Desulfuration spray gun for molten iron refining

A desulfurization spray gun and molten iron technology, which is applied in the field of molten iron desulfurization equipment, can solve the problems of reducing tail nozzle pressure, large iron loss, and obvious temperature drop of molten iron, and achieve the effects of accelerating the import or export speed, improving desulfurization efficiency, and accelerating desulfurization operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

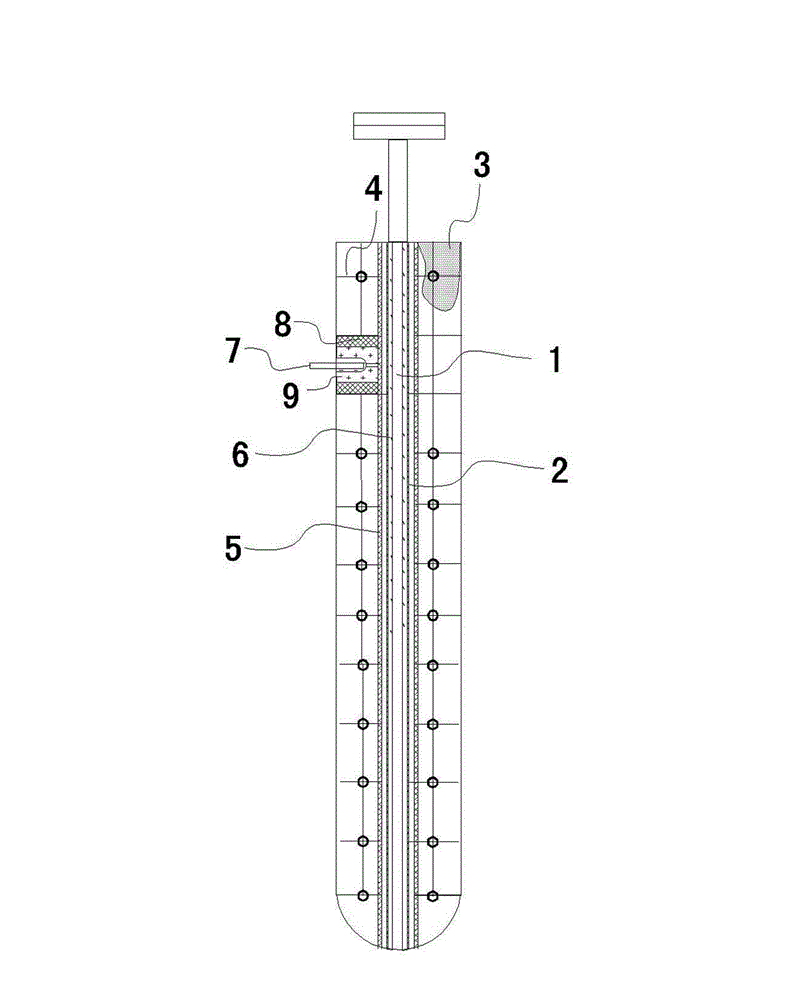

[0017] As shown in the figure, the desulfurization spray gun for molten iron refining includes a central nozzle 1, an air-cooled cyclone stirring tube 2, a refractory material layer 3, a protective tube 5 and a skeleton 4; the refractory material layer 3 is matched with the air-cooled cyclone stirring tube 2; the central nozzle 1 is placed in the air-cooled cyclone stirring tube 2; the air-cooling cyclone stirring tube 2 is set in the protective tube 5; the skeleton 4 is located in the refractory material layer 3 and is connected with the protective tube 5 The outer walls of the outer walls are fixedly connected; the outer wall of the center nozzle 1 is fixed with a scroll piece 6; on the upper part of the protective tube 5, a power supply connection port assembly 7 is fixed in the refractory material layer 3; the power supply The signal port of the wiring port assembly 7 is connected to the protection tube 5 .

[0018] The power connection port assembly 7 of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com