Method for designing low-Mach-number flight total enthalpy platform based on existing hypersonic wind tunnel

A hypersonic and Mach number technology, applied in aircraft component testing, machine/structural component testing, instruments, etc., can solve problems such as inability to simulate local conditions, achieve rapid formation of test capabilities, improve test capability systems, and reduce investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

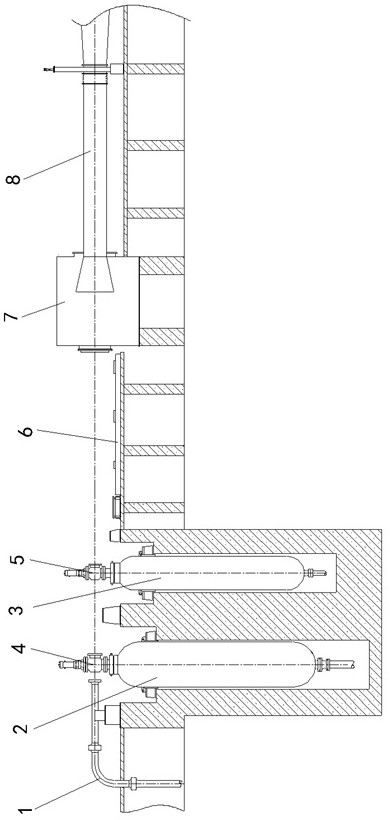

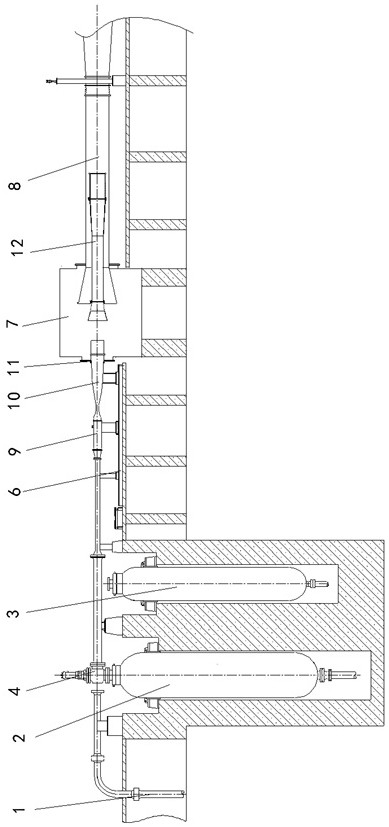

[0082] This embodiment is a wind tunnel test platform for reproducing the total flight enthalpy of Mach number 2-3.

[0083] Such as figure 2 As shown, in this embodiment, the Mach number 8 heater 2 in the existing wind tunnel is selected to establish a wind tunnel test platform for reproducing the total flight enthalpy of Mach number 2-3. On the existing wind tunnel equipment supporting device 6, the existing wind tunnel high-pressure air source system 1, the existing wind tunnel Mach number 8 thermal valve 4, the Mach number 2-3 stable section and transition section 9, and the Mach number 2-3 are sequentially connected. 3 The nozzle 10, the connecting section 11 between the new nozzle with Mach number 2-3 and the original test section, the existing wind tunnel test section 7 and the existing wind tunnel diffuser 8, and in the existing wind tunnel diffuser 8 A platform diffuser 12 is installed in the cavity suit.

Embodiment 2

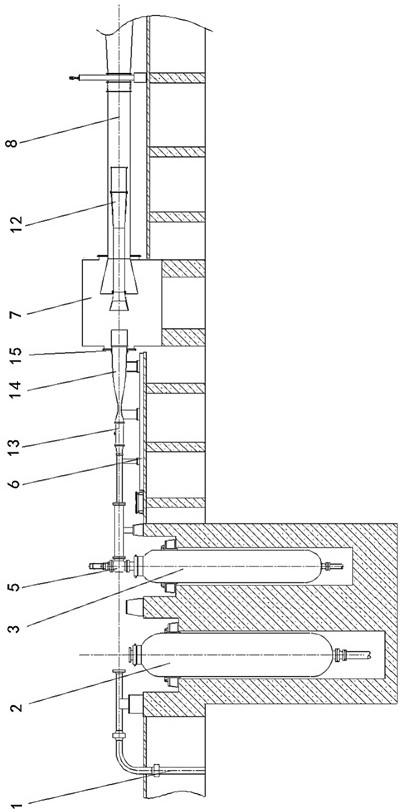

[0085] This embodiment is a wind tunnel test platform for reproducing the total flight enthalpy of Mach number 3.5-4.

[0086] Such as image 3 As shown, in this embodiment, the existing wind tunnel Mach 10 heater 3 is selected to establish a wind tunnel test platform for reproducing the total flight enthalpy of Mach 2-3. On the existing wind tunnel equipment supporting device 6, the existing wind tunnel high-pressure air source system 1, the existing wind tunnel Mach number 10 thermal valve 5, the Mach number 3.5-4 stable section and the transition section 13, and the Mach number 3.5-4 are sequentially connected. 4 The nozzle 14, the connection section 15 between the new nozzle with Mach number 3.5-4 and the original test section, the existing wind tunnel test section 7 and the existing wind tunnel diffuser 8, and in the existing wind tunnel diffuser 8 A platform diffuser 12 is installed in the cavity suit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com