Dust collection filtering box of tobacco cutter

A shredding machine and filter box technology, which is applied in the direction of removing smoke, tobacco, chemical instruments and methods, etc., can solve the problems of easy-blocking equipment and shutdown, and achieve the effects of avoiding shutdown, increasing the filtration area, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

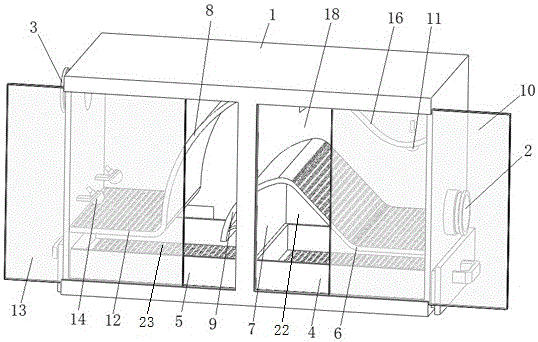

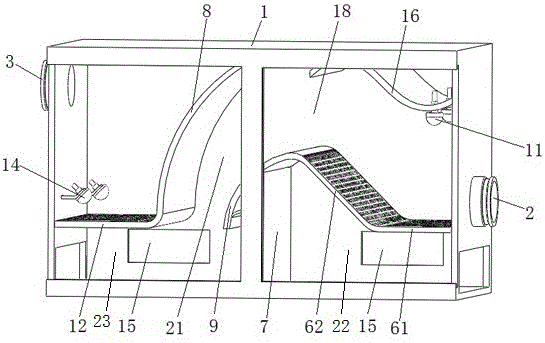

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

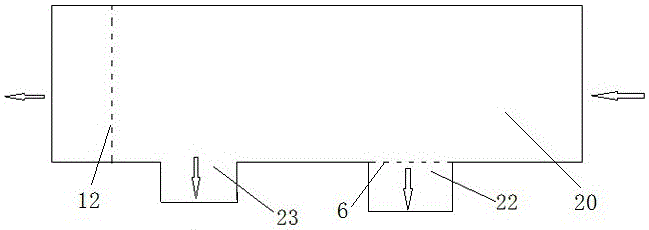

[0024] Specific embodiment 1 of the dust removal filter box of the shredded machine of the present invention, at first introduce the working principle of the dust removal filter box of the shredded machine of the present invention; the schematic diagram of the dust removal filter box of the shredded machine is as follows figure 1 As shown, the present invention uses the wind-passing and dust-removing channel 20 in the box as the main channel. When the dust-extracting fan draws air, the airflow flows from the dust-removing inlet to the dust-removing outlet, driving the materials in the wind-passing and dust-removing channel to move from upstream to downstream. A filter chamber 22 and a blanking cavity 23 are provided on the lower side of the wind-passing dust removal channel 20. In other embodiments, there may be two or more filter chambers, and two or mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com