Staggered roller-type super-precise polishing device of precise ball and processing method of same

The technology of a polishing device and a processing method is applied in metal processing equipment, surface polishing machine tools, grinding/polishing equipment, etc., to achieve the effects of low production cost, high surface quality, and easy-to-implement functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

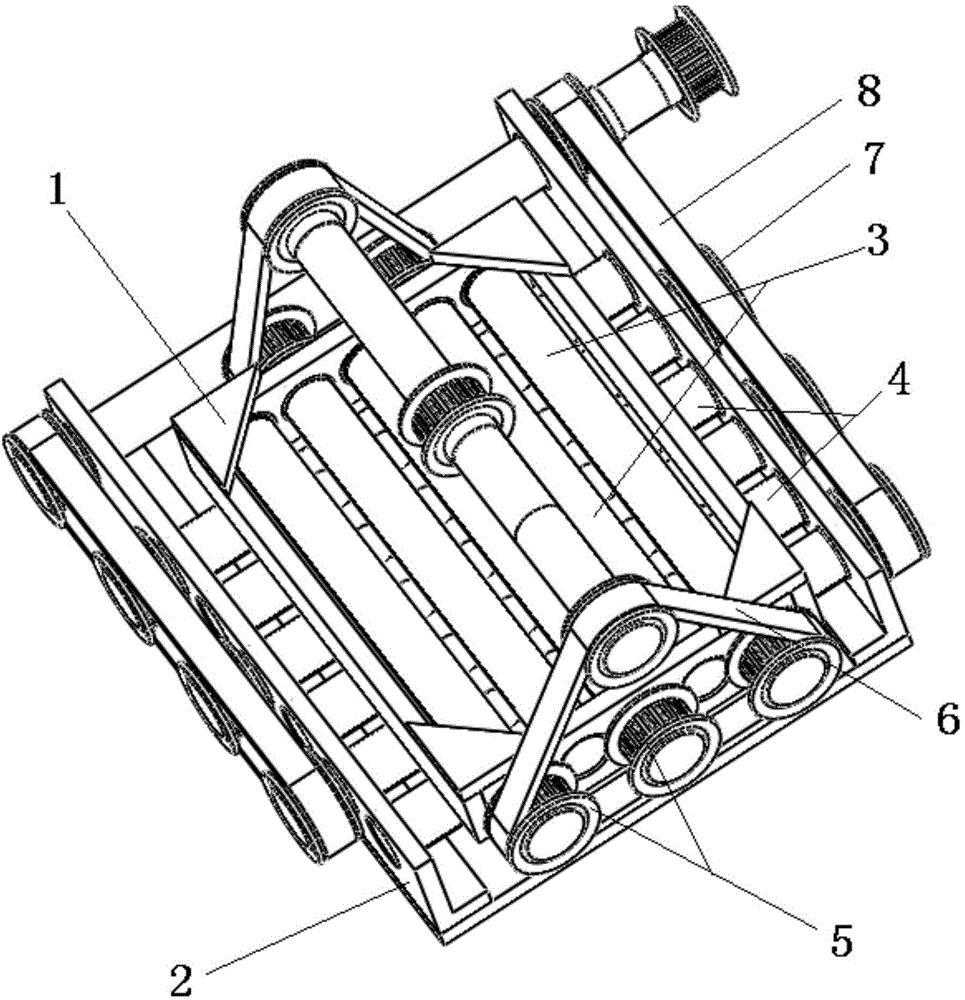

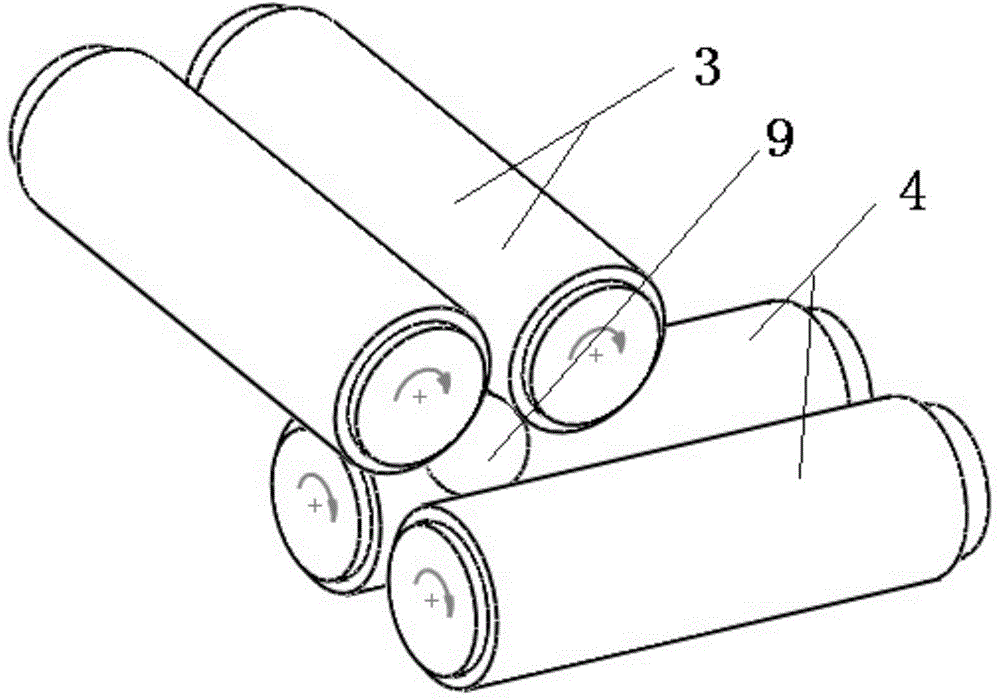

[0023] Such as Figure 1~2 As shown, a precision ball staggered roller ultra-precision polishing device includes a frame, an upper polishing roller layer, a lower polishing roller layer and a driving device. The upper polishing roller layer is arranged directly above the lower polishing roller layer, and the upper polishing roller layer The first layer and the lower polishing roller layer are distributed in staggered orientation and are fixed on the frame by bearings; the upper polishing roller layer includes at least two upper polishing roller units 3 distributed in parallel, and the lower polishing roller layer includes at least two lower polishing roller units distributed in parallel. The roller unit 4; the precision ball 9 to be processed is clamped between the upper polishing roller unit and the lower polishing roller unit gap between the upper polishing roller layer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com