Dust-collection head applicable to textile fabrics

A cleaning head and textile technology, applied in the field of cleaning heads, can solve the problems of single function, simple structure, poor dust disturbing effect, etc., and achieve the effect of improving the dust raising effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

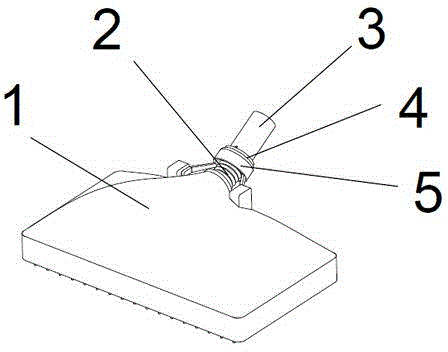

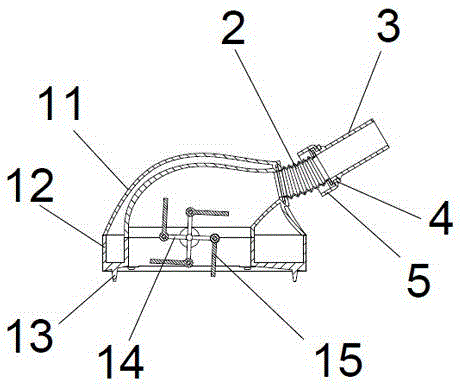

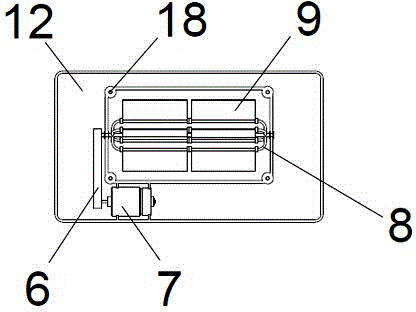

[0019] With reference to accompanying drawing, a kind of cleaning head that is suitable for textile, shell 1 comprises upper shell 11, lower shell 12, and upper shell and lower shell are fixedly connected by screw; The two ends are provided with grooves 83, and the upper and lower housings are provided with clamping ribs 14, 15 corresponding to the grooves. The clamping ribs are respectively provided with semicircular holes 16, 17, and the grooves of the bracket are stuck in the upper and lower housings. In the semicircular hole; one end of the support is fixedly connected with a pulley 82, the pulley is connected with the motor 7 through the belt 6, and the motor is installed in the housing; in this example, the support is divided into 4 supporting shafts along the parallel direction of the rotating shaft, each supporting There are two beating boards 9 set on the shaft, and the beating board and the supporting shaft are interference fit, so that the beating board can rotate ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com