Automobile door assembly gauge

An assembly and inspection tool technology, which is applied to measuring devices, instruments, and mechanical devices, etc., can solve the problems of single function of the door assembly inspection tool and inability to perform deep hole measurement, and achieve the effect of improving investment benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

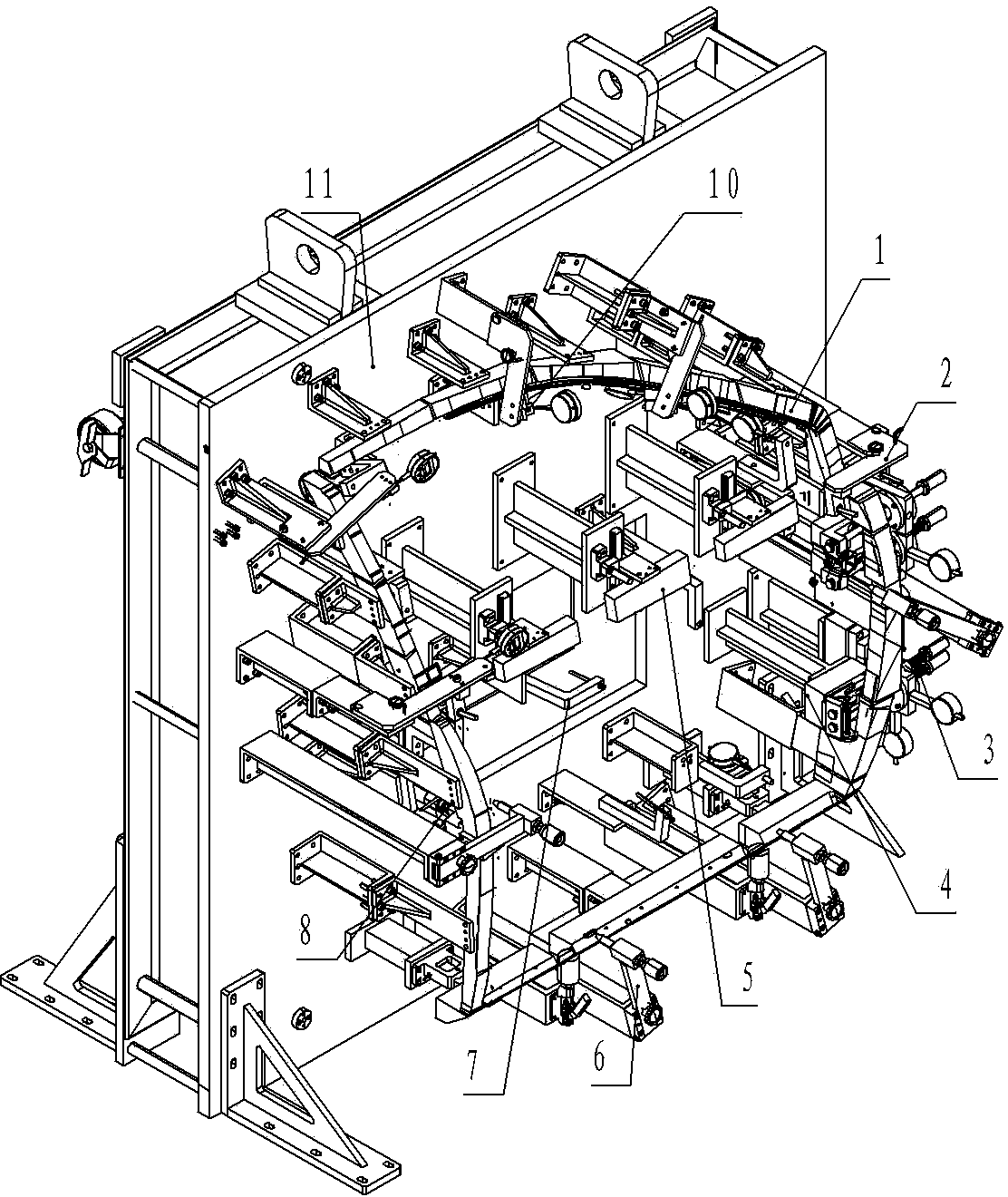

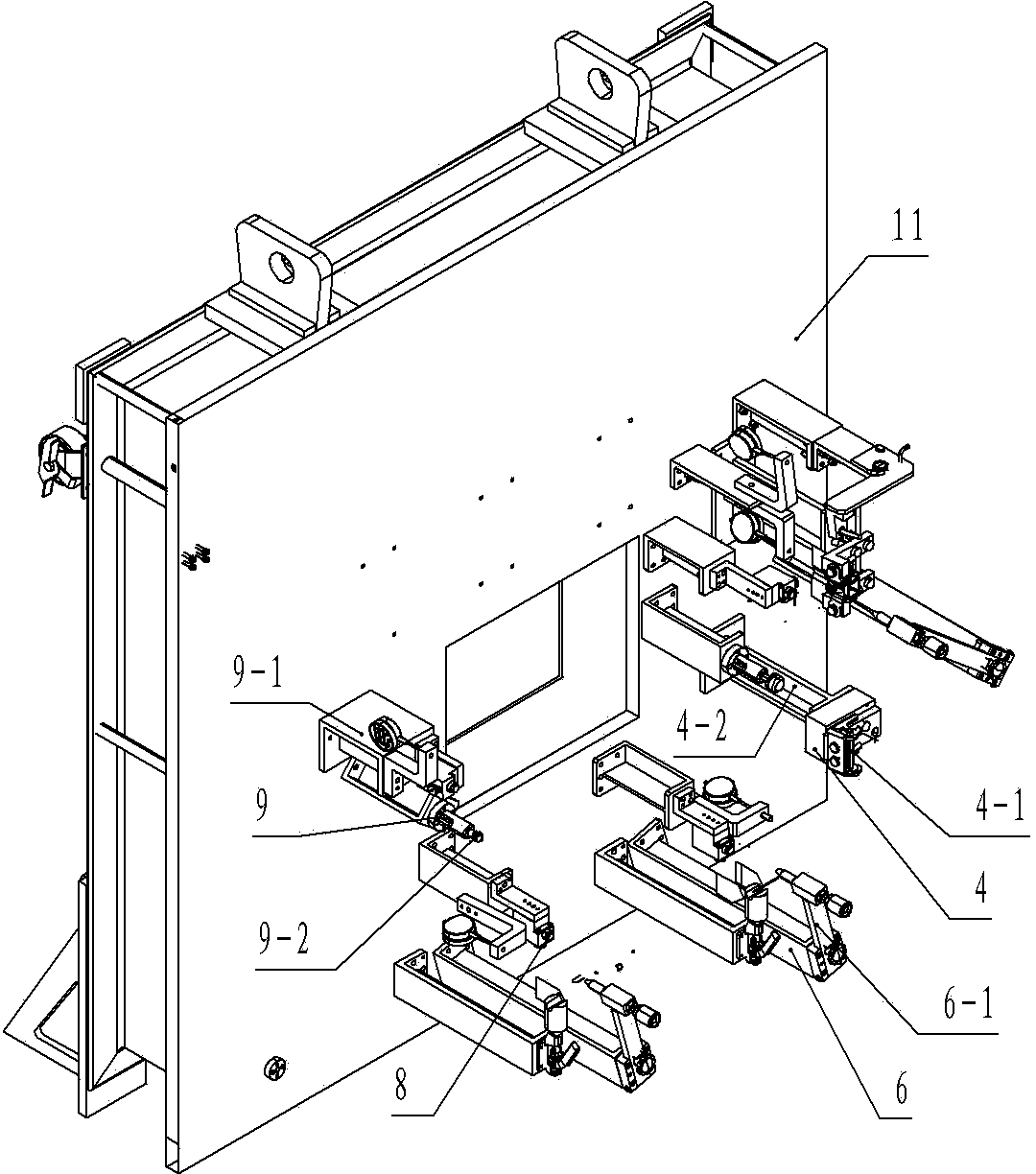

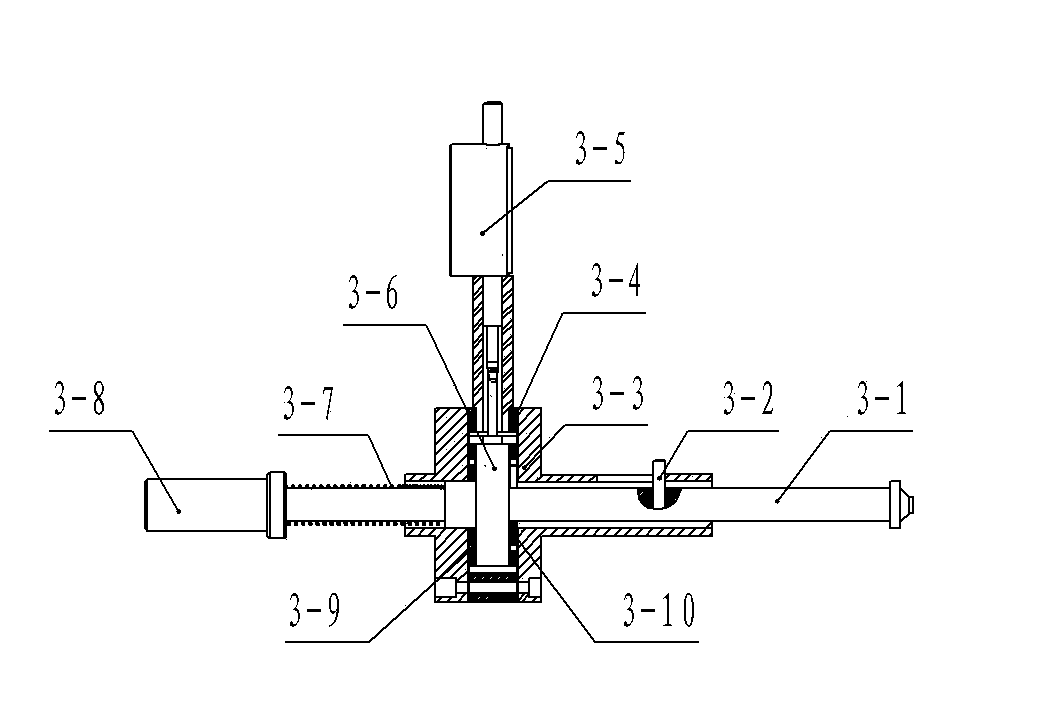

[0014] Such as figure 1 , figure 2 and image 3 The vehicle door assembly inspection tool shown includes a base 11, on which a profiled annular detection block 1 installed by a plurality of positioning devices is installed. The positioning device of this embodiment includes a telescopic positioning unit 9, a telescopic positioning unit 9 There is a positioning seat 9-1 with a threaded hole on the top and a positioning pin 9-2 mounted on the threaded hole through threads, and a telescopic positioning unit 8 whose positioning surface of the positioning element is larger than that of the positioning pin 9-2; The removable positioning unit 4 has a positioning seat 4-1 with a connecting piece 4-1 on the top and a dismantling positioning piece connected by its connecting piece 4-1; the flipping positioning unit 6 has a positioning seat and is hinged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com