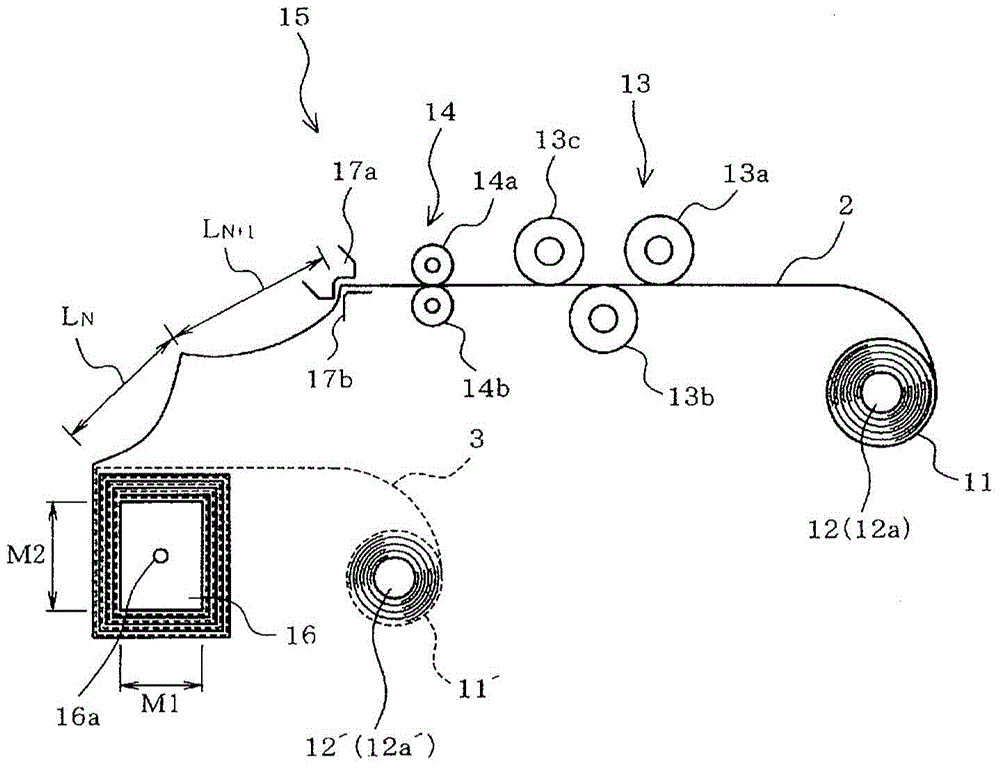

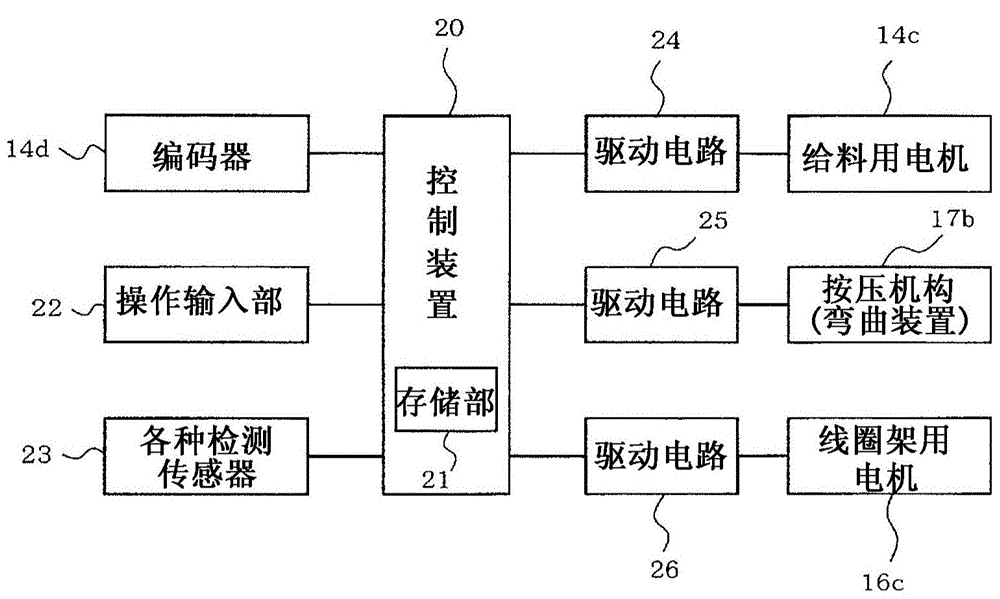

[0021] exist figure 1 In the manufacturing device of the coil 1 shown, the reference numeral 11 is a winding b...

no. 2 Embodiment approach

[0051] Figure 5 The second embodiment is shown, and the same reference numerals and the like are attached to the same parts as those already described to omit description, and the different points will be described below.

[0052] The bobbin 30 of the second embodiment has a cylindrical shape in which the outer peripheral shape is annular when viewed from the axial direction of the rotating shaft 16a. The bending device 31 as a bending unit is composed of, for example, a plurality of forming rollers 31 a to 31 c, and is configured to form bending marks corresponding to the curvature of the bobbin 30 or the curvature of the metal sheet 2 wound on the bobbin 30 .

[0053] Specifically, in the storage unit 21 , data on the feeding amount of the metal piece 2 and the radius of curvature corresponding to each type of the bobbin 30 are stored in advance as coil information. In addition, the control device 20 changes the feeding amount in conjunction with the data on the radius of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap