Method and equipment for detecting misfire of diesel engine

A diesel engine and equipment technology, applied in the direction of internal combustion engine testing, etc., can solve problems such as inaccurate judgment, achieve the effects of improving judgment accuracy, resisting signal interference, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand and implement the technical solution provided by the present invention, several technical terms in this field are introduced below.

[0043] Misfire: A phenomenon in which the fuel injector does not inject fuel or the fuel injected basically does not burn.

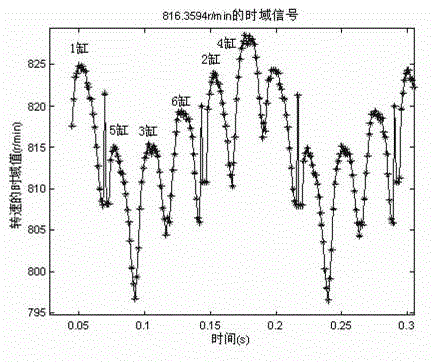

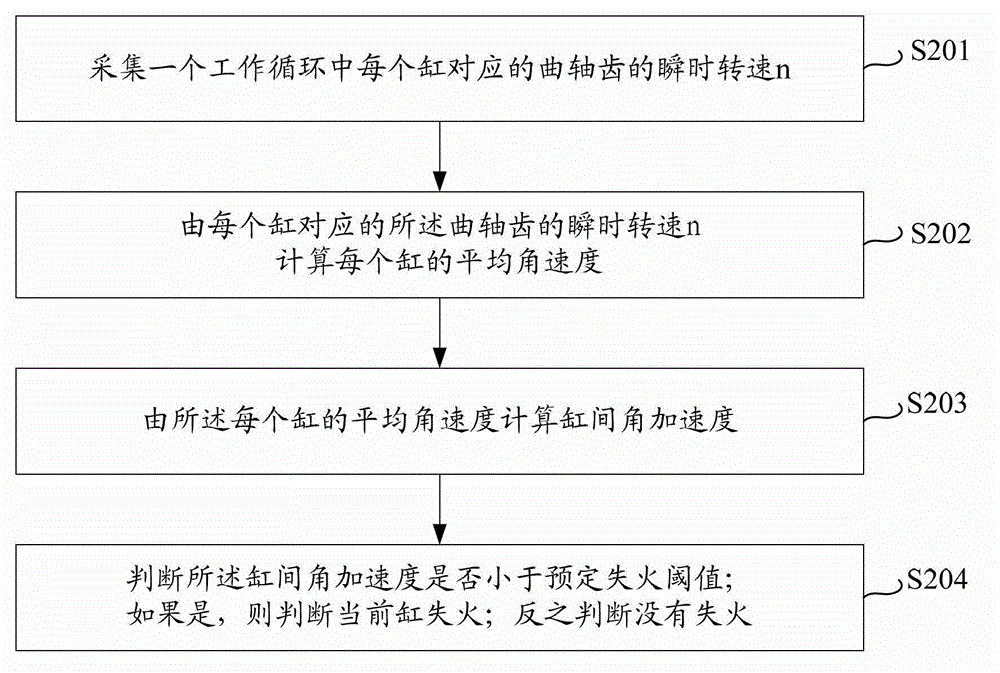

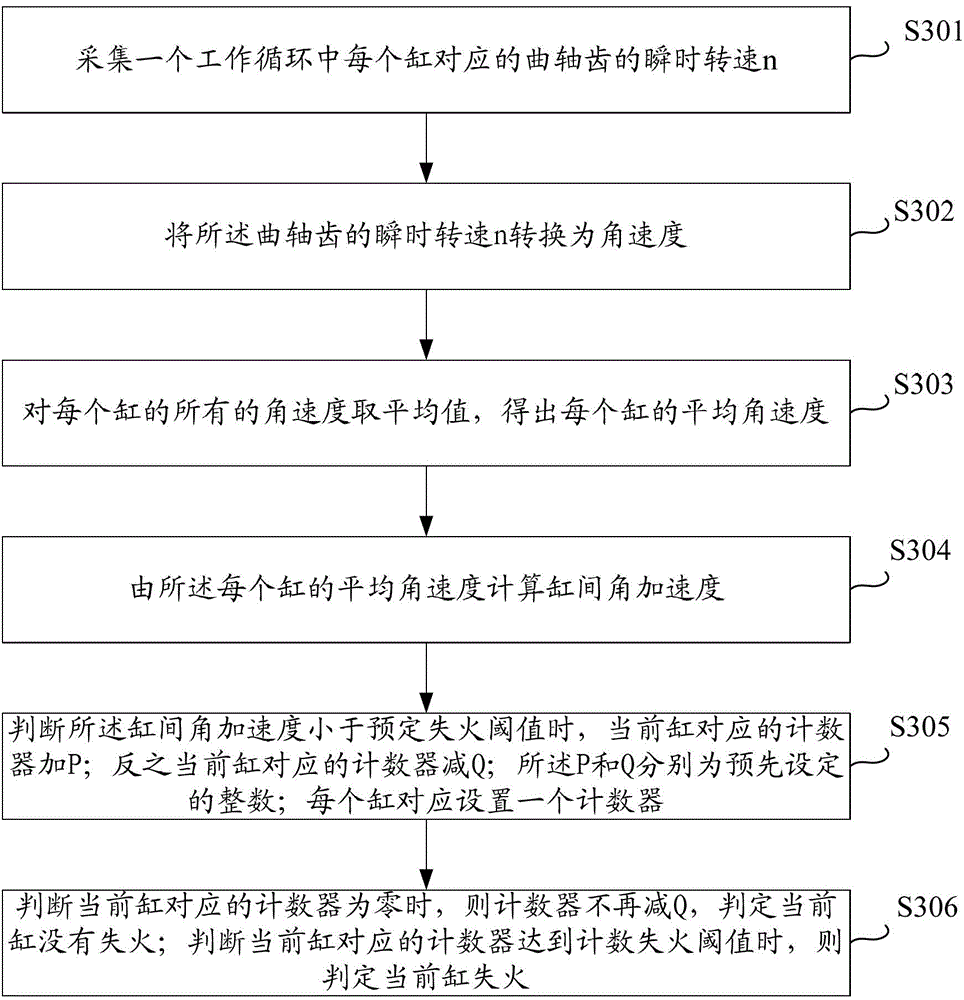

[0044] Acceleration between cylinders: calculate the angular acceleration between cylinders = (the average angular velocity of the current cylinder - the average angular velocity of the previous cylinder) / the sum of the time of the corresponding teeth of the two cylinders;

[0045] For example: for a crankshaft with 60 teeth in one circle, spray 3 times; then, the average angular velocity: extract the instantaneous rotational speed corresponding to 20 teeth of the current cylinder, multiply it by 2π and divide by 60 to get the instantaneous angular velocity corresponding to 20 teeth, and then take the average value;

[0046] Note: For the first cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com