Air cooling cyclonic magnesium agent desulphurization spray gun

A desulfurization spray gun, air-cooled technology, applied in the field of air-cooled cyclone magnesium agent desulfurization spray gun, can solve the problems of spray gun head corrosion, melt splashing, inability to effectively destroy the blowing bubbles, etc., and achieve the effect of improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

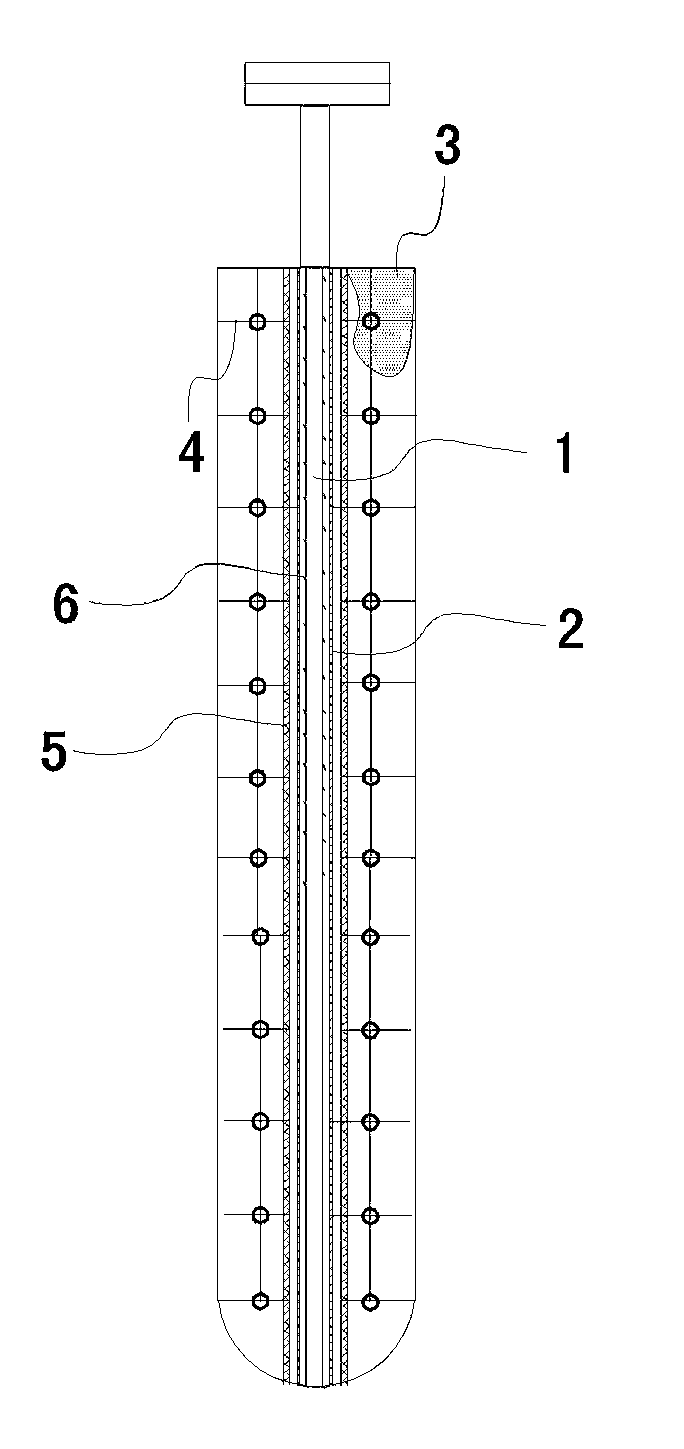

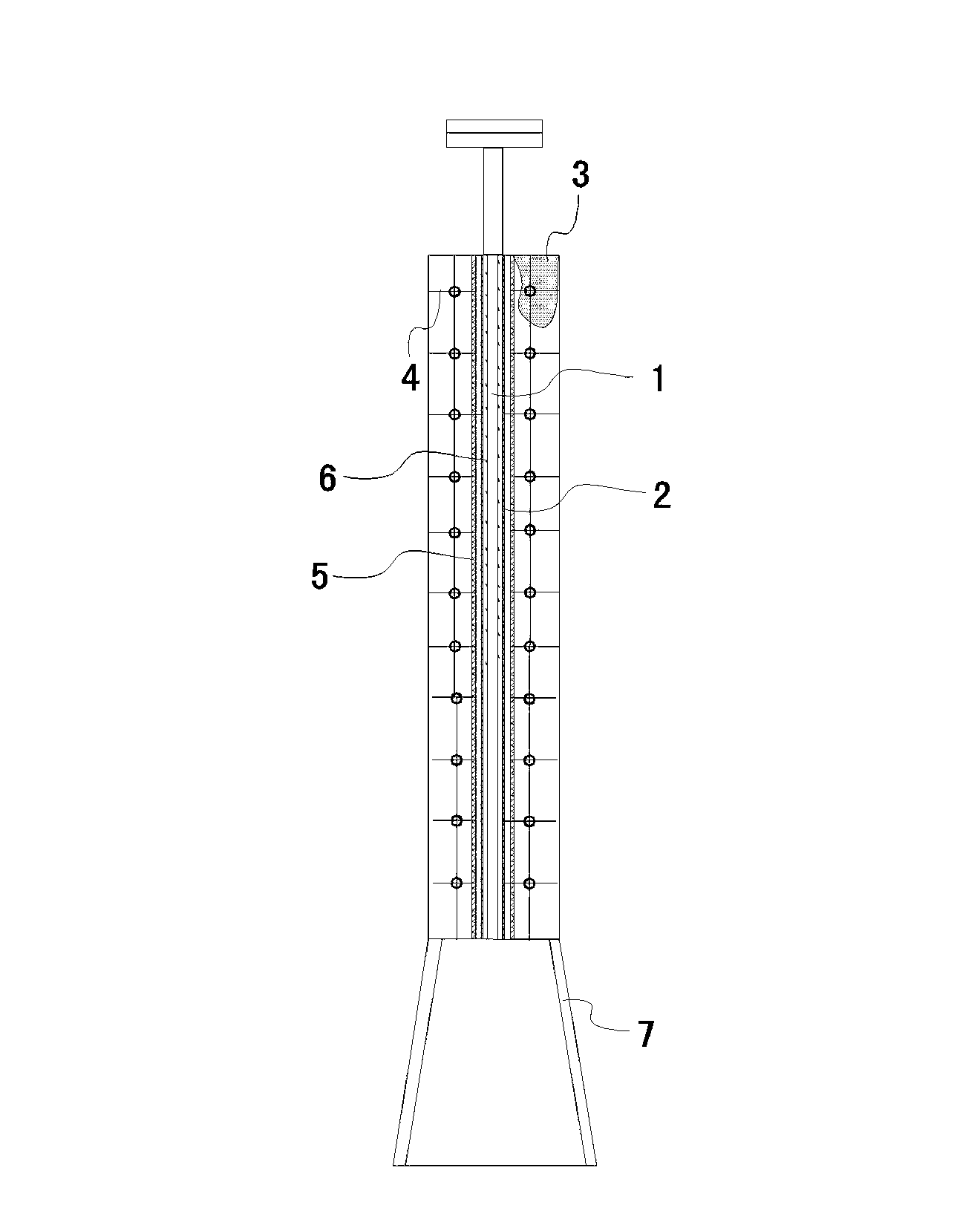

[0014] As shown in the figure, the air-cooled cyclone magnesium desulfurization spray gun includes a central nozzle 1, an air-cooled cyclone stirring tube 2, a refractory material layer 3, a protective tube 5 and a skeleton 4; the refractory material layer 3 is equipped with an air-cooled The outside of the cyclone stirring tube 2; the central nozzle 1 is placed in the air-cooled cyclone stirring tube 2; the air-cooling cyclone stirring tube 2 is set in the protective tube 5; the skeleton 4 is located in the refractory material layer 3 and is connected with the The outer walls of the protective pipe 5 are fixedly connected; the outer wall of the central nozzle 1 is fixed with a scroll piece 6 .

[0015] In order to improve the stress distribution between different materials of the gun body and increase the service life of the spray gun, the framework 4 of the present invention can adopt a cross-fixed network structure of transverse annular ribs and longitudinal ribs.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com