High-lift spiral blade impeller

A technology of helical blade and high lift, applied in the components of pumping device for elastic fluid, non-variable-capacity pump, machine/engine, etc. Achieving the effect of significant boosting effect and increased cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

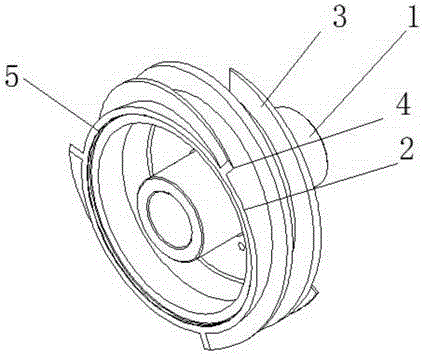

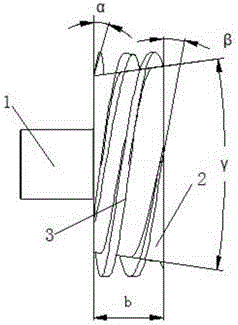

[0023] A high-lift helical blade impeller, including a pump shaft sleeve 1, a mouth ring 2 and blades 3, the mouth ring 2 is set on the end of the pump shaft sleeve 1, and the mouth ring 2 is provided with a blade 3, the blade 3 is Helical, the spiral wrap angle of the blade 3 is 200°, the inlet installation angle α of the blade 3 is 10°, the outlet installation angle β of the blade 3 is 14°, the mouth ring 2 is conical, and The cone angle γ of the mouth ring 2 is 6°, the width b of the mouth ring is 40mm, and a plurality of keyholes 4 are evenly opened on the mouth ring 2, the blades 3 are 3-5 pieces, and the mouth ring 2 There is a groove 5 at the end, the depth of the groove 5 is 1mm, the degree of installation angle of each point on the blade 3 is distributed in a wave pattern, the thickness of the blade 3 changes according to a linear rule, and the thickness of the blade is as small as From large to small, blade 3 is thinner at the outlet and inlet end faces;

Embodiment 2

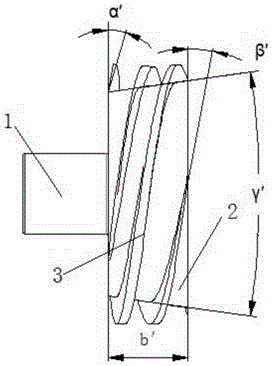

[0025] A high-lift helical blade impeller, including a pump shaft sleeve 1, a mouth ring 2 and blades 3, the mouth ring 2 is set on the end of the pump shaft sleeve 1, and the mouth ring 2 is provided with a blade 3, the blade 3 is Helical, the spiral wrap angle of the blade 3 is 220°, the inlet installation angle α' of the blade 3 is 12°, the outlet installation angle β' of the blade 3 is 18°, the mouth ring 2 is conical, And the cone angle γ' of the mouth ring 2 is 10°, the width b' of the mouth ring 2 is 52mm, and a plurality of keyholes are uniformly opened on the mouth ring 2, and the blades 3 are 3-5 pieces. The mouth ring 2 ends have groove 5, and the depth of described groove 5 is 2mm, and the degree of the installation angle of each point on the described blade 3 is wave-shaped distribution, and described blade 3 thickness changes according to linear rule, and blade 3 The thickness of the vane 3 is distributed from small to large and then to small, and the blade 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com