Enclosures with tool-less opening

An opening device, tool-free technology, applied in the container handle, packaging, transportation and packaging, etc., can solve the problems of limited height and freedom of arrangement, and the upper cover does not slide smoothly, and achieves the effect of labor-saving operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

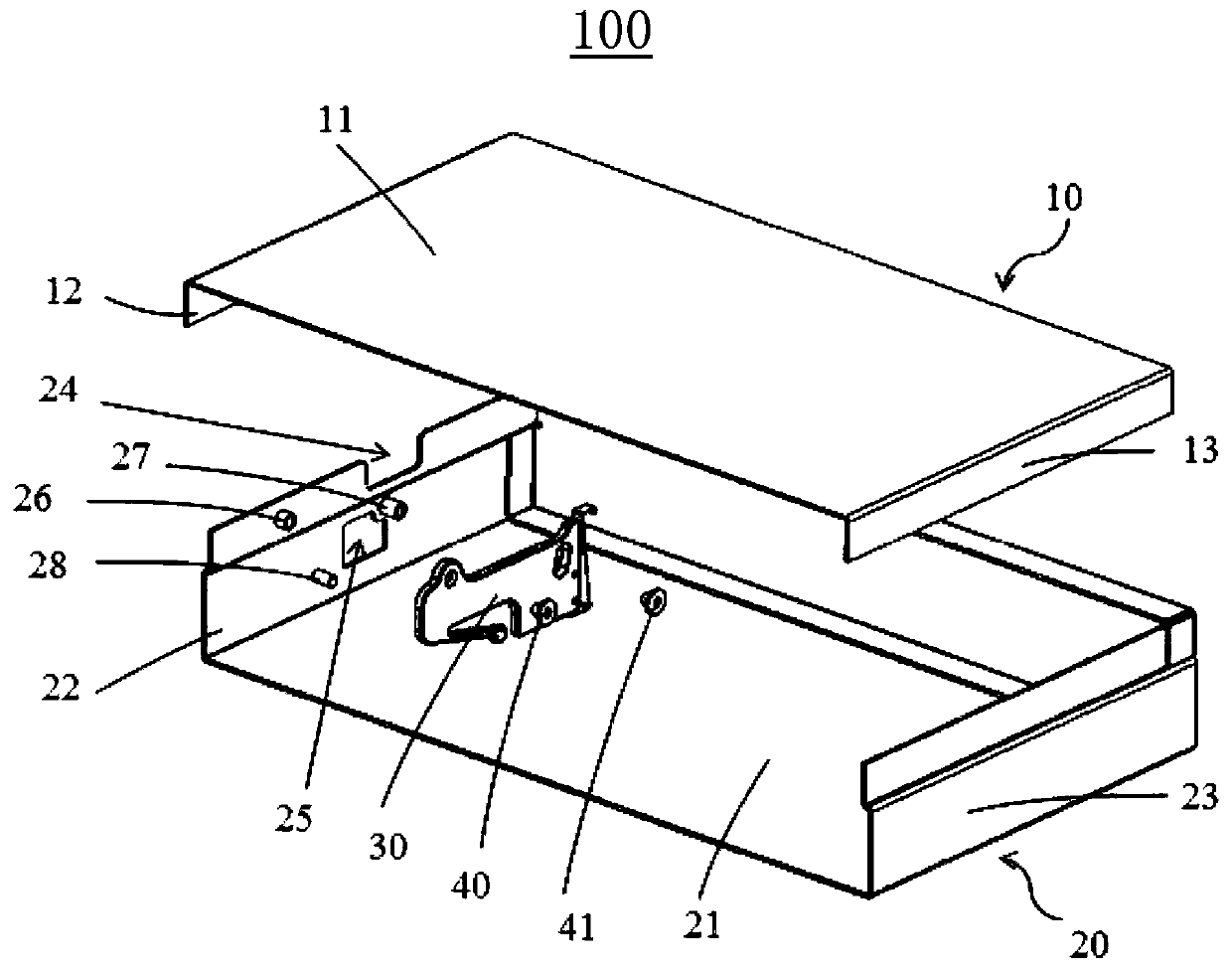

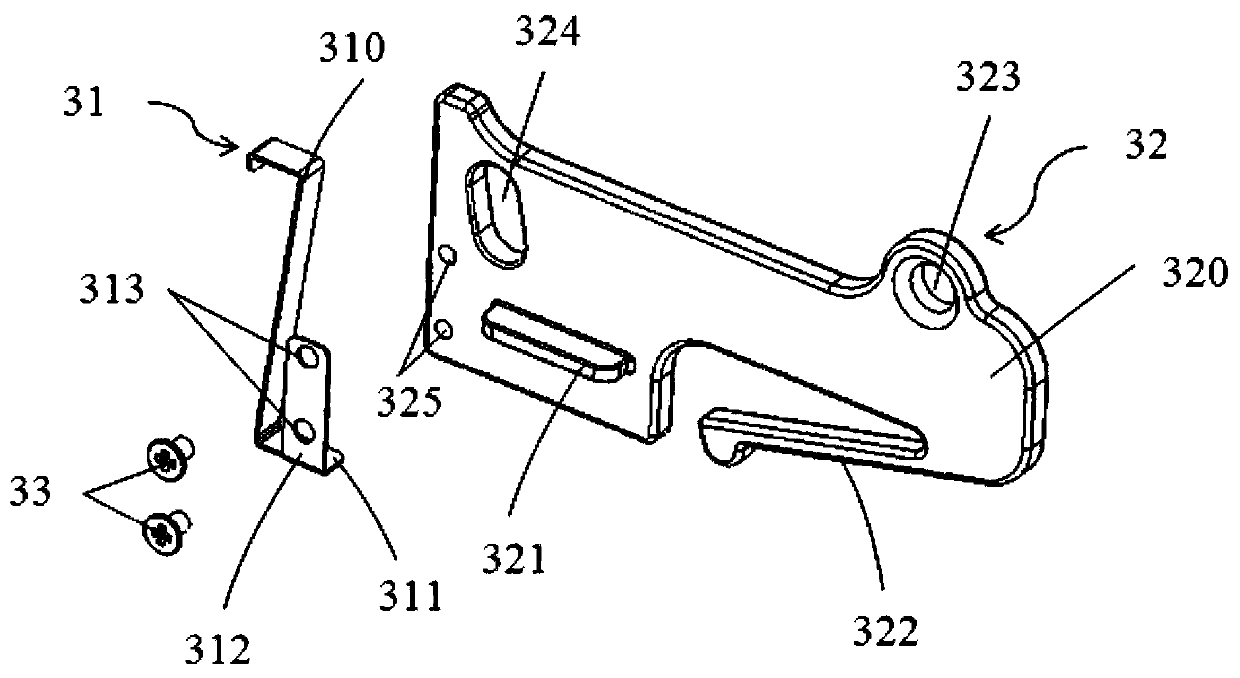

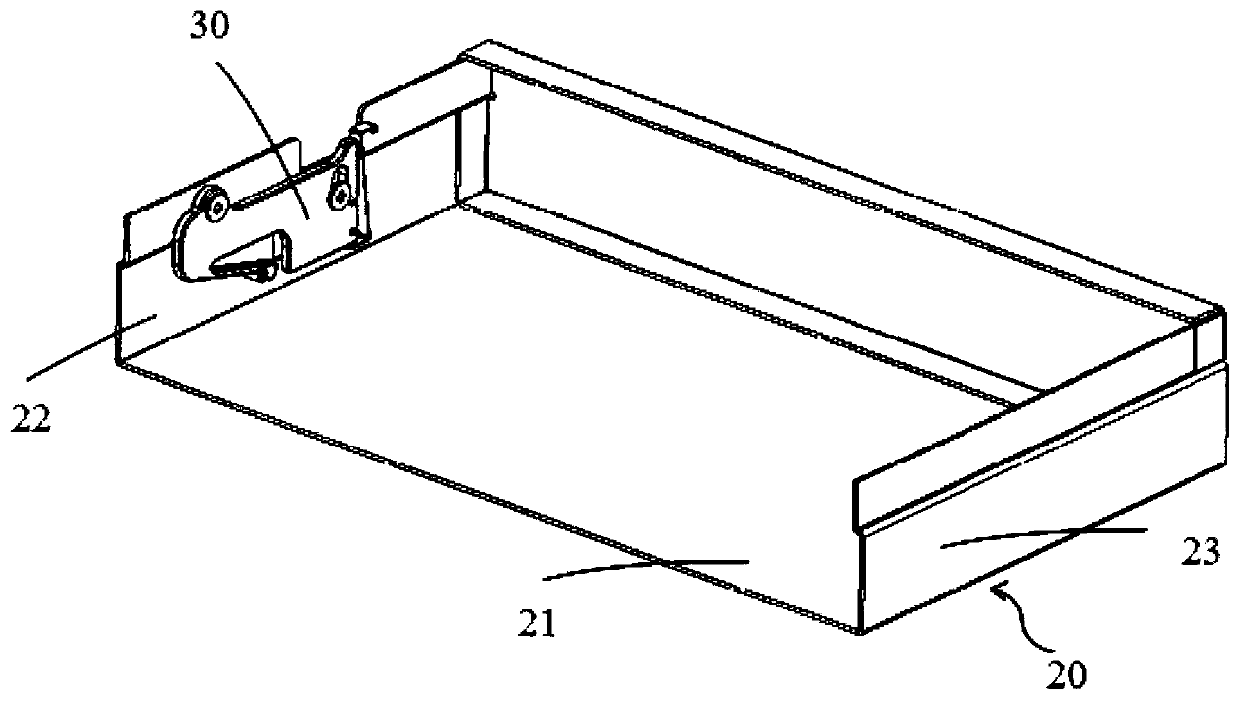

[0056] figure 1 Shown is an exploded view of a chassis according to an embodiment of the present invention. Please refer to figure 1 According to an embodiment of the present invention, the chassis 100 includes a top cover 10, a base 20 and a handle assembly 30, the top cover 10 is slidably arranged on the base 20, the handle assembly 30 is fixed on the base 20, and the top cover 10 includes a top plate 11 and the first side plate 12 and the second side plate 13 extending relatively from the two ends of the top plate 11, the first side plate 12 has a block 14 (see Figure 4 );

[0057] The base 20 includes a bottom plate 21 and a third side plate 22 and a fourth side plate 23 extending oppositely from the two ends of the bottom plate 21. On the third side plate 22 opposite to the first side plate 12, there is a slide groove 24, a receiving groove 25, The first connecting portion 26, the second connecting portion 27 and the stop portion 28, the upper end of the chute 24 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com