Tight oil fractured horizontal well productivity main control factor judgment and productivity prediction method

A technology of main control factors and production capacity prediction, applied in prediction, instrument, complex mathematical operation, etc., can solve problems such as difficult judgment and low production capacity prediction accuracy, and achieve the effect of meeting production needs, improving judgment accuracy, and high matching degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

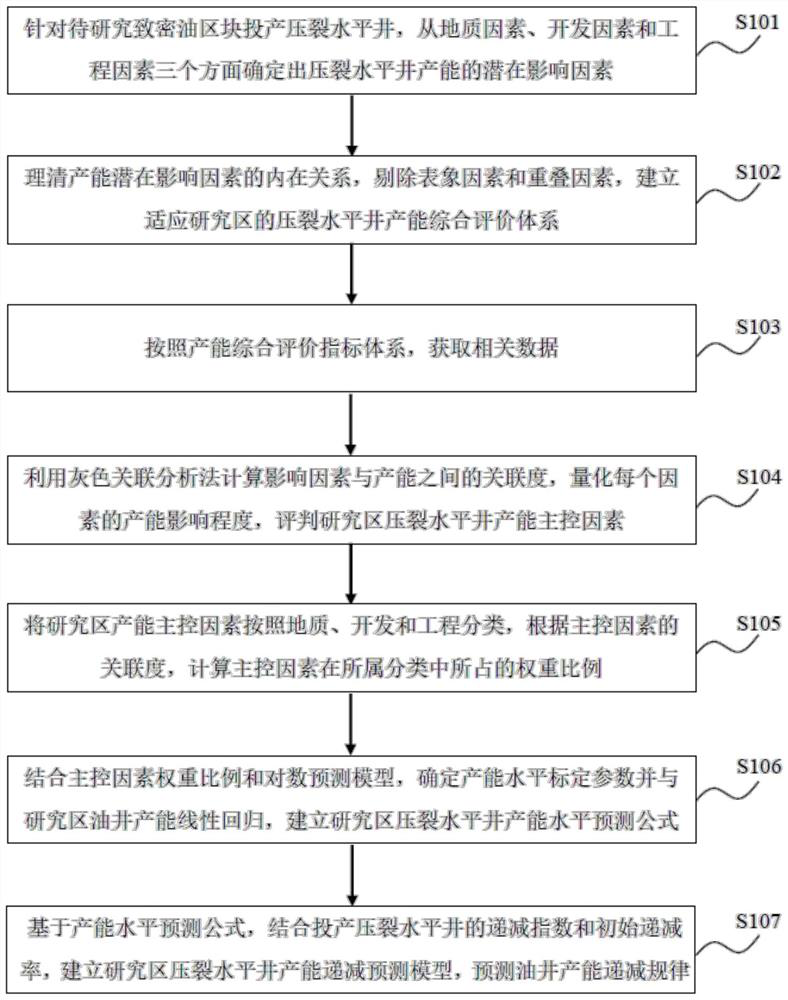

[0064]This embodiment relates to a method for judging and predicting the main controlling factors of the productivity of a tight oil fracturing horizontal well, including the following steps:

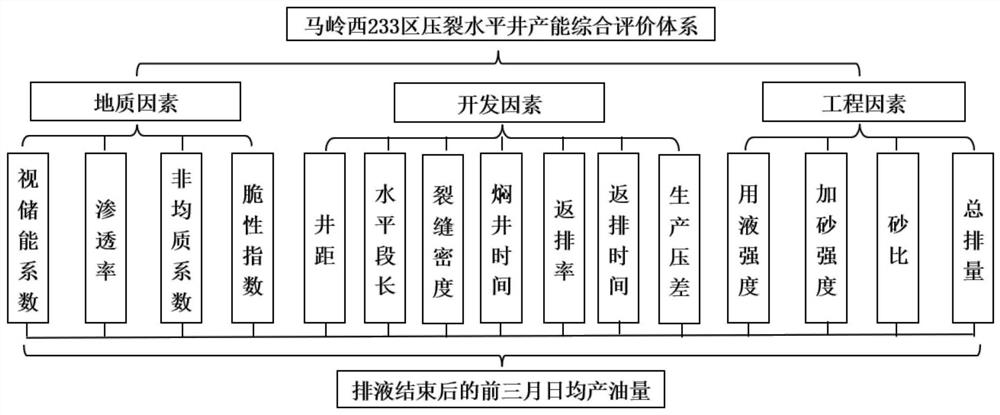

[0065] Step 1: For the production of fractured horizontal wells in the tight oil blocks to be studied, determine the potential influencing factors of the productivity of tight oil fractured horizontal wells from three aspects: geological factors, development factors and engineering factors;

[0066] Step 2: Clarify the internal relationship of potential influencing factors on productivity, eliminate appearance factors and overlapping factors, and establish a comprehensive evaluation system for fractured horizontal well productivity suitable for the study area;

[0067] Step 3: Obtain relevant data according to the comprehensive evaluation index system of production capacity;

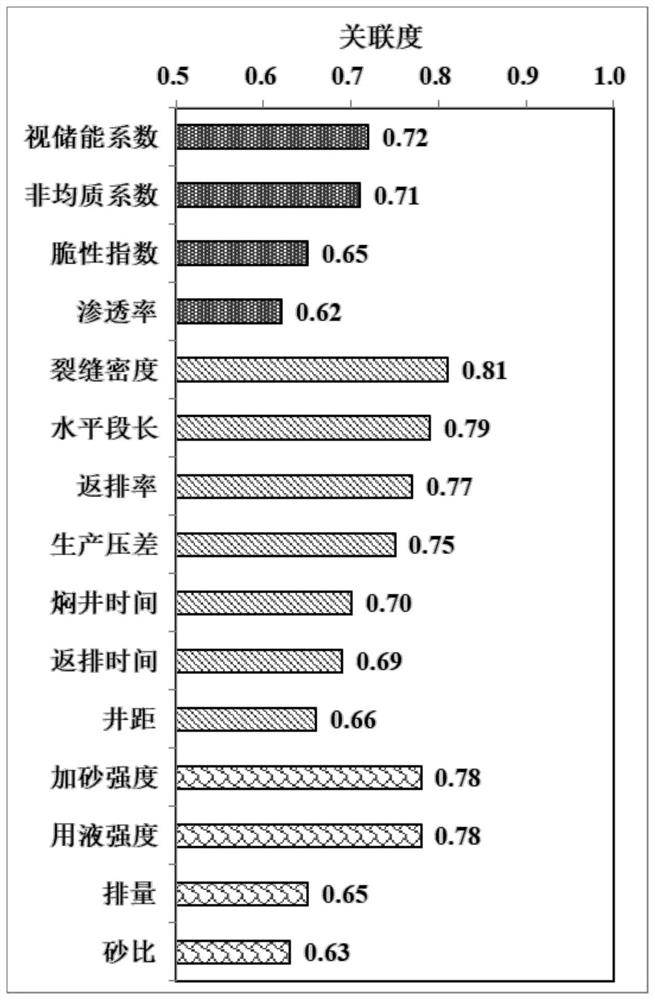

[0068] Step 4: Use the gray correlation analysis method to calculate the correlation between influencing factor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com