Forklift hood

A hood and forklift technology, applied in the direction of lifting devices, etc., can solve the problems of laborious operation, troublesome, heavy steel plate, etc., and achieve the effect of labor-saving operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

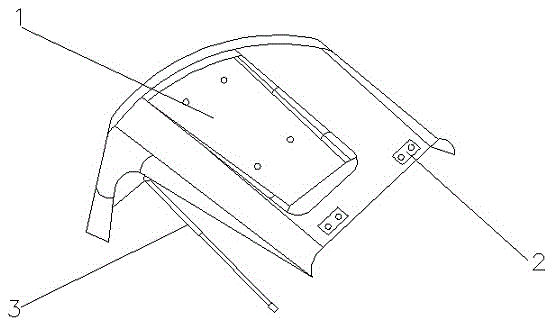

[0008] see figure 1 , a forklift hood, which includes a hood 1, a hinge 2, and a spring brace 3, the hood 1 is provided with a hinge 2 on one side connected to the forklift body, and a spring is also provided on the inner side of the hood 1 Support 3, one end of spring support 3 is connected with machine cover 1, and the other end is fixed on one side of forklift engine.

[0009] When installing the forklift hood, first use a hinge to fix the hood to one side of the forklift engine, which acts as a shaft. When opening, you only need to lift the opposite side, and then fix one end of the spring brace on the engine side , and fix the other end on the inner side of the forklift hood at a certain angle. When the hood is lifted to a certain position, the spring brace will generate an upward force, and the hood will open easily. When the hood is pressed to this position, The spring stays create a downward force and the hood closes automatically.

[0010] For the forklift hood of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com