Patents

Literature

61results about How to "Speed up import" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

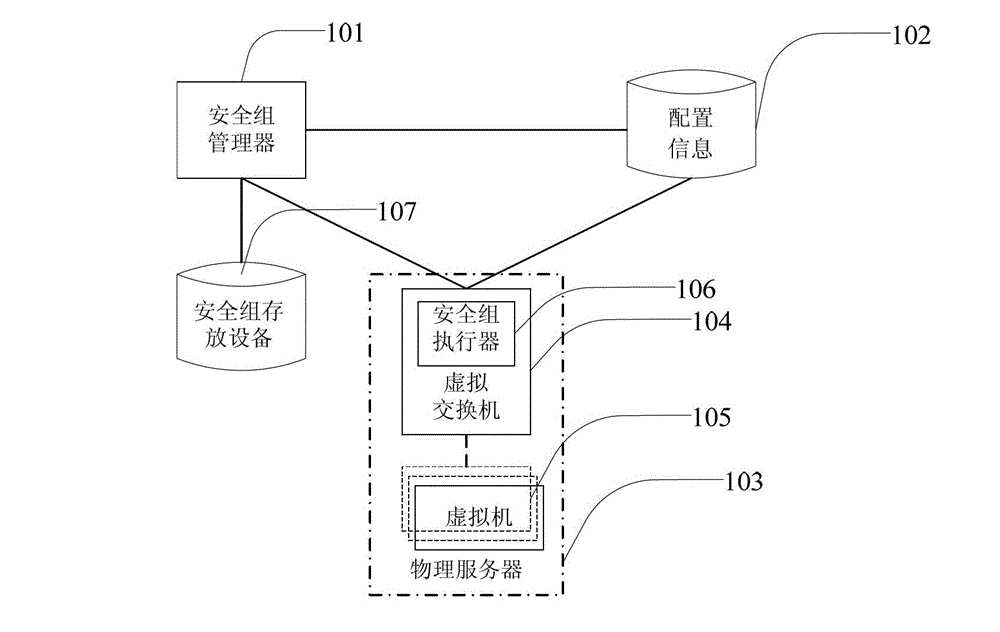

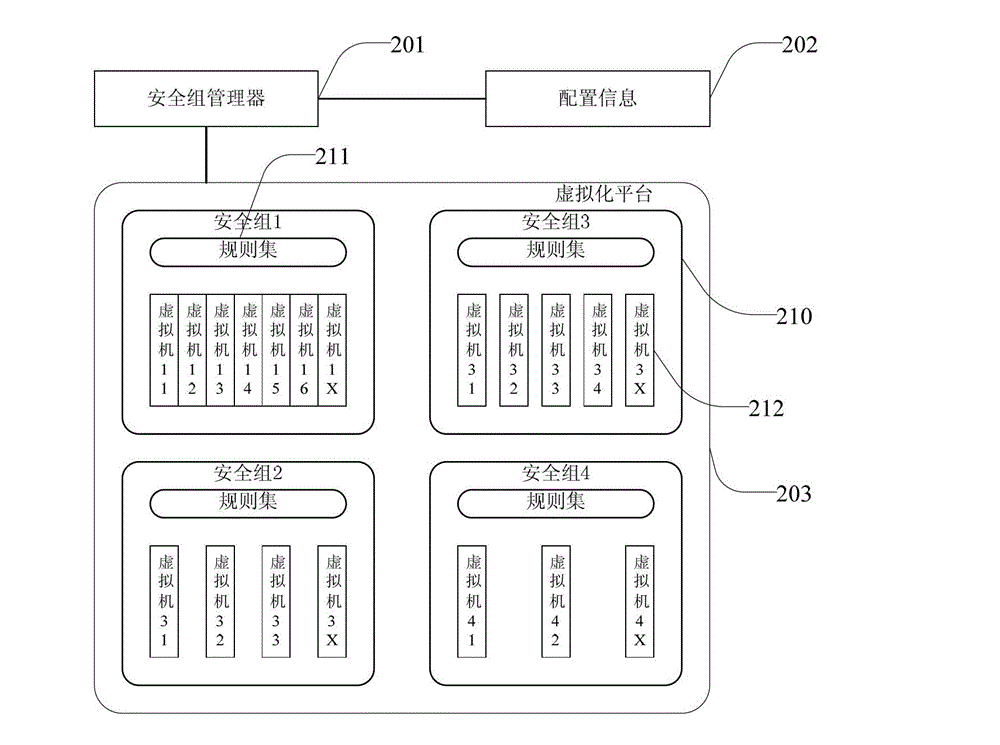

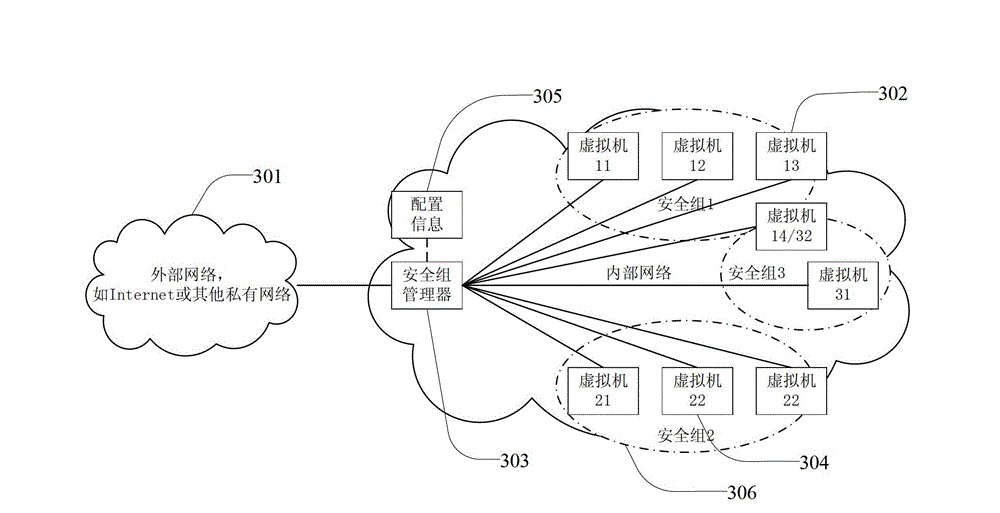

Virtual machine security group configuration method and device

InactiveCN104007997ASpeed up importFunction increaseComputer security arrangementsProgram loading/initiatingVirtualizationVirtual platform

Disclosed are a method and a device for configuring a virtual machine and a security group. The method comprises: upon receiving an operation request for binding, updating, or unbinding a virtual machine and a security group, a virtual platform binding, updating, or unbinding the virtual machine and the security group; upon receiving an operation request for importing and exporting a designated security group, the virtual platform importing and exporting the designated security group. Through the present invention, the user can conveniently and flexibly configure the virtual machine and the security group according to the requirements of an application service.

Owner:ZTE CORP

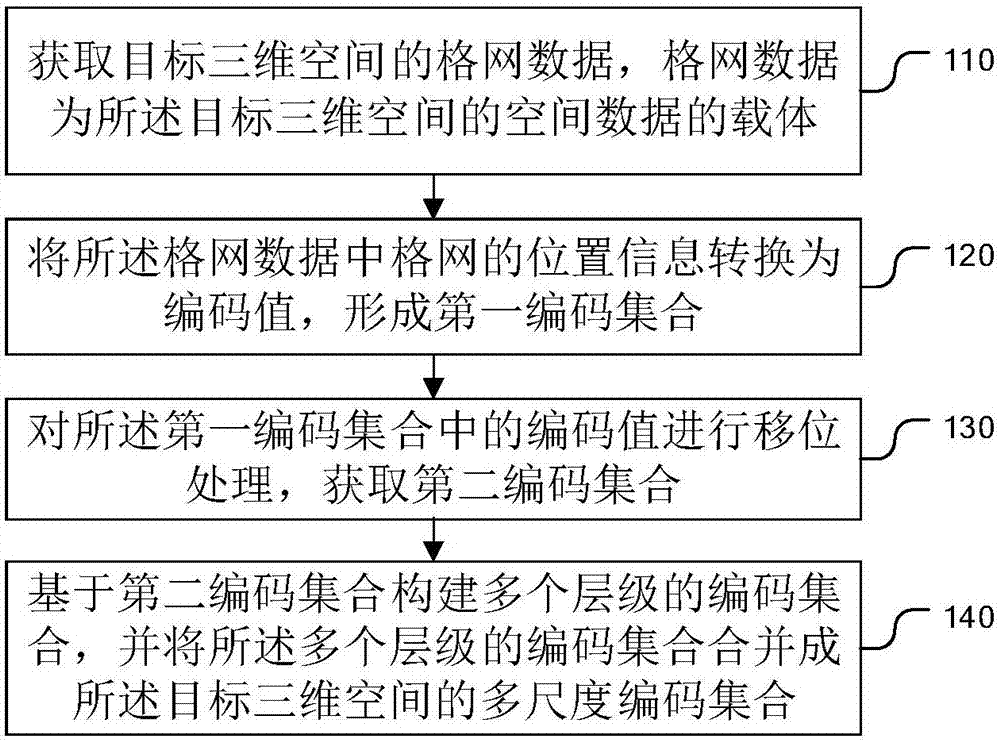

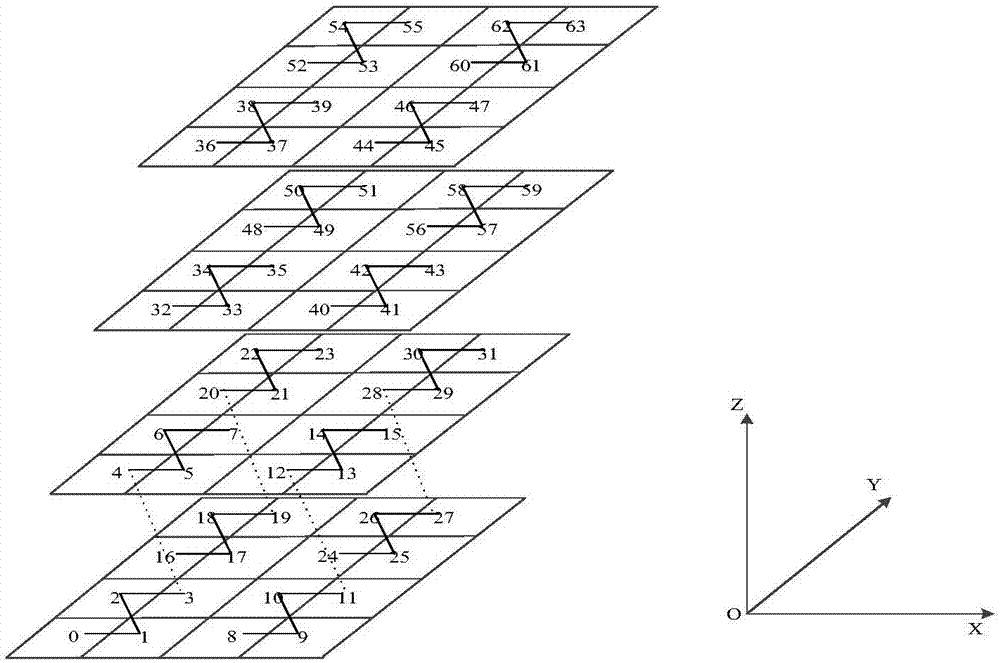

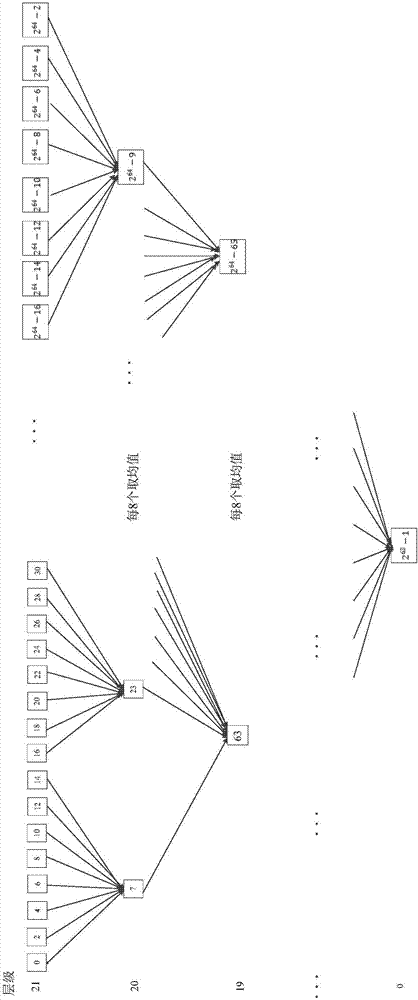

Multi-scale integralization coding method and device of three-dimensional space

ActiveCN107341191AImplement multi-scale encodingReduce data volumeDetails involving 3D image dataImage codingThree-dimensional spaceComputer science

The invention discloses a multi-scale integralization coding method and device of three-dimensional space. The method includes: acquiring grid data of the three-dimensional space of a target, wherein the grid data is a carrier of spatial data of the three-dimensional space of the target; converting grid location information in the grid data into code values to form a first code set; shifting the code values in the first code set to acquire a second code set; and constructing a plurality of levels of code sets on the basis of the second code set, and merging the plurality of levels of code sets into a multi-scale code set of the three-dimensional space of the target. According to the method and device, integralization is carried out on grid locations, then a base is laid for fast use of codes on the basis of integer addition, subtraction and bitfield operations, correlations between the codes are found through analyzing the codes, and multi-scale coding and calculation of the three-dimensional space are realized. Compared with the prior art, the method and device have the advantage of high coding efficiency.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

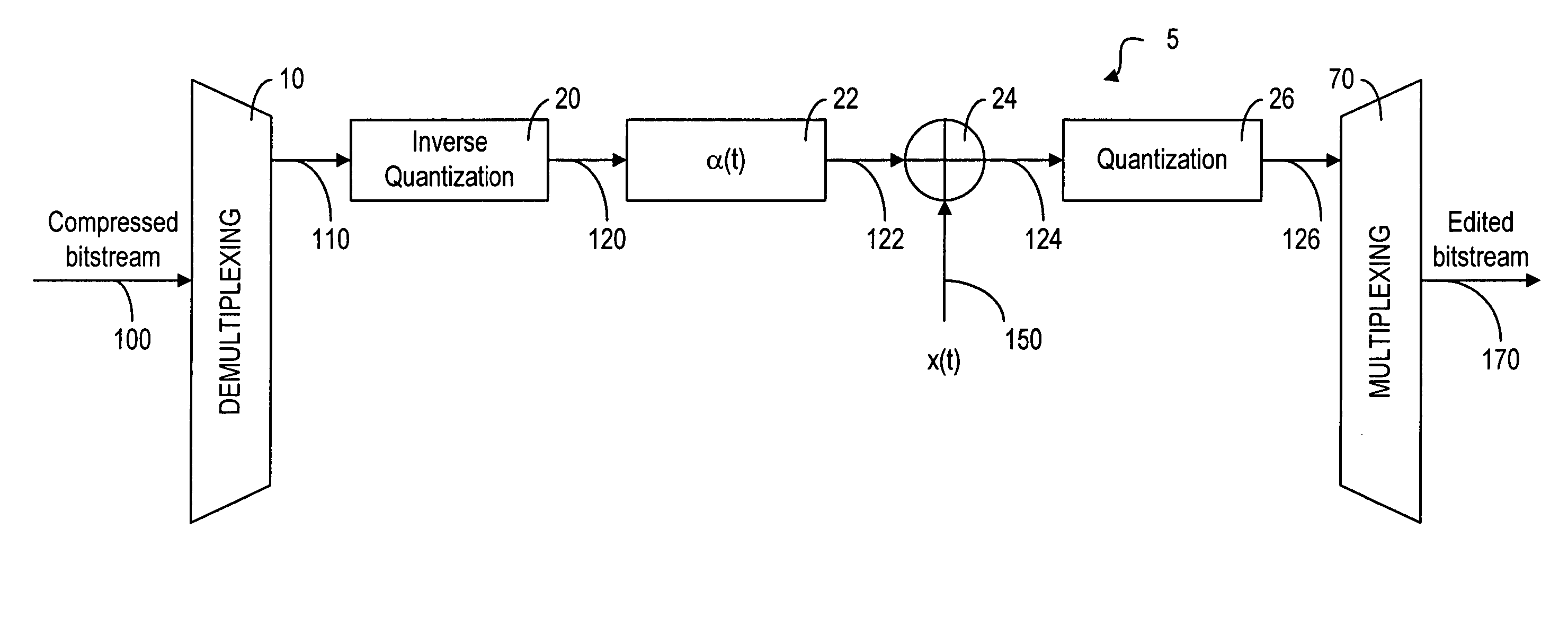

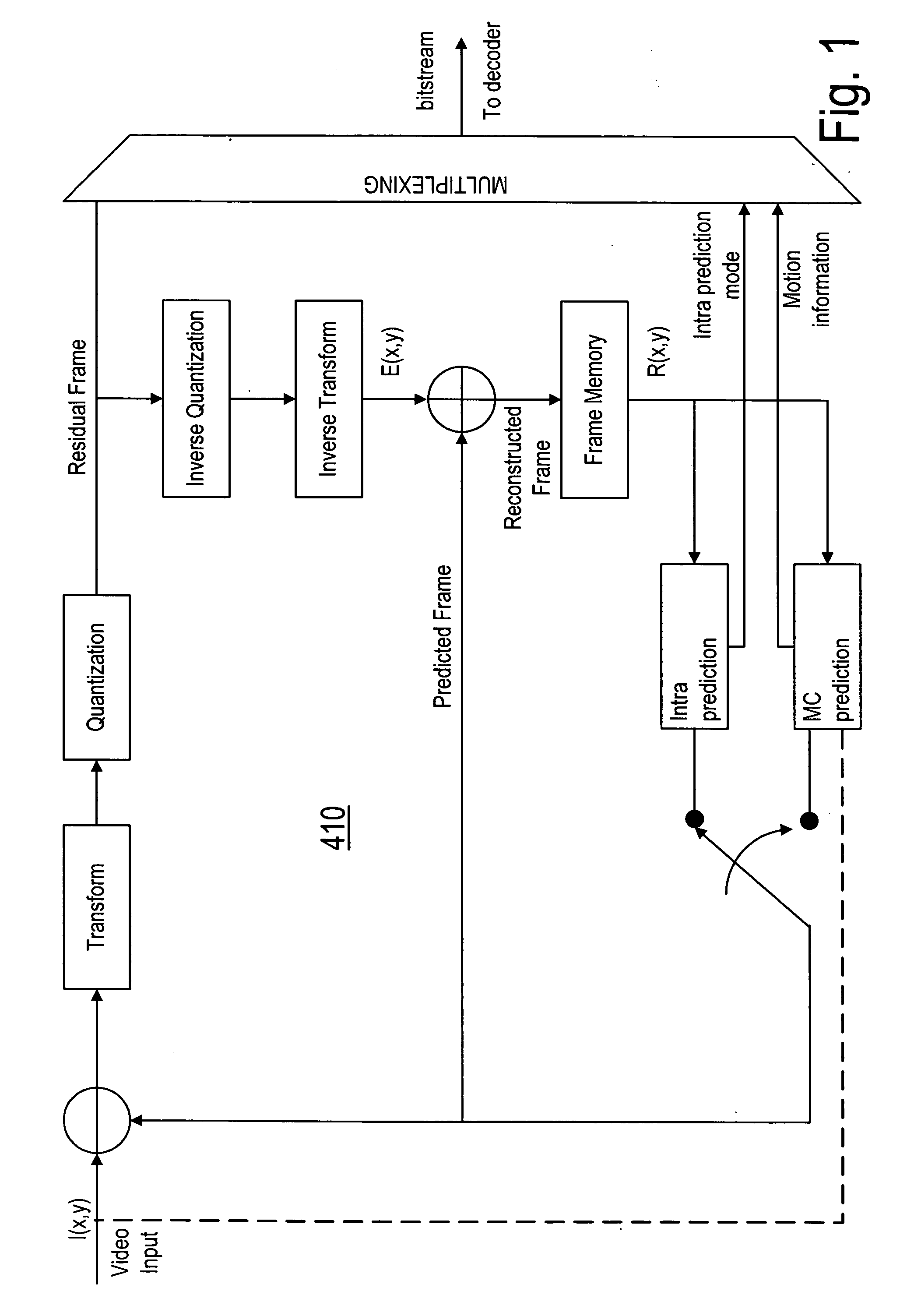

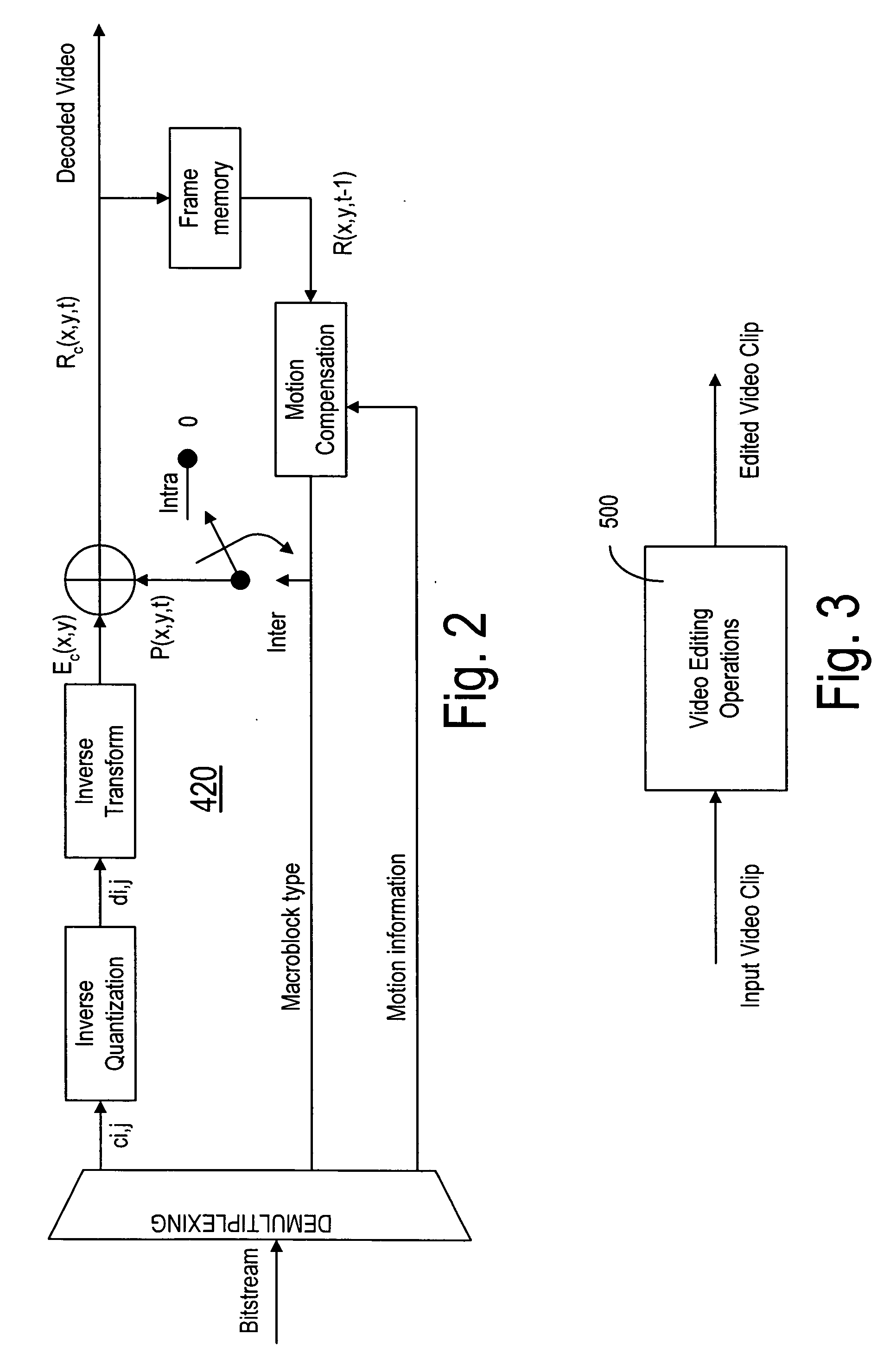

Transform-domain video editing

InactiveUS20050129111A1Meet complex requirementsSpeed up importPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningData conversionBitstream

A method and device for editing a video sequence while the sequence is in a compressed format. In order to achieve a video effect, editing data indicative of the video effect is applied to residual data from a compressed bitstream. The residual data can be residual error data, transformed residual error data, quantized transformed residual error data or coded, quantized, transformed residual error data. The video effects include fading-in to a color or to a set of colors, fading-out from a color or a set of color, or fading-in from color components in color video frames to color components in monochrome video frames. The editing operations can be multiplication or addition or both.

Owner:NOKIA CORP

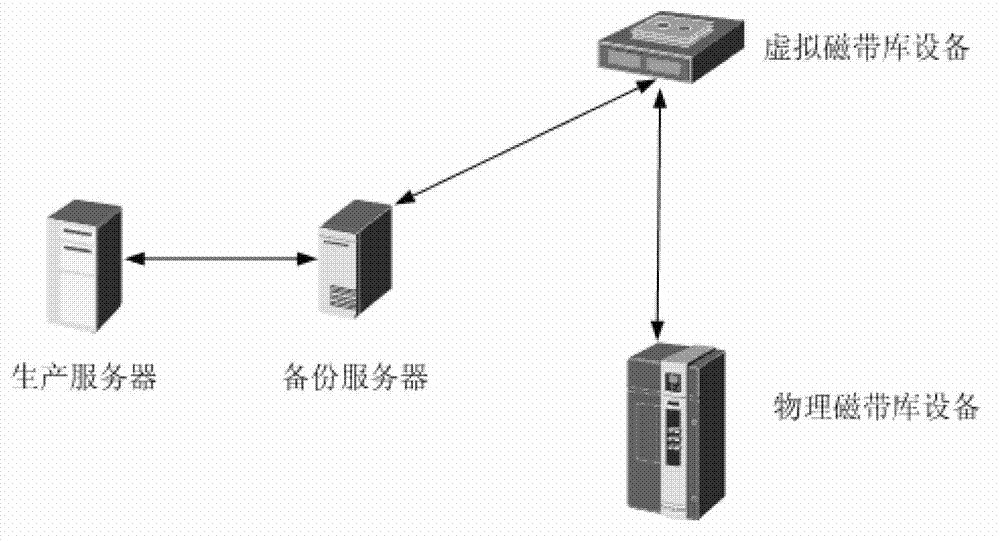

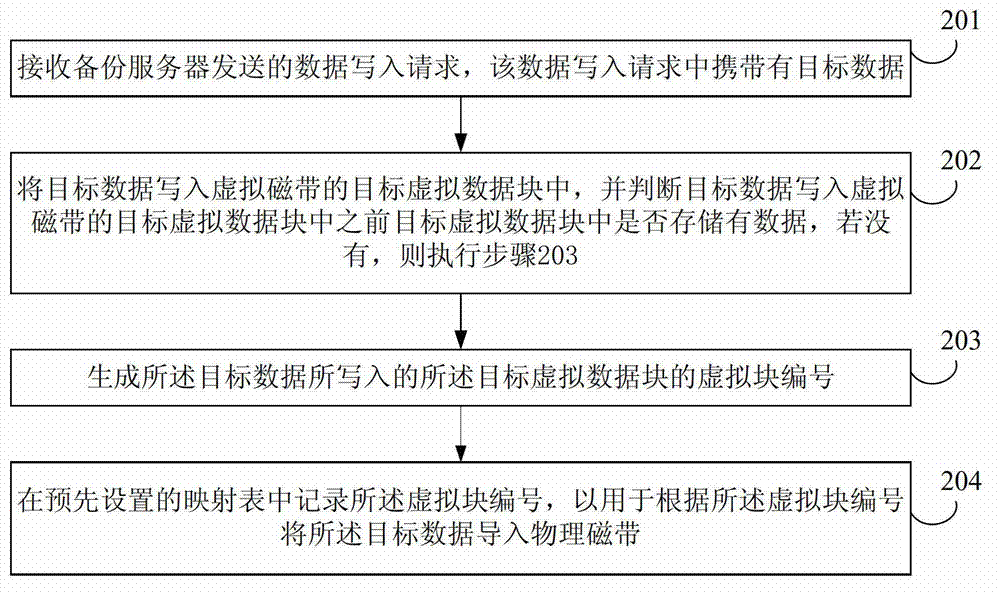

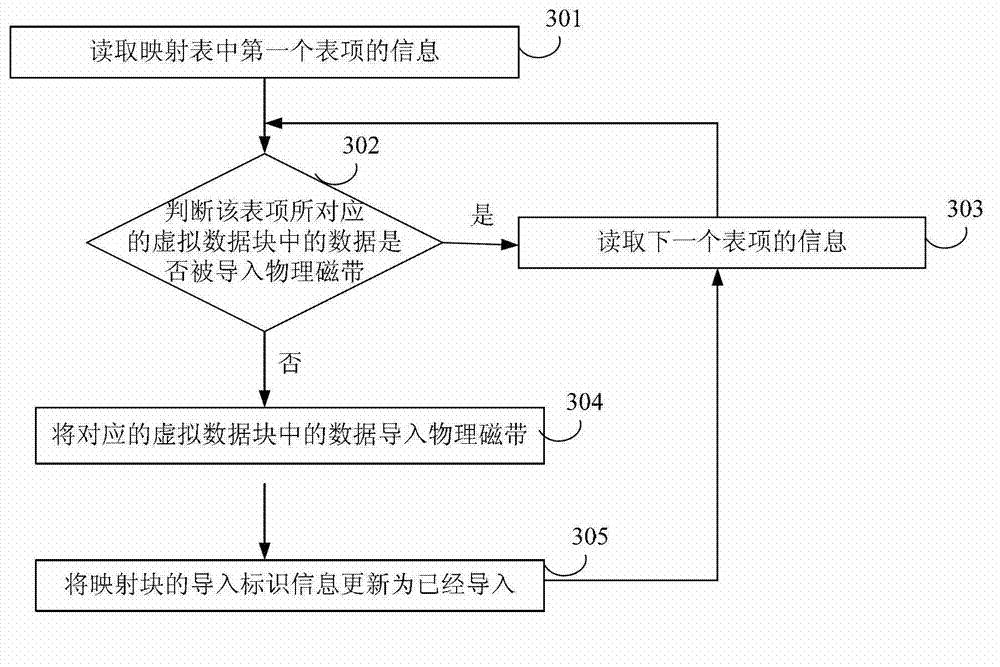

Method, device and system for importing data into physical tape

The invention relates to a method, a device and a system for importing data into a physical tape. The method includes receiving a data writing request transmitted by a backup server; writing target data into a virtual data block of a virtual tape, and judging whether data are stored in the virtual data block before the target data are written into the virtual data block of the virtual tape or not; generating a virtual block number of the virtual data block written with the target data if the data are not stored in the virtual data block before the target data are written into the virtual data block of the virtual tape; and recording the virtual block number in a preset mapping table. Accordingly, the target data can be imported into the physical tape according to the virtual block number. The data writing request carries the target data. The method, the device and the system have the advantage that the data in the virtual tape can be imported into the physical tape in a differential importing mode or an incremental importing mode according to the mapping table.

Owner:ANHUI RONGJING FENGDAN BIOTECH

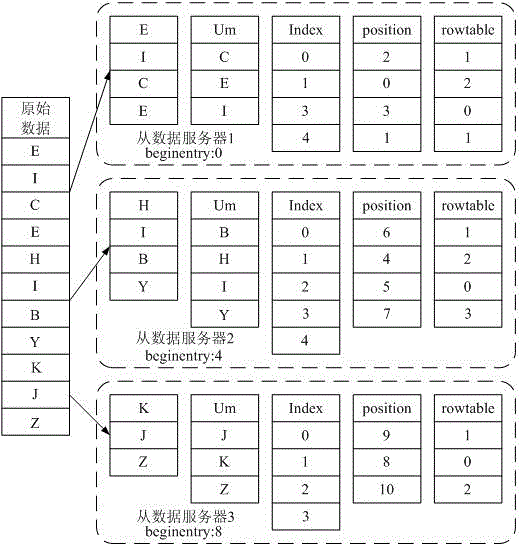

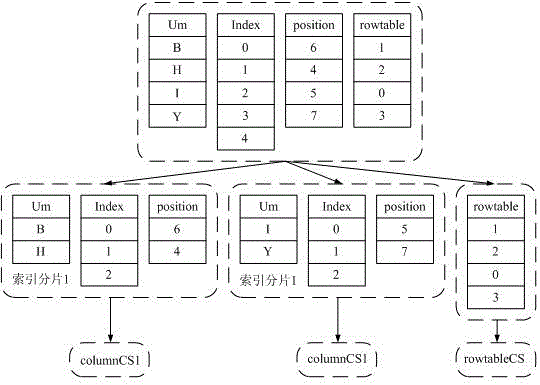

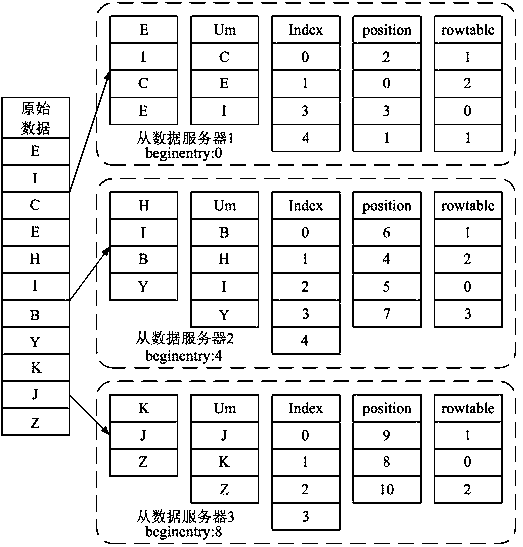

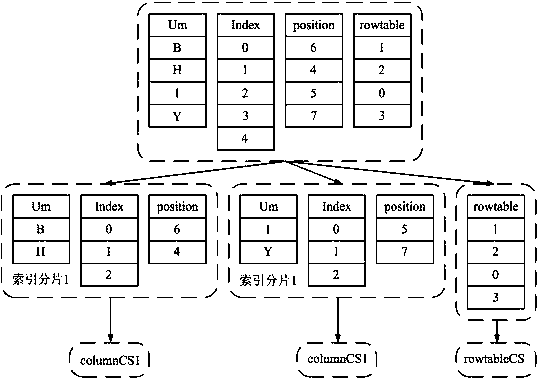

Index building method for distributed memory columnar database

ActiveCN105843933AQuick buildQuick importSpecial data processing applicationsDistributed memoryDatabase

The invention discloses an index building method for a distributed memory columnar database. The method comprises the following steps: segmenting a single column of data into at least two data fragments; computing intermediate data of columnar compression indexes of the data fragments and intermediate data of row table vectors in parallel, wherein the columnar compression indexes include dictionary vectors, index vectors and position vectors; and sequentially storing and updating the intermediate data of the columnar compression indexes of the data fragments and the intermediate data of the row table vectors in order to form the columnar compression indexes and the row table vectors. Through adoption of the index building method for the distributed memory columnar database provided by the invention, an excessively large memory is not required for import computing nodes of a huge table, so that the hardware cost can be reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

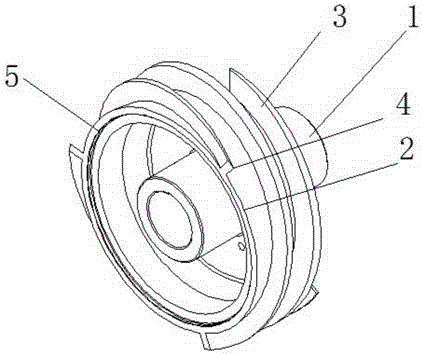

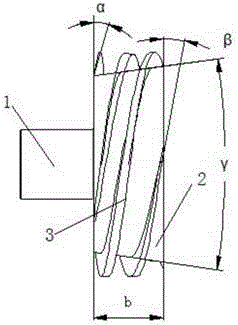

High-lift helical-blade impeller

InactiveCN104832454AIncreased capacity for media with high air contentSolve the problem of low capacity of high gas content mediaPump componentsPumpsHelical scanImpeller

The invention relates to a high-lift helical-blade impeller which comprises a pump shaft sleeve, an impeller ring and a blade. The impeller ring is arranged at the end portion of the pump shaft sleeve, and the impeller ring is provided with the blade; the blade is in a helical shape; the spiral wrap angle of the blade is 200-220 degrees; the entrance installation angel of the blade is 10-12 degrees; the exit installation angel of the blade is 14-18 degrees; the impeller ring is of a cone shape; the cone angle of the impeller ring is 6-10 degrees; the width of the impeller ring is 40-52 mm; and the impeller ring is uniformly provided with a plurality of keyholes. The high-lift helical-blade impeller improves delivery capacity of a pump in transmitting a high gas content medium.

Owner:江苏永一泵业科技集团有限公司

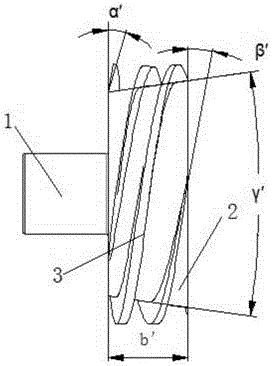

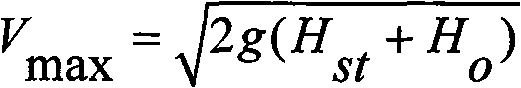

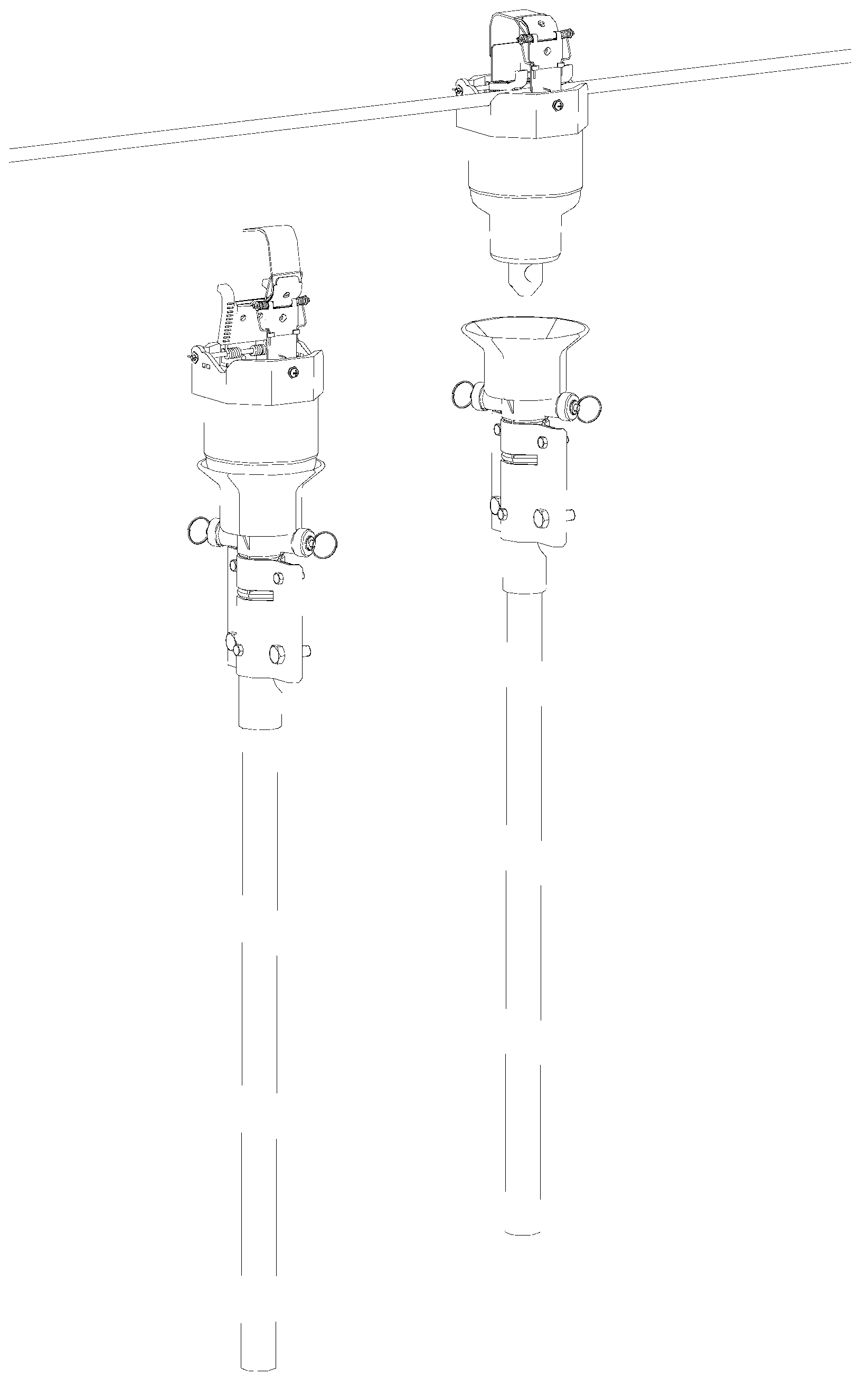

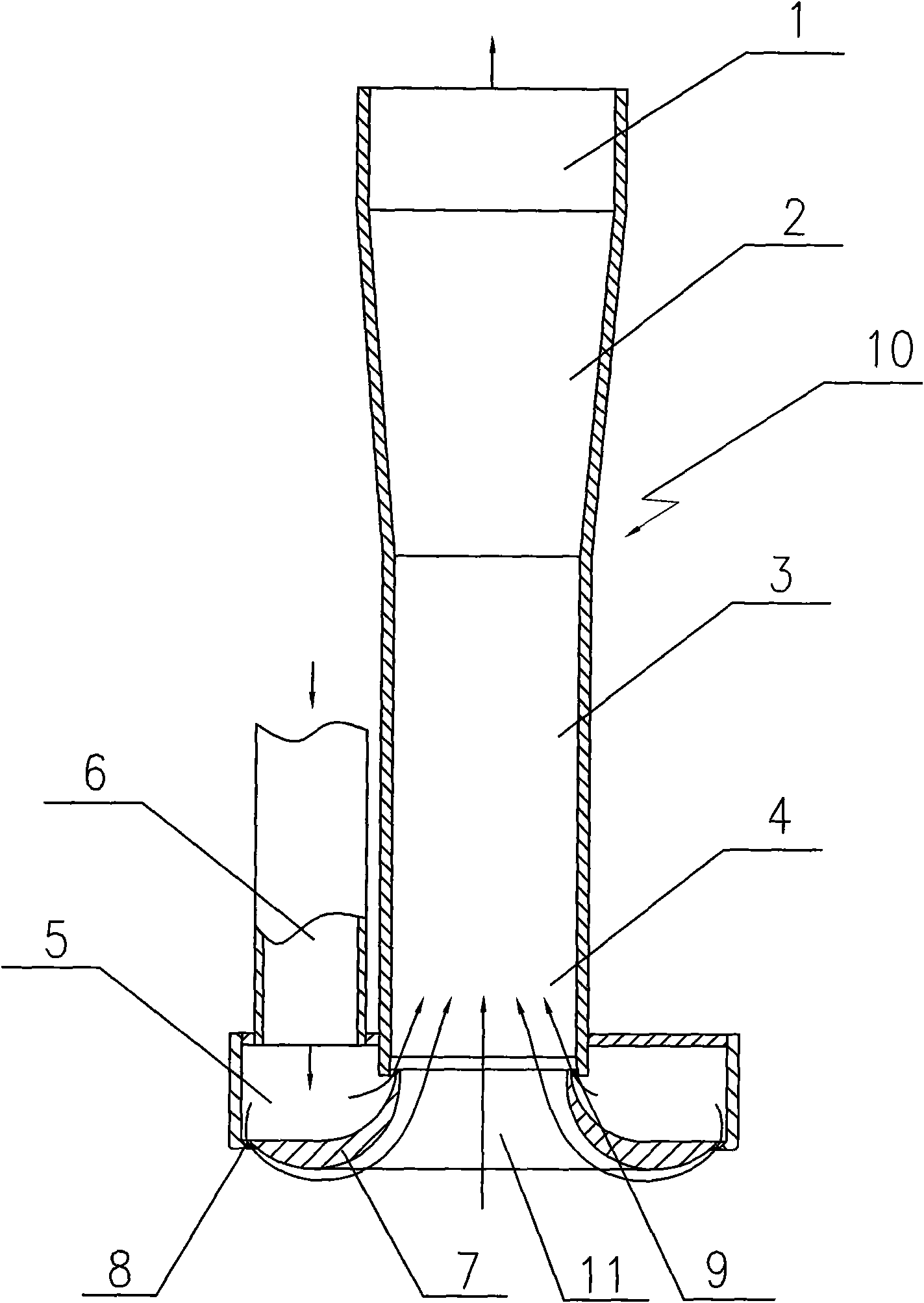

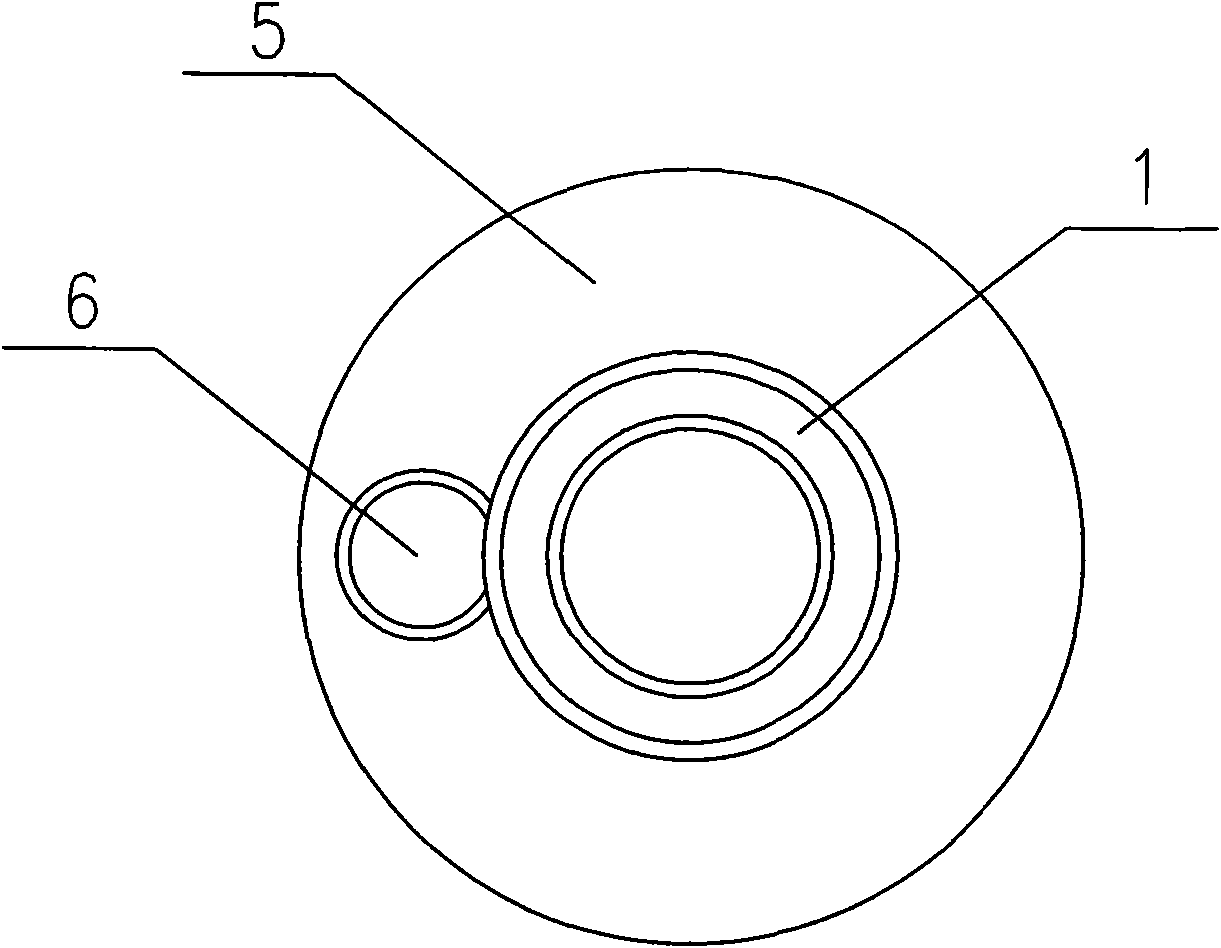

Ecological dredging jet pump

InactiveCN101571148AImprove driving pressure and mud suction capacityImprove mixing efficiencyJet pumpsMachines/enginesCoal dustHigh pressure

The invention discloses an ecological dredging jet pump, which comprises a jet water inlet pipe, a high-pressure distribution cavity and a silt outlet pipe which are connected in turn. Jet water is jetted into the outlet pipe through a primary jet spout and a secondary jet spout in the high-pressure distribution cavity, wherein the primary jet spout directly jets the jet water into the outlet pipe; and the secondary jet spout introduces the jet water into the outlet pipe through a streamline inlet. The ecological dredging jet pump utilizes the hydrodynamics Coanda effect to realize high speed flow, can avoid secondary pollution caused by using rotating components, and can be widely applied to ecological dredging and environment-friendly dredging of river courses, lakes and the like, and absorption of coal dust on the mine bottom of a coal mine.

Owner:中国船舶重工集团公司第七〇二研究所

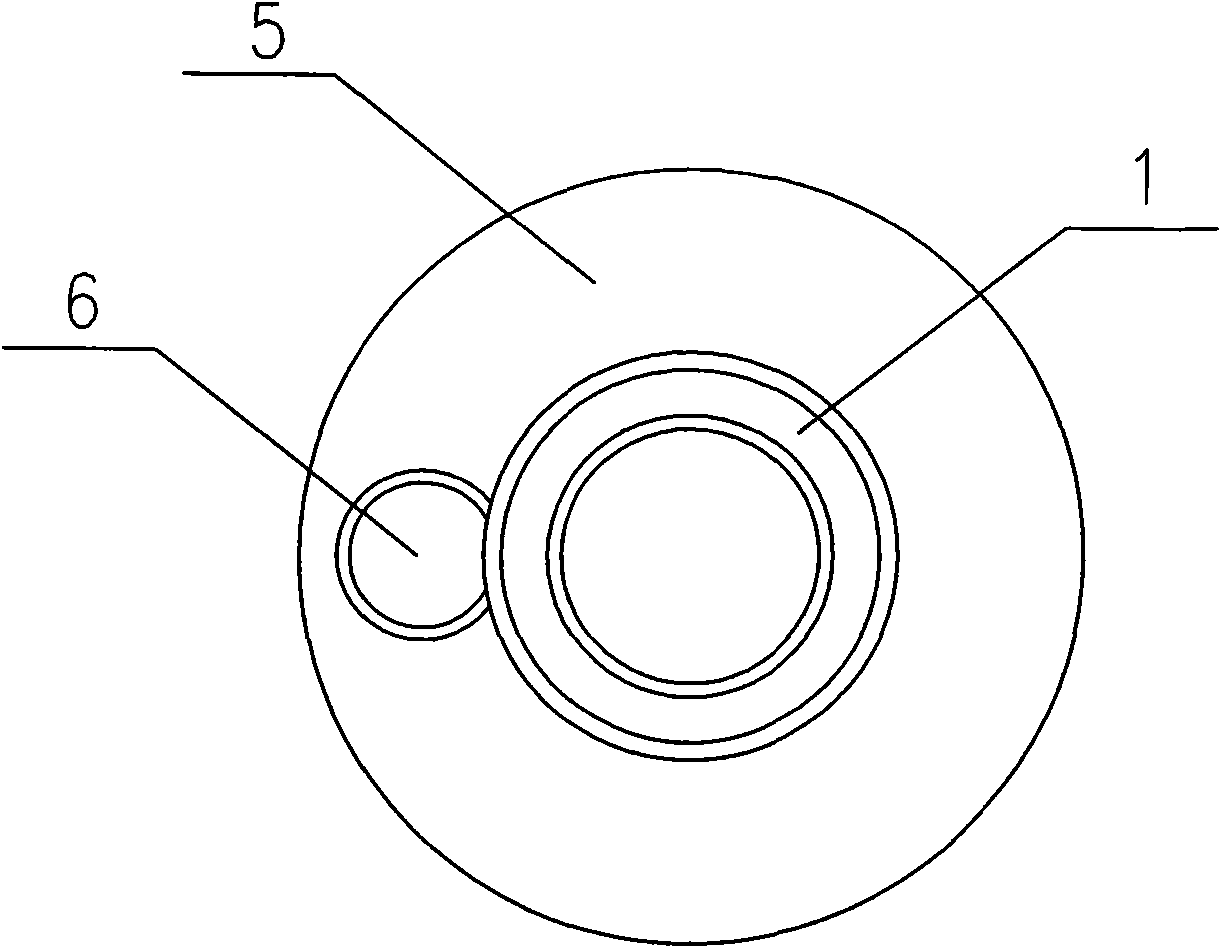

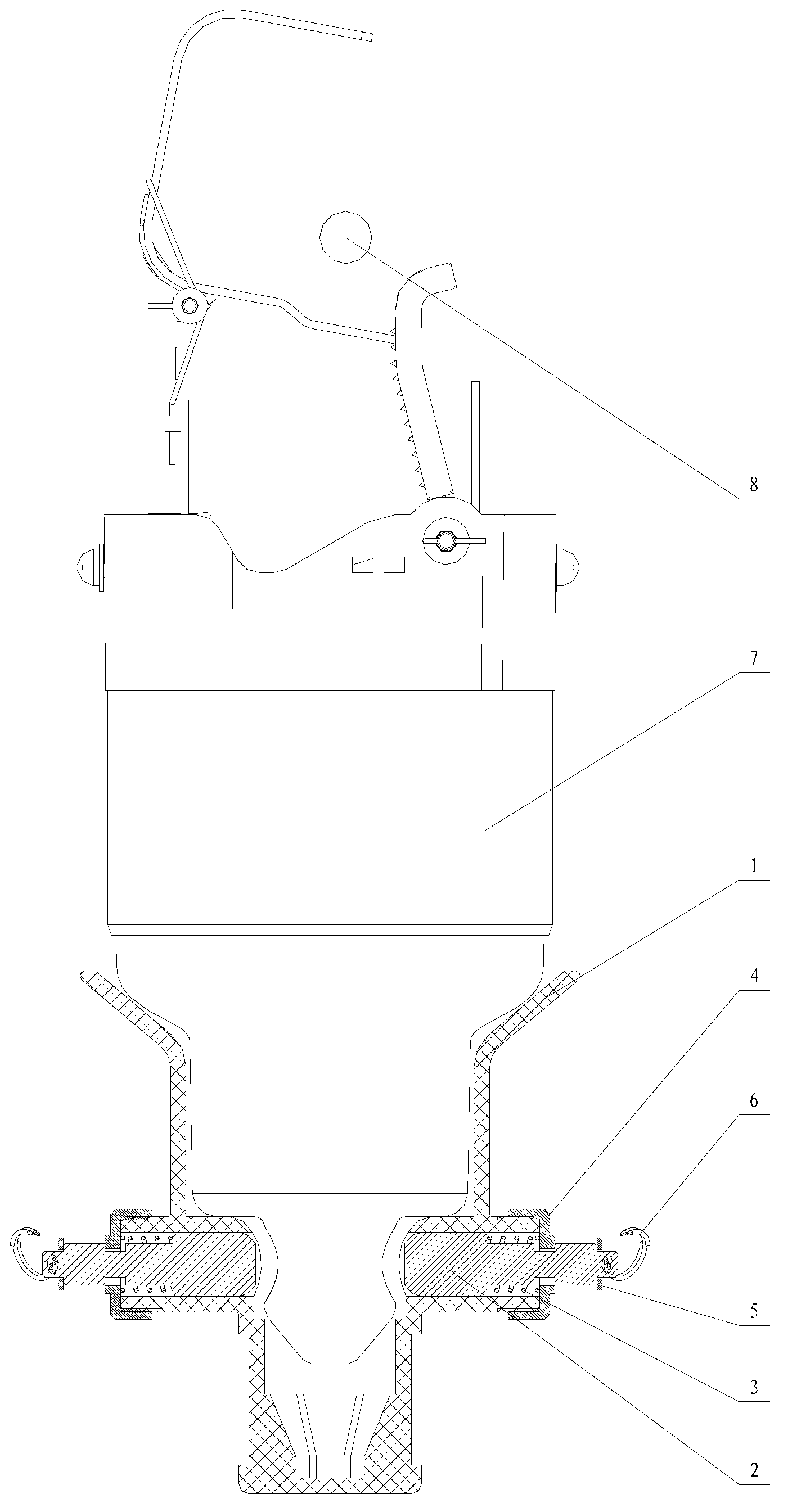

Assembling and disassembling tool of electric power fault indicator

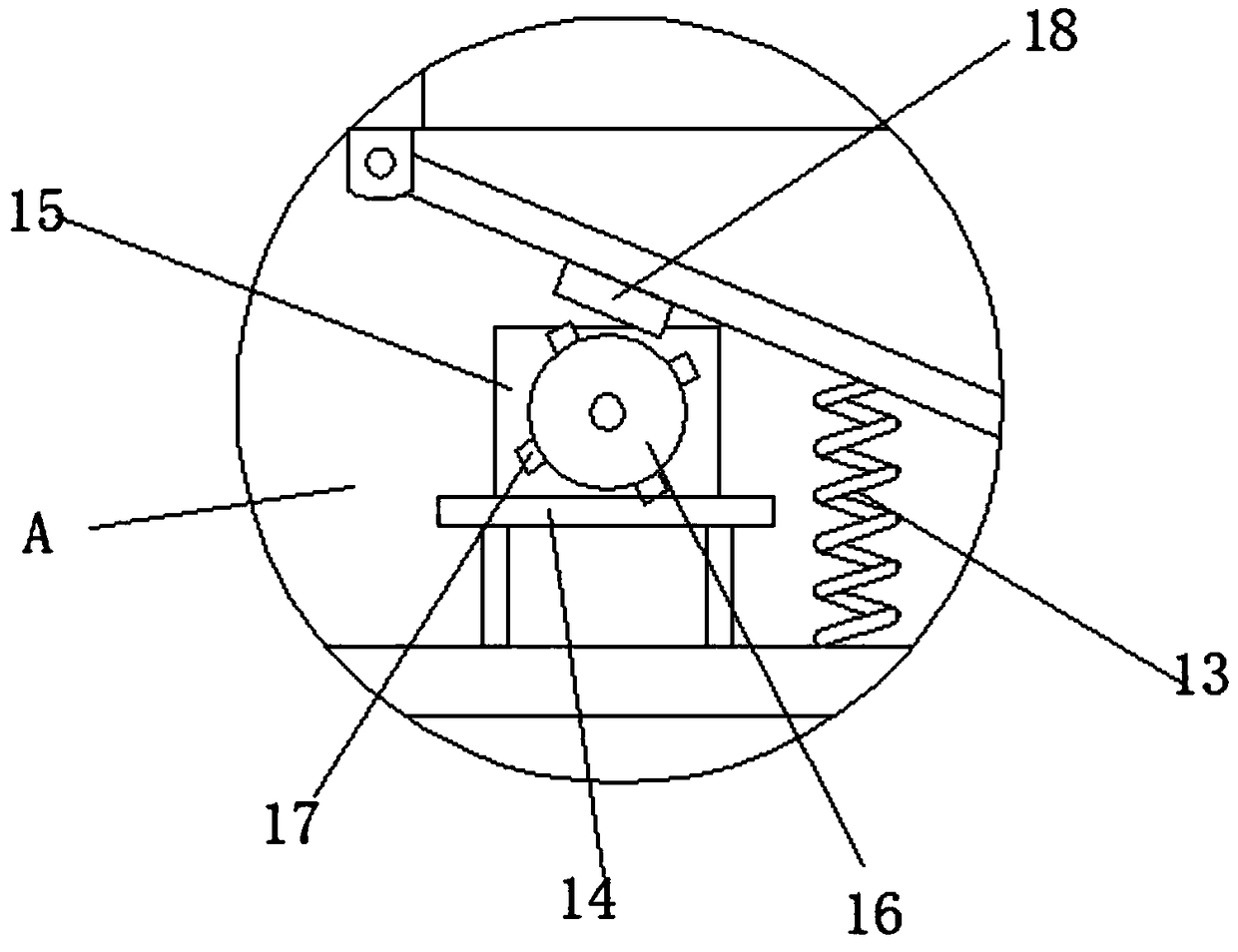

ActiveCN103259220AImprove efficiencyEven by forceApparatus for overhead lines/cablesHollow cylinderEngineering

The invention discloses an assembling and disassembling tool of an electric power fault indicator. The assembling and disassembling tool of the electric power fault indicator comprises a shell body, cylindrical pins, covers and springs. The upper portion of the shell body is of a hollow cylinder structure with a horn-shaped opening, and the lower portion of the shell body is provided with a cylindrical groove, wherein the diameter of the cross section of the cylindrical groove is smaller than the diameter of the cross section of the upper portion. The left side and the right side at the upper end of the cylindrical groove at the lower portion of the shell body are respectively provided with a cylinder pipeline. An open pore formed in the cylindrical groove is formed at one end of each cylinder pipeline, and a cover with an opening is arranged at the other end of each cylinder pipeline. The cylindrical pins are in the shape of a step-shaped cylinder, and are arranged in the cylinder pipelines arranged at the left side and the right side respectively. One end, with the largest diameter, of each cylindrical pin is capable of penetrating through the open pore formed in the cylindrical groove, and the other end of each cylindrical pin penetrates through the opening of each cover. A spring is arranged between one end, with the largest diameter, of each cylindrical pin and each cover. Opening grooves are formed in the cylindrical pins to be matched with the covers to carry out clamping and fixing. Assembling operation and disassembling operation can be carried out on the fault indicator conveniently, and the assembling and disassembling tool of the electric power fault indicator has the advantages of being convenient to assemble and use, balanced in stress, good in stability, attractive in appearance and the like.

Owner:BEIJING SIFANG JIBAO AUTOMATION +1

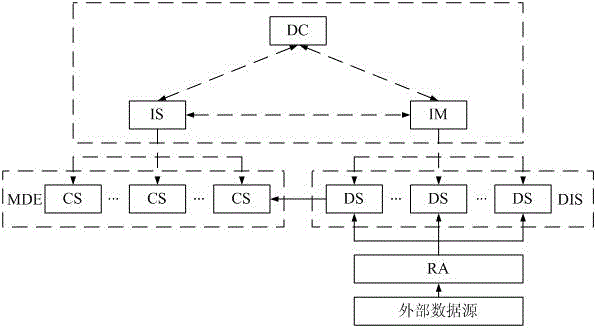

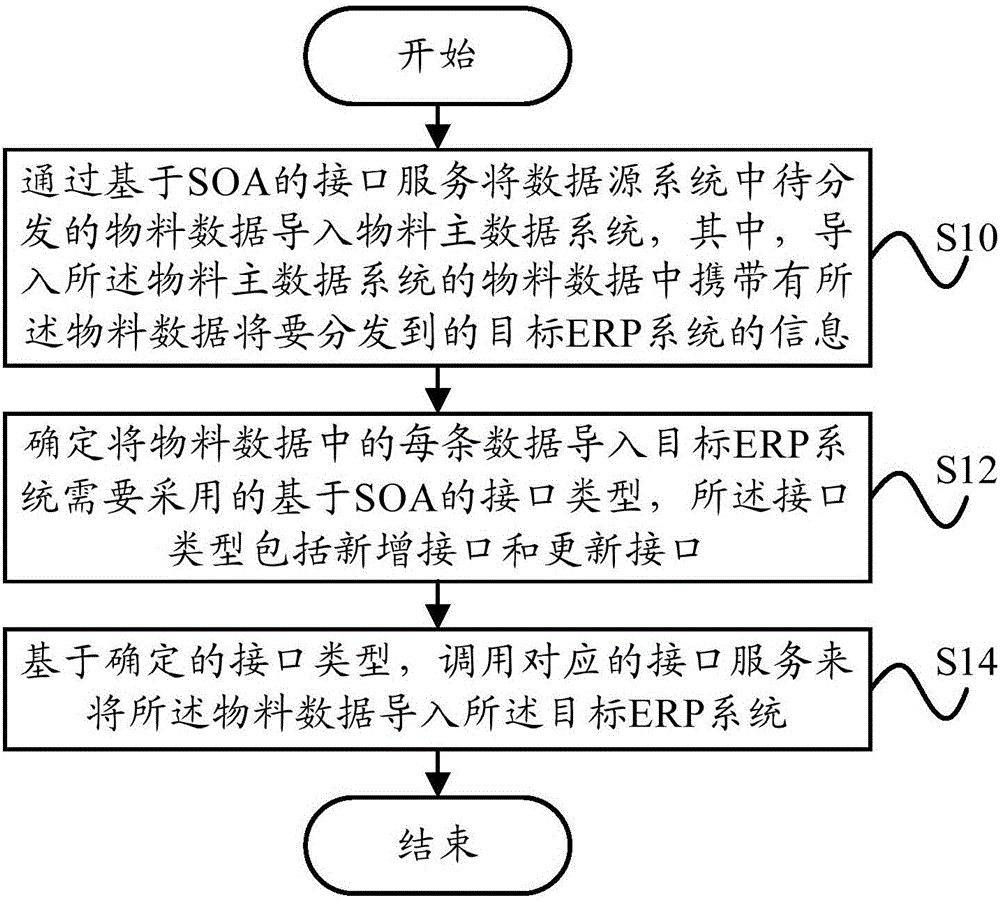

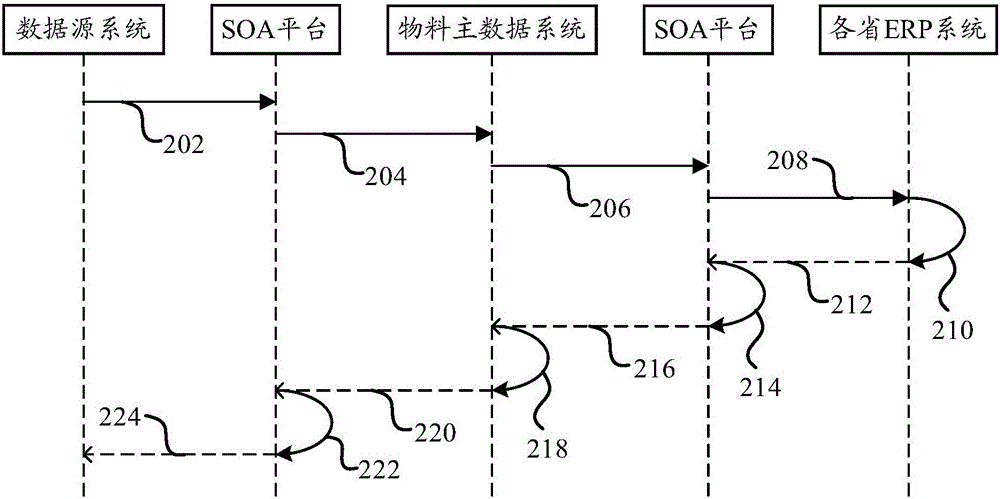

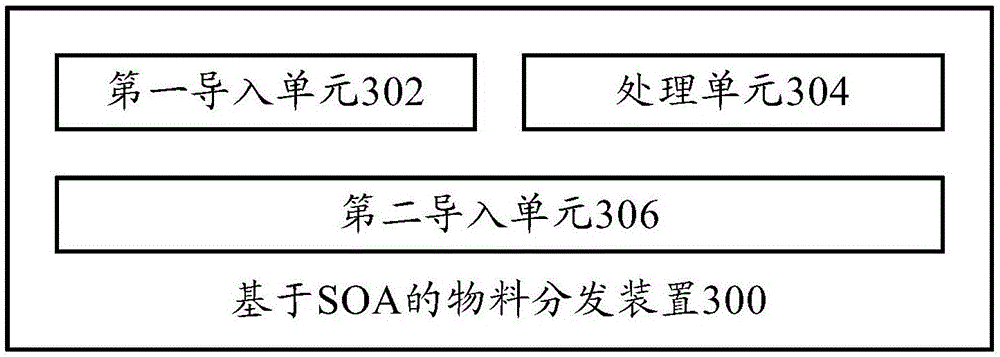

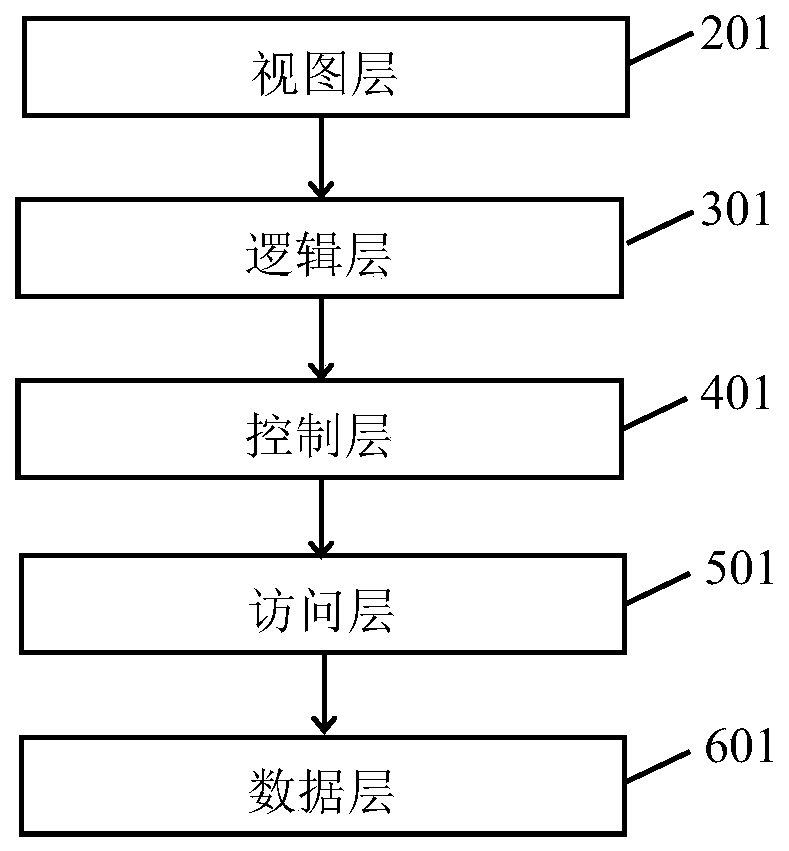

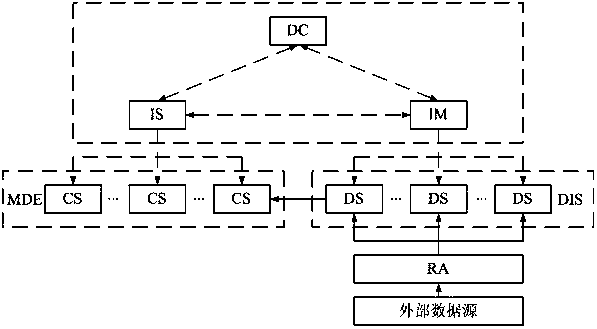

Service-oriented architecture (SOA)-based material distribution method and material distribution apparatus

InactiveCN106484778AQuick importDistribute quicklyDatabase updatingDatabase management systemsData sourceService-oriented architecture

The present invention provides a service-oriented architecture (SOA)-based material distribution method and material distribution apparatus. The SOA material distribution method comprises the steps of importing to-be-distributed material data in a data source system into a material master data system by using an SOA-based interface service, wherein the material data imported into the material master data system carries information of a target ERP system to which the material data is to distributed; determining types of the SOA-based interfaces to be used for importing each piece of data in the material data into the target ERP system, wherein the interfaces fall into new interfaces and upgraded interfaces; and invoking, based on the determined interface type, a corresponding interface service to import the material data into the target ERP system. Through adoption of the SOA-based material distribution method and material distribution apparatus, the material data can be rapidly imported and distributed, the importing and distributing rates of the material data are improved effectively, and a probability of wrong importing is lowered.

Owner:ZICT TECH CO LTD

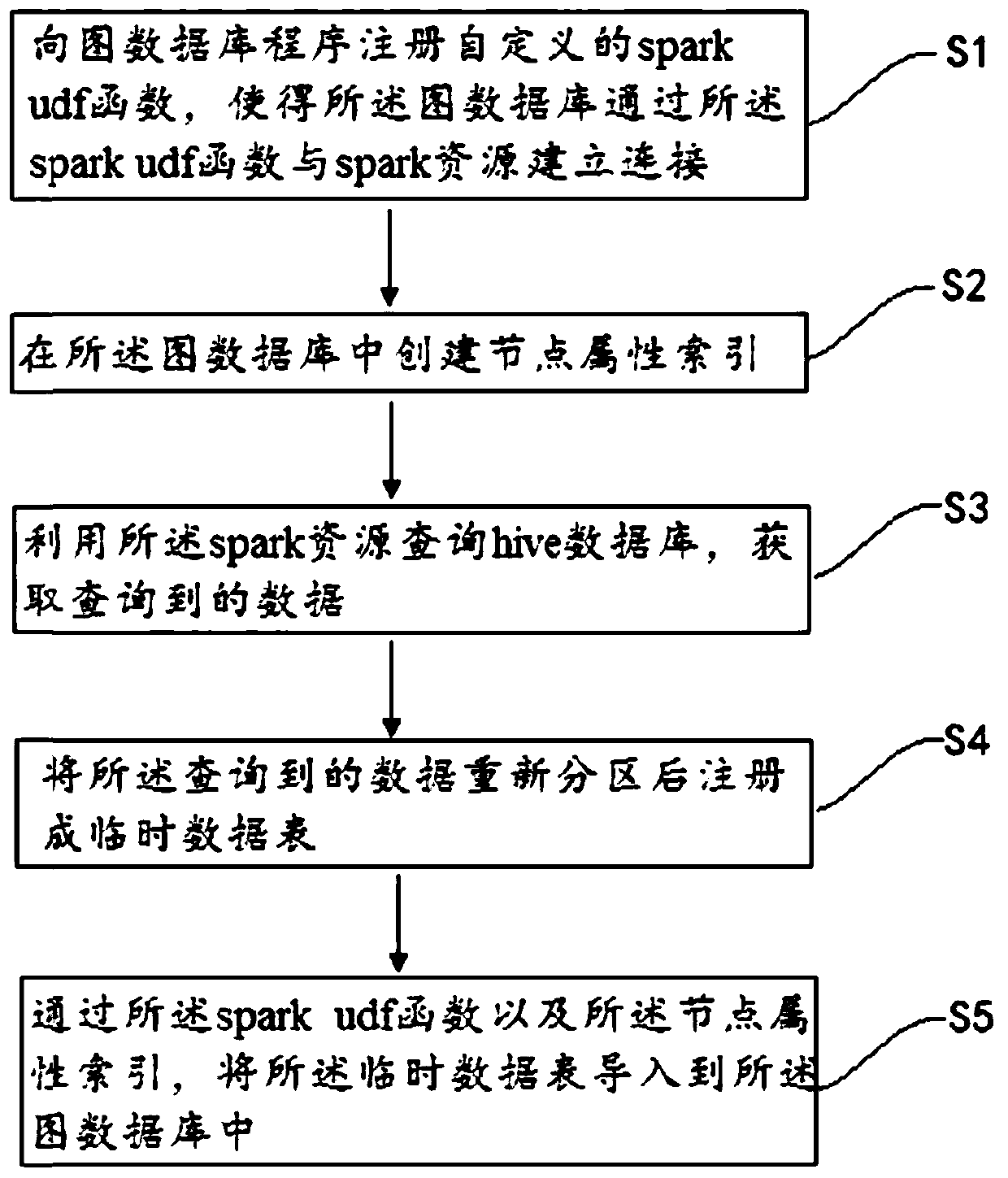

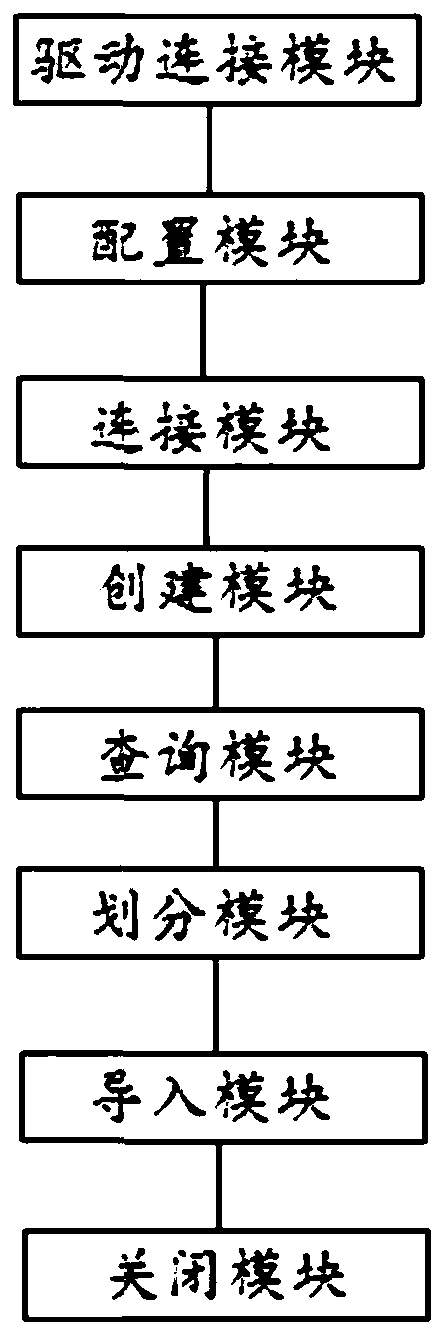

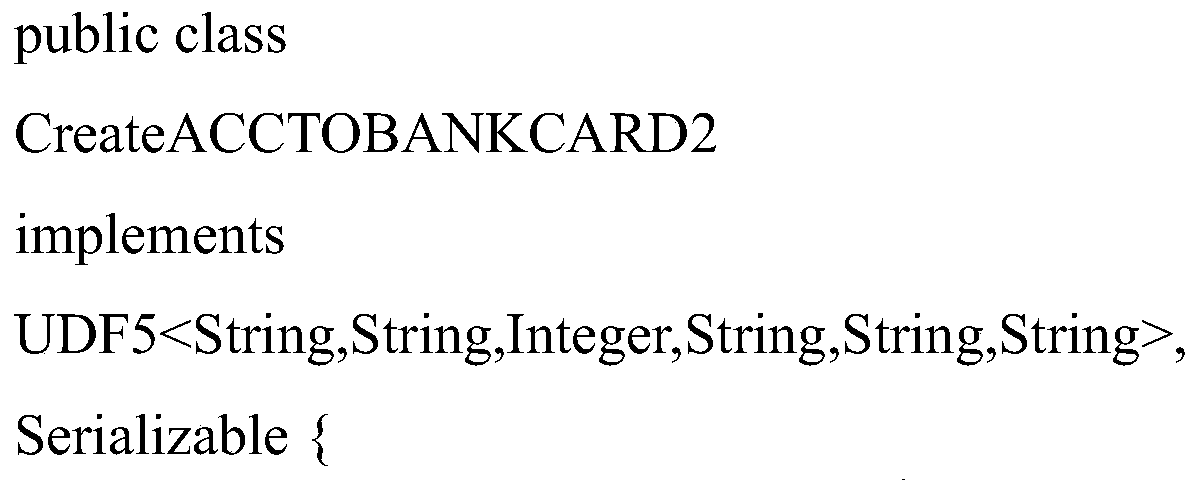

Data importing method and device for graph database

ActiveCN110110108AImport real timeAdjust the import speedStill image data indexingStill image data queryingTable (database)Datasheet

The invention discloses a data importing method and device for a graph database, and the method comprises the steps: registering a self-defined Spark udf function in a graph database program, and enabling the graph database to be connected with a Spark resource through the Spark udf function; creating a node attribute index in the graph database; inquiring a hive database by utilizing the spark resources to obtain inquired data; re-partitioning the queried data, and registering the re-partitioned data as a temporary data table; and importing the temporary data table into the graph database through the Spark udf function and the node attribute index. According to the method, the spark is combined with the graph database, real-time data import can be realized, the data does not need to be exported into a csv format. The Spark performance can be conveniently adjusted and the data import speed can be conveniently adjusted by utilizing the Spark technology, and by utilizing the concurrencycharacteristic of the Spark, the data import can be accelerated, and meanwhile, data loss is avoided.

Owner:南京星云数字技术有限公司

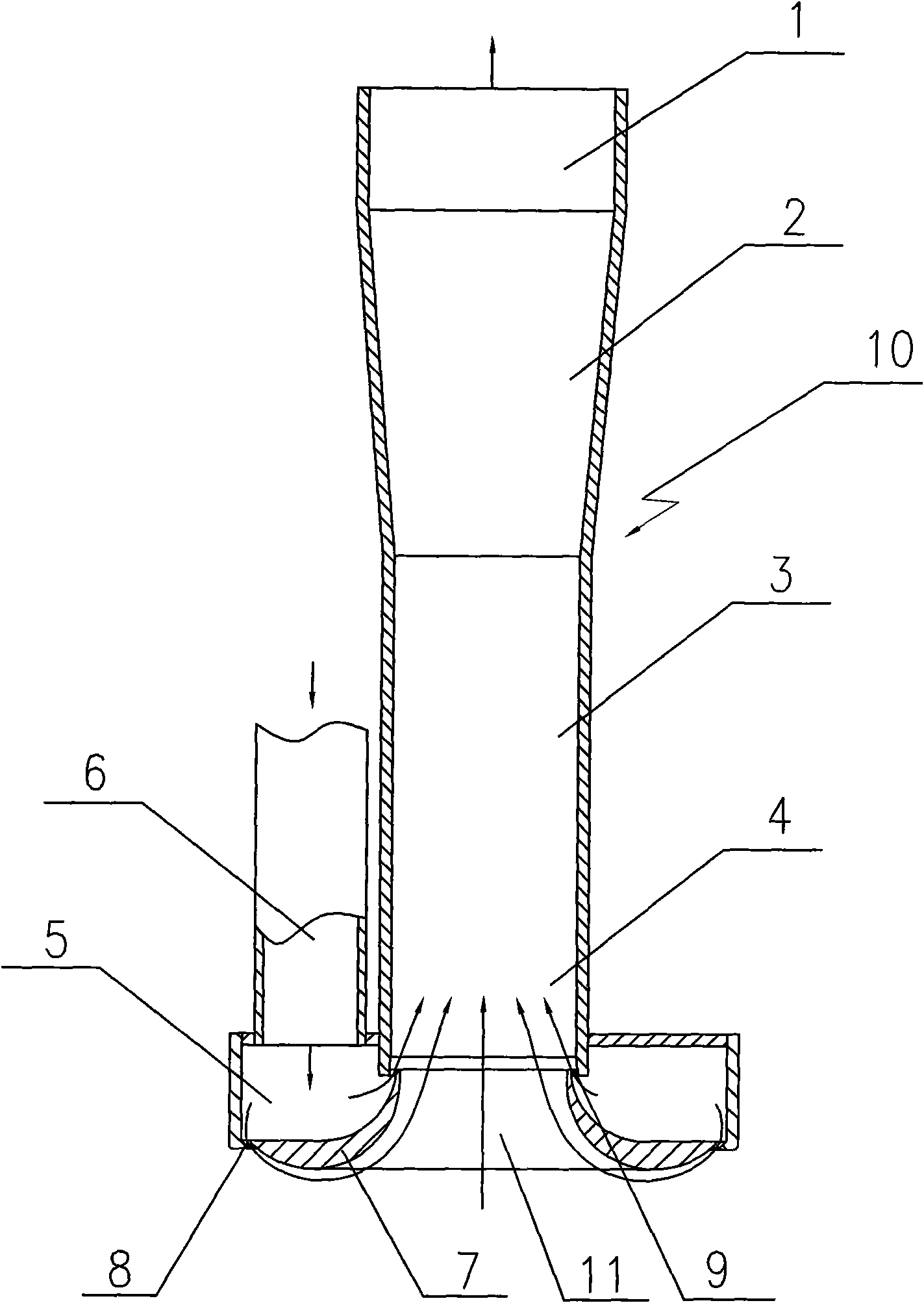

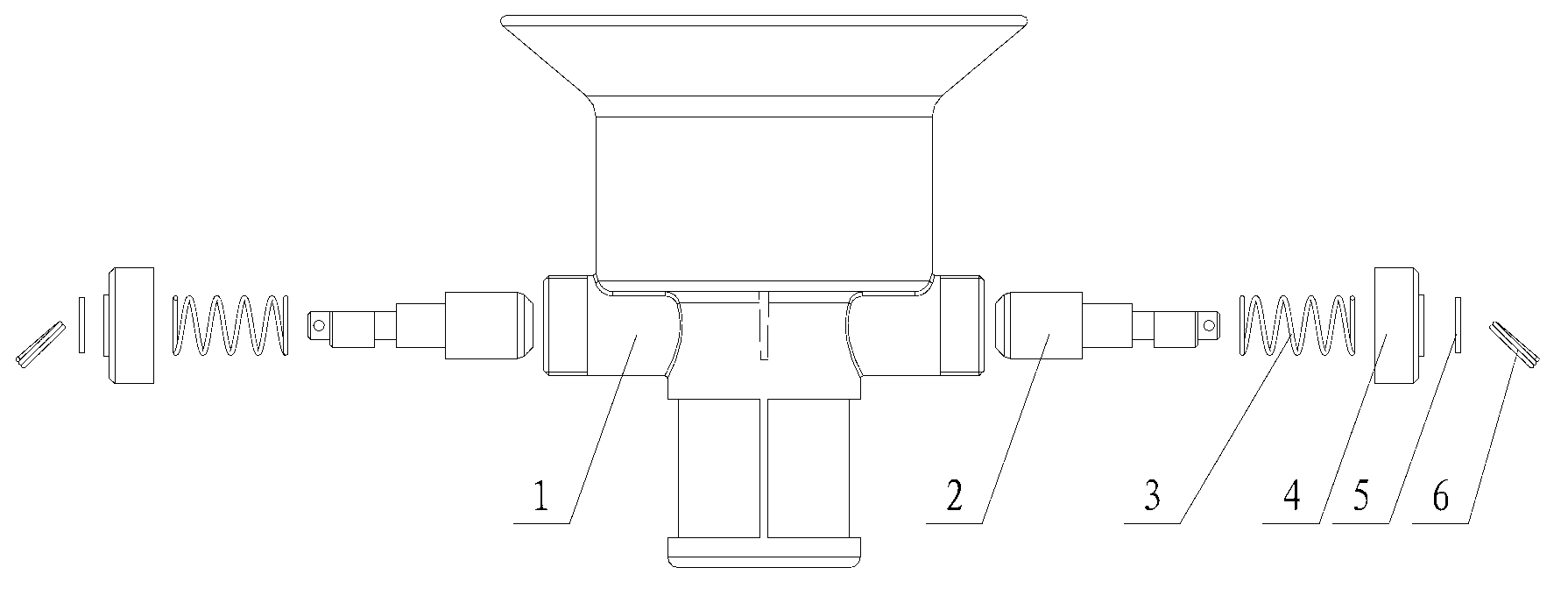

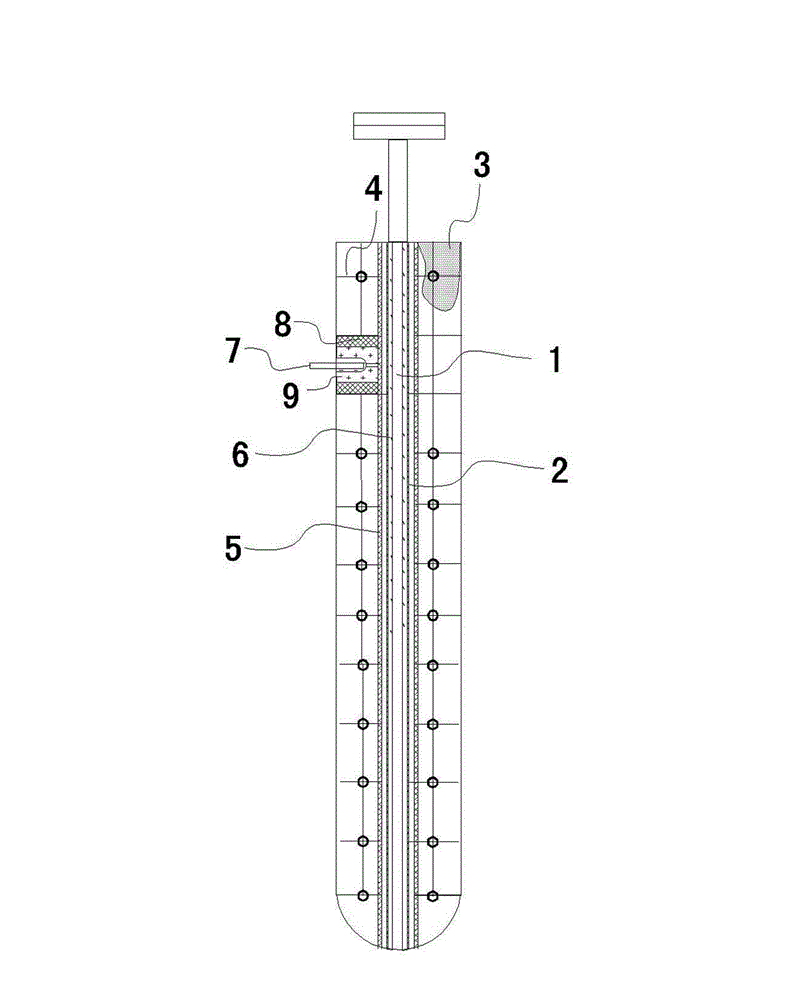

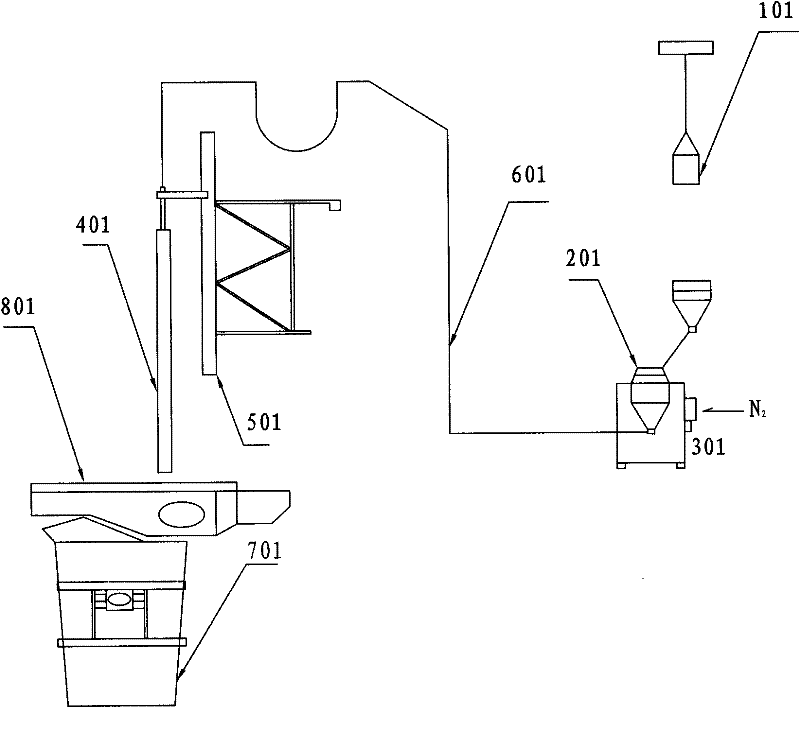

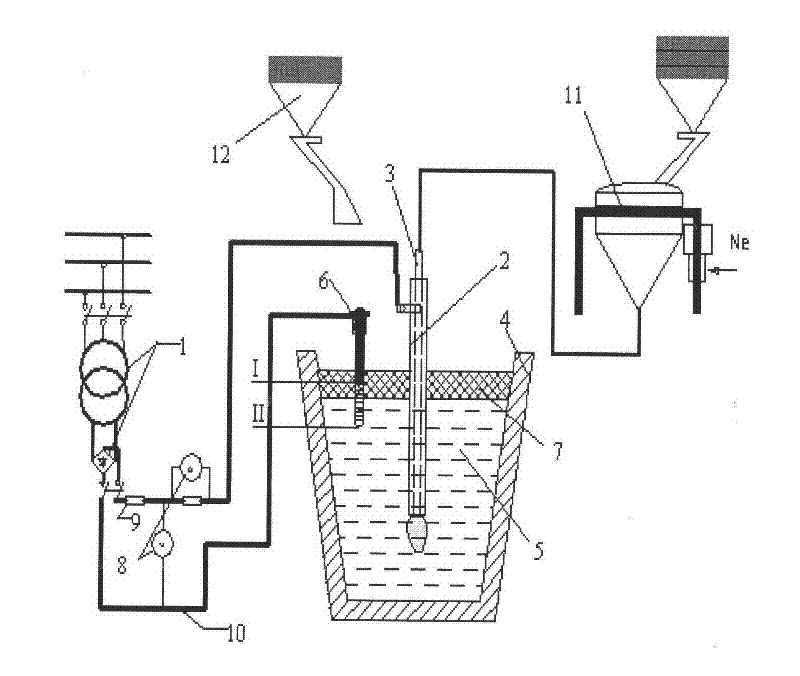

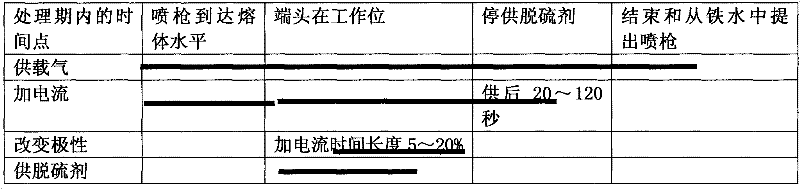

Desulfuration spray gun for molten iron refining

InactiveCN102978341AAchieve swirl effectImprove desulfurization efficiencyManufacturing engineeringIndustrial engineering

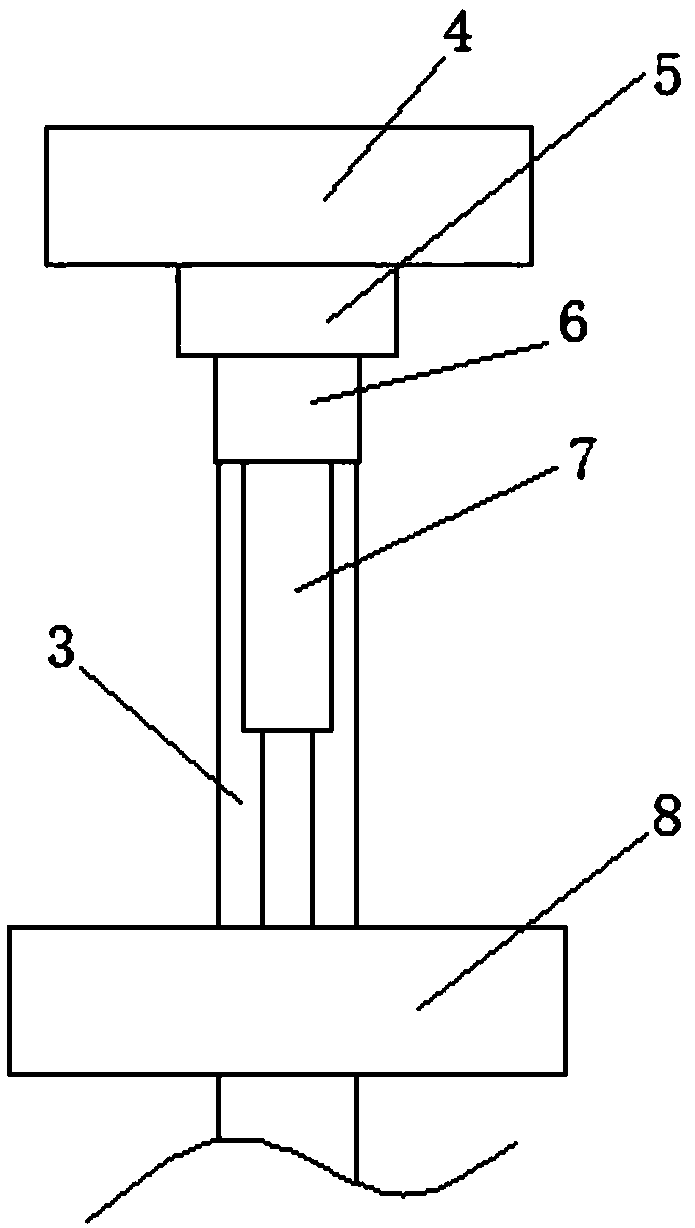

The invention belongs to the field of molten iron desulfuration equipment, and in particular relates to a desulfuration spray gun for molten iron refining. The desulfuration spray gun comprises a central spray pipe (1), an air cooling cyclone agitating pipe (2), a refractory material layer (3), a protection pipe (5) and a framework (4); the refractory material layer (3) is matched with the outer part of the air cooling cyclone agitating pipe (2); the central spray pipe (1) is arranged in the air cooling cyclone agitating pipe (2); the air cooling cyclone agitating pipe (2) is sleeved in the protection pipe (5); the framework (4) is positioned in the refractory material layer (3) and is fixedly connected with the outer wall of the protection pipe (5); a vortex sheet (6) is fixedly arranged on the outer wall of the central spray pipe (1); a power supply wiring port component (7) is fixedly arranged on the upper part of the protection pipe (5); and a signal port of the power supply wiring port component (7) is connected with the protection pipe (5). By the desulfuration spray gun, the utilization rate of a desulfurizing agent which is directly used for removing sulfur can be increased, heat loss is reduced, melt splashing during a molten iron desulfuration process can be effectively reduced, and the desulfuration efficiency is high.

Owner:YINGKOU DSMK TECH DEV

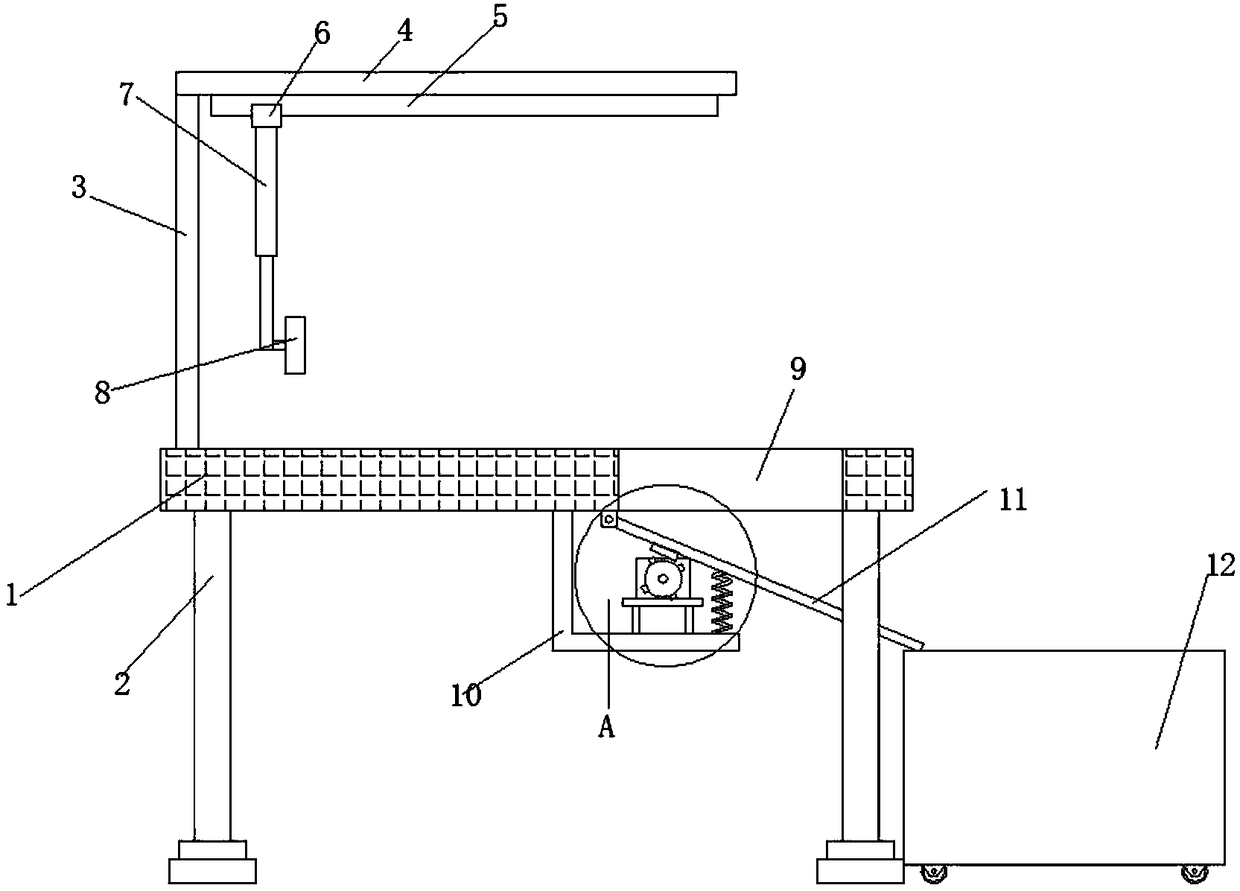

Mechanical arm accessory machining waste collecting device

The invention discloses a mechanical arm accessory machining waste collecting device. The mechanical arm accessory machining waste collecting device comprises a machining platform. Four supporting columns are arranged at the bottom of the machining platform. A stand column is vertically welded to one side of the upper portion of the machining platform. A beam is horizontally arranged on the top ofthe stand column. An electric guide rail is fixed to the bottom of the beam in the length direction through screws and provided with a sliding block. A telescopic air cylinder is fixed to the bottomof the sliding block. A pushing plate is fixed to a push rod of the telescopic air cylinder. A discharging port is formed in one side of the machining platform. A fixing support is welded to the bottom of the machining platform, and one end of the discharging port in the bottom of the machining platform is connected with an unloading guide plate. By means of the mechanical arm accessory machiningwaste collecting device, waste on the mechanical arm machining platform can be rapidly and conveniently removed, the tidiness of the machining platform is kept, and accordingly, the mechanical arm accessory machining quality is improved; and the waste can be rapidly guided into a waste box, the waste is prevented from being stacked and blocked at the discharging port, and the waste recycling efficiency is improved.

Owner:JINGDE COUNTY HANHAI NEBULA INTELLIGENTIZE TECH RES & DEV CO LTD

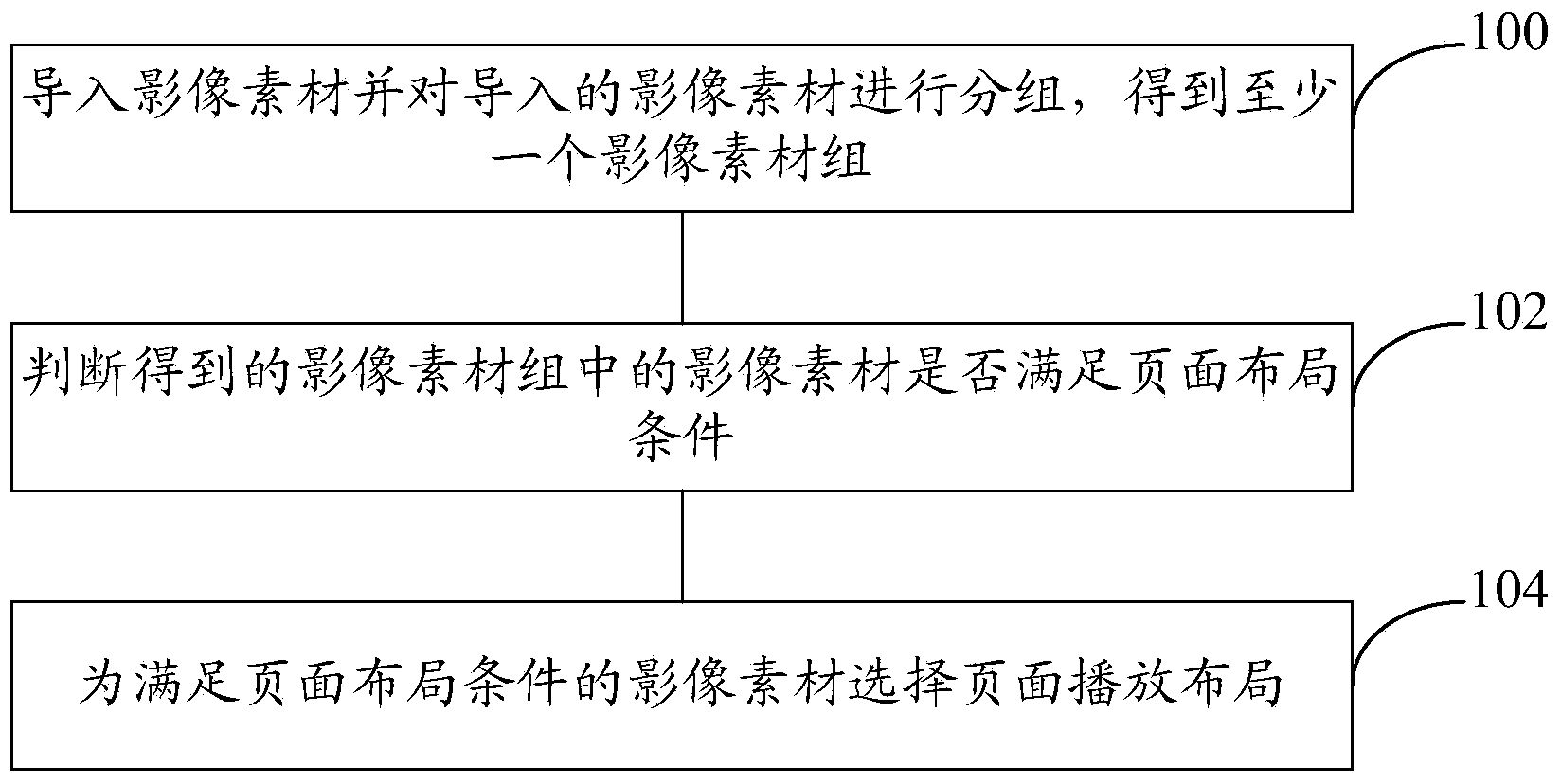

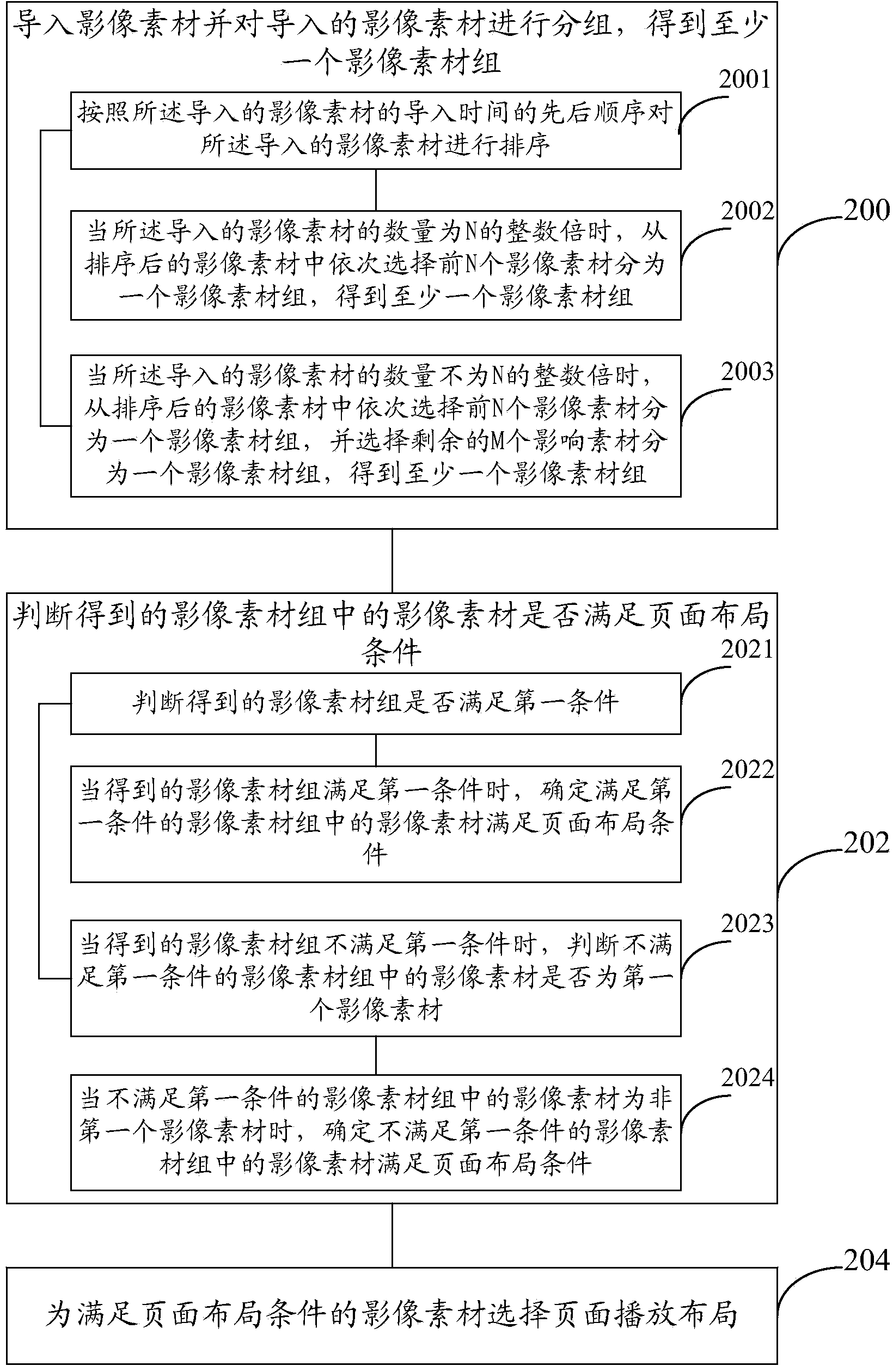

Editing method and system of image materials

ActiveCN103455474AAdd supportIncrease playback speedSpecial data processing applicationsComputer graphics (images)

The embodiment of the invention provides an editing method and an editing system of image materials, which are used for solving the problems that the existing editing method of the image materials only supports importing of pictures, and each frame only displays one picture when video is played to cause long playing time of the video. The method comprises the following steps of: importing the image materials, and grouping the imported image materials to obtain at least one image material group; the image materials comprise pictures and / or videos; judging whether the image materials in the obtained image material group meet the page layout condition, and selecting page playing layout for the image materials meeting the page layout condition, wherein the page playing layout comprises the quantity of the image materials played by each frame and a picture displaying structure of the image materials played by each frame; each frame comprises at least one image material. The editing method and system provided by the embodiment of the invention have the advantages that the limitation on the types of files of imported image materials are removed, so that the playing speed of the image materials is increased.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

A power lithium battery temperature equalization heat dissipation system composed of graphene thermal conductive film

The invention relates to the technical field of heat dissipation of electric vehicle batteries, in particular to a power lithium battery uniform temperature heat dissipation system composed of a graphene heat conduction film. It includes a lithium battery body and a copper-based graphene nano-chip composite heat-conducting film coated on the lithium-ion battery body. The copper-based graphene nano-chip composite heat-conducting film includes a copper foil base layer and a graphene nano-chip in turn from the inside to the outside. Thermal conduction layer; according to parts by mass, the graphene nanoplatelet heat conduction layer uses copper naphthenate and edge graphene oxide nanoplatelets as the main components of the graphene nanoplatelet heat conduction layer, through the edge graphene oxide nanoplatelet The conjugation between the aromatic layer and copper naphthenate constructs a graphene oxide-copper matrix composite material with a three-dimensional porous structure, which effectively improves the heat dissipation performance through the porous structure.

Owner:ZHEJIANG LUYUAN ELECTRIC VEHICLE +1

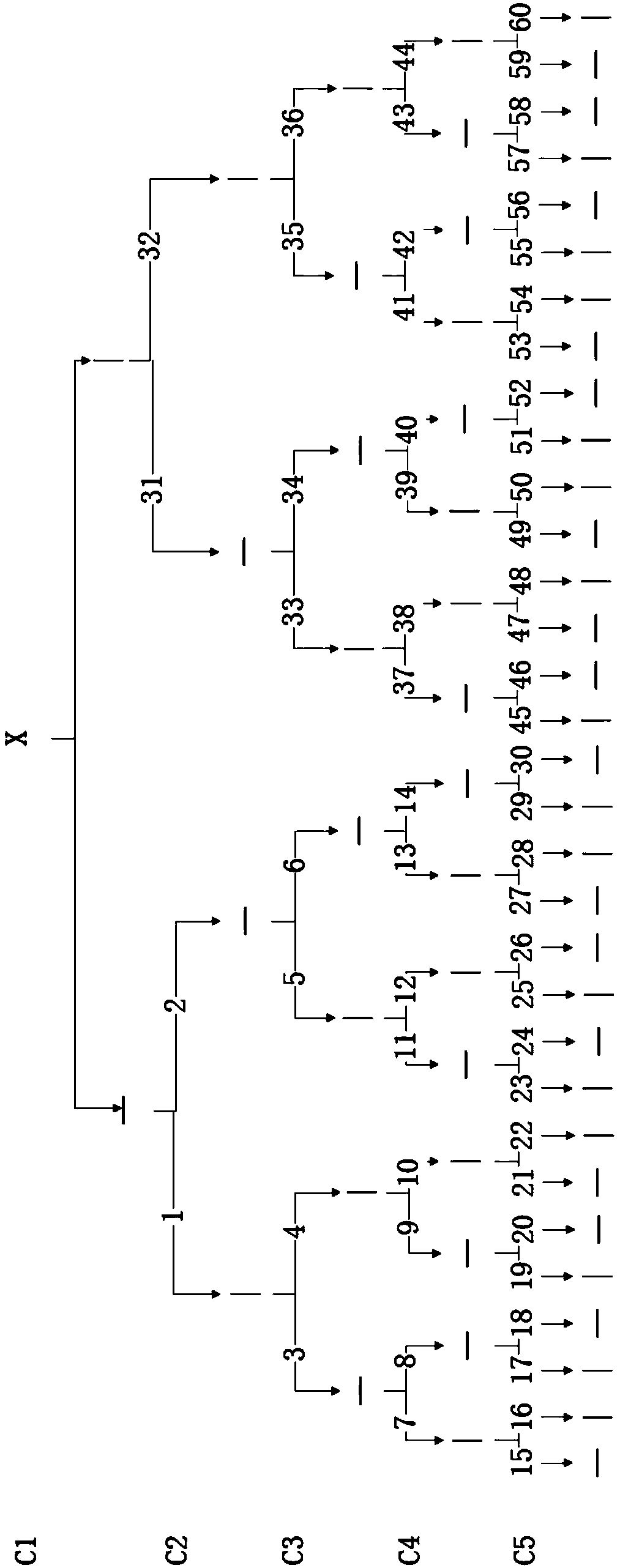

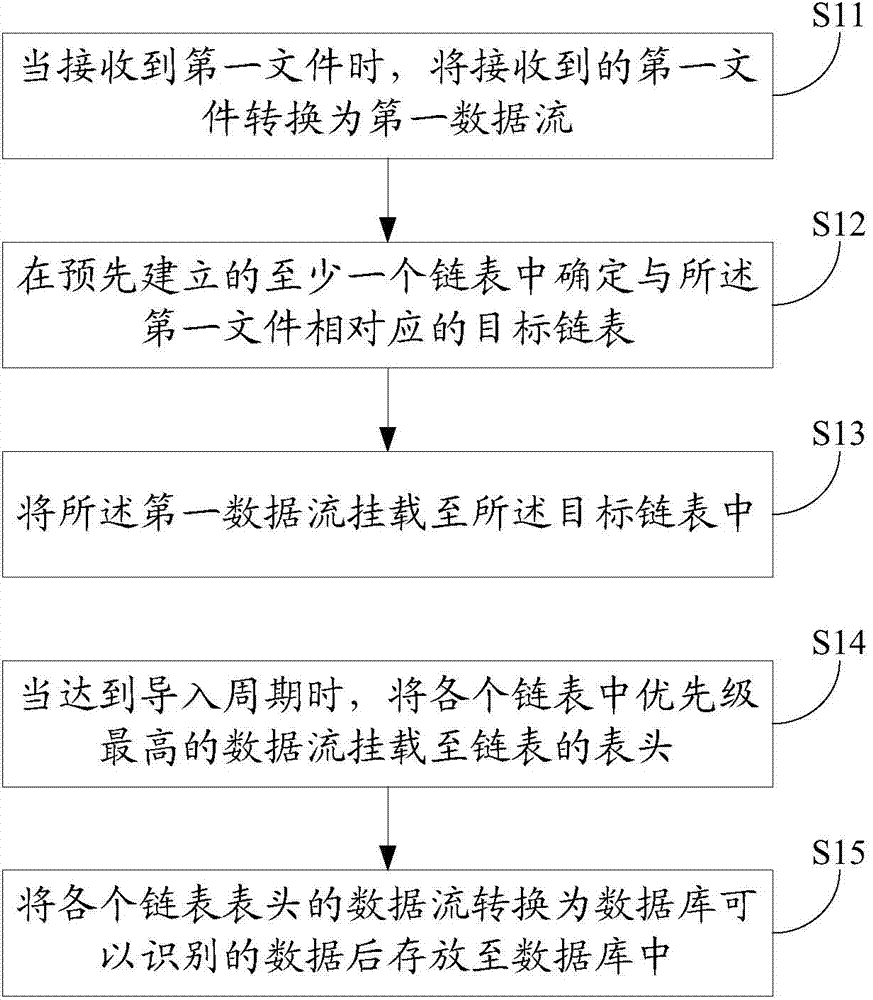

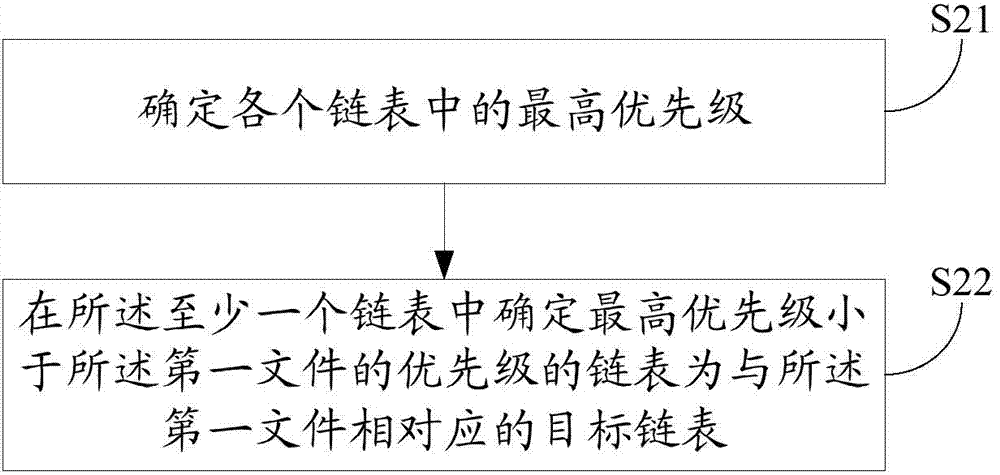

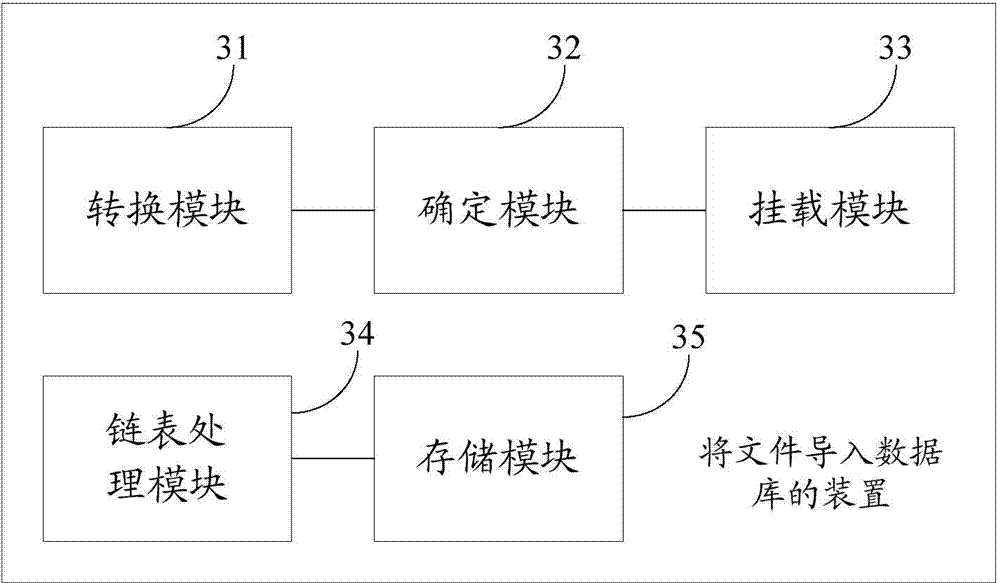

Method and device for importing files into database

ActiveCN104268294AImprove efficiencyRaise priorityFile/folder operationsSpecial data processing applicationsLinked listDatabase

An embodiment of the invention provides a method and a device for importing files into a database. The method comprises establishing at least a linked list, converting the received files into data flows, mounting the data flows into the linked list and mounting the highest priority of data flow in every linked list at a list head of the linked list when reaching an import cycle and converting the data flows of every list head of the corresponding linked list into first data which can be identified by the database to be stored in the database. According to the method and the device for importing the files into the database, a user can give the high priority to important files and accordingly the high priority of files can be imported into the database preferentially and the efficiency of the important files being imported into the database is improved.

Owner:CHINA CONSTRUCTION BANK

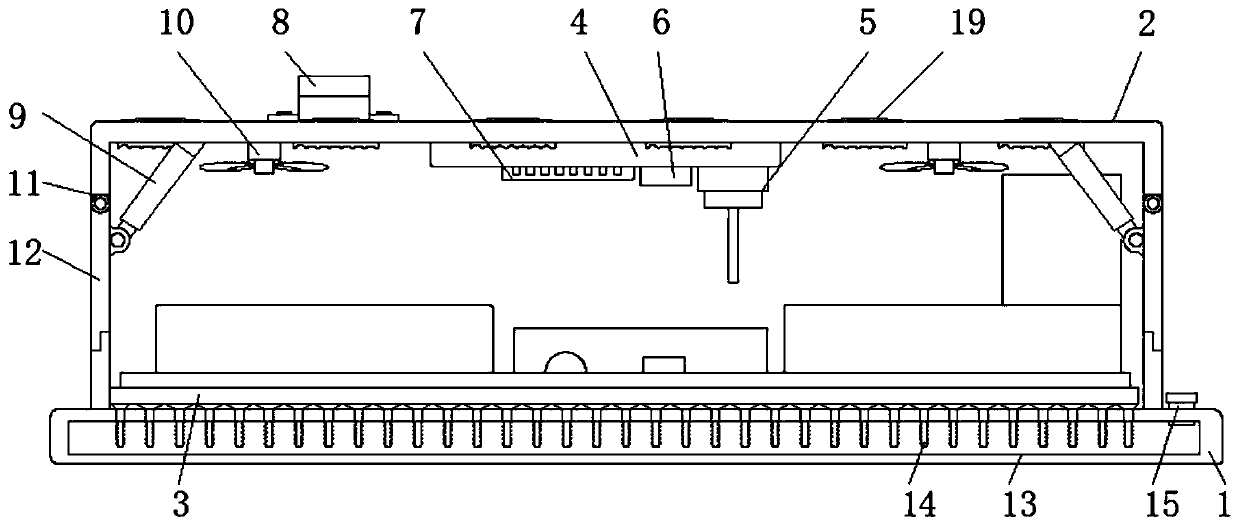

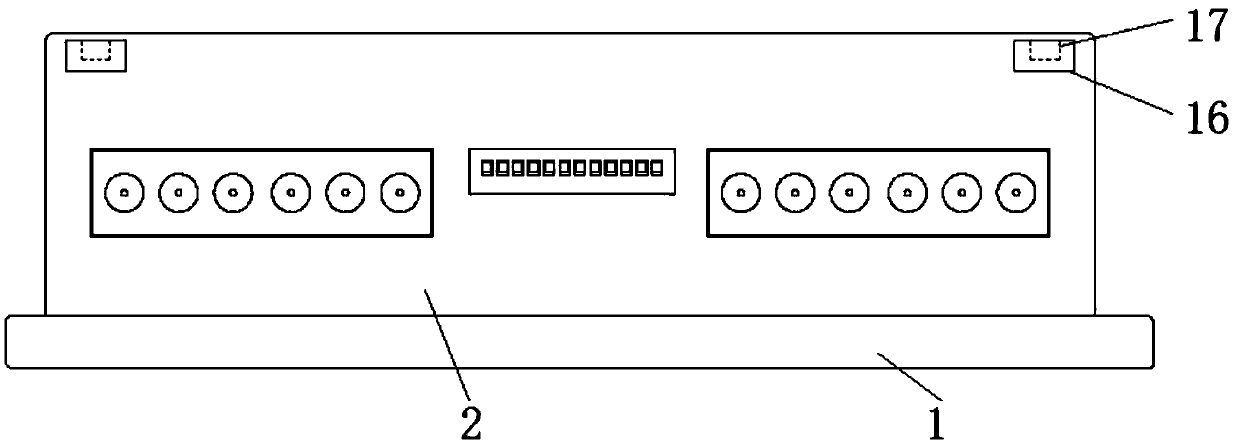

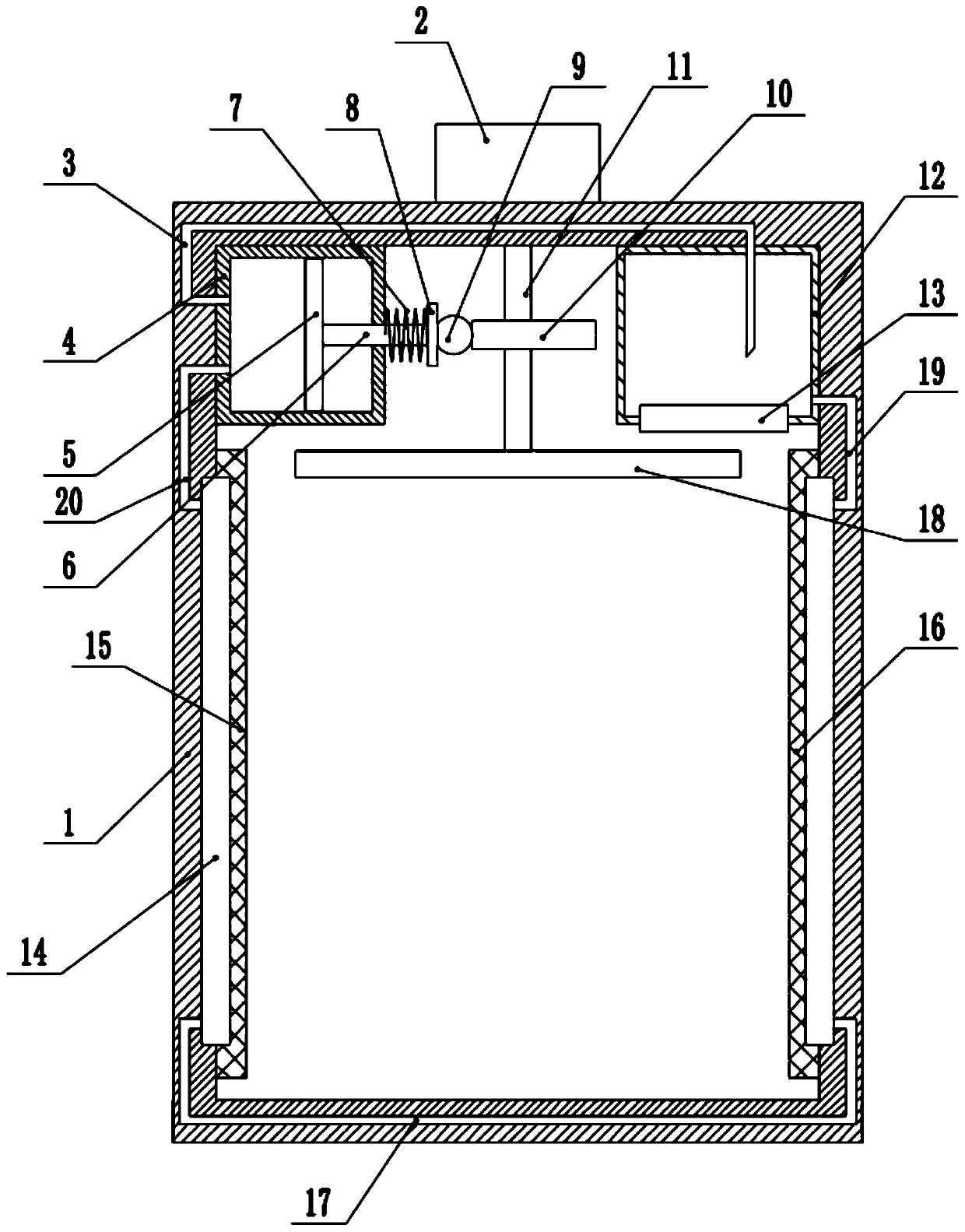

Stepper motor micro-driver

InactiveCN109546907AReduce damageImprove cooling effectThermometer detailsCasings/cabinets/drawers detailsHeat conductingEngineering

The invention discloses a stepper motor micro-driver, which comprises a base, a shell fixedly installed on the top of the base, a fixed plate fixed between the left and right sides of the inner wall of the shell, a circuit board fixed to the top of the inner surface of the shell, and a temperature sensor arranged on the right side of the bottom of the circuit board. The invention relates to the technical field of stepper motor drivers. The stepper motor micro-driver can automatically detect the short circuit of the micro-driver and give an alarm to remind the staff to power off the micro-driver for maintenance quickly. The heat inside the driver can be dissipated quickly, so that the damage degree of the driver is greatly reduced. Through a first heat conducting block, a second heat conducting block and coolant, the heat inside the micro-driver can be dissipated quickly, and the micro-driver can be maintained at high working efficiency. A dust cover can prevent dust from entering the interface of the micro-driver.

Owner:FOSHAN UNIVERSITY

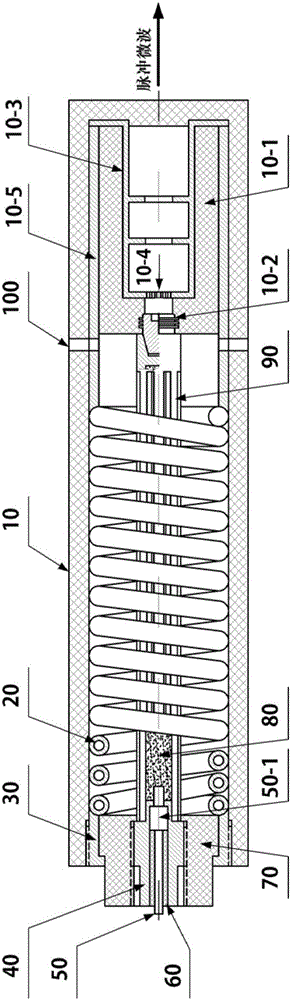

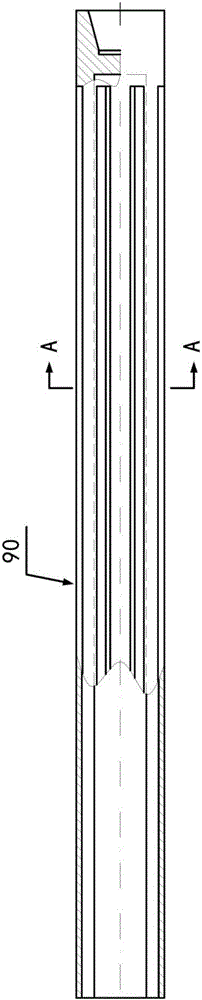

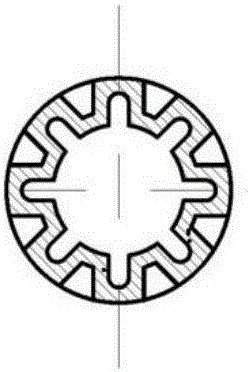

High-temperature plasma gas superconducting electromagnetic coil and microwave pulse generation device

ActiveCN106057396ASpeed up importPulse generation by galvano-magnetic devicesSuperconducting magnets/coilsDetonatorElectromagnetic field

The invention discloses a high-temperature plasma gas superconducting electromagnetic coil and a microwave pulse generation device. The superconducting electromagnetic coil comprises an insulating outer body, wherein an electromagnetic coil, an electric detonator and explosive are packaged in the insulating outer body; the electromagnetic coil is wound to be spiral from a tubular electric conductor; the tubular electric conductor is in a vacuum state and is filled with mercury; two ends of an inner hole of the tubular electric conductor are welded and sealed; the explosive and the electric detonator are filled in a voltage cathode expansion body; and a gas-guide hole is formed in the insulating outer body at the end, away from the electric detonator, of the voltage cathode expansion body. The electromagnetic coil is wound to be spiral from the tubular electric conductor, the tubular electric conductor is sealed and vacuumized and is filled with mercury, the mercury inside the electric conductor is gasified instantly to form the high-temperature plasma gas superconducting electromagnetic coil under the effects of high voltage and strong current during electrification, and an ultrastrong electromagnetic field is generated; and therefore, current leading to a virtual cathode microwave generator can be improved conveniently, and ultrastrong microwave pulse waves are generated.

Owner:上海航空机械有限公司

Ecological dredging jet pump

InactiveCN101571148BIncrease driving pressureImprove suction effectJet pumpsMachines/enginesRiver routingCoal dust

The invention discloses an ecological dredging jet pump, which comprises a jet water inlet pipe, a high-pressure distribution cavity and a silt outlet pipe which are connected in turn. Jet water is jetted into the outlet pipe through a primary jet spout and a secondary jet spout in the high-pressure distribution cavity, wherein the primary jet spout directly jets the jet water into the outlet pipe; and the secondary jet spout introduces the jet water into the outlet pipe through a streamline inlet. The ecological dredging jet pump utilizes the hydrodynamics Coanda effect to realize high speedflow, can avoid secondary pollution caused by using rotating components, and can be widely applied to ecological dredging and environment-friendly dredging of river courses, lakes and the like, and absorption of coal dust on the mine bottom of a coal mine.

Owner:中国船舶重工集团公司第七〇二研究所

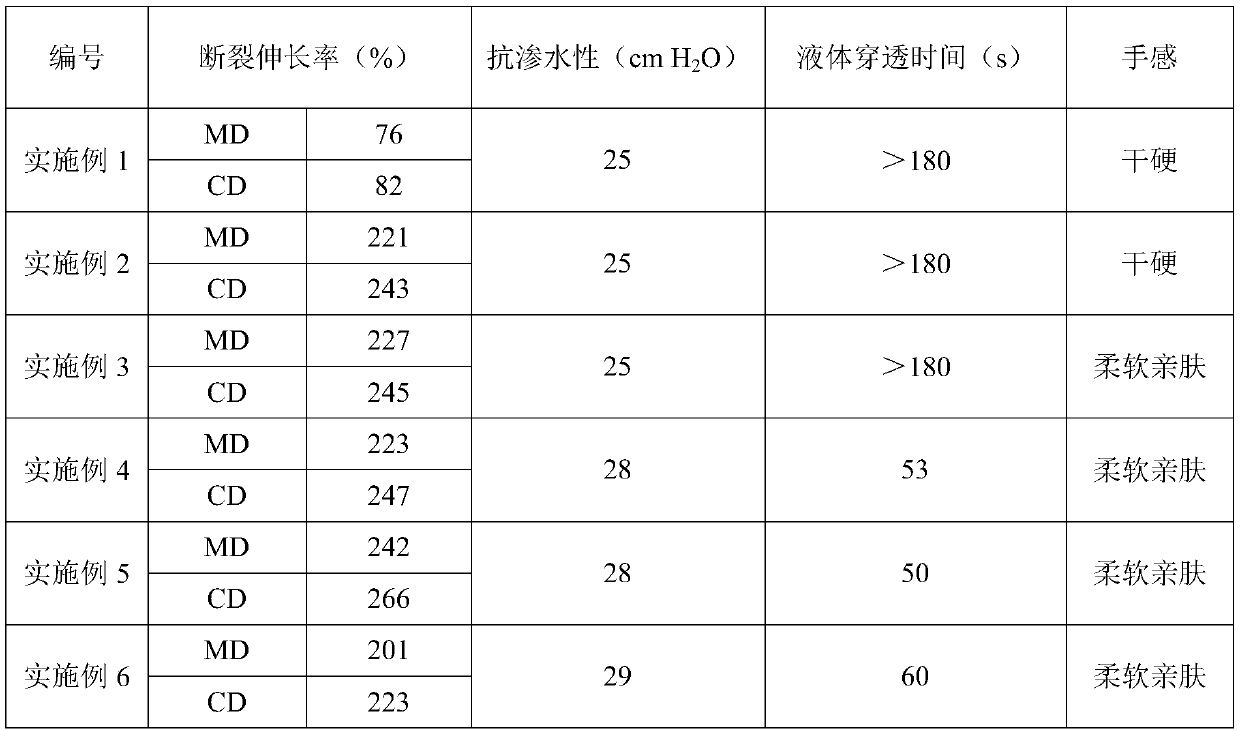

Comfortable protective glove and manufacturing method thereof

ActiveCN111501204AImprove the protective effectImprove wearing effectGlovesNon-woven fabricsElastomerPolymer science

The invention discloses a comfortable protective glove and a manufacturing method of the comfortable protective glove. The comfortable protective glove comprises an SMS non-woven fabric layer, a dampguide layer and a PE membrane layer. The SMS non-woven fabric layer, the damp guide layer and the PE membrane layer are arranged in sequence. The SMS non-woven fabric layer comprises spunbond non-woven fabric layers located on the two sides and one or more melt-blown non-woven fabric layers located between the spunbond non-woven fabric layers on the two sides. Each melt-blown non-woven fabric layer comprises, by weight, 20-40 parts of polysiloxane-polypropylene block copolymers and 60-80 parts of polyolefin elastomers. Each spunbond non-woven fabric layer comprises, by weight, 20-40 parts of polysiloxane-polypropylene block copolymers and 60-80 parts of polyolefin elastomers. The damp guide layer comprises, by weight, 30-60 parts of thermoplastic rubber, 30-45 parts of alginic acid salinegel, 5-10 parts of tackifying resin, 0-1 part of antioxidant, 1-10 parts of nano-silica and 1-10 parts of foaming agents. According to the comfortable protective glove and the manufacturing method ofthe comfortable protective glove, an SMS non-woven fabric material is adopted to manufacture the protective glove, and the protection property is good. Meanwhile, the SMS non-woven fabric material ishigh in porosity and good in air permeability, a user is not prone to feeling stuffy when wearing the glove, and the comfort is excellent.

Owner:陈美荷

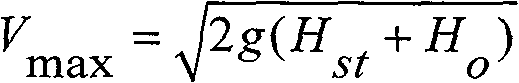

Refining method of molten iron in ladle and devices required by same

The invention belongs to the black metallurgy field and particularly relates to a molten iron refining method for treating and desulfurizing molten iron outside the furnace in a ladle, and devices required by the same. The desulfurizing process is performed by applying a low electric potential in melt (5); and the way of forming the low electric potential is that one pole of a power supply (1) applies current on the molten iron space of the outlet of a spray gun (2) through the spray gun, and the other pole of the power supply (1) provides current through a conductive electrode (6) soaked in molten iron. The method for forming the low electric potential comprises the following steps: the conductive electrode (6) is soaked in molten iron to ensure that the electrode is at 5-15% of the height of molten iron, the conductive electrode (6) is moved into slag after the first half of converting and is at 40-60% of the depth of slag, and current is applied on the power supply (1) under the condition that the voltage is 10-60V. By adopting the refining method, the utilization rate of desulfurizer for direct desulfurization can be increased, heat loss can be reduced, and the number of iron particles can be lowered so as to increase the yield of qualified molten iron.

Owner:YINGKOU DSMK TECH DEV

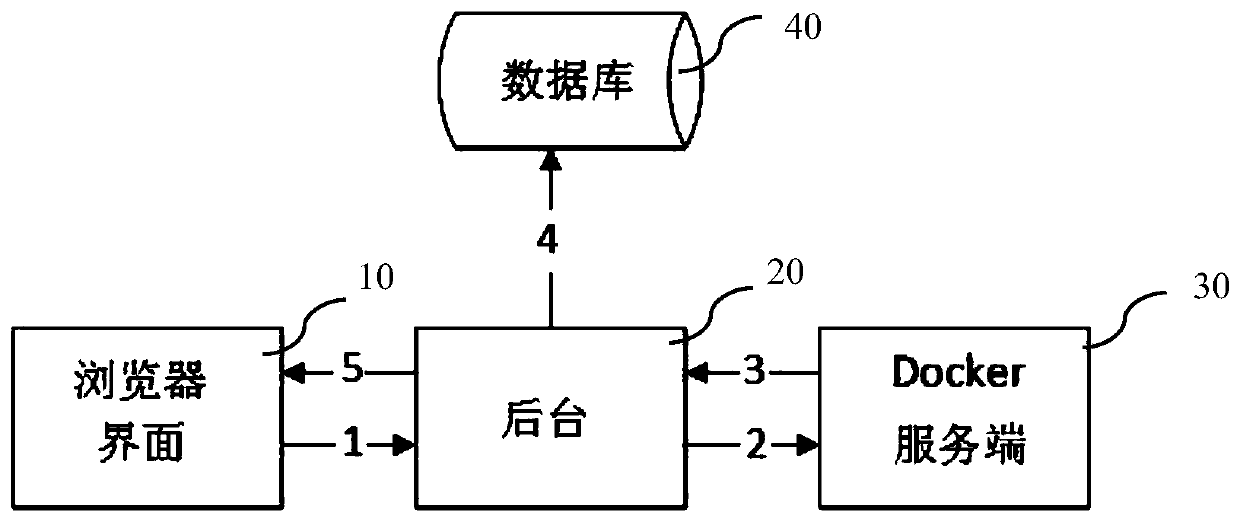

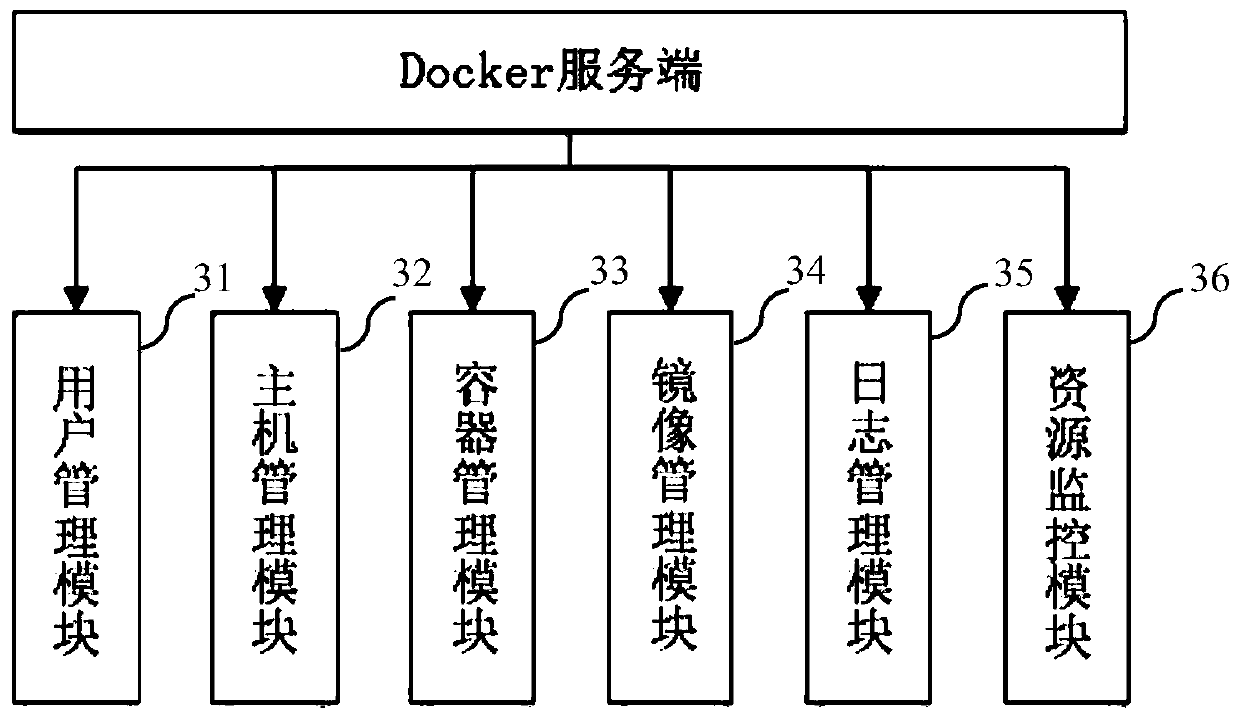

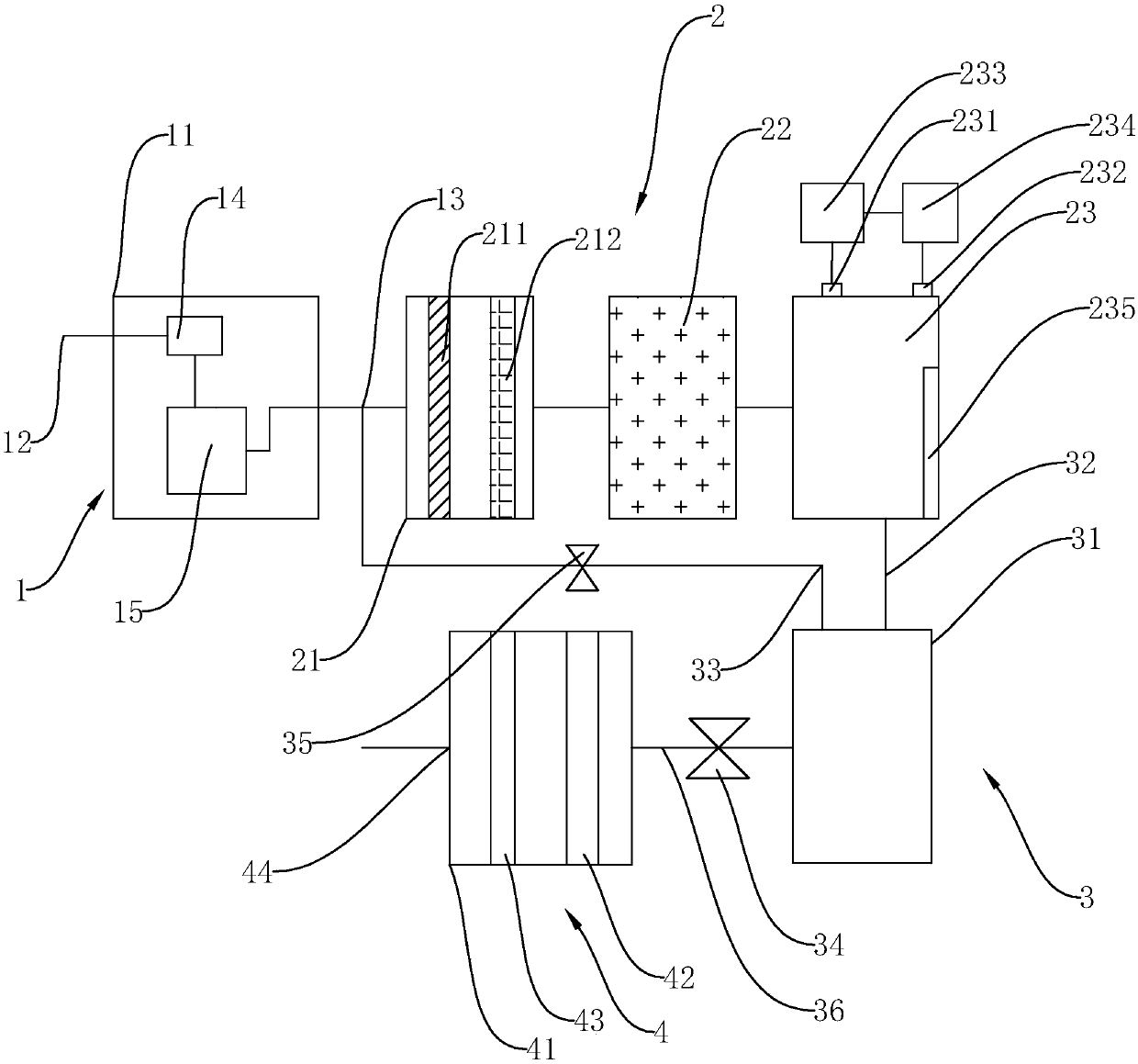

Container visualization system based on Docker

PendingCN111158856AAdd login verification functionAdd connection managementTransmissionSoftware simulation/interpretation/emulationSoftware engineeringConnection management

The invention discloses a container visualization system based on a Docker. The container visualization system comprises a browser interface 10, a background 20, a Docker server 30 and a database 40.The browser interface 10 is used for accessing a Docker Remote API so as to realize interactive operation between the background 20 and the Docker server 30; the background 20 realizes host resource monitoring through an SSH remote login function of a PHP; and the Docker server comprises a user management module 31, a host management module 32, a container management module 33, a mirror image management module 34, a system log module 35 and a resource monitoring module 36. According to the invention, a user login verification function and multi-host connection management are added, and a front-end development framework Angular is used, so that the compatibility is good.

Owner:TIANJIN UNIV

Automobile tail gas purification treatment system

InactiveCN109578110ASpeed up importFully purifiedGas treatmentInternal combustion piston enginesExhaust gasProcess engineering

The invention discloses an automobile tail gas purification treatment system. The automobile tail gas purification treatment system comprises a tail gas collection device, a tail gas purification device, a tail gas detection device and a tail gas exhaust device. The tail gas collection device comprises a reaction box. The reaction box comprises a first gas inlet pipe and a first gas outlet pipe, wherein the first gas inlet pipe and the first gas outlet pipe are connected with an exhaust pipe of an automobile. A gas pump is further fixedly arranged in the reaction box, one end of the gas pump is connected with the first gas inlet pipe, the other end of the gas pump is connected with a gas cooling box, and a gas outlet of the gas cooling box is connected with the first gas outlet pipe. The tail gas purification device comprises a coarse filtration chamber, a biological purification chamber and a chemical purification chamber. The coarse filtration chamber is connected with the first gasoutlet pipe. The tail gas detection device comprises a detection box, a second gas inlet pipe, a second gas outlet pipe and a backflow pipe, wherein the second gas inlet pipe, the second gas outlet pipe and the backflow pipe are arranged on the detection box. The second gas inlet pipe is connected with the chemical purification chamber, the second gas outlet pipe is connected with the tail gas exhaust device, and the backflow pipe is connected with the coarse filtration chamber. The automobile tail gas purification treatment system has the advantages that the cost is low, the structure is simple, and the purification effect is good.

Owner:CHONGQING UNIV

Method for improving appearance machining efficiency

InactiveCN109807964AAvoid scrappingReduce scrapMetal working apparatusEngineeringIndustrial engineering

The invention provides a method for improving the appearance machining efficiency. The method is characterized by comprising the following steps that S1, a machining parameter table of circuit boardsis formulated; S2, the machining parameter table for special-material circuit boards is formulated; and S3, parameters in the step S1 and the step S2 are input a CNC program, and the machining parameters comprise the gong cutter diameter, the rotating speed, the cutter feeding speed, the cutter retracting speed, the cutter life, the cutter compensation value and the gong plate speed. By means of the method for improving the appearance machining efficiency, scrap caused by human operation errors can be effectively reduced, the finished product quality is guaranteed, and the efficiency is improved, so that the purpose of reducing the production cost is achieved.

Owner:奥士康精密电路(惠州)有限公司

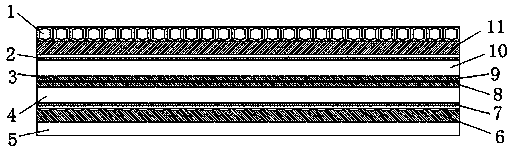

Solar battery with power grid conversion layer and manufacturing method

InactiveCN107946390ASpeed up importIncrease the amount of imported solar cellsMaterial nanotechnologyFinal product manufactureElectricityElectrical battery

The invention discloses a solar battery with a power grid conversion layer and a manufacturing method. The solar battery comprises an upper silicon plate and a lower silicon plate; upper silicon plateconductive strips are distributed and embedded in the upper surface of the upper silicon plate; a tempered glass layer is glued on the upper surface of the upper silicon plate; a lens layer is gluedon the upper surface of the tempered glass layer; a phosphorus-doped layer is integrally formed on the lower surface of the upper silicon plate; lower silicon plate conductive strips are distributed and embedded in the lower surface of the lower silicon plate; a reflective layer is glued on the lower surface of the lower silicon plate; a bearing layer is glued on the lower surface of the reflective layer; a boron-doped layer is integrally formed on the upper surface of the lower silicon plate; the boron-doped layer is tightly fitted with the phosphorus-doped layer; a power grid conversion layer is sandwiched between the boron-doped layer and the phosphorus-doped layer; through the lens layer, light ray polymerization is performed, so that the amount of light rays guided to the solar battery is increased, and absorption amount is further increased; and then by enabling the power grid conversion layer to be sandwiched in the PN junction, electron flowing speed in the PN junction is improved, the original conductive efficiency is improved, and the conversion efficiency of the solar battery is improved.

Owner:孙健春

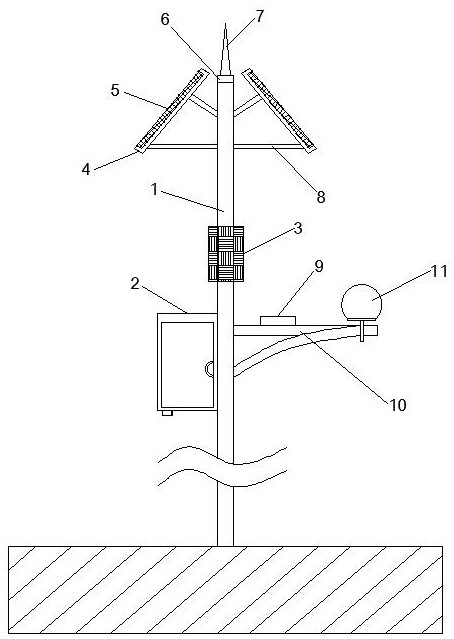

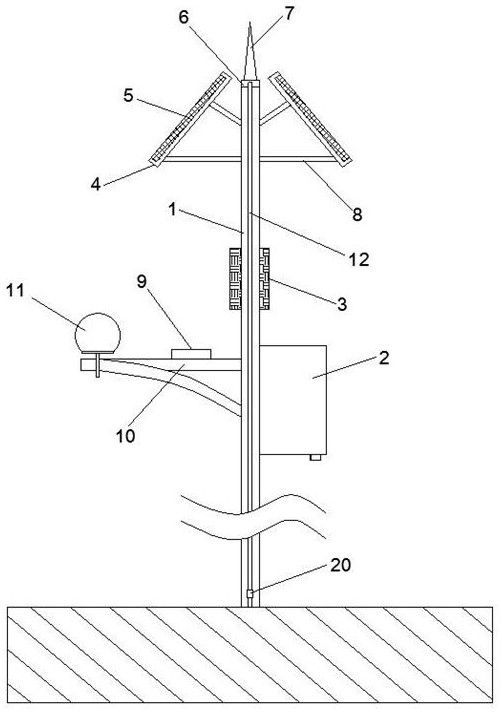

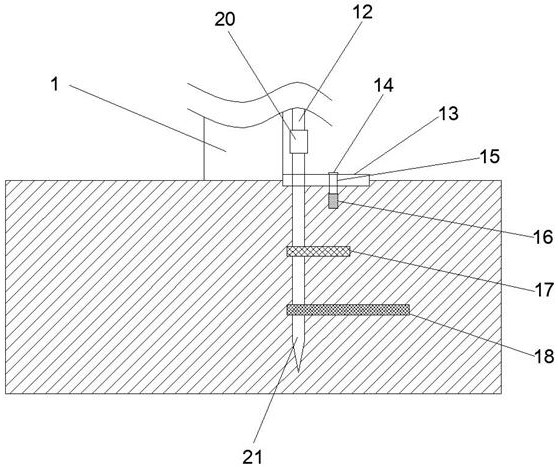

Independent power supply energy-saving street lamp with lightning protection structure

PendingCN111720785AReduce lossReduce labor maintenance costsMechanical apparatusElectric circuit arrangementsGrounding gridLightning strokes

The invention relates to the technical field of energy-saving street lamps, in particular to an independent power supply energy-saving street lamp with a lightning protection structure, and the independent power supply energy-saving street lamp is additionally provided with the lightning protection structure on the basis of an existing independent power supply energy-saving street lamp, so that the probability that due functions of the street lamp are lost due to lightning stroke can be greatly reduced, and the manual maintenance cost is greatly reduced. The grounding grid system adopting thegrounding grid and the liquid injection pipe can increase the rate of guiding charges into the ground, so that the stability of the whole lightning protection structure is greatly improved. The problems that an existing independent power supply energy-saving street lamp loses the due function due to accidental lightning stroke in actual use, and the manual maintenance cost in the environment is greatly increased are solved.

Owner:四川新金鑫照明科技有限公司

Index building method for distributed memory columnar database

ActiveCN105843933BImprove import performanceLow costSpecial data processing applicationsDatabase indexingNODALDistributed memory

The invention discloses a method for establishing an index of a distributed memory columnar database, comprising: dividing single-column data into at least two data fragments; and calculating in parallel the intermediate data and the row table of the columnar compression index of each data fragment The intermediate data of the vector, the columnar compression index includes a dictionary vector, an index vector and a position vector; store and update the intermediate data of the columnar compression index and the intermediate data of the row table vector of each data slice in order to form a column compressed index and row table vectors. The index establishment method of the distributed memory column database provided by the present invention does not require much memory for importing huge tables into computing nodes, and can save hardware costs.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

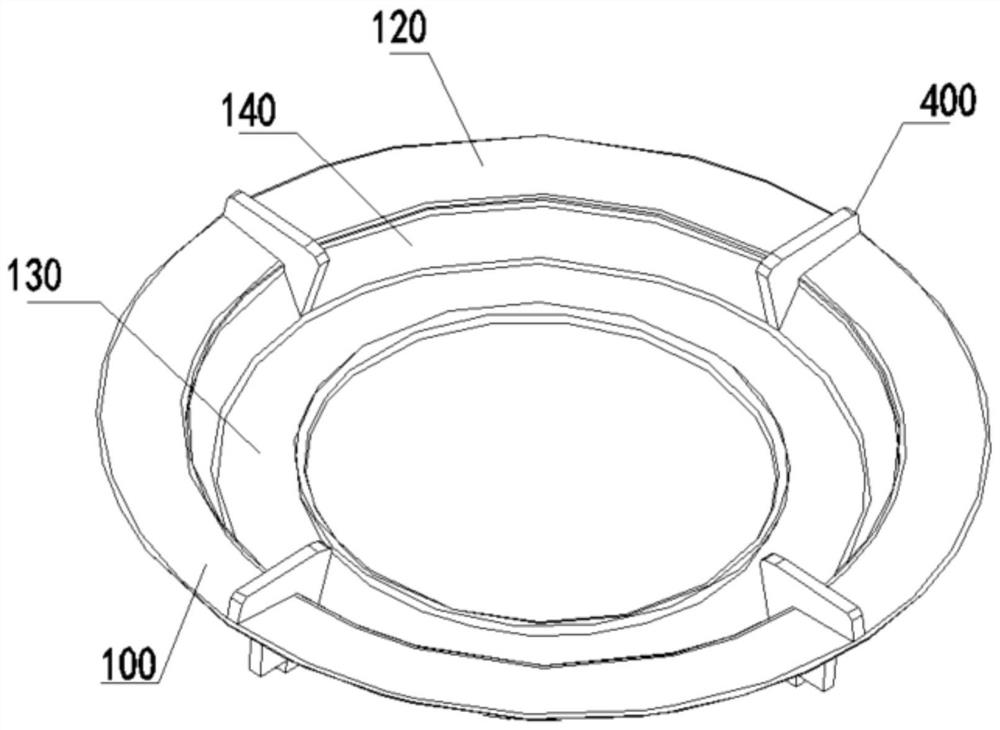

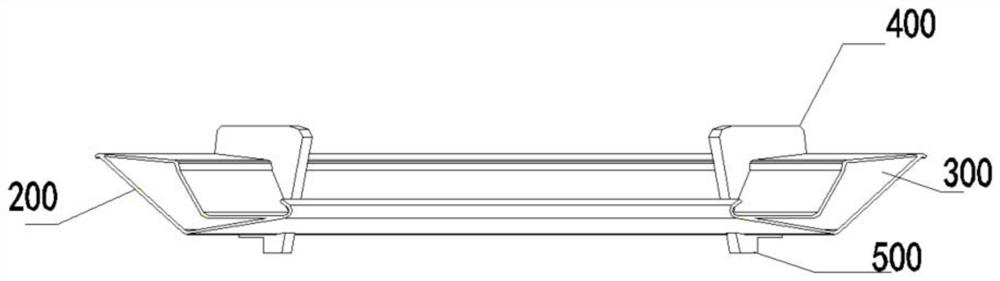

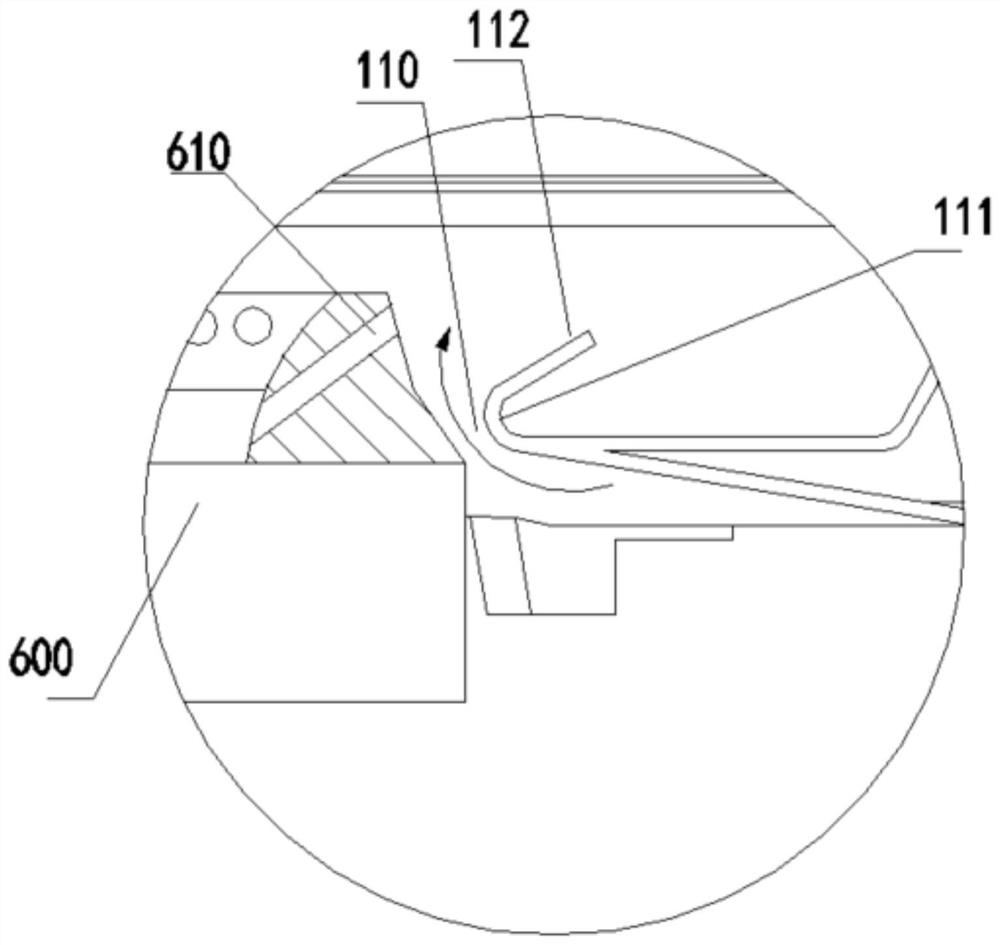

Energy gathering ring and gas stove

PendingCN112923409AReduce areaSpeed up importDomestic stoves or rangesLighting and heating apparatusKitchen utensilsEngineering

The invention provides an energy gathering ring and a gas stove, and relates to the technical field of kitchen utensils. The energy gathering ring comprises a first disc body and a second disc body, wherein the first disc body is arranged in the second disc body in a sitting mode; the first disc body and the second disc body are both annular, and the inner ring of the first disc body and the inner ring of the second disc body are connected in a sealed mode to form an inner connecting edge; the outer ring of the first disc body and the outer ring of the second disc body are connected in a sealed mode to form an outer connecting edge; an annular cavity is formed between the first disc body and the second disc body at intervals; and a rotating edge which faces the outer connecting edge and surrounds the annular cavity is arranged on one side of the first disc body of the inner connecting edge in a rotating mode. According to the energy gathering ring and the gas stove, the technical problems that an existing energy gathering ring cannot efficiently utilize smoke in the early stage of combustion, excessive secondary air can be sucked to reduce the flame temperature, and the heat efficiency is reduced are solved.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

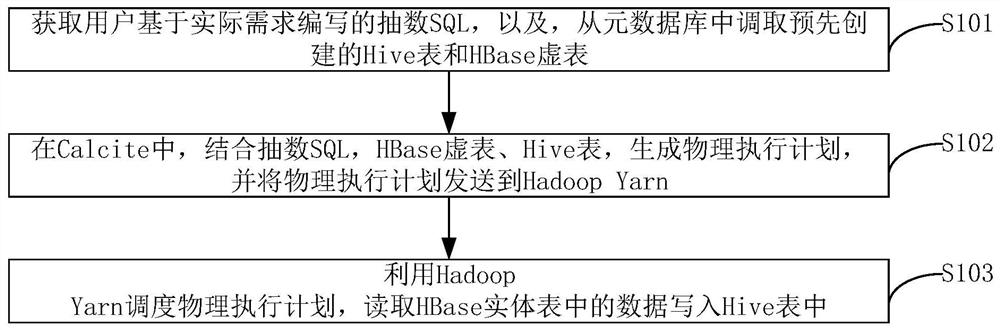

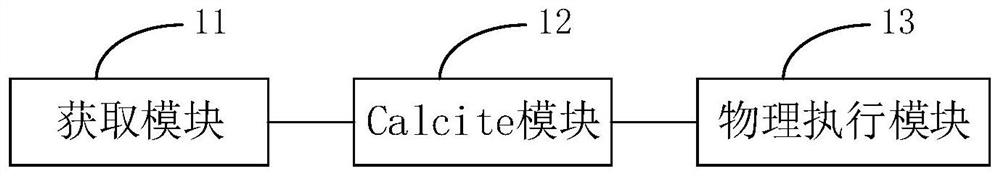

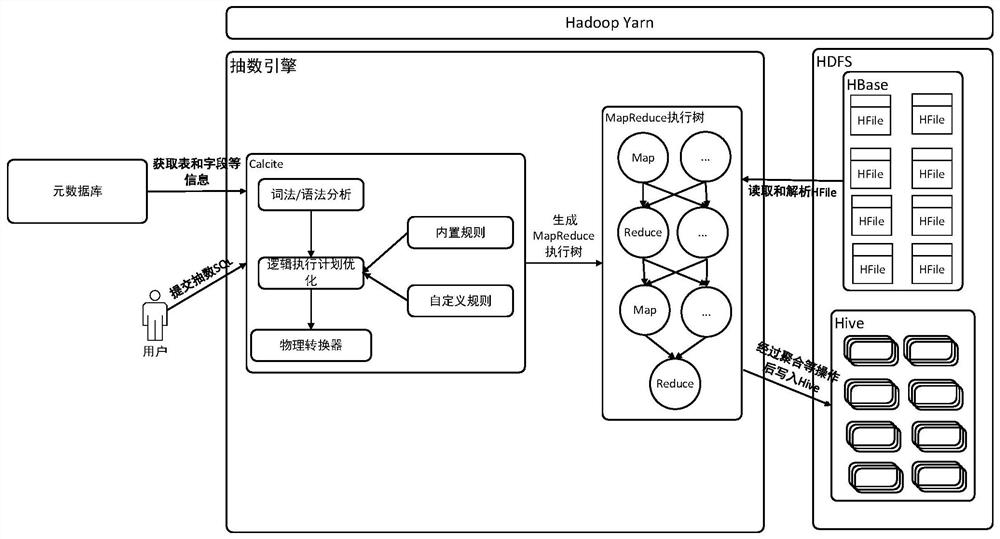

SQL-based data processing method, device and equipment

PendingCN112632170ASpeed up importRelieve stressDatabase management systemsRelational databasesExecution planTable (database)

The invention relates to an SQL-based data processing method, device and equipment, and the method comprises the steps of obtaining an extraction SQL written by a user, and calling a Hive table and an HBase virtual table which are created in advance from a meta-database, wherein the HBase virtual table is used for mapping an HBase entity table; in the Calcite, in combination with the extraction SQL, the HBase virtual table and the Hive table, generating a physical execution plan, and sending the physical execution plan to the Hadoop Yarn; and scheduling the physical execution plan by utilizing the Yarn, reading the data in the HBase entity table, and writing the data into the Hive table. According to the invention, data extraction can be performed without using an HBase Region Server, pressure on HBase service is avoided, a user only needs to compile a simple extraction SQL on a scheduling platform, the labor cost is saved, and the efficiency of importing the data in the HBase database into the Hive database is effectively improved.

Owner:SHANGHAI ZHONGTONGJI NETWORK TECH CO LTD

Portable vehicle-mounted ozone generating device

InactiveCN111268651AReasonable structureInnovative designChemical industryElectrical discharge ozone preparationRotational axisElectric machine

The invention relates to the technical field of ozone generators and discloses a portable vehicle-mounted ozone generating device, which includes a cylinder body; a rotating motor is mounted in the upper end of the barrel; an output shaft of the rotating motor is connected with a rotating shaft; rotating blades are mounted at the bottom of the rotating shaft; a cam is mounted in the middle of therotating shaft; the left side of the cam contacts a guide ball; guide plates are fixedly mounted at the left ends of the guide balls; telescopic rods are fixedly mounted at the left ends of the guideplates; piston plates are mounted at the left ends of the telescopic rods; a piston cavity is formed outside the piston plate; a positive electrode and a negative electrode are installed at the two ends in the cylinder respectively, heat dissipation plates are installed on the outer sides of the positive electrode and the negative electrode respectively, heat dissipation elbows are installed in the heat dissipation plates, a heat dissipation box is installed at the upper end in the cylinder, wherein the heat dissipation box, the heat dissipation box, the piston cavity, the heat dissipation plates on the positive electrode, the heat dissipation plates on the negative electrode and the heat dissipation box sequentially form a loop. According to the ozone generation device, the heat dissipation plates are arranged on the outer sides of the positive electrode and the negative electrode, efficient heat dissipation of the ozone generation unit is achieved, and the ozone generation efficiencyof the whole device is improved.

Owner:NANJING COMM INST OF TECH

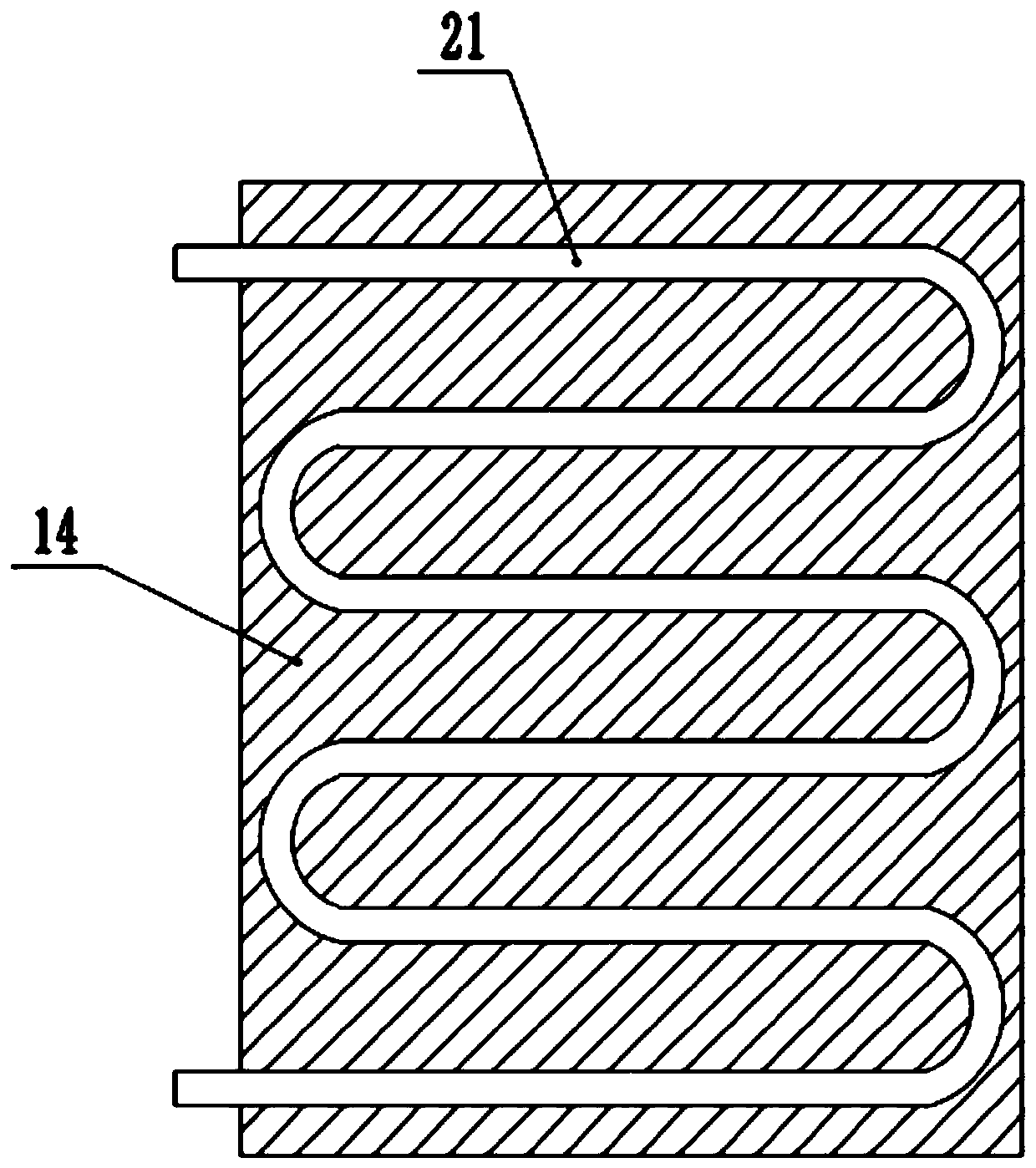

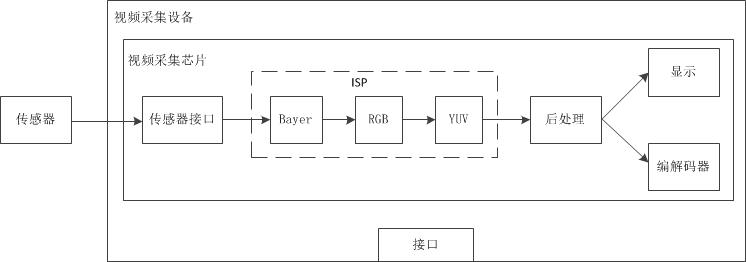

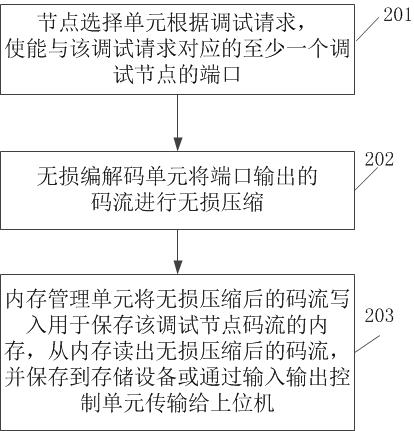

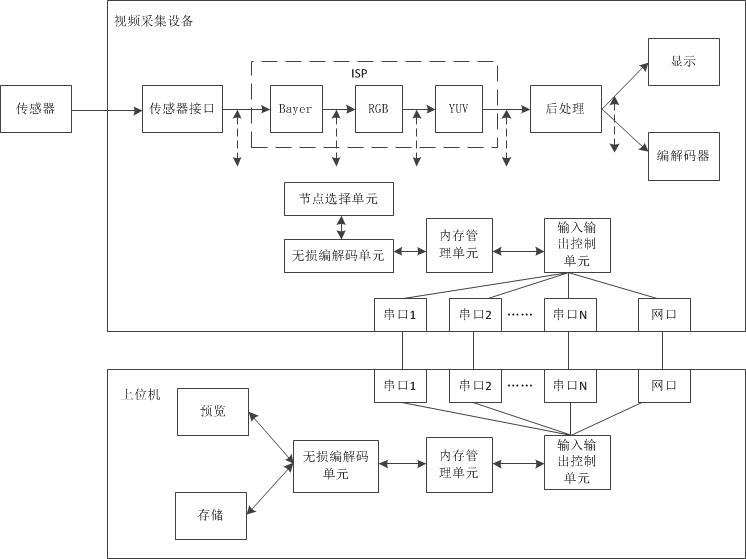

Method and device for exporting and importing debug code stream for image processing

ActiveCN113905230BSpeed up importHigh speedTelevision systemsDigital video signal modificationImaging processingParallel computing

Owner:SHENZHEN MICROBT ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com