A method of picking glue

A technology for harvesting rubber and rubber trees, applied in forestry, application, agriculture and other directions, can solve the problems of low economic benefit of rubber trees, and achieve the effects of reducing recovery time, increasing rubber production, and avoiding shrinkage or blockage of milk duct openings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0023] The rubber picking method of the present invention, comprises the steps:

[0024] Step A, cut part of the bark on the surface of the rubber tree to form a notch, in order to expose the bark outside the yellow bark inner layer of the rubber tree (generally the inside of the notch is 1.4-2 mm from the xylem of the rubber tree), for the subsequent bark The cutting provides the lower knife position, and the milk duct of the rubber tree bark is cut off at the lower edge of the notch;

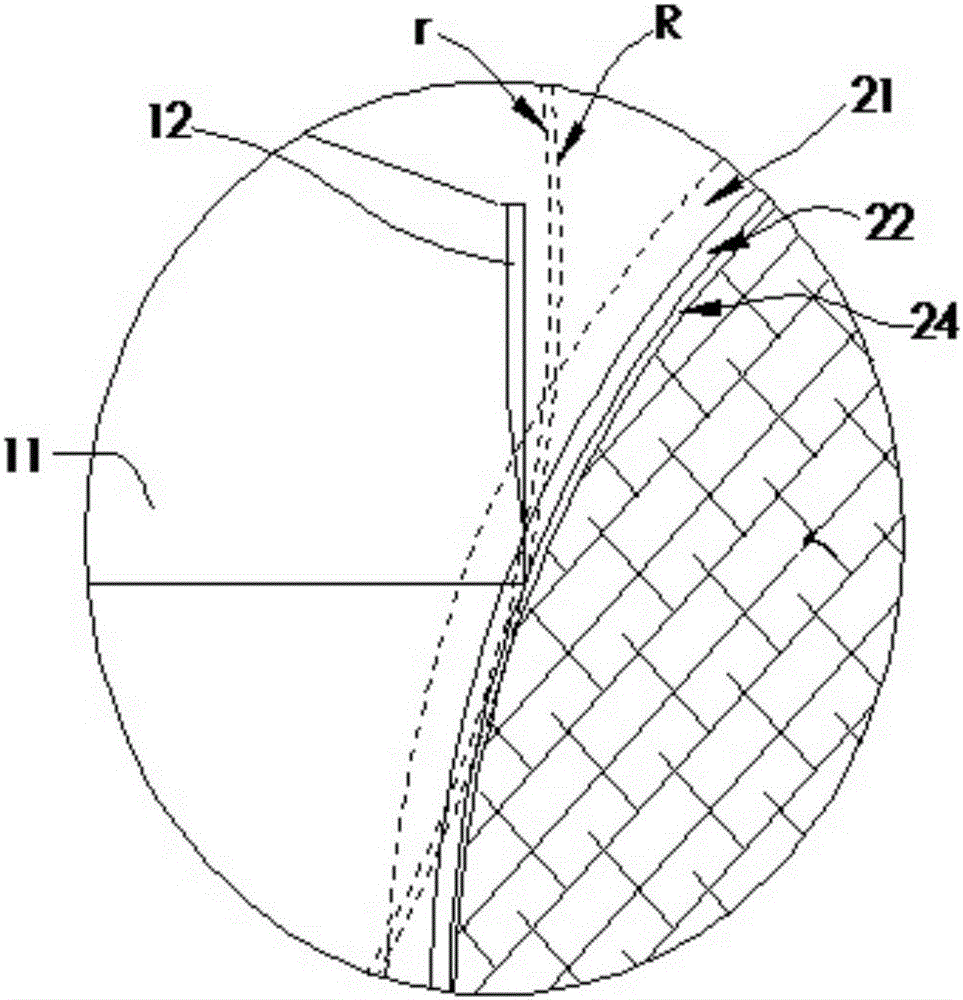

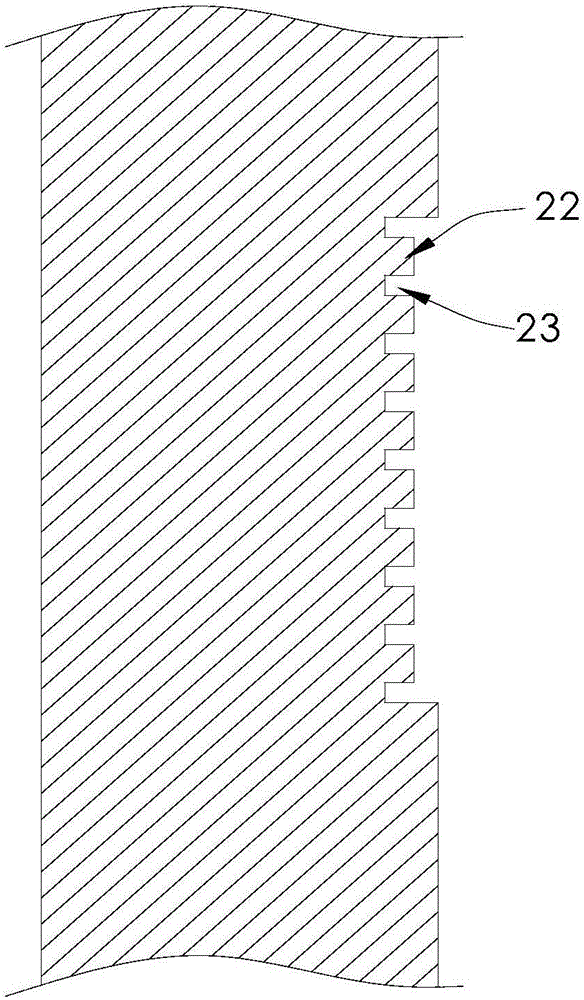

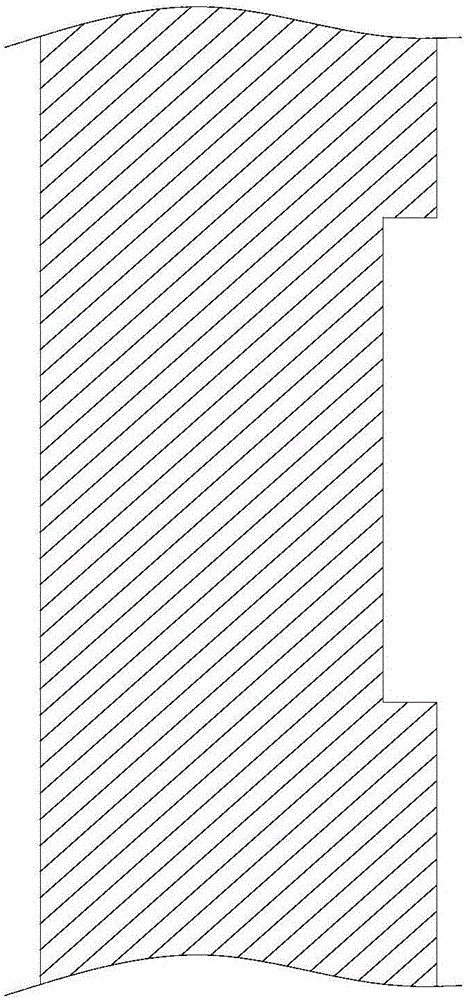

[0025] Step B, utilize a rotating cutter to remove the bark along the lower edge of the notch, see figure 1 As shown, the cutter includes a first blade 11 and a second blade 12, the second blade 12 is formed by bending the tail end of the first blade 11 upwards, the tail end of the first blade 11 has a protruding portion, and the protruding portion Protrude from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com