Comfortable protective glove and manufacturing method thereof

A technology of protective gloves and comfort, applied in the field of comfortable protective gloves and their preparation, can solve the problems of incompatibility of protection and comfort, poor air permeability and moisture permeability, poor elasticity of PE gloves, etc., and achieves high porosity. , Not easy to get hot, easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

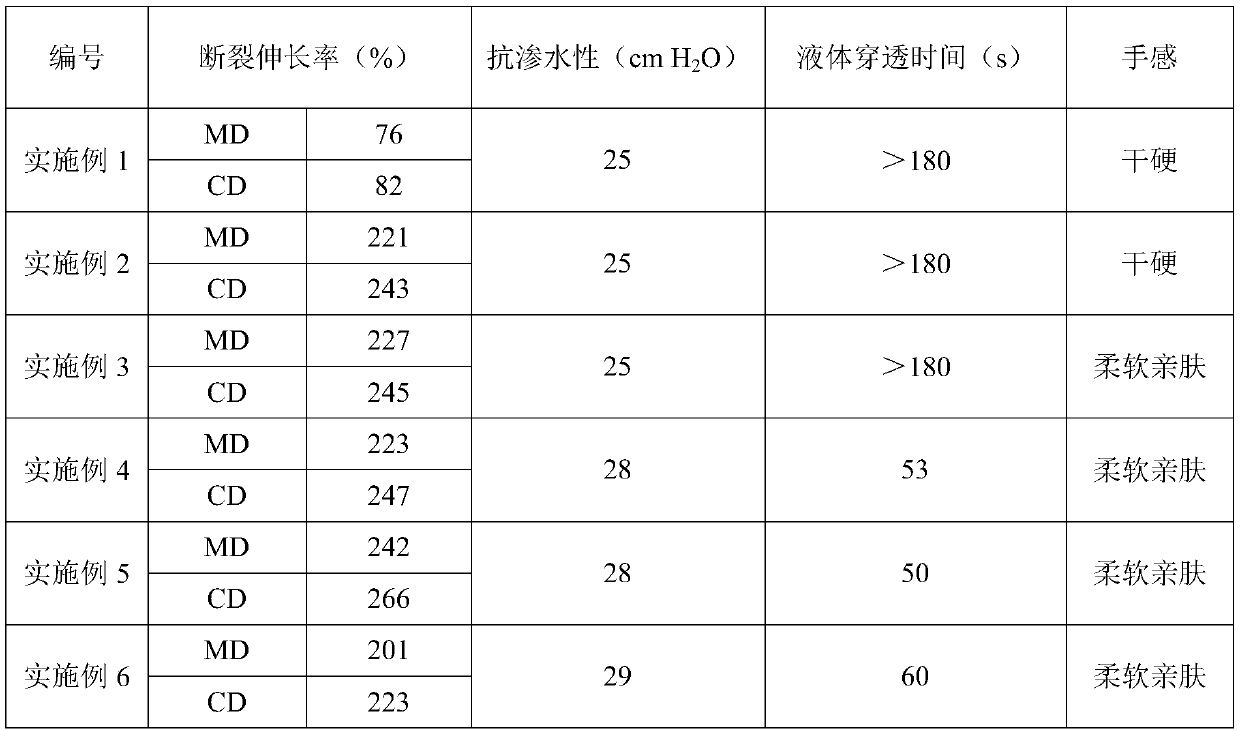

Examples

Embodiment 1

[0037] A kind of comfortable protective glove, material comprises 0.3mm SMS non-woven fabric layer, and SMS non-woven fabric layer comprises the spun-bonded non-woven fabric layer on both sides and a layer of melt-blown non-woven fabric in the middle of the spun-bonded non-woven fabric layer on both sides. The raw material of the woven fabric layer, the meltblown nonwoven fabric layer and the spunbonded nonwoven fabric layer is polypropylene.

[0038] The preparation method of above-mentioned comfortable protective gloves comprises the steps:

[0039] (1) Preparation of SMS non-woven fabric layer: Two layers of spunbond non-woven fabric layer and one layer of melt-blown non-woven fabric layer were prepared by spunbond process and melt blown process respectively. The spinning temperature was 170 °C and the spinning speed was 1000m / min; the melt-blown non-woven fabric layer is placed between two layers of spun-bonded non-woven fabric layers, hot-pressed at 140°C, and the line pr...

Embodiment 2

[0042] A kind of comfortable protective glove, material comprises 0.3mm SMS non-woven fabric layer, and SMS non-woven fabric layer comprises the spun-bonded non-woven fabric layer on both sides and a layer of melt-blown non-woven fabric in the middle of the spun-bonded non-woven fabric layer on both sides. The woven fabric layer is recorded in parts by weight, and the raw materials of the meltblown nonwoven fabric layer and the spunbonded nonwoven fabric layer include 30 parts of polypropylene and 70 parts of ethylene-1-octene copolymer.

[0043] The preparation method of above-mentioned comfortable protective gloves comprises the steps:

[0044] (1) Preparation of SMS non-woven fabric layer: Two layers of spunbond non-woven fabric layer and one layer of melt-blown non-woven fabric layer were prepared by spunbond process and melt blown process respectively. The spinning temperature was 170 °C and the spinning speed was 1000m / min; the melt-blown non-woven fabric layer is placed...

Embodiment 3

[0047] A kind of comfortable protective glove, material comprises 0.3mm SMS non-woven fabric layer, and SMS non-woven fabric layer comprises the spun-bonded non-woven fabric layer on both sides and a layer of melt-blown non-woven fabric in the middle of the spun-bonded non-woven fabric layer on both sides. The woven fabric layer is recorded in parts by weight, and the raw materials of the meltblown nonwoven fabric layer and the spunbonded nonwoven fabric layer include 30 parts of polysiloxane-polypropylene block copolymer and 70 parts of ethylene-1-octene copolymer.

[0048] The preparation method of polysiloxane-polypropylene block copolymer comprises the steps:

[0049] A) Add polypropylene powder into nitric acid with a mass fraction of 65%, stir and react at 120°C for 3 hours, cool, filter, wash the product repeatedly with water, and dry to obtain carboxyl-terminated polypropylene. The mass ratio of polypropylene powder to nitric acid is 1 : 1.2;

[0050] B) Add carboxy-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com