Component Mounting Machine

A technology for installing machines and components, applied in the direction of electrical components, electrical components, etc., can solve the problems of narrow focus height range and inability to shoot clearly at the same time, and achieve the effect of improving judgment accuracy and position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

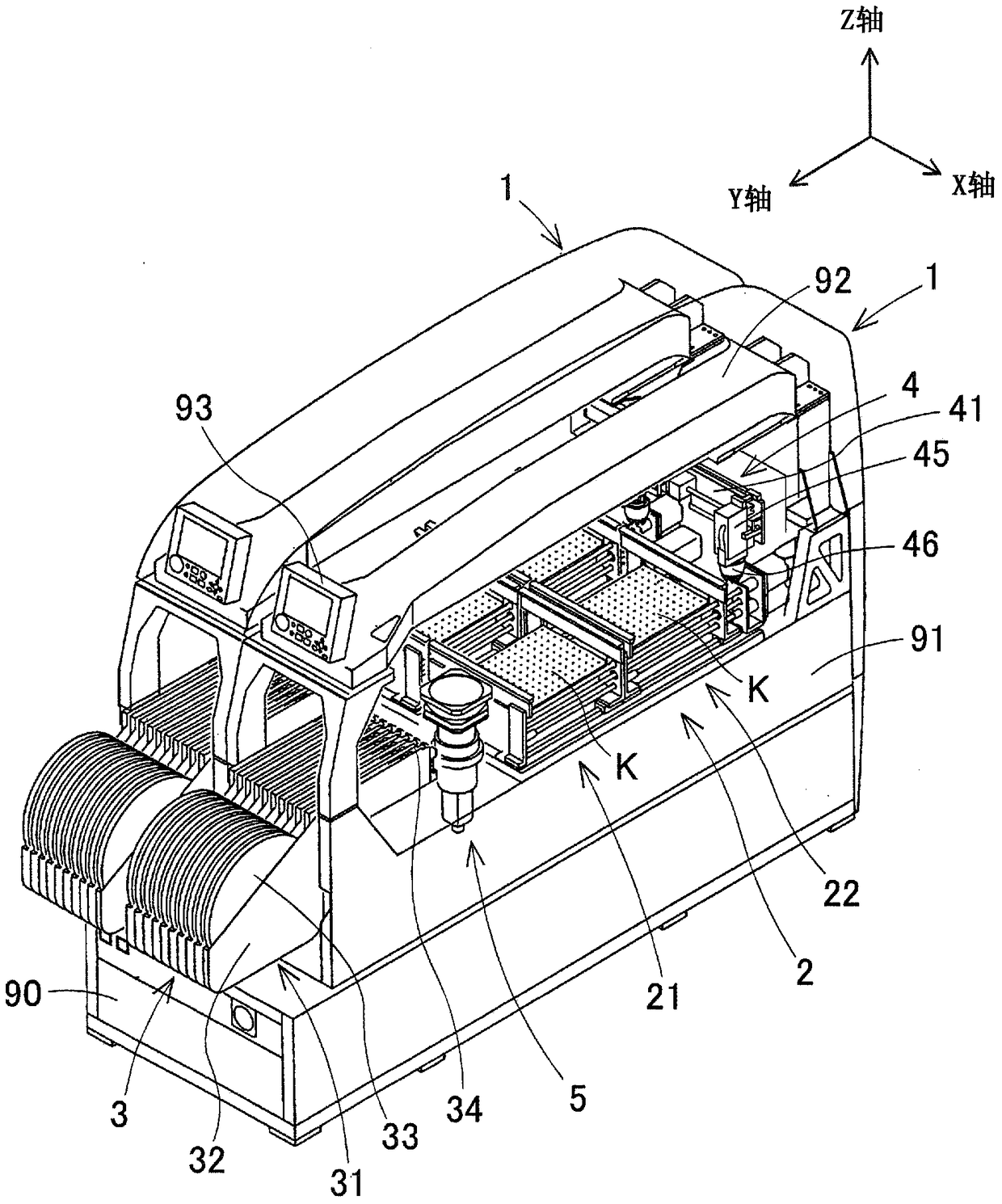

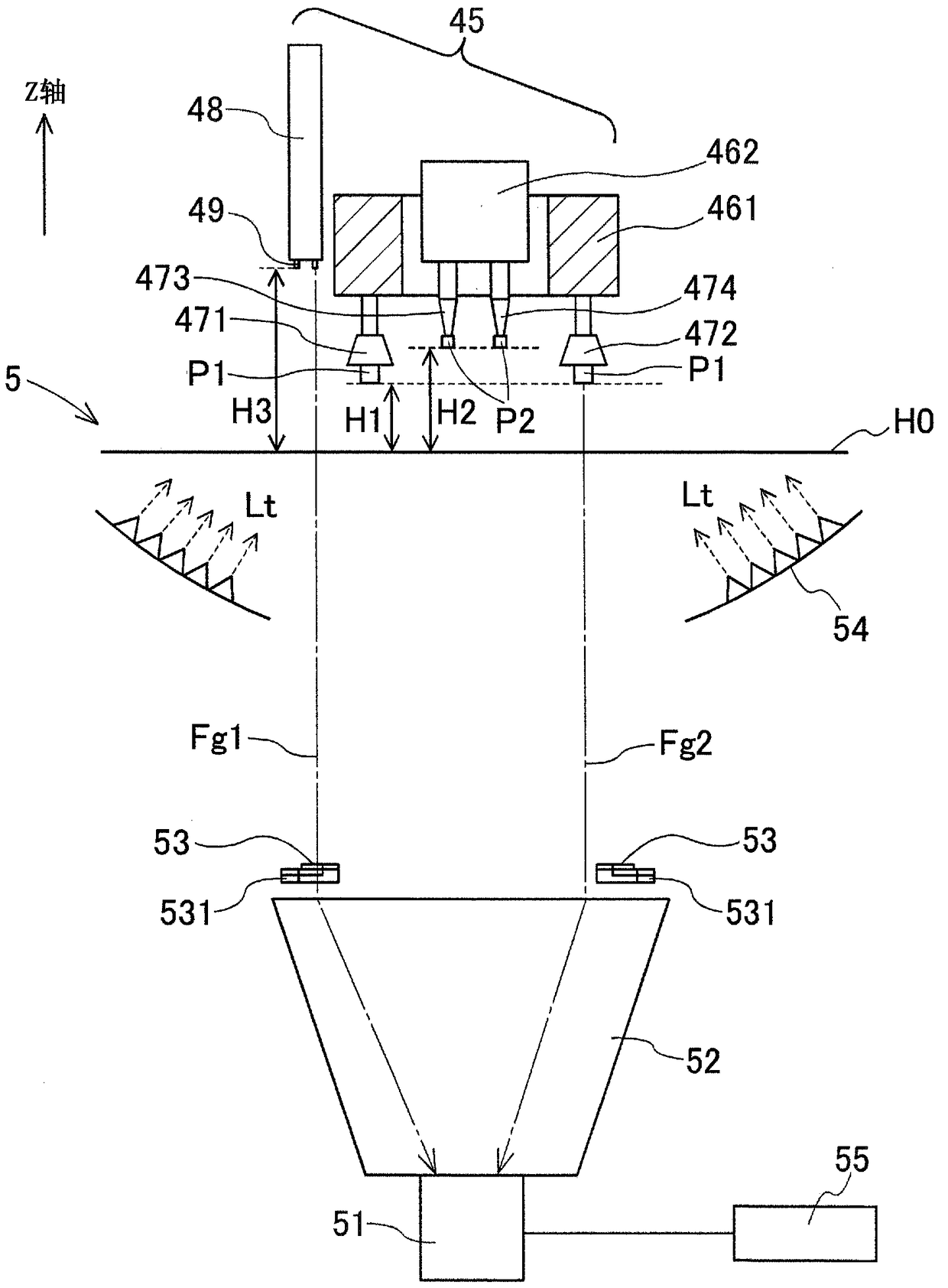

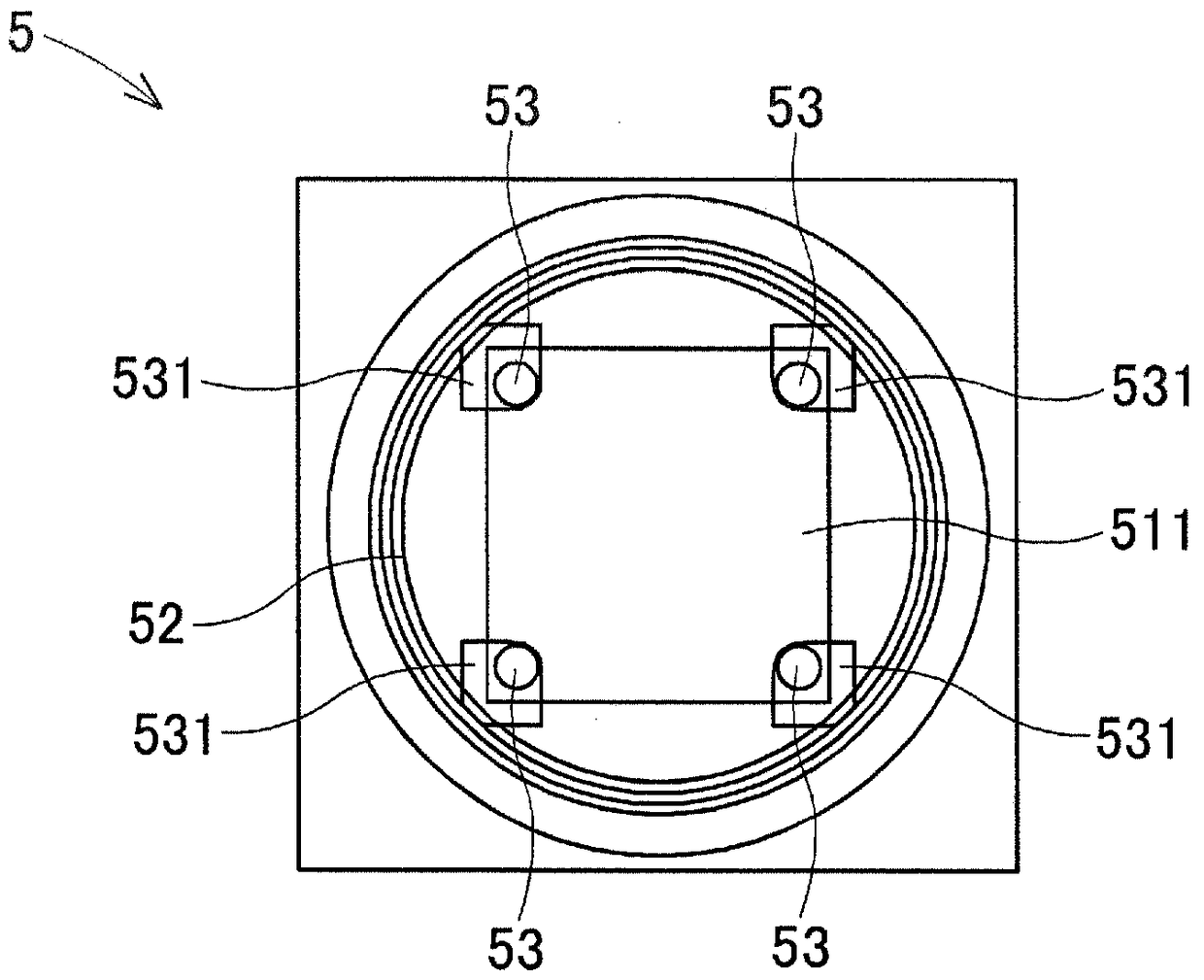

[0035] refer to Figure 1 ~ Figure 3 The component mounting machine 1 according to the first embodiment of the present invention will be described. figure 1 It is a perspective view which shows the whole structure of the component mounting machine 1 of 1st Embodiment. figure 1 It is shown that two component mounting machines 1 are arranged side by side on the common base 90 , and one will be described later. The component mounting machine 1 is configured by assembling a substrate conveying device 2, a component supply device 3, a component transfer device 4, an imaging device 5, and a control computer not shown in the figure on a machine table 91 (the reference numerals are only assigned to the components on the right front side). Installer 1). Such as figure 1 As shown by the XYZ coordinate axes on the upper right, the horizontal width direction of the component mounting machine 1 ( figure 1 The direction from the upper left to the lower right of the paper surface) is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com