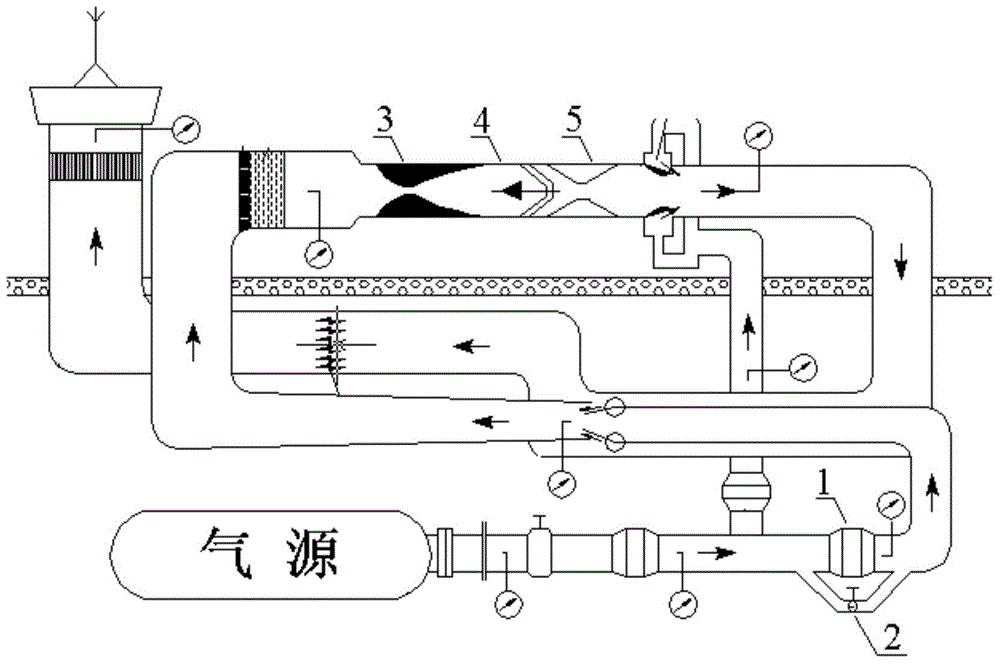

Low Mach number system of trisonics wind tunnel

A three-sonic wind tunnel and Mach number technology, applied in the field of wind tunnel testing, can solve the problems of small flow, small opening of the main pressure regulating valve, difficulty in manufacturing and processing large-diameter valves, etc., to expand the scope of test capabilities and simple technical transformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

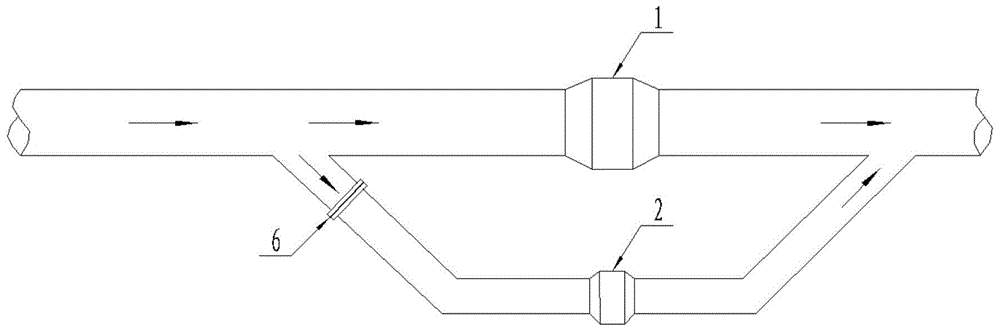

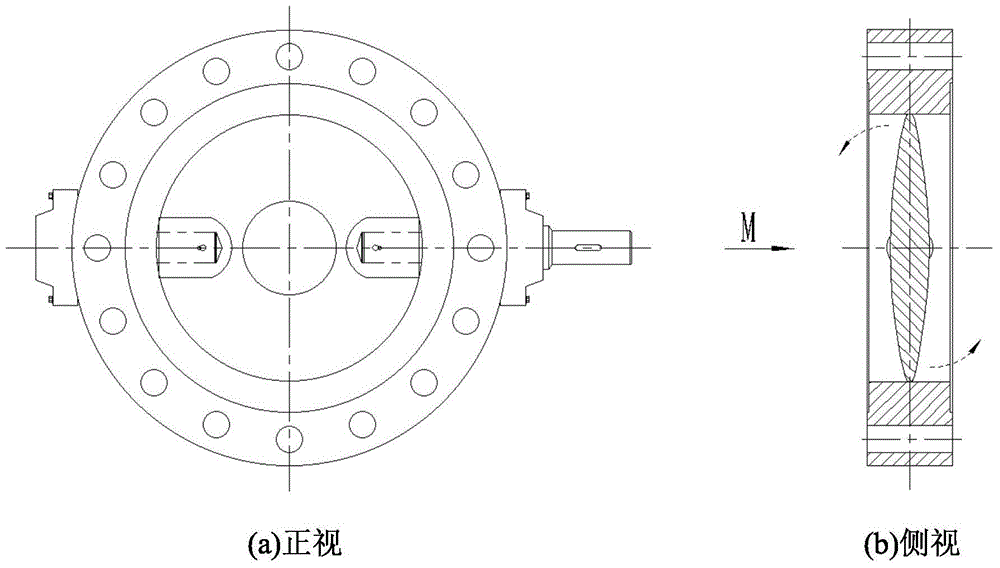

[0022] In order to solve the problem that it is difficult to use the pressure regulating valve to adjust all the pressures required in the test section in the existing transient three-sonic wind tunnel system, it is considered to erect a bypass pipeline with a smaller flow cross-sectional area next to the main pressure regulating pipeline, namely The main function of the bypass valve is to improve the pressure regulation characteristics of the main pressure regulating valve. When the bypass valve is closed, the main pressure regulating valve needs a certain amount of pressure to pass the flow G. The slit area F1 corresponds to the stroke X1; when the bypass valve is opened, the same flow G passes through the main pressure regulating valve and the bypass valve at the same time in two parts. At this time, the slit area of the main valve is F2<F1, corresponding to the stroke X2<X1 ; Since the pressure regulation characteristics of the main valve are generally only good within a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com