Socket ratchet wrench

A ratchet wrench and socket technology, which is applied to wrenches, hand-held tools, wrenches, etc., can solve the problems of increasing sealing parts, increasing production and processing procedures, and insufficient strength of the handle, achieving convenient operation, uniform compression strength, Strong and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

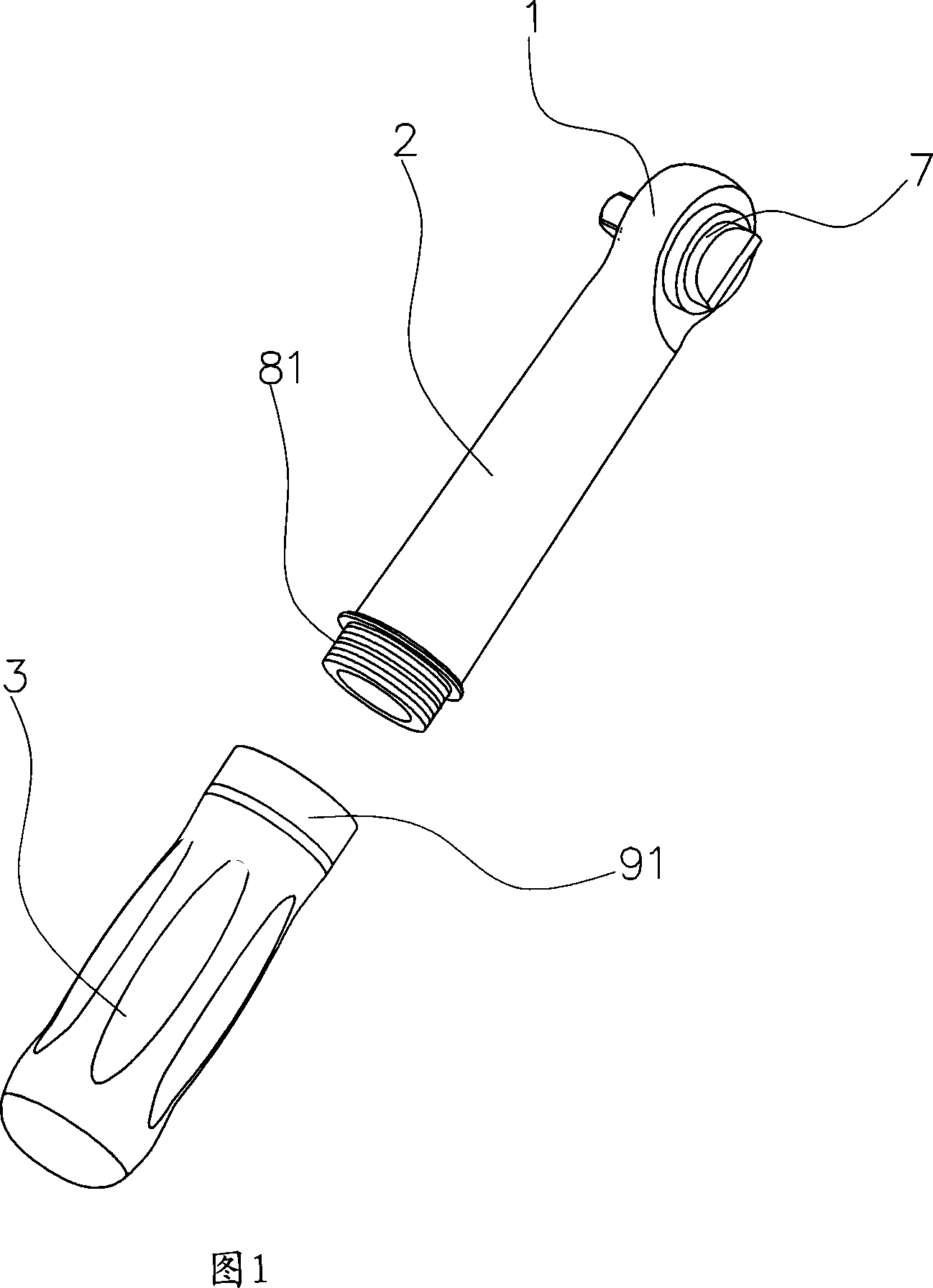

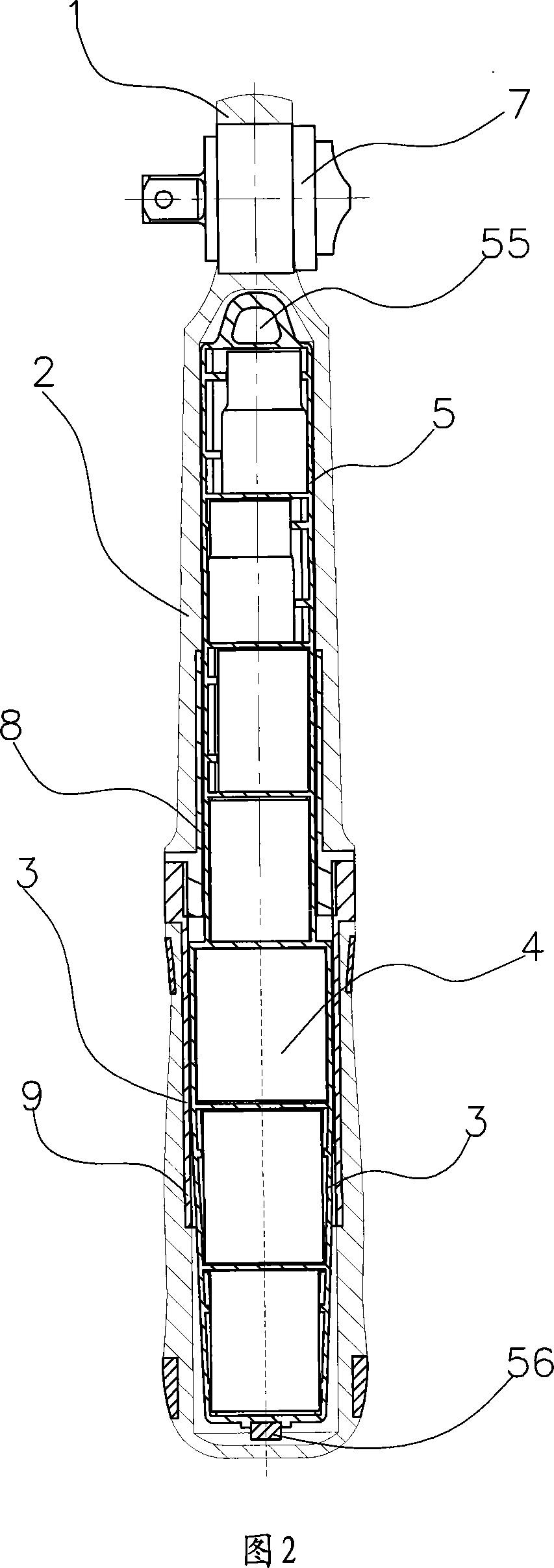

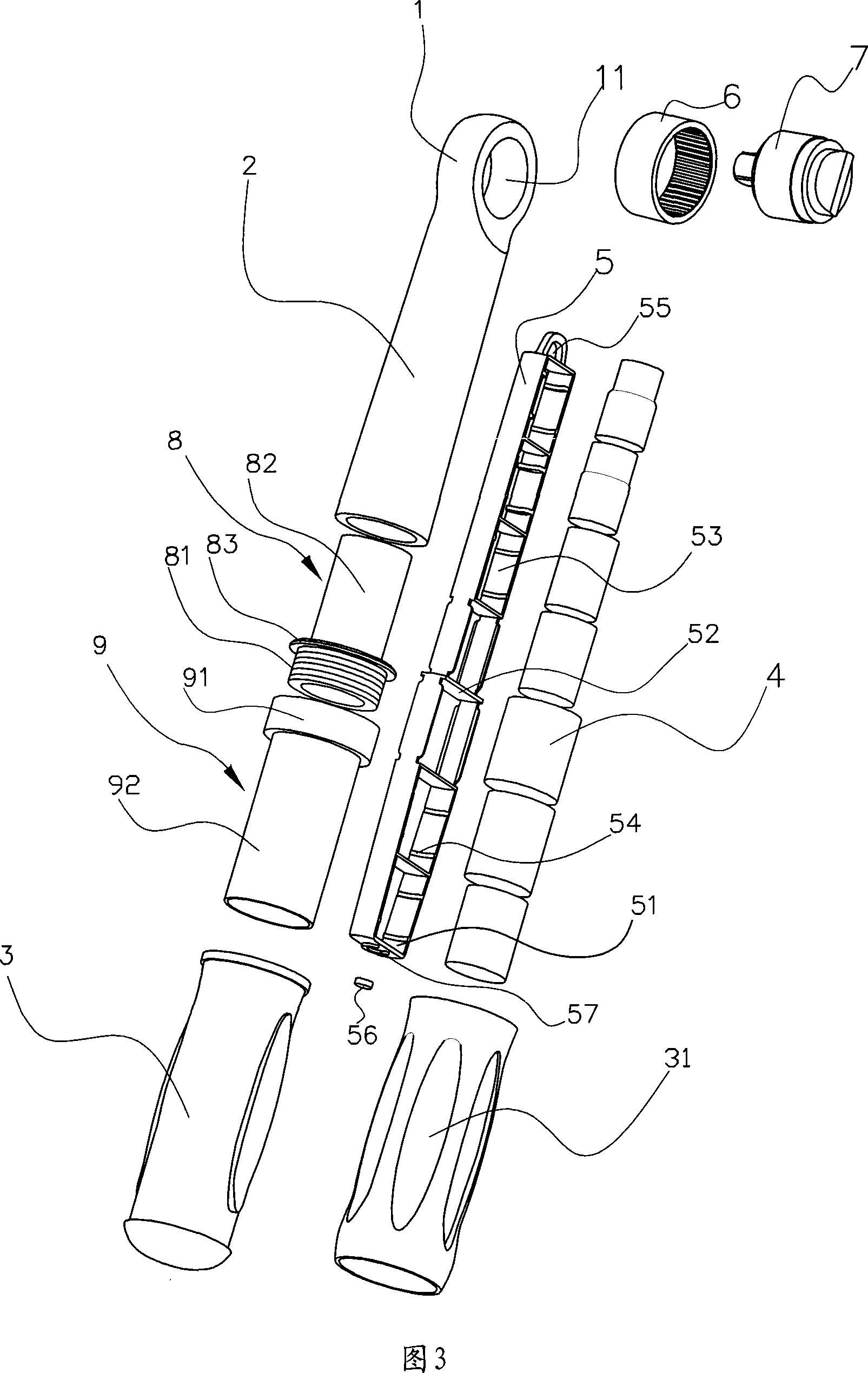

[0017] 1 to 3 are specific embodiments of the present invention.

[0018] The socket ratchet wrench of the present invention has a head 1 of a ratchet 6 and a driving member 7, a rod-shaped wrench body 2 and a handle portion 3, wherein the wrench body is hollow and contains a socket frame 5 capable of accommodating a sleeve 4, the socket frame 5 is a frame profile, and the lever body 2 and the handle part 3 are two separate parts, which are connected together in a detachable manner. At the same time, the handle part 3 is also a hollow structure, and the hollow part of the handle part 3 and the hollow part of the lever body 2 Together constitute the entire space for accommodating the sleeve frame 5 .

[0019] In this embodiment, the sleeve frame 5 is in the shape of expanding in the middle and tapering toward both ends. The sleeve frame 5 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com