A seat belt retractor and a car seat belt device

A technology for a seat belt retractor and a sensing device, which is applied in the field of seat belts, can solve the problems of increased cost and assembly difficulty, complex structure of the seat belt retractor, etc., and achieves the effects of low cost, simplified structure and simple assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

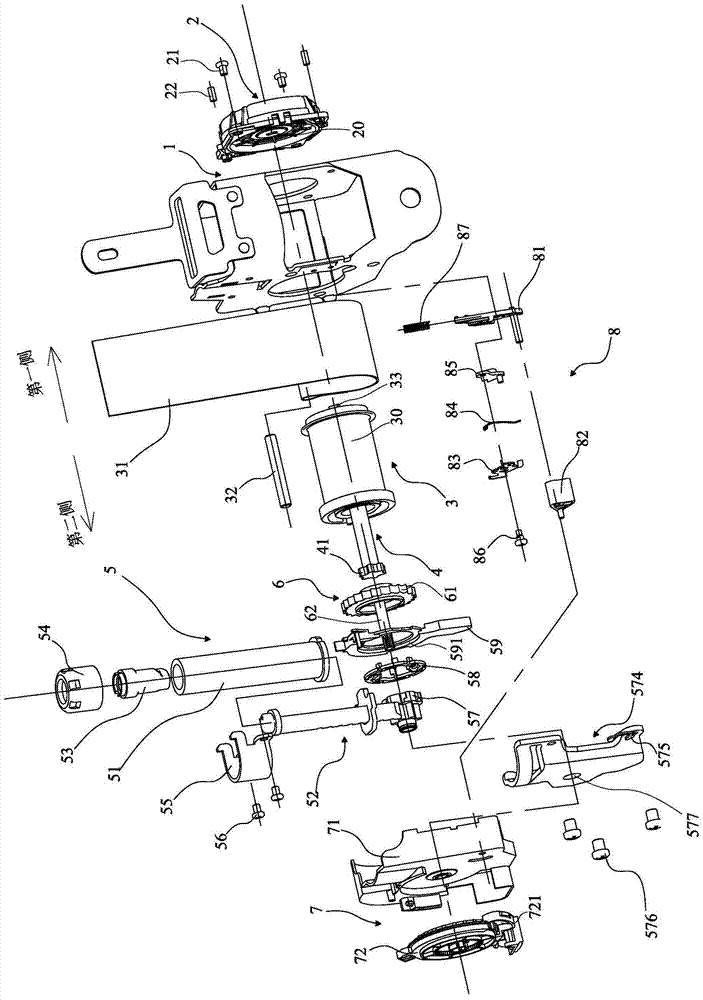

[0077] Such as figure 1 As shown, it includes a frame 1, a reel 3 (also known as a ribbon shaft, a winding shaft, etc.), a rewinding elastic part 2, a limiting part 4, a locking gear 6, a locking device 8, a pre-tensioning device 5 and a mechanical sensor device 7;

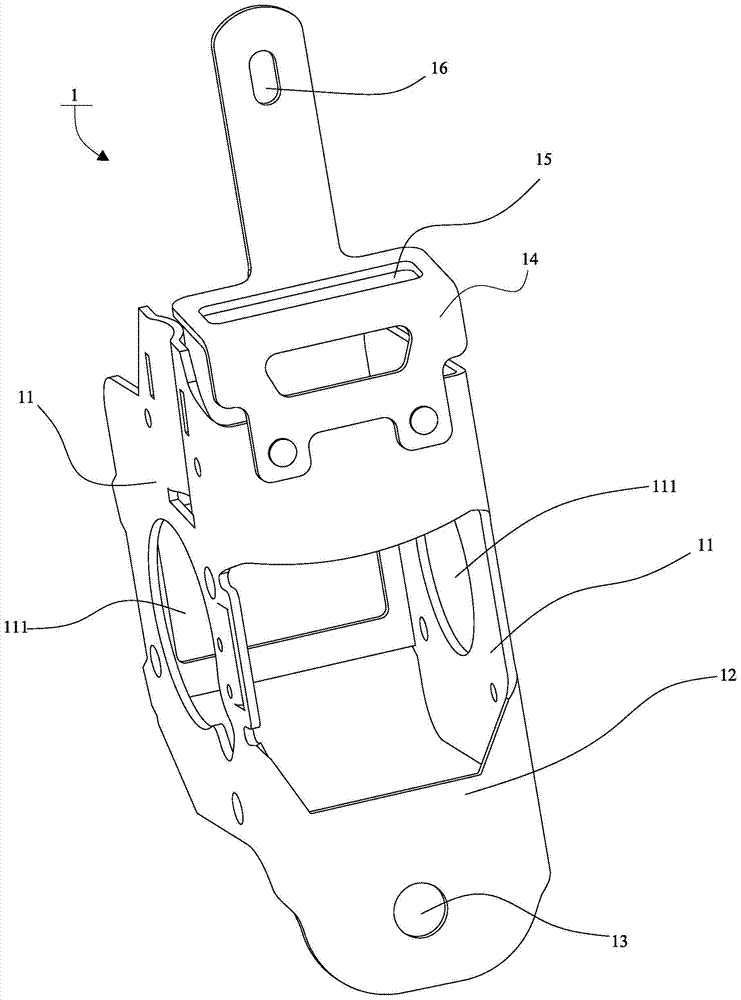

[0078] The frame 1 is fixedly installed on the vehicle body;

[0079] The reel 3 is installed in the frame 1, and is used to retract inwardly or outwardly release the webbing 31 wound thereon for restraining passengers;

[0080] The rewinding elastic member 2 is installed on one side of the frame 1 for automatically retracting the webbing 31;

[0081] The limiting member 4 is arranged at the center of the reel 3, and the two ends are respectively connected to the reel 3 and the locking gear 6;

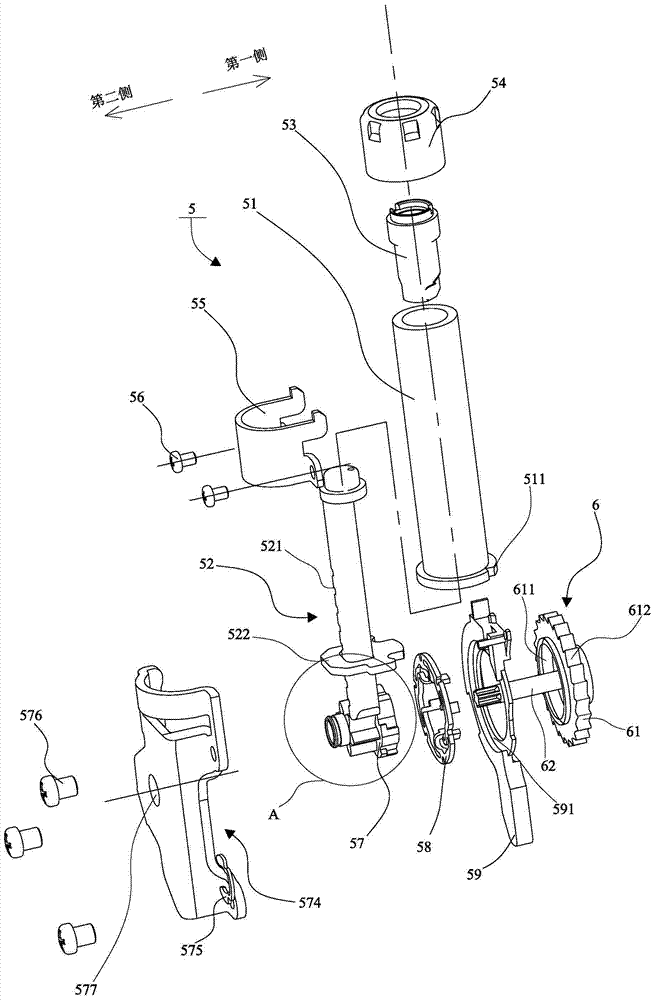

[0082] The locking gear 6 is arranged on one side of the reel 3, and is connected with the reel 3 through the limiting member 4; The content groove 611 is provided with a cylindrical long axis portion 62 connected with...

Embodiment 2

[0128] This example provides a seat belt device, including the seat belt retractor mentioned in the first embodiment, the tongue slidably arranged on the webbing 31, and the seat belt installed on the vehicle body or the vehicle seat. Buckle with tongue fastening.

[0129] Because the seat belt retractor has been specifically introduced in Embodiment 1, and the tongue, buckle, etc. are well known to those skilled in the art, therefore, no more details are given.

[0130] Adopting the automobile safety belt device disclosed in this example, only one locking device 8 is provided in the safety belt retractor provided by it, and the locking device 8 can be activated by the mechanical sensing device 7 or the pretensioning device 5 respectively. , to lock the locking gear 6 . Integrating the two locking functions into one locking device 8 can avoid the problem that the webbing 31 of the seat belt retractor is pulled out after the pretensioning device 5 acts. At the same time, its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com