A rubber picker

A technology of a rubber picking machine and a driving mechanism is applied in the field of rubber picking machines, which can solve the problems of low economic benefit of rubber trees, and achieve the effects of improving the efficiency of rubber picking, reducing labor intensity and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

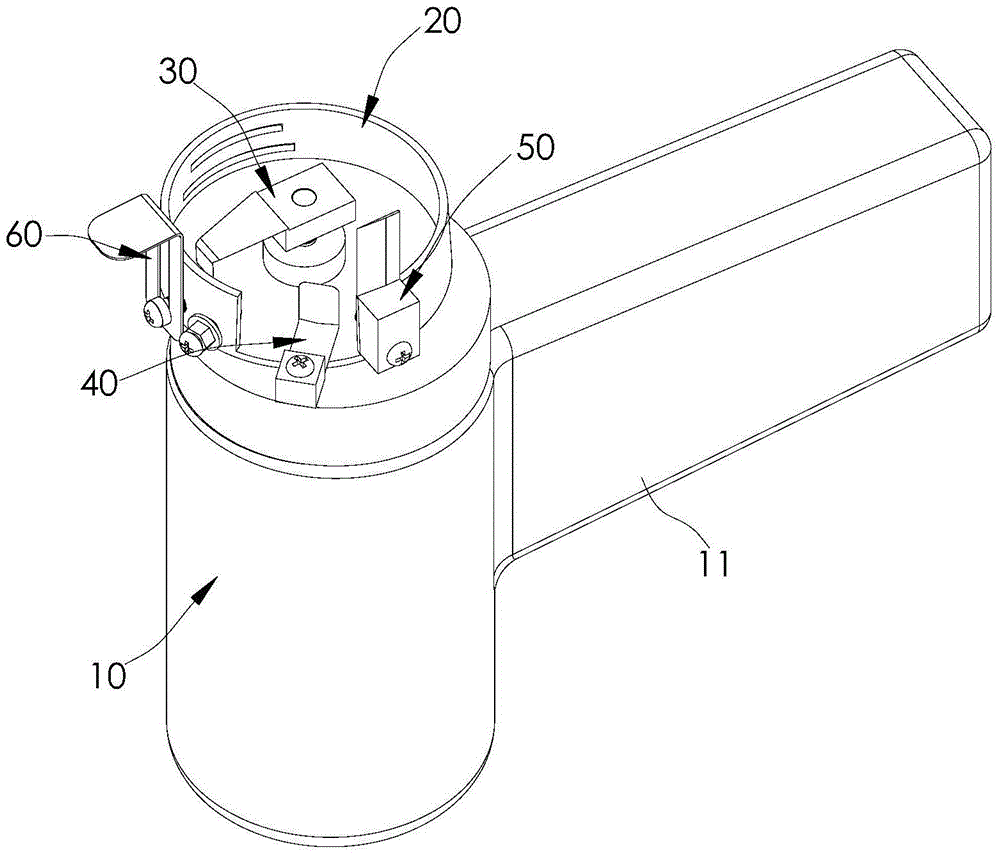

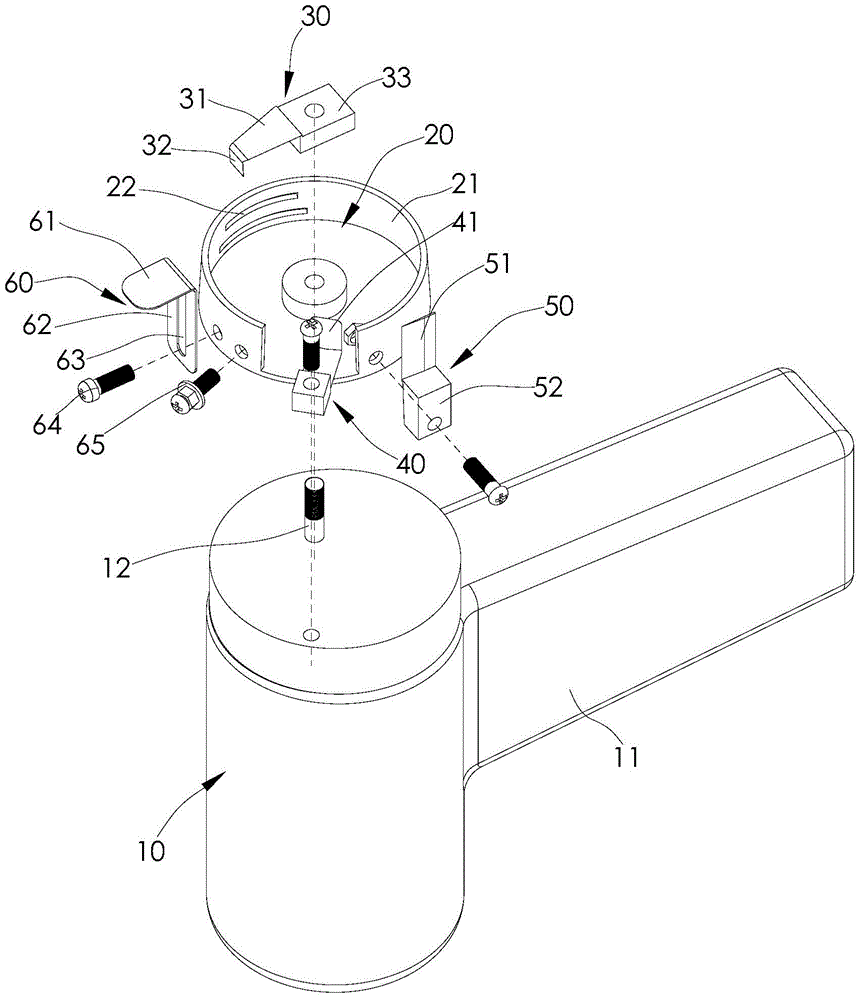

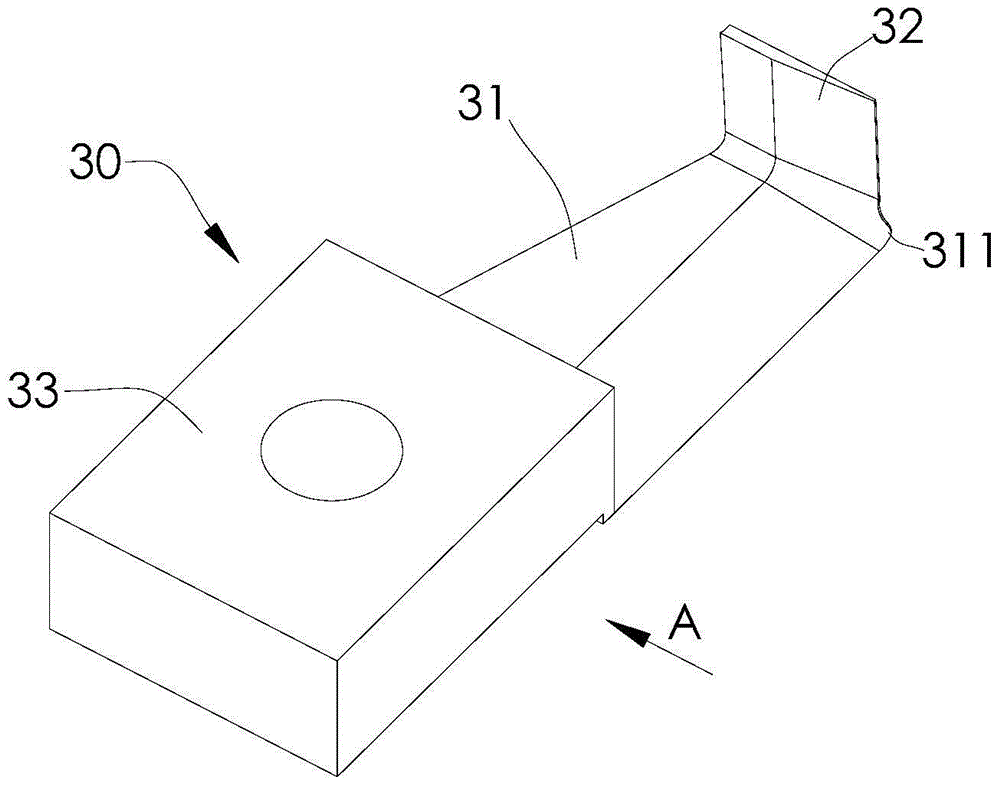

[0035] Such as figure 1 , 2 As shown, it is a rubber picking machine of the present invention, which includes a housing 10, an outer cover 20, a first cutter 30 and a bracket 60, wherein a handle 11 is provided on the housing 10 for holding by human hands, of course , it is also possible to set other gripping parts on the housing 10 to replace the handle 11, in a word, as long as the gripping parts can be operated conveniently. A main shaft 12 is pivotally connected to the bottom of the housing 10. A drive mechanism for driving the main shaft 12 to rotate is arranged inside the housing 10. The driving mechanism may include a motor and a reducer driven by the motor. The main shaft 12 is connected to the reducer. The output end, of course, the driving mechanism is not limited to the above-mentioned motor and reducer, it can also be other mechanisms tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com