A kind of recycled concrete and preparation method

A technology of recycled concrete and recycled coarse aggregate, applied in the field of concrete, can solve the problems of large crushing index, poor durability, large porosity, etc., and achieve the effects of saving resources, improving coupling effect, and uniform compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

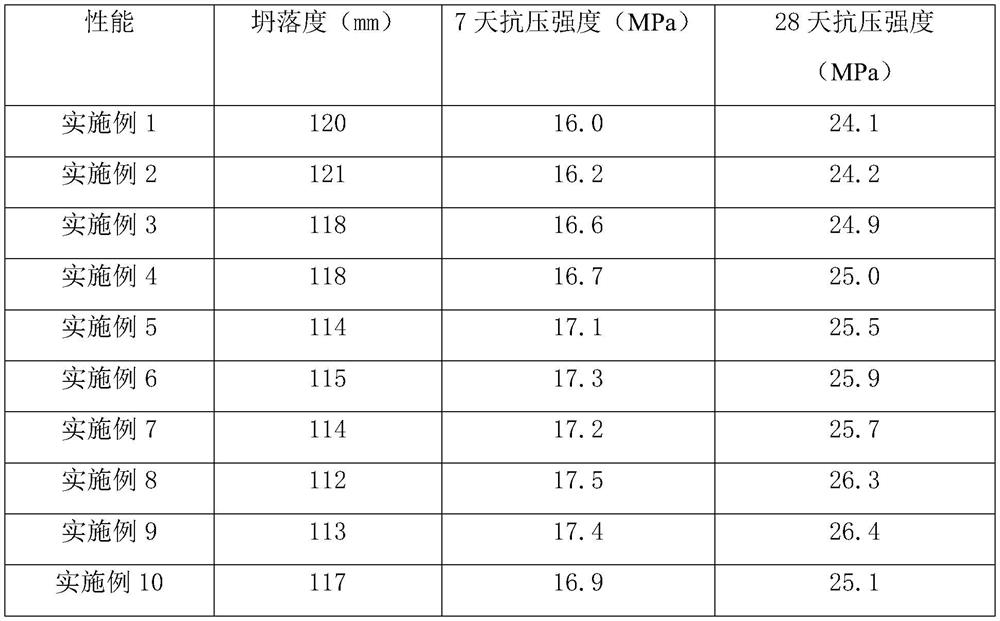

Examples

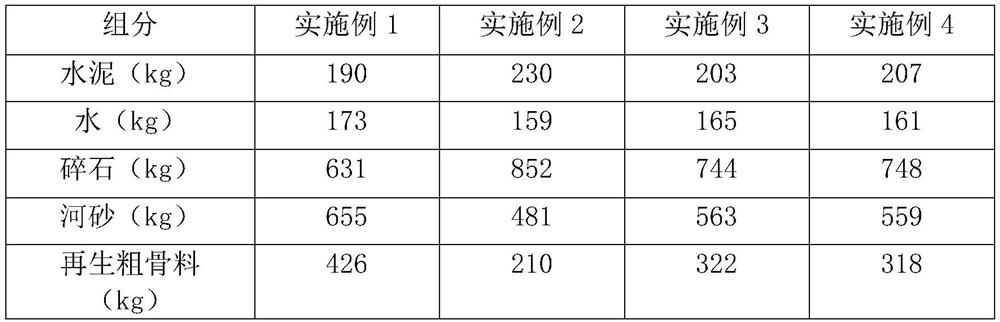

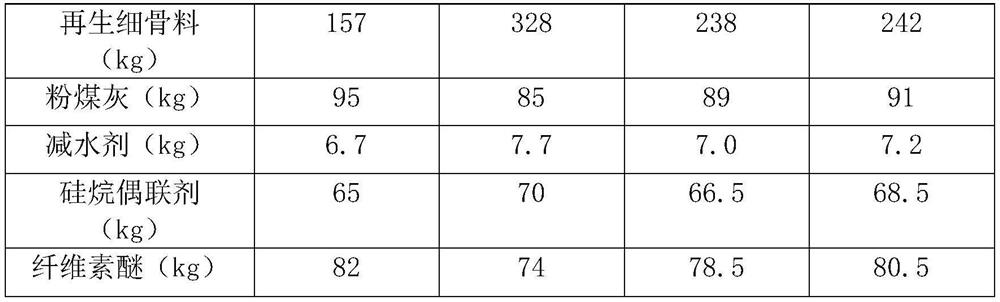

Embodiment 1

[0071] A preparation method of recycled concrete:

[0072] Divide 65kg of KH-550 silane coupling agent and 74kg of hydroxypropyl methylcellulose into two equal parts, and half of the silane coupling agent and hydroxypropyl methylcellulose are poured into a concrete mixer, 631kg of crushed stone, 157kg of regeneration The fine aggregate was stirred for 1 hour; at the same time, the other half of the silane coupling agent and hydroxypropyl methyl cellulose was poured into another concrete mixer and mixed with 426kg of regenerated coarse aggregate and 655kg of river sand for 1 hour; after the stirring, the first The mixture is mixed with the second mixture, and together with 190 kg of cement, 173 kg of water, and 6.7 kg of water reducing agent are poured into a concrete mixer for mixing and stirring for 10 minutes to obtain recycled concrete.

Embodiment 2

[0074] Divide 70kg of KH-550 silane coupling agent and 82kg of hydroxypropyl methylcellulose into two equal parts, and pour half of the silane coupling agent and hydroxypropyl methylcellulose into a concrete mixer, 852kg of crushed stone, 328kg of regeneration The fine aggregate was stirred for 2 hours; at the same time, the other half of the silane coupling agent and hydroxypropyl methyl cellulose was poured into another concrete mixer and mixed with 210kg of recycled coarse aggregate and 481kg of river sand for 2 hours; after the stirring, the first The mixture was mixed with the second mixture, and together with 230 kg of cement, 159 kg of water, and 7.7 kg of water reducing agent were poured into a concrete mixer and mixed for 10 minutes to obtain recycled concrete.

Embodiment 3

[0076] Divide 66.5kg of KH-550 silane coupling agent and 78.5kg of hydroxypropyl methylcellulose into two equal parts, and half of the silane coupling agent and hydroxypropyl methylcellulose are poured into a concrete mixer and 744kg of crushed stone, 238kg of regenerated fine aggregate was stirred for 1.5h; at the same time, the other half of the silane coupling agent and hydroxypropyl methyl cellulose was poured into another concrete mixer, 322kg of regenerated coarse aggregate and 563kg of river sand were stirred for 1.5h; , the first mixture and the second mixture are mixed, and together with 203kg of cement, 165kg of water, and 7kg of water reducing agent are poured into a concrete mixer for mixing and stirring for 10 minutes to obtain recycled concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com