A drilling device for measuring residual stress by blind hole method

A residual stress, drilling device technology, applied in the direction of boring/drilling, drilling/drilling equipment, components of boring machine/drilling machine, etc., can solve the difficulty of drilling, difficult to control the size of the pressure, and slow drilling speed and other problems, to achieve the effect of intuitively aligning the drilling position, saving labor and making the operation more convenient, and improving the drilling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

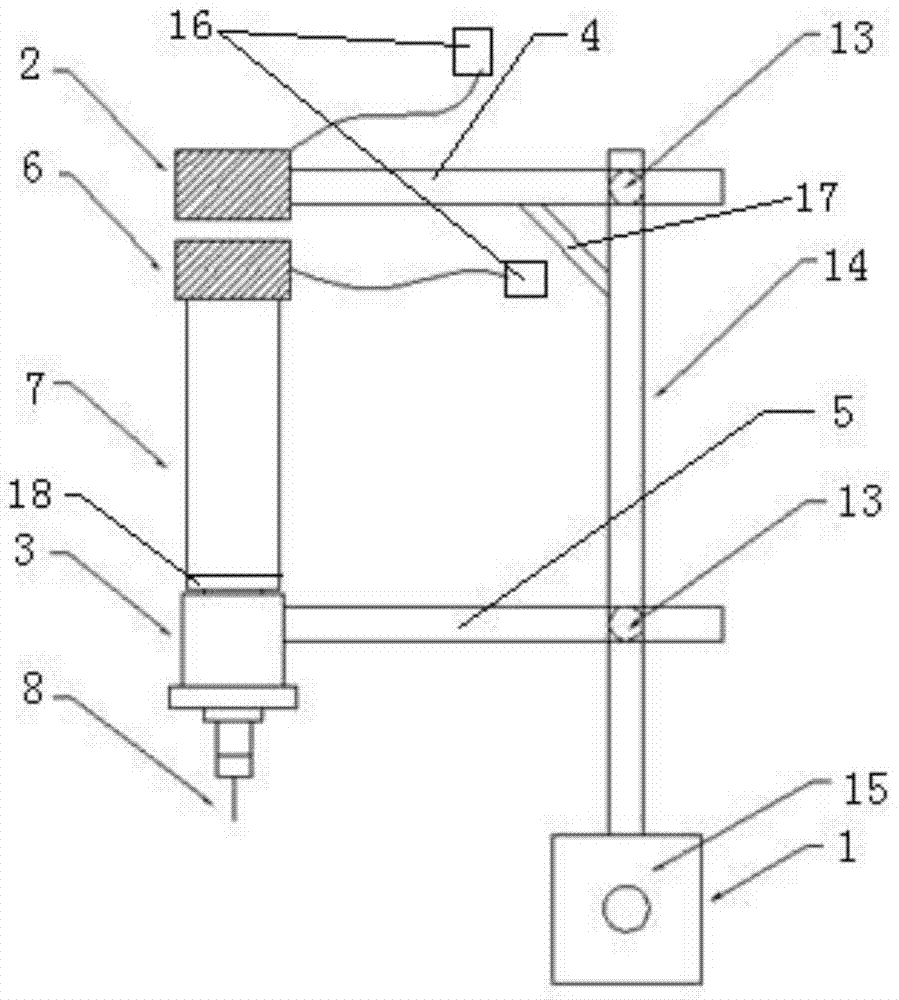

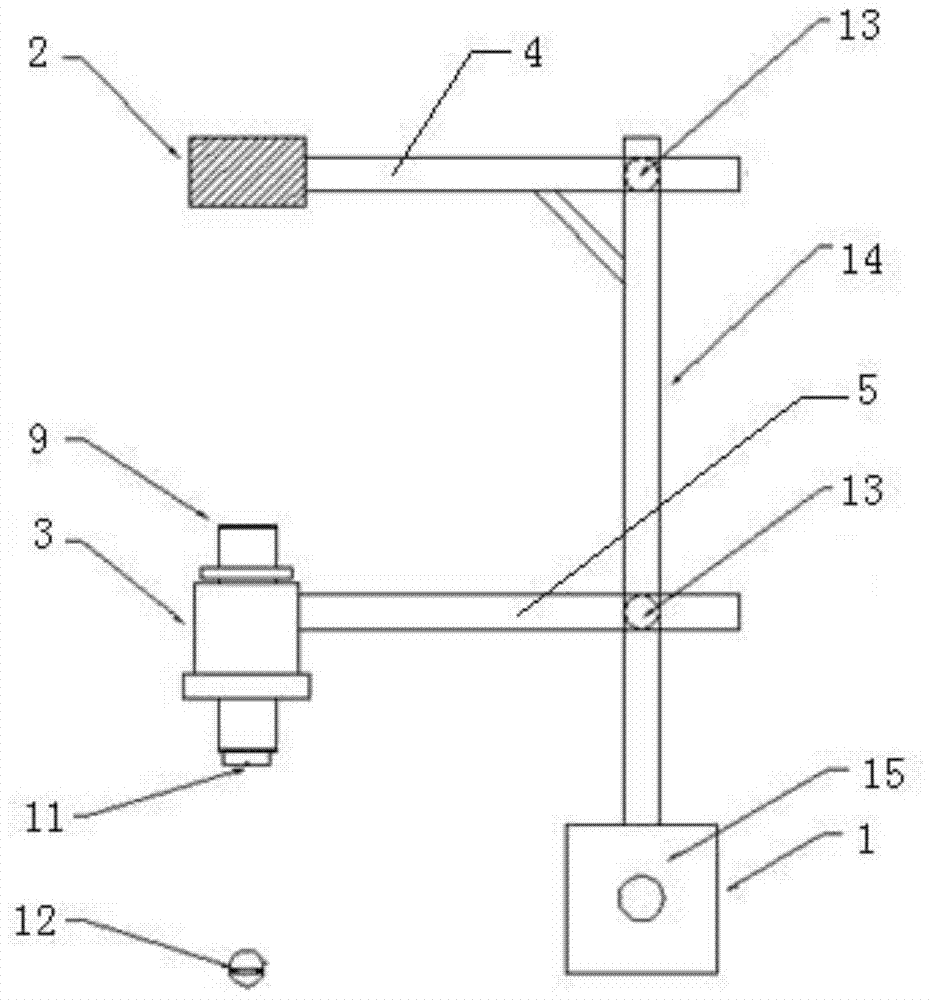

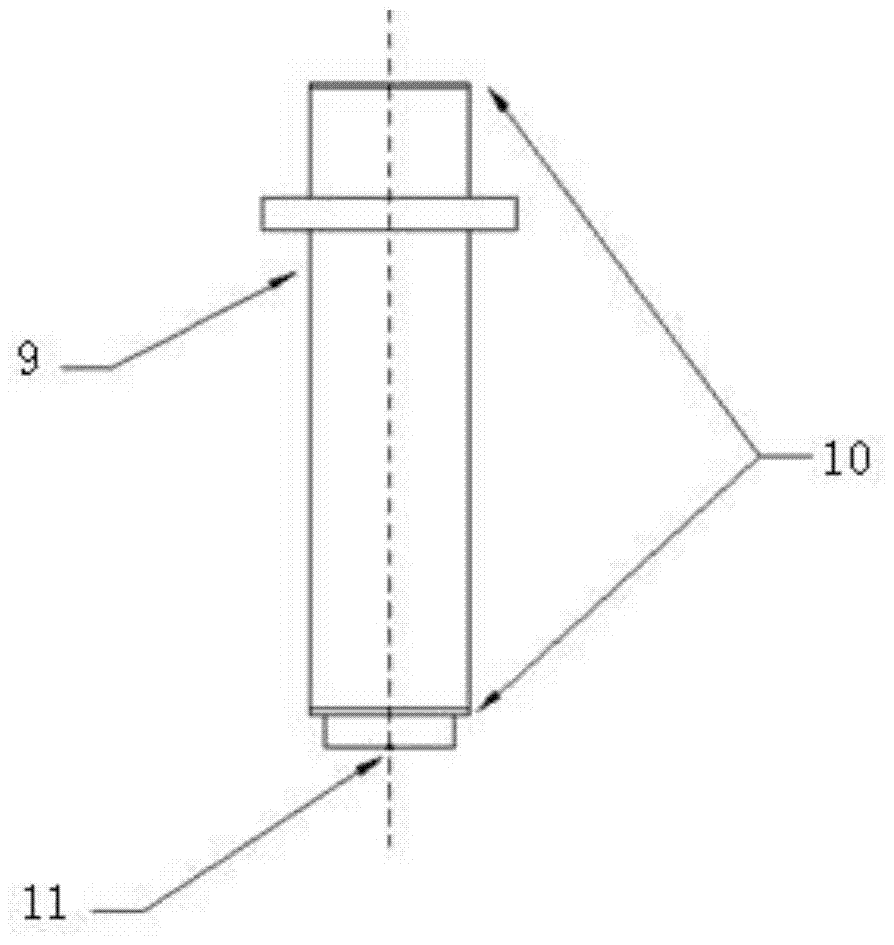

[0028] like Figure 1-5 As shown, the present invention provides a drilling device for measuring residual stress by blind hole method, comprising an I-shaped support, the support includes an upper beam 4, a lower beam 5 and a vertical rod 14, and the upper beam 4 and the lower beam 5 pass through the steering bolts 13 is connected to the two ends of the vertical rod 14, and the lower end of the vertical rod 14 is provided with a support base 1; one end of the lower beam 5 is fixedly connected with a guide sleeve 3, and when the drilling position needs to be positioned, the guide sleeve 3 is provided with an alignment device , when drilling is required, a drill is provided in the guide sleeve 3, and the drill includes a drill sleeve 7 arranged on the guide sleeve 3. The bottom end of the drill sleeve 7 is provided with a drill bit 8, and the drill bit 8 passes through the In the guide sleeve 3, a continuous force device is provided between the top of the drill sleeve 7 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com